Evaluating Top OEMs for High-Strength Nitinol Tubing in 2025

Selecting the right OEM supplier for high-strength Nitinol tubing has become critical as the industry continues to expand. Market projections reveal significant growth, with the Nitinol tubing market expected to grow from USD 1.2 billion in 2024 to USD 2.5 billion by 2033, driven by a 9.5% CAGR from 2026 to 2033. This growth underscores the need for suppliers capable of meeting increasing demands for precision and scalability. Advanced innovations, such as the Nitinol DNA Intelligence Engine, further highlight the importance of choosing experienced partners who leverage AI-driven insights to enhance product development. Among these, AccuPath stands out as a trusted provider, known for its reliable solutions in high-strength Nitinol tubing for vascular stents OEM applications.

Key Takeaways

Pick OEM suppliers who are skilled in making strong Nitinol tubes. This helps ensure good quality and trust for medical use.

Check if suppliers can customize products to fit specific medical device needs. This improves how well they work and follow rules.

Choose suppliers with good quality checks and certifications. This ensures they meet industry rules and standards.

Look at how often suppliers deliver on time and how long it takes. This helps avoid delays in making products.

Think about after-sale help and repair services from suppliers. This keeps things running smoothly and customers happy for a long time.

Understanding High-Strength Nitinol Tubing

Key Properties of Nitinol Tubing

Nitinol tubing stands out due to its unique combination of mechanical and thermal properties. Its superelasticity allows it to bend significantly and return to its original shape without permanent deformation. This characteristic is particularly valuable in applications requiring flexibility and durability. Shape memory is another defining feature, enabling the material to recover its pre-defined shape after exposure to heat or mechanical stress. These properties stem from a diffusionless phase transformation between the austenite and martensite phases, which ensures reliable performance under extreme conditions.

The tubing also excels in biocompatibility and corrosion resistance, making it ideal for medical applications. Its ability to withstand harsh bodily environments reduces the risk of implant degradation, ensuring patient safety and minimizing the need for replacement procedures. Additionally, Nitinol's fatigue resistance allows it to endure millions of stress cycles, making it indispensable in high-stress environments.

Key attributes include:

Exceptional shape memory and superelasticity for precise applications.

Thermal stability and mechanical performance in high-temperature environments.

Corrosion resistance due to its protective oxide layer.

These properties make Nitinol tubing a preferred choice for industries requiring reliability and precision.

Applications in Vascular Stents and Bioresorbable Stents

Nitinol tubing plays a critical role in the development of vascular stents and bioresorbable vascular stents. Its superelasticity enables stents to navigate complex anatomical pathways without kinking, ensuring smooth deployment. The shape memory property allows self-expanding stents to adapt to the body's natural movements, providing consistent support to blood vessels. These features are particularly beneficial in bioresorbable vascular stents, which dissolve over time, reducing long-term complications.

In vascular stents, Nitinol's fatigue resistance ensures durability, even in high-stress environments like pulsating arteries. The material's biocompatibility and corrosion resistance further enhance its suitability for medical implants, ensuring safety and reliability. Bioresorbable vascular stents benefit from these properties by offering temporary support while gradually resorbing into the body, eliminating the need for invasive removal procedures.

Applications include:

Self-expanding stents that leverage shape memory for adaptability.

Guidewires utilizing superelasticity to navigate intricate pathways.

Bioresorbable vascular stents designed for temporary support and safe resorption.

These innovations highlight Nitinol tubing's transformative impact on modern medical devices, particularly in cardiovascular treatments.

Top OEM Suppliers for High-Strength Nitinol Tubing in 2025

AccuPath: Innovation and Reliability

AccuPath has established itself as a leader among Nitinol tubing suppliers, particularly in the medical device sector. The company’s reputation stems from its ability to deliver high-quality nitinol tubing tailored to meet the stringent demands of vascular stents OEM applications. AccuPath’s advanced manufacturing techniques ensure exceptional fatigue resistance, a critical factor for applications requiring durability and precision. This capability makes their products ideal for high-stress environments, such as cardiovascular systems.

