Everything About the Distinct Properties of Nitinol Tubing for Heart Stents

Material choice in heart stents affects safety and results for each patient. Studies with many patients show that stent breaks are often caused by the material. These breaks can mean more surgeries and higher risks for problems.

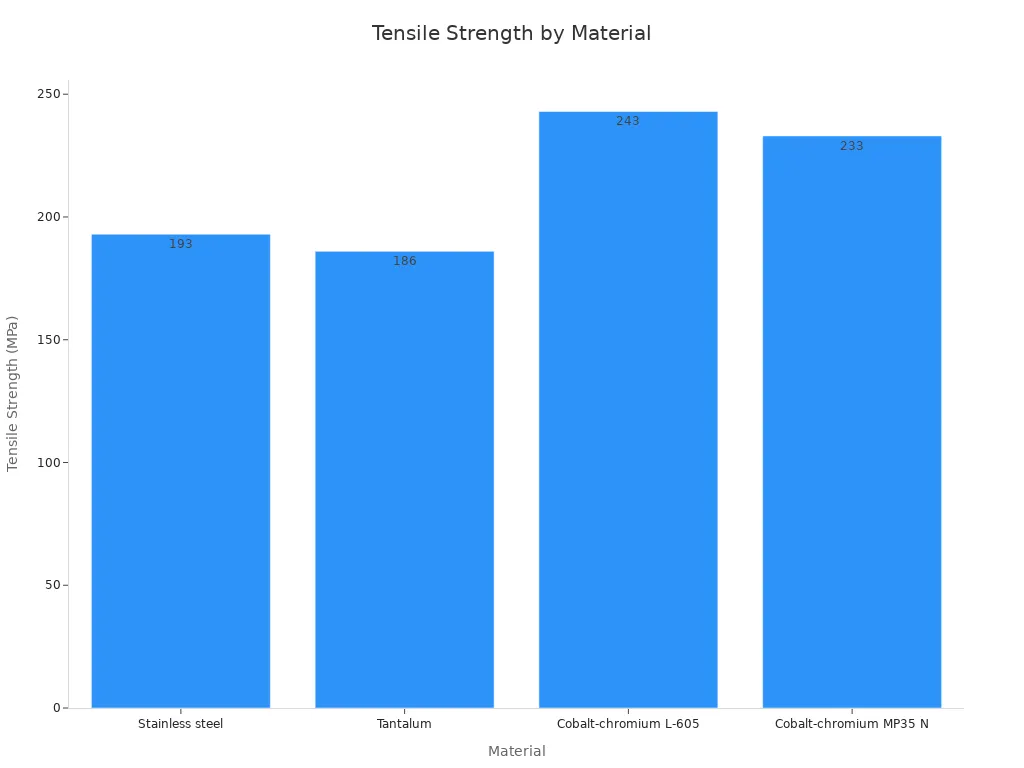

Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elastic Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|

Stainless steel | 193 | 595 | 231.14 | 40 |

Tantalum | 186 | 285 | 514.70 | N/A |

Nitinol | 45–50 | 1200 | 436.12 | ~20 |

Cobalt-chromium L-605 | 243 | 1020 | 536.20 | 50 |

Cobalt-chromium MP35 N | 233 | 930 | 529.82 | 45 |

Nitinol Tubing for Cardiovascular Stents is special because it is very strong and also bends easily. This helps stents move with the blood vessel and not break. It helps patients heal better and have fewer problems.

Key Takeaways

Nitinol tubing is strong and flexible. It lets heart stents bend with blood vessels. The stents do not break. This helps keep patients safe. It also helps them heal better.

The shape memory effect helps nitinol stents go back to their first shape. This happens inside the body. It makes it easier for doctors to place the stents. It also helps doctors be more exact.

Superelasticity lets nitinol stents bend and stretch many times. The stents do not break easily. This lowers the chance of stent failure. It helps the stents last a long time.

Nitinol has a special surface. It does not rust. It also lets out less nickel. This makes it safe for people. It is less likely to cause allergies or blood clots.

Clinical studies show nitinol stents last for many years. They fit blood vessels well. They lower the need for more surgeries. This helps people with heart and artery problems.

Nitinol Tubing for Cardiovascular Stents

Alloy Composition

Nitinol tubing for cardiovascular stents is made from a mix of nickel and titanium. Makers use almost the same amount of each metal, about 50% nickel and 50% titanium by weight. This careful mix gives nitinol its special features. The table below shows what is in nitinol used for medical devices:

Element | Percentage by Weight | Tolerance (%) | Impurities (%) |

|---|---|---|---|

Nickel | ~50 | ±1 | <0.2 |

Titanium | ~50 | ±1 | <0.2 |

Nitinol is called a shape memory alloy. The almost equal mix of nickel and titanium is important for the shape memory effect and superelasticity. This mix lets nitinol tubing for cardiovascular stents work well inside the body. The high purity also lowers the chance of bad reactions, so it is safer for heart implants.

