How to cut Nitinol tubing using wire EDM for precise results

If you want to wire edm cut nitinol tubing for accuracy, you need to know about nitinol’s special traits. In hospitals and factories, careful cutting keeps nitinol’s superelasticity and helps it resist breaking. For example, nitinol tubing can last through 600 million cycles before wearing out. Cutting as close as 0.2 to 0.5 mm makes it safe for use in medicine.

Metric | Value/Range |

|---|---|

Fatigue Life Cycles | Up to 600 million |

Kerf Width (precision) | 0.2 – 0.5 mm |

Tensile Strength | 500–900 MPa |

You must handle problems with edm on nitinol, like tiny cracks or burned spots, by choosing the right settings. The wire edm cut nitinol tubing process needs you to watch the cutting power and surface finish, especially for medical tools.

Key Takeaways

Wire EDM can cut nitinol tubing very accurately. It makes the surface smooth and keeps its special properties safe.

Picking the right tubing is important. Holding it still and cleaning it before cutting helps stop problems. This also makes the results better.

Setting up the machine carefully is needed. Adjusting the cutting settings stops burns, cracks, and wire breaks.

Using the right cooling fluids is important. CH-oil or deionized water keeps the tubing safe. These fluids help make clean and safe cuts.

Checking the tubing after cutting is needed. This makes sure the quality is good. It helps find problems early for medical and industrial use.

Why Choose Wire EDM for Nitinol

Precision and Surface Quality

When you cut nitinol, you need to be very careful. Wire EDM helps you make very exact cuts. You can cut with a tolerance as small as ±10 µm. This is important for medical tools. Even a tiny mistake can cause problems. Wire EDM does not leave rough edges or dirt on the nitinol. You do not have to do extra cleaning. This saves time and keeps the nitinol smooth and safe.

Tip: Always look at the surface after you cut. A smooth surface helps medical tools work better.

