Why choose thin-wall nitinol tubing micro-laser cutting in 2025

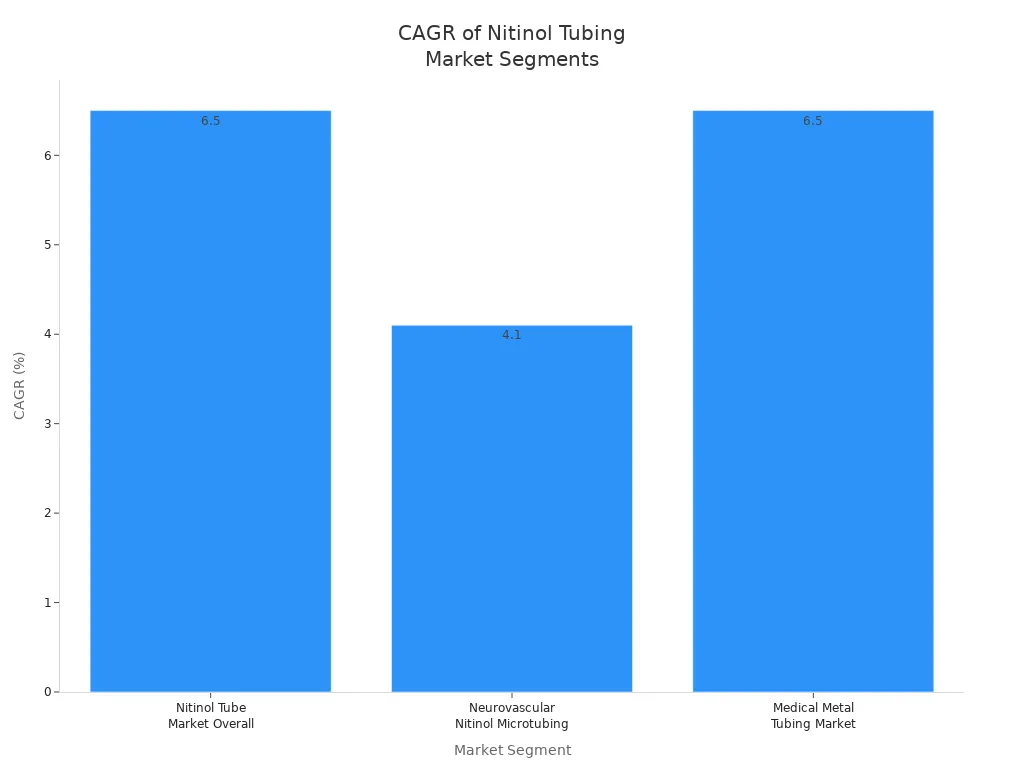

Thin-wall nitinol tubing micro-laser cutting is the top method in 2025. Nitinol has superelasticity and is safe for the body. This makes it important for medical tools like stents and guidewires. More tubing is needed in medical and industrial areas. This is because advanced manufacturing is growing fast. Micro-laser cutting gives exact cuts, is flexible, and keeps quality steady. It also keeps nitinol’s special features safe. The process works for very thin nitinol tubing and tricky shapes. The chart below shows strong growth in the market for laser cut nitinol tubing used in medical devices.

Key Takeaways

Micro-laser cutting makes very exact and neat cuts on thin nitinol tubing. It keeps the tubing’s special features safe for medical use.

This cutting method makes smooth edges without hurting the tubing. This helps medical devices like stents work better and last longer.

The process is quick and always the same. Companies can make many good tubes fast and with trust.

Micro-laser cutting lowers waste and tooling costs. It saves money and helps with new designs and big production runs.

New technologies like femtosecond lasers, AI, and robotics make cutting more exact and better. This makes micro-laser cutting the top choice for nitinol tubing in 2025.

Precision in Thin-Wall Nitinol Tubing

Micro-Laser Cutting Accuracy

Micro-laser cutting helps makers get very exact cuts. It uses a strong laser beam to melt or take away material. The laser follows very tiny paths. Cuts can be smaller than 10 microns wide. The space made by the cut is between 20 and 30 microns. The laser can move along tricky shapes with great accuracy. It can be better than 5 microns. This level of detail matters for medical devices. Nitinol stents need fine mesh shapes.

Nitinol tubing can be as thin as 0.0011 inches. That is about 28 microns. Laser cut nitinol tubing can also use thicker tubes. Some tubes are up to 0.016 inches thick. The process works for both thin and thick tubing. Special lasers, like femtosecond and picosecond, keep heat low. This makes the edges smooth and clean. No burrs are left behind. Smooth edges are important for medical implants. They help stop irritation and make the device safe for the body.

Makers can change the laser’s power and speed. They can also change how many times the laser passes. This helps control heat and keeps nitinol’s special features safe. These features include superelasticity and shape memory. Companies use machines to check every piece of laser cut nitinol tubing. These machines use pictures and measurements. They make sure each part is made just right for medical use.

Tip: Micro-laser cutting works for making new designs fast. It also works for making lots of parts. This helps companies create new medical devices quickly. They can also make more devices without losing accuracy.

Complex Geometries

Laser cut nitinol tubing is great for making tiny shapes. The process uses CNC control and special optics. These guide the laser along hard paths. This lets makers build small medical parts. Examples are nitinol stents and micro-grippers. These parts fit the body’s needs.

Micro-laser cutting makes very small features on nitinol tubing. This is needed for advanced medical devices.

The process does not touch the tubing. It does not crush or bend it, even when the walls are thin.

Fiber lasers give steady beams for good, easy cutting.

Changing the laser’s pulse and timing gives more control. Makers can shape each cut better.

Special lasers, like femtosecond lasers, make clean edges. No burrs are left, which is important for safe implants.

The table below shows how micro-laser cutting compares to other ways:

Method | Minimum Cut Width | Dimensional Accuracy | Heat-Affected Zone | Geometries Supported | Risk of Deformation |

|---|---|---|---|---|---|

Micro-Laser | 0.001 inch | ±0.0005 inch | Minimal | Complex, 5-axis possible | None (non-contact) |

EDM | ~0.004 inch | ±0.001 inch | Moderate | Simple to moderate | Low |

Mechanical | ~0.004 inch | ±0.002 inch | None | Simple | High (thin tubing) |