Note: The nickel in nitinol can cause allergies in some people. But the titanium makes a special layer that stops nickel from leaking out. This layer also helps the body accept the stent.

Shape Memory Effect

The shape memory effect is a key feature of nitinol tubing for cardiovascular stents. This means the material can go back to its original shape. Doctors can cool or squeeze the stent to change its shape. When the stent is inside the body, it warms up and goes back to its set shape. This happens at a certain temperature called the transformation temperature.

Shape memory helps doctors put stents in the right place. The stent can be made small to fit in a tube, then it grows to fit the blood vessel. This is called shape memory and deployment precision. The shape memory effect lets the stent fit the vessel and keep its shape, even when the vessel moves.

Tests like Differential Scanning Calorimetry and Bend Free Recovery show that nitinol tubing for cardiovascular stents can get its shape back after being bent. These tests prove the shape memory effect helps the stent work well for a long time. The stent can open up by itself, so doctors do not need a balloon. This makes the surgery easier and safer for the patient.

Superelasticity and Flexibility

Superelasticity is another important feature of nitinol tubing for cardiovascular stents. This means the material can bend and stretch more than most metals, then go back to its shape. Superelasticity lets the stent handle the movement and pressure inside blood vessels.

Tests show that nitinol tubing for cardiovascular stents can take a lot of stress, from 500 MPa to 900 MPa, and still keep its shape memory. Tensile and cyclic tests show nitinol can get back over 90% of its shape after two bends and over 96% after ten bends. The material can stretch over 6.5% and still return to normal, which shows it is strong and flexible.

Superelasticity and flexibility help the stent fit the curves of the vessel. This lowers the chance of the stent breaking or moving out of place. Computer tests show that nitinol tubing for stents can adjust to the changing conditions in the body, so the stent stays in the right spot and gives good support.

Clinical studies show why these features are helpful:

The MISAGO 1 trial showed better results for patients with nitinol stents than with regular angioplasty.

The ORION trial found nitinol stents kept vessels open and were more flexible.

The Supera™ Stent, made from nitinol tubing for cardiovascular stents, did not break in over 2,000 patients after one year.

High-cycle fatigue life studies show nitinol tubing for cardiovascular stents can take repeated stress, so it works well for a long time.

Superelasticity and flexibility help stents move with the vessel and keep blood flowing. These features, along with the shape memory effect, make nitinol tubing for cardiovascular stents a top pick for doctors and patients.

Biocompatibility for Safe Medical Use

Corrosion Resistance

Nitinol tubing for heart stents is safe for the body. It does not rust easily because of a titanium dioxide layer. This layer forms on its own and acts like a shield. It stops nickel from getting into the body. This helps lower the chance of allergies. Scientists use different tests to check this layer:

If the breakdown potential is over 600 mV, the stent resists rust well.

They check if the titanium dioxide layer is thin and even. A smooth, thin layer gives better protection.

Nickel release tests show how much nickel comes out over time.

Electropolished nitinol tubing lets out less nickel than heat-treated tubing. This means a smooth finish is better.

Animal tests show less nickel in blood and tissue with polished stents.

Other tests, like cyclic potentiodynamic polarization, also help check safety. Immersion in fake body fluids is another test. These tests make sure the stent is safe inside the body.

Reduced Thrombogenicity

Being safe for the body helps stop blood clots. Nitinol with a smooth finish has fewer signs of clotting. It also has less platelet stickiness than rough surfaces. This finish helps body cells grow over the stent. That makes it safer for people. In animal tests, both smooth and rough nitinol stents caused fewer clots than stainless steel ones. Some surface treatments make nitinol very water-loving. This stops proteins from sticking and stops clots from forming. These changes make nitinol safer and lower the chance of problems.

Long-Term Implantation

It is important for implants to be safe for a long time. Studies and trials show nitinol stents work well for many years. The ORION trial watched 123 patients for nine months. No big safety problems were found. Researchers use a “durability tripod” method. This uses real-life data, computer models, and stress tests. It shows nitinol stents can last through millions of cycles in the body. One big study followed 1,824 patients and 2,211 limbs for up to ten years. No device safety problems were found. This proves nitinol is safe for long-term use in people.

Clinical Benefits of Nitinol Tubing for Stents

Fatigue Resistance

Nitinol tubing for stents is known for being strong and lasting long. Stents inside the body bend and stretch all the time. This happens because blood flows and vessels move. Nitinol’s superelasticity lets it bend many times without breaking. The stent can flex and go back to its shape again and again. It does this even when stretched a lot.