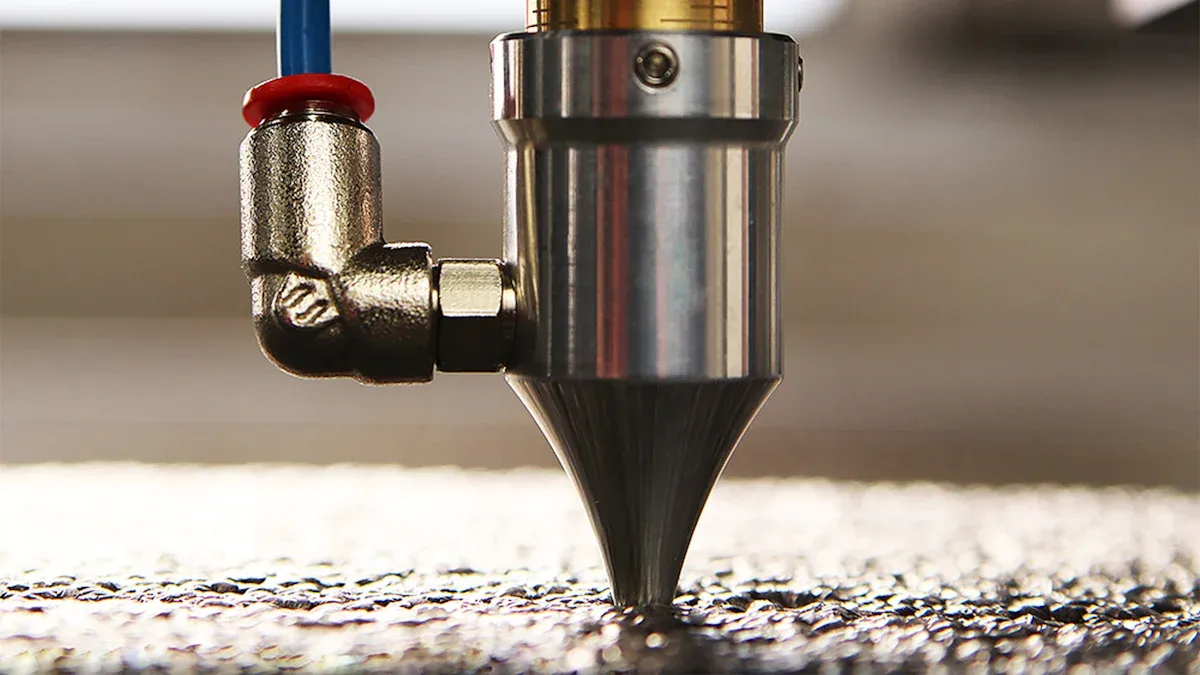

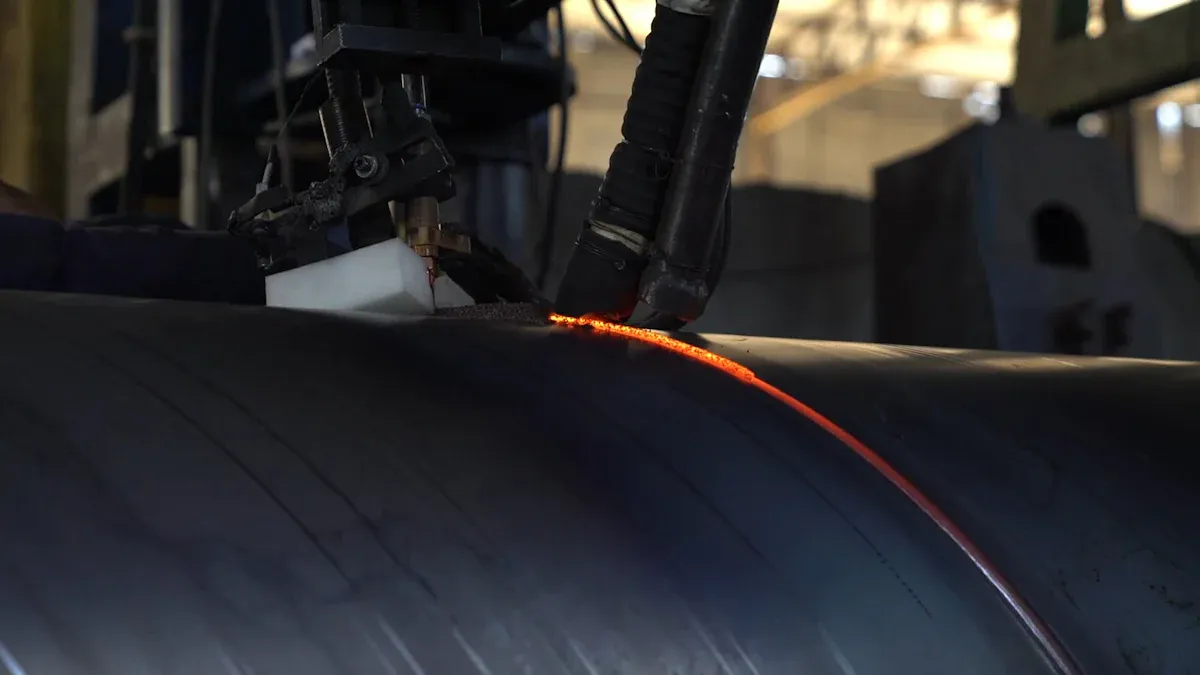

Wire EDM uses a thin wire to cut nitinol. The process does not change how the nitinol acts. There is no heat damage, so nitinol stays superelastic and keeps its shape memory. Other ways of cutting, like waterjet-guided laser, can heat up the nitinol. This heat can make nitinol weaker and less safe for medical tools.

Advantages for Nitinol Cutting

Wire EDM is better than other ways to cut nitinol. It cuts faster and costs less money. The table below shows how wire EDM and waterjet-guided laser are different:

Specification/Metric | Wire EDM (Finecut FAW300) | Waterjet-guided Laser Cutting |

|---|---|---|

Cutting speed | Up to 469 mm/min (max), average 126 mm/min | About 30 mm/min |

Cutting time (example batch) | 9 min 52 sec (including piercing) | Longer (4 times slower) |

Surface quality | No burrs, oxides, or slag; no after treatment needed | Heavy slag formation, requires post-processing |

Tolerances | ±10 µm | Not specified, implied less precise |

Heat impact on material | None; no changes in material structure | Present (implied by slag and heat effects) |

Investment cost | 50% lower than waterjet-guided laser | Higher |

Operational cost per piece | 2.47 EUR/component (at 15 EUR/h) | Higher (implied by slower speed and post-processing) |

Number of set-ups | 1 | More (hole making separate) |

Wire EDM gives you faster cuts, lower costs, and better accuracy. You also need fewer set-ups, so your work is easier. For medical nitinol, you must stop heat from hurting the material. Wire EDM lets you control the energy and stops sparks. This keeps nitinol strong and safe for medical use.

Wire EDM is the best way to cut nitinol. You get smooth cuts, high accuracy, and you protect nitinol’s special features. If you use wire EDM, your medical and factory parts will be top quality.

Preparation for EDM Cutting

Selecting Nitinol Tubing

You must pick the right nitinol tubing for your job. Make sure the tubing has the right size and wall thickness. Nitinol comes in different types, so check the details before you cut. Micro-EDM is good for nitinol because it cuts hard materials without pushing on them. You can use a wire as thin as 0.010 inch, usually made of copper. Machines like CHMER help you make very exact cuts. Always look at the tubing to see if it is straight and smooth before you cut. This helps stop problems during cutting.