Customization is another hallmark of AccuPath’s offerings. The company provides tailored solutions that address specific client needs, enhancing the performance and reliability of medical devices. Their focus on precision and structural integrity ensures that their high-strength nitinol tubing for vascular stents OEM applications meets the highest industry standards. AccuPath’s customer-centric approach further solidifies its position as a trusted partner in the Nitinol tubing market.

Key Strengths of AccuPath:

High fatigue resistance for demanding applications.

Advanced manufacturing techniques for superior structural integrity.

Customization options tailored to client requirements.

Dynalloy: High Fatigue Resistance

Dynalloy is another prominent name among Nitinol tubing suppliers, known for its commitment to quality and innovation. The company specializes in producing high-quality nitinol tubing with exceptional fatigue resistance, making it a preferred choice for medical device manufacturers. Dynalloy’s advanced manufacturing processes ensure consistent product performance, even under extreme conditions.

The company’s dedication to quality extends to its rigorous testing protocols, which guarantee that each product meets or exceeds industry standards. Dynalloy’s expertise in high-strength nitinol tubing for vascular stents OEM applications has earned it a strong reputation in the market. Their focus on reliability and precision makes them a valuable partner for clients seeking durable and efficient solutions.

Market Trends Supporting Dynalloy’s Growth:

Increasing adoption of Nitinol-based medical tubing for stents and guidewires.

Rising demand for customized solutions to enhance patient outcomes.

Fort Wayne Metals: Advanced Manufacturing Capabilities

Fort Wayne Metals stands out as a global leader in the production of high-quality nitinol tubing. The company’s extensive manufacturing capabilities enable it to meet the growing demand for high-strength nitinol tubing for vascular stents OEM applications. Fort Wayne Metals leverages cutting-edge technology to innovate Nitinol properties, ensuring superior performance and reliability.

The company’s expertise extends beyond medical devices to include aerospace applications, showcasing its versatility and technical prowess. Fort Wayne Metals’ commitment to research and development has led to significant advancements in Nitinol tubing, making it a top choice among Nitinol tubing suppliers. Their ability to scale production while maintaining quality sets them apart in a competitive market.

Company | Unique Features | Specialization |

|---|---|---|

AccuPath | Focus on precision and customization, customer-centric approach | Medical devices |

Dynalloy | Advanced manufacturing techniques, commitment to quality | Medical devices |

Fort Wayne Metals | Global leader, extensive production capabilities, innovation in nitinol properties | Medical devices, aerospace |

Fort Wayne Metals’ dedication to innovation and quality ensures that their high-strength nitinol tubing meets the rigorous demands of modern applications. Their products are designed to deliver exceptional performance, making them a trusted supplier in the industry.

Confluent Medical Technologies: Premier Medical Supplier

Confluent Medical Technologies has earned recognition as a premier supplier of high-quality nitinol tubing for medical applications. The company specializes in producing tubing that meets the stringent requirements of the healthcare industry, particularly for vascular stents and other implantable devices. Its expertise in nitinol tubing manufacturing stems from decades of experience and a commitment to innovation.

Confluent Medical Technologies focuses on precision engineering to deliver products that meet exact specifications. Their advanced manufacturing processes ensure consistent quality, making them one of the most reliable nitinol tubing suppliers in the market. The company also offers a wide range of customization options, allowing clients to tailor tubing dimensions, mechanical properties, and surface finishes to suit specific applications.

Notable Achievements:

Development of proprietary technologies for enhanced fatigue resistance.

Collaboration with leading medical device manufacturers to create cutting-edge solutions.

Confluent Medical Technologies emphasizes quality assurance through rigorous testing protocols. Each batch of tubing undergoes comprehensive evaluations to ensure compliance with industry standards. This dedication to quality has positioned the company as a trusted partner for OEMs seeking high-quality nitinol tubing for critical applications.