Researchers found nitinol can handle strain from 4% to 12%. Most other metals break at much lower levels. Nitinol’s special phase change and superelasticity stop cracks from starting. They also stop cracks from getting bigger. Makers use electropolishing and coatings to make the surface smooth. This helps stop cracks and makes the stent last longer. Tests show nitinol tubing for stents keeps its strength and shape over time.

Some things help nitinol resist fatigue:

Smooth, shiny surfaces stop cracks from forming.

Hydrophilic coatings protect from rust and damage.

Strict rules (ISO 13485, FDA, ASTM F2063) keep quality high.

Clinical trials back up these facts. The DURABILITY II trial watched 272 patients. Only 0.9% of stents broke after two and three years. Patients did better and needed fewer repeat surgeries. These results show nitinol stents work well for a long time. Patients can trust their treatment.

Device | Sample Size | Technical Success Rate | Complication Rate | Occlusion Rate (Immediate / Follow-up) | Notes on Catheter Failure or Complications |

|---|---|---|---|---|---|

PulseRider | 34, 63, 54 aneurysms | 96.2% | 3 major in 54 cases | 82.4% immediate; 87.9% at 6 months | No direct catheter failure; low complications |

LVIS Jr | 30 patients | N/A | N/A | 89.6% immediate; 96% at 5.2 months | Smaller catheter, easier vessel access |

Cascade | 12 aneurysms | N/A | None reported | 75% complete occlusion | No catheter failure reported |

pCONus | 203 aneurysms | 100% | 0% technical; 7% morbidity; 0% mortality | 60% complete; 14% retreatment | No catheter failure; no hemorrhagic complications |

These results show nitinol stents are strong and last long in real life.

Vessel Conformity

Vessel conformity is very important for stent success. Blood vessels twist and turn in the body. Nitinol’s superelasticity and flexibility help stents fit these shapes. This means the stent does not hurt or bother the vessel. The stent fits close to the vessel wall. This helps blood flow and lowers the chance of restenosis.

Imaging studies with flat-panel CT show segmented nitinol stents keep the vessel’s shape best. Open-cell nitinol stents, like Neuroform2, fit curved vessels well. They help keep the vessel’s natural shape. Braided stents can bend but sometimes flatten or crimp. This can change blood flow. Segmented nitinol stents do not change the vessel’s shape much. They fit the wall better.

A study with silicone models compared stent types. Segmented nitinol stents kept the vessel’s curve. Other stents made the vessel straighter. A close fit lowers the risk of restenosis and problems. Patients heal better and need fewer extra procedures.

Tip: Stents that are flexible and can adapt lower the risk of vessel injury and help keep blood flowing well.

Self-Expansion

Self-expansion is a big plus for nitinol stents. Nitinol’s superelasticity lets the stent open by itself in the vessel. Doctors can squeeze the stent to make it small for delivery. When released, it goes back to its set shape and size. This helps place the stent right and gives gentle support to the vessel wall.

Clinical trials like RELIABLE and BIOFLEX-COF studied self-expanding nitinol stents in real patients. They checked how well the stents opened and how much force they used. Results showed nitinol stents expand evenly and fit the vessel well. They work even in tricky vessel shapes. The stents can change as the vessel changes over time. This helps stop restenosis.

Patients with self-expanding nitinol stents have fewer problems. They also do better over time. There is less risk of restenosis and fewer repeat surgeries. This means a better life for patients. The stent’s flexibility and ability to adapt help blood flow and healing.

Applications in Coronary and Peripheral Artery Treatments

Coronary Artery Stents

Coronary artery stents help open blocked heart arteries. These stents need to be strong and flexible. They also must be safe for long-term use. Nitinol tubing gives the stent superelasticity and shape memory. This helps the stent fit the vessel and stay in place. Doctors use catheters to put the stent in the heart. This way is safe and accurate. In the SCORES Registry, a self-expanding nitinol stent worked well. It had a 96.8% success rate during the procedure. There were few major heart problems after 30 days. After nine months, most patients did not need another procedure. This shows nitinol stents lower the need for repeat treatments. These results support using nitinol in heart implants.

Peripheral Artery Stents

Peripheral artery stents treat blockages outside the heart. These are often in the legs. These arteries bend and twist when people move. Nitinol tubing lets the stent flex and go back to its shape. This works even in hard-to-reach places. The table below shows how nitinol works in these stents:

Performance Metric | Outcome |

|---|---|

Superelasticity | Stents recover shape and fit complex vessel curves. |

Flexibility | Easy navigation through vessel bends, less trauma. |

Fatigue Resistance | Survives 10 million cycles, no fractures or strength loss. |

Biocompatibility | Resists corrosion, safe for long-term use. |

Clinical Success Rates | Up to 98% success, patency rates from 58% to over 90% at 12 months. |

Stent Fracture Rates | 0% in many trials at 12 months. |

Adaptation to Anatomy | Interwoven wires give strength and flexibility for complex shapes. |

Long-term Durability | Meets safety standards for years of use. |

Clinical Trial Example | SUPERB trial: 86.3% patency at 12 months, 0% fracture, 88.7% clinical improvement. |

These features help patients move more easily. They also lower the risk of stent failure.