Micro-EDM works well with nitinol’s low heat flow and high bendiness.

Use machines that have low energy, fast sparks, and small spark gaps.

Change voltage, capacitance, and electrode type for the best cut.

Keep the area clean to protect the tubing’s surface.

Fixturing and Cleaning

Holding the tubing the right way is very important. You need to keep the nitinol tubing straight and still. Many companies use special holders or tools to keep the tubing in place. This stops the tubing from bending or changing shape while you cut. Holding the tube tight helps you get smooth cuts with no rough edges. Clean the tubing before you start. Take off any oil or dust that could mess up the cut. Clean tubing gives better results and keeps your machine safe.

Tip: Always check your holders before you cut. A steady setup gives you better and repeatable cuts.

Safety and Coolants

Safety is always important when cutting nitinol. Wear gloves and safety glasses to keep safe from sparks and bits of metal. Use special fluids like CH-oil or deionized water to cool the tubing and wire. These fluids help control heat and stop burns on the nitinol. Good cooling keeps the tubing’s superelasticity safe. Always check the fluid levels before you start. Change the fluids if needed to keep cutting smooth.

Coolant/Dielectric | Purpose | Benefit for Nitinol Cutting |

|---|---|---|

CH-oil | Cools and insulates | Reduces heat, prevents burns |

Deionized water | Removes debris, cools | Keeps surface clean and smooth |

If you follow these steps, you will get safe and accurate EDM cuts on nitinol tubing.

Wire EDM Cut Nitinol Tubing: Process Steps

Machine Setup and Calibration

You must set up the machine carefully before cutting nitinol tubing. Calibration helps make sure your cuts are exact every time. Always check the machine’s settings before you start. Use the right wire size, like 0.010 inch copper or zinc-coated brass. Pick a machine that lets you make small changes, such as a CHMER model.

Pay attention to these calibration settings and what they do:

Calibration/Setup Parameter | Critical Performance Metric | Effect/Insight |

|---|---|---|

Pulse time (Ton) | Surface Roughness (SR) | Lower Ton with lower Toff and higher wire feed (WF) and servo voltage (SV) leads to lower SR (< 2 µm), desirable for biomedical use |

Pause time (Toff) | Surface Roughness (SR) | Lower Toff combined with lower Ton and higher WF and SV improves surface quality |

Wire feed (WF) | Surface Roughness (SR), Tool Wear Rate (TWR) | Higher WF with lower Ton and Toff reduces SR; WF influences TWR significantly |

Servo Voltage (SV) | Surface Roughness (SR), Material Removal Rate (MRR), Tool Wear Rate (TWR) | SV is the most significant factor for surface quality; higher SV improves SR but lower SV increases MRR; SV and WF strongly influence TWR |

Electrode Wire Type | Surface Roughness (SR), Tool Wear Rate (TWR), MRR | Zinc coated brass wire reduces SR and TWR and increases MRR compared to uncoated wire |

Optimization Method | Calibration Procedure | Response Surface Methodology (RSM) combined with Modified Differential Evolution (MDE) algorithm used to optimize parameters for simultaneous minimization of SR and TWR and maximization of MRR |

Watch these numbers during setup. This helps stop burns and wire breaks. Use response surface methodology to fine-tune your settings for better cuts.

Tip: Try a short test cut on scrap nitinol tubing first. This helps you find mistakes before you start the real job.

Parameter Optimization for Nitinol

Getting your settings right is important for good cuts. When you wire edm cut nitinol tubing, you need to balance speed, smoothness, and tool wear. Studies show pulse-off time changes how rough the surface is. Pulse-on time changes how wide the cut is. Discharge current controls how fast you remove material.

Here are the best settings for nitinol:

Parameter | Optimal Value for Max MRR | Optimal Value for Min SR | Effect on EDM Process of Nitinol Tubing |

|---|---|---|---|

Discharge Current | 5 A | 1 A | Higher current increases MRR but may increase SR |

Pulse-on Time (Ton) | 110 μs | 1 μs | Longer Ton improves MRR; shorter Ton reduces SR |

Pulse-off Time (Toff) | 1 μs | 24 μs | Short Toff favors MRR; longer Toff improves SR |

MWCNT Concentration | 1 g/L | 1 g/L | Addition of MWCNTs improves MRR by 75.42% and reduces SR by 19.15% |

Use lower discharge current and shorter pulse-on time for a smoother surface. If you want to cut faster, use more current and longer pulse-on time, but the surface may get rougher. Always change pulse-off time to help the surface finish. Adding multi-walled carbon nanotubes (MWCNTs) to the fluid can help you cut faster and make the surface smoother.