Resonetics: Precision and Tailored Grades

Resonetics stands out among nitinol tubing suppliers for its focus on precision and tailored solutions. The company leverages advanced laser micromachining technology to produce tubing with unparalleled accuracy. This capability is particularly valuable for applications requiring intricate designs, such as minimally invasive medical devices.

Resonetics offers a diverse portfolio of high-quality nitinol tubing, catering to various industries, including healthcare and aerospace. Their ability to customize tubing grades and dimensions ensures that clients receive products optimized for specific performance requirements. Resonetics also excels in producing tubing with specialized surface treatments, enhancing biocompatibility and corrosion resistance.

The company’s commitment to innovation extends to its research and development efforts. Resonetics invests heavily in exploring new applications for nitinol tubing, ensuring its products remain at the forefront of technological advancements. Their dedication to precision and customization has made them a preferred choice among nitinol tubing suppliers.

Key Features | Benefits |

|---|---|

Laser micromachining technology | Enables intricate designs for minimally invasive devices. |

Tailored tubing grades | Provides optimized solutions for specific applications. |

Surface treatments | Enhances biocompatibility and corrosion resistance for medical implants. |

Resonetics continues to push the boundaries of what is possible with nitinol tubing, delivering solutions that meet the evolving needs of modern industries. Their focus on precision and tailored grades ensures exceptional product performance and reliability.

Comparing OEM Suppliers: Key Evaluation Criteria

Product Variety and Customization Options

When evaluating OEM suppliers, product variety and customization options play a pivotal role. Suppliers with extensive design expertise can create innovative solutions tailored to specific applications. This capability ensures that the tubing meets the unique demands of medical devices, such as vascular stents. Prototyping capabilities further enhance this process by allowing rapid testing and refinement of custom designs before full-scale production.

Access to diverse material options is another critical factor. Suppliers offering a wide range of materials provide flexibility for OEMs to select the most suitable grade for their applications. Collaboration between the supplier and the OEM during the design and production phases ensures that customization options align with the intended use. This partnership fosters innovation and guarantees that the final product meets both functional and regulatory requirements.

Factor | Description |

|---|---|

Design Expertise | Ability to create innovative and practical designs. |

Prototyping Capabilities | Availability of rapid prototyping to refine custom designs. |

Material Options | Access to a wide range of materials for diverse applications. |

Collaboration | Close cooperation with OEMs during design and production phases. |

Quality Standards and Certifications

Quality standards and certifications are non-negotiable when selecting an OEM supplier. A robust Quality Management System (QMS) ensures that the supplier adheres to industry standards and regulatory requirements. Good Manufacturing Practices (GMP) further validate the cleanliness and process controls essential for medical-grade tubing. Suppliers must also demonstrate compliance with FDA regulations and other applicable standards.

Evaluating process control measures and validation procedures is equally important. These practices ensure consistency in production and adherence to agreed-upon specifications. Historical performance, including audit and inspection history, provides insights into the supplier's ability to maintain quality over time. Additionally, a well-implemented Corrective and Preventive Actions (CAPA) system highlights the supplier's commitment to resolving quality issues effectively.

Area of Focus | Description |

|---|---|

Quality Management System (QMS) | Alignment with industry standards and regulatory requirements. |

Good Manufacturing Practices (GMP) | Adherence to cleanliness and process controls. |

Regulatory Compliance | Compliance with FDA and other applicable regulations. |

Process Control and Validation | Measures to ensure consistency and adherence to specifications. |

Audit and Inspection History | Review of past audits and resolutions. |

Corrective and Preventive Actions | Effective identification and resolution of quality issues. |

Pricing and Cost-Effectiveness

Pricing and cost-effectiveness are crucial factors in supplier selection. Understanding cost drivers enables OEMs to negotiate better terms, focusing on labor and overhead rather than individual prices. This approach streamlines negotiations and ensures transparency in pricing structures. Selecting a supplier based on overall value, rather than the lowest bid, often yields better long-term benefits.

True cost reduction should remain a priority. Suppliers that optimize production processes and minimize waste can offer competitive pricing without compromising quality. Evaluating the supplier's ability to cover production costs, set selling prices, and add reasonable markups ensures financial sustainability for both parties.

Key Pricing Strategies:

Control price negotiations by understanding cost drivers.

Focus on value rather than the lowest bid.

Streamline negotiations by targeting labor and overhead costs.

Prioritize true cost reduction through process optimization.

Set Selling Price: Determine pricing based on total production and distribution costs.

Cover Production Costs: Ensure revenue covers all incurred costs to achieve profitability.

Add Markup for Profit: Include a reasonable markup to enhance profit margins.

Customer Service and Technical Support

Customer service and technical support are critical factors when evaluating OEM suppliers for high-strength Nitinol tubing. Effective support ensures that clients receive timely assistance, minimizing disruptions in production and enhancing overall satisfaction. Suppliers with robust customer service frameworks often stand out due to their ability to address inquiries, resolve issues, and provide technical guidance efficiently.

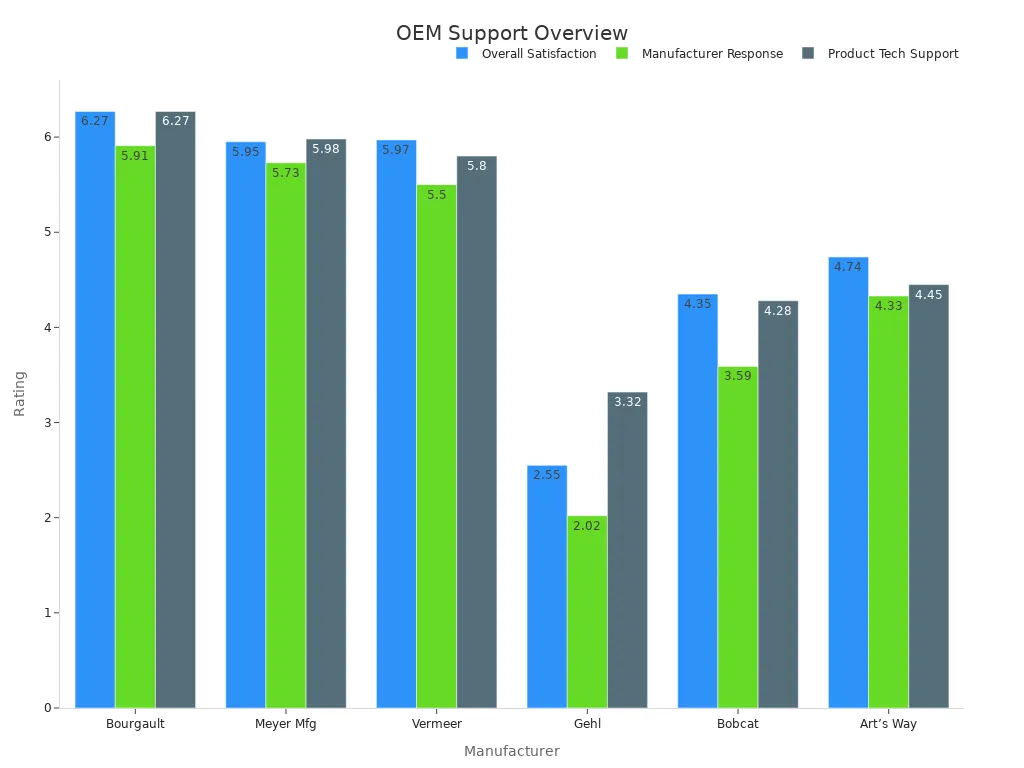

A recent survey highlights the varying levels of customer satisfaction and technical support among manufacturers. The data reveals that Bourgault leads in overall satisfaction and technical support, scoring 6.27 in both categories. In contrast, Gehl scored the lowest, with a technical support rating of 3.32. These insights emphasize the importance of selecting suppliers with proven customer service capabilities.

Manufacturer | Overall Satisfaction | Manufacturer Response | Product Technical Support |

|---|---|---|---|

Bourgault | 6.27 | 5.91 | 6.27 |

Meyer Mfg | 5.95 | 5.73 | 5.98 |

Vermeer | 5.97 | 5.50 | 5.80 |

Gehl | 2.55 | 2.02 | 3.32 |

Bobcat | 4.35 | 3.59 | 4.28 |

Art’s Way | 4.74 | 4.33 | 4.45 |

Suppliers with high ratings in technical support often provide dedicated teams to assist clients with product integration and troubleshooting. They also invest in training programs to ensure their staff remains knowledgeable about the latest advancements in Nitinol tubing technology. This commitment to excellence fosters trust and long-term partnerships with OEMs.

Tip: When selecting a supplier, prioritize those with a proven track record of responsive and knowledgeable technical support. This ensures seamless collaboration and minimizes operational challenges.

Delivery Reliability and Lead Times

Delivery reliability and lead times significantly impact the efficiency of supply chains, especially in industries relying on high-strength Nitinol tubing. Suppliers must demonstrate consistent on-time delivery and maintain short lead times to meet the demands of OEMs. Delays in delivery can disrupt production schedules, leading to increased costs and missed deadlines.

Key metrics for assessing delivery reliability include on-time delivery rates, defect rates, and lead times. Studies show that late shipments and inconsistent quality are common challenges faced by OEMs. Additionally, delays often stem from raw material shortages and inefficient production processes. Suppliers with robust inventory management systems and streamlined production workflows are better equipped to mitigate these issues.

Key Assessment Areas | Metrics to Analyze | Common Findings |

|---|---|---|

Supplier performance | On-time delivery rates, defect rates | Late shipments, inconsistent quality |

Production processes | Lead times, idle hours | Delays due to raw material shortages |

Inventory management | Stock levels, turnover rate | Overstocking or stockouts |

To improve delivery reliability, suppliers should focus on the following strategies:

Proactively managing multiple tiers of suppliers for better visibility.

Leveraging digital technologies to enhance supply chain transparency and risk management.

Note: Suppliers that consistently meet delivery deadlines and maintain high-quality standards contribute to smoother operations and reduced downtime for OEMs.

By selecting suppliers with a strong track record in logistics performance, OEMs can ensure timely access to high-strength Nitinol tubing, enabling them to meet production goals and maintain competitive advantages.

Additional Considerations When Choosing an OEM Supplier

Post-Sale Support and Maintenance

Post-sale support and maintenance are vital for ensuring long-term reliability and customer satisfaction. Suppliers offering robust post-sale services help OEMs address operational challenges efficiently. Quick responses to complaints, product replacements, and proactive maintenance practices foster trust and loyalty among clients.

Several studies highlight the importance of post-sale support in driving customer satisfaction:

Research in Nigeria’s telecommunications sector emphasizes that prompt complaint resolution and product replacements significantly enhance customer loyalty.

An integrated framework for post-sales performance measurement, applied to durable consumer goods, demonstrates the value of structured support systems.

Findings from Nairobi City County reveal that high-quality customer service and maintenance practices strongly predict customer satisfaction.

OEMs should prioritize suppliers with proven post-sale support systems. These suppliers often provide dedicated teams for troubleshooting, regular maintenance schedules, and training programs to ensure seamless product integration. By choosing partners with strong post-sale capabilities, OEMs can minimize downtime and optimize the performance of critical components like bioresorbable polymer stents.

Innovation and R&D Capabilities

Innovation and research capabilities distinguish leading OEM suppliers in the competitive Nitinol tubing market. Suppliers investing in advanced manufacturing technologies and digital transformation initiatives demonstrate their commitment to staying ahead of industry trends.

Key data underscores the scale of R&D investments:

The United States spent $738 billion on R&D in 2021, with $404 billion allocated to industrial manufacturing.

Advanced manufacturing companies collectively invest over $500 billion annually in digital transformation.

AI-related patents have surged between 2020 and 2022, reflecting the growing role of artificial intelligence in medical device development.

Suppliers leveraging these investments often deliver cutting-edge solutions, such as bioresorbable metallic stents with enhanced thrombogenicity profiles. Their focus on innovation ensures products meet evolving regulatory standards and address challenges like in-stent restenosis. OEMs should evaluate suppliers’ R&D capabilities to ensure access to the latest advancements in Nitinol tubing technology.

Industry Reputation and Client Testimonials

A supplier’s reputation and client feedback provide valuable insights into their reliability and performance. Industry rankings and testimonials from healthcare professionals highlight suppliers excelling in customer engagement and product quality.

Key Takeaways | Description |

|---|---|

Industry Leaders | Identifies top-ranked suppliers based on Reputation Scores. |

Performance Insights | Highlights how leading dealerships and brands excel in customer sentiment. |

Improvement Strategies | Offers strategies for suppliers to enhance their reputation and drive sales. |

Transparent rankings, free from financial incentives, ensure unbiased evaluations. Authentic feedback from healthcare professionals further validates suppliers’ trustworthiness. Suppliers with strong reputations often prioritize accountability and continuous improvement, making them ideal partners for OEMs seeking reliable solutions.

OEMs should consider testimonials and rankings when selecting suppliers for critical applications like bioresorbable polymer stents. Positive feedback from industry leaders and end-users reflects a supplier’s ability to deliver high-quality products and maintain strong client relationships.

Choosing the right OEM supplier for high-strength Nitinol tubing remains critical for industries requiring precision and reliability. Suppliers with proven expertise in innovation, quality, and delivery performance ensure seamless integration into demanding applications. AccuPath exemplifies these qualities, offering tailored solutions and advanced manufacturing techniques that meet stringent industry standards.

To make informed decisions, procurement teams should prioritize suppliers with robust data systems, operational focus, and market awareness. The table below synthesizes expert insights on supplier evaluation:

Expert Role | Key Insight |

|---|---|

Manager data strategy automotive | Integrates risk data into systems to enhance supplier reliability decisions. |

Head of data analytics procurement | Focuses on deadlines and performance, emphasizing future-oriented strategies. |

Senior data analyst controlling | Stresses cooperation to access supplier data for effective procurement. |

Head of data platforms and solutions | Highlights challenges in data availability and quality for decision-making. |

Associate partner business intelligence | Warns procurement to stay informed about market data and innovations. |

OEMs should evaluate suppliers based on customization capabilities, quality certifications, and delivery reliability. AccuPath’s commitment to innovation and customer-centric solutions positions it as a preferred choice for high-strength Nitinol tubing.

FAQ

What makes Nitinol tubing ideal for medical applications?

Nitinol tubing offers unique properties like superelasticity, shape memory, and biocompatibility. These features ensure flexibility, durability, and safety in medical devices such as vascular stents. Its corrosion resistance further enhances its suitability for long-term implantation in the human body.

How do OEM suppliers ensure the quality of Nitinol tubing?

OEM suppliers implement rigorous quality control measures, including advanced testing protocols and adherence to certifications like ISO 13485. These practices ensure that the tubing meets industry standards for performance, durability, and safety in critical applications.

Why is customization important when selecting a Nitinol tubing supplier?

Customization allows OEMs to tailor tubing dimensions, mechanical properties, and surface finishes to specific applications. This flexibility ensures optimal performance and compliance with regulatory requirements, particularly in medical devices like bioresorbable stents.

What factors influence the pricing of high-strength Nitinol tubing?

Pricing depends on factors like material grade, manufacturing complexity, and customization requirements. Suppliers offering process optimization and waste reduction can provide cost-effective solutions without compromising quality.

How can OEMs evaluate a supplier’s delivery reliability?

OEMs should assess on-time delivery rates, lead times, and inventory management practices. Suppliers with robust logistics systems and proactive supply chain management consistently meet deadlines, minimizing production disruptions.

Tip: Always request performance data and client testimonials to verify a supplier’s reliability.

See Also

Nitinol Tubing: The Next Generation of Medical Technology

Nitinol Tubing Versus Stainless Steel: A Strength Comparison

Nitinol Tubing Uses in Modern Healthcare Equipment