Advanced Stent Designs

Engineers use nitinol’s special features to make better stents. Interwoven and self-expanding stents use superelasticity and shape memory. This makes the stents work better. Studies show nitinol changes shape under stress without damage. Finite Element Method simulations help test wire sizes and braiding angles. These tests show wire size changes the force the stent gives. Braiding angle changes how stiff the stent feels. Microanalyses show how nitinol tubing is made affects how long the stent lasts. Better tubing means fewer cracks and longer life. These new designs make stents safer and more reliable. This helps patients with both heart and peripheral artery problems.

Practical Selection of Nitinol Tubing for Stents

Dimensions and Mechanical Properties

Picking the right nitinol tubing for stents needs careful measuring. Doctors and engineers check wire diameter, ring mean diameter, number of turns, and bundle diameter. These measurements help the stent fit the vessel well. The table below shows some common numbers:

Parameter | Typical Range | Importance |

|---|---|---|

Wire Diameter | 0.16–0.22 mm | Flexibility and strength |

Ring Mean Diameter | 27–48 mm | Vessel size matching |

Number of Turns | 8–14 | Stent expansion and support |

Bundle Diameter | 0.53–0.95 mm | Overall stent profile |

Wall Thickness | Tight tolerances | Fatigue resistance and durability |

Flexibility, elasticity, and fatigue strength are very important. How the tubing is made changes how long it lasts. The TM-1 technique can make the tubing last two or three times longer. The tubing must bend at different angles and keep its shape. These features help the stent support the vessel for years. The stent can also fit each patient’s needs.

Surface Finish and Customization

The surface finish is important for stent safety and how it works. Electropolishing makes the surface smooth. This lowers the chance of blood clots and helps the body accept the stent. Custom stent designs use micro-patterns, laser cutting, and special roughness. These choices help the stent fit better and work safely.

Micro-patterns like stripes or circles make more surface area. This helps remove clots more easily.

Electropolished surfaces let out less nickel, which is safer for people.

Controlled roughness helps tissue grow over the stent and keeps it stable.

New ways to make stents allow for exact changes. This means each stent can fit the patient and vessel better.

Manufacturing and Quality Standards

Companies that make nitinol tubing follow strict rules for safety. They use ASTM F2063 to check what is in the tubing and how strong it is. ISO 13485 shows the factory meets world medical device rules. Factories use cleanrooms, check equipment, and do audits to keep quality high.

Standard/Requirement | Description | Impact on Quality and Compliance |

|---|---|---|

ISO 13485 Certification | Medical device quality management system | Ensures safety and global compliance |

ASTM F2063 | Chemical and mechanical property standards | Verifies tubing strength and durability |

FDA Compliance | U.S. regulatory approval for medical devices | Allows market access and patient safety |

Surface Finishing | Electropolishing and polishing | Improves biocompatibility and function |

Quality checks include pulling tests, bending tests, and rust tests. Factories use special controls to find problems early. These steps help make sure every tube is safe for patients.

Nitinol tubing is special for heart stents because it is safe for the body, bends easily, and lasts a long time. Studies show that being safe for the body helps stop bad reactions and keeps people safe for years. The tubing can bend with the blood vessel as it moves. It also stays strong after being used many times. Being safe for the body also means less swelling and less nickel gets out, which keeps patients safer. New ways to make stents and custom designs help make them even safer and work better. As more people need stents, new research and careful ways of making them will bring better choices. Safety and being good for the body will be very important for stents in the future.

FAQ

What makes nitinol tubing different from stainless steel in stents?

Nitinol tubing can bend and then go back to its shape. Stainless steel cannot do this. Nitinol’s superelasticity lets stents fit vessels better. It also helps them last longer. Doctors pick nitinol because it is strong and flexible.

Can nitinol stents cause allergic reactions?

Nitinol has nickel, and nickel can cause allergies. But the titanium in nitinol makes a shield. This shield stops most nickel from getting out. Most people do not have allergies with nitinol stents.

How long do nitinol stents last inside the body?

Nitinol stents can stay in the body for many years. Studies show they are strong and do not break easily. Most people do not need another stent after getting one made of nitinol.

Are nitinol stents safe for MRI scans?

Nitinol stents are safe for MRI scans. Nitinol is not magnetic. People with nitinol stents can get MRI pictures safely. Doctors still check each person before the scan.

Why do doctors prefer self-expanding nitinol stents?

Doctors like self-expanding nitinol stents because they open by themselves. This helps the stent fit close to the vessel wall. Self-expanding stents lower the chance of hurting the vessel. They also help patients get better results.