Note: If you see burns or tiny cracks, lower the discharge current and pulse-on time. This keeps nitinol’s superelasticity safe.

Executing the EDM Cut

After setup and picking your settings, you can start cutting. Hold the nitinol tubing tight in the fixture. Make sure the tubing stays straight and does not move. Start the wire edm cut nitinol tubing process by slowly feeding the wire through the tube wall. Use the right fluid, like CH-oil or deionized water, to cool the wire and wash away bits.

Follow these steps for the best cut:

Begin with low energy to stop burns.

Slowly make the wire tighter to keep it from breaking.

Watch the cut for sparks or color changes.

Change settings if you see rough spots or wire breaks.

The fluid is very important when cutting nitinol. It keeps the tubing cool and removes bits of metal. This protects the tubing and makes the cut smooth. After cutting, check the tubing for smoothness and size. If needed, use gentle cleaning, like ultrasonic cleaning, to get rid of leftover bits.

Tip: Always look at the tubing under a microscope after cutting. If the surface is clean and smooth, your settings worked well.

You can get very exact and smooth cuts by following these steps. The right setup, good settings, and careful work will help you wire edm cut nitinol tubing for medical and factory uses.

Troubleshooting and Optimization

Common EDM Issues

When you cut nitinol tubing, you can run into problems. You need to watch for these to keep your work steady and accurate.

Acoustic emission monitoring helps you find tool wear and wire breaks.

Vibration monitoring lets you check the wire’s position and spot breaks early.

Electrical pulse detection shows you if there is trouble in the discharge gap.

You might see wire blocking, short circuits, or broken wires while cutting.

If the electrodes touch too long, wires can break and cracks can form.

After a short circuit, you may see tiny melted fibers. These can cause more short circuits and make your cuts worse.

Use these checks to find problems fast. They help you fix issues quickly and keep your cutting process running well.

Tip: Always look for broken wires or short circuits. Finding them early saves time and keeps your nitinol tubing safe.

Tips for Best Nitinol Cutting Results

You can get better results by using smart steps. Cleaner nitinol lasts longer and has a smoother surface. Studies show that less non-metal stuff and better melting and drawing help a lot. High-purity nitinol has fewer problems and lasts longer. Cracks often start at tiny particles, so clean material is important.

Watch your process closely. How hard the mandrel is, how you draw, and how you heat the tubing all matter. Using polycrystalline diamond dies instead of tungsten carbide dies makes the surface better. Final steps like centerless grinding and aging help nitinol stay superelastic for medical tools.

Always check your tubing after you cut it. Look for smoothness and any surface problems. If you want to cut nitinol bars or tubing very well, follow these tips:

Pick high-purity nitinol.

Make your drawing and heating steps better.

Use advanced dies for drawing.

Do final surface treatments.

Watch for defects during the process.

Remember: Checking quality every time after cutting makes sure your nitinol tubing is good enough for medical and factory use.

You get good results if you pay attention to each step. Getting ready, picking the right settings, and fixing problems help you avoid mistakes. Always check things like how fast you remove material, how rough the surface is, and how wide the cut is. Use tools like SEM imaging and Ra meters to make sure your nitinol meets tough rules. When you make your process better, you work faster and waste less. Follow these tips to make sure your nitinol cutting jobs are high quality and dependable.

FAQ

What wire size works best for cutting Nitinol tubing?

You should use a wire size of 0.010 inch for most Nitinol tubing. This size gives you precise cuts and helps prevent wire breakage. Always check your machine’s manual for the best wire size for your specific job.

How do you prevent burns or cracks during EDM cutting?

Lower the discharge current and pulse-on time to reduce heat. Use proper cooling fluids like CH-oil or deionized water. Always monitor the process for sparks or color changes. Quick adjustments help you avoid surface burns and micro-cracks.

Can you reuse Nitinol tubing after EDM cutting?

You can reuse Nitinol tubing if the surface remains smooth and free of defects. Inspect the tubing under a microscope. If you see cracks or rough spots, do not reuse it for critical applications.

What is the best way to clean Nitinol tubing after cutting?

Use ultrasonic cleaning to remove debris.

Rinse with deionized water.

Dry the tubing with clean air.

This process keeps the surface smooth and safe for medical or industrial use.

Why does wire break during EDM cutting?

Wire breaks when tension is too high or the discharge gap is too small. You should check your machine settings and reduce wire tension. Make sure the tubing stays steady in the fixture to prevent sudden breaks.

See Also

A Complete Guide To Choosing Proper Nitinol Tubing

The Process Behind Manufacturing Nitinol Tubing For Medicine

Detailed Steps To Create Nitinol Microtubing For Neurovascular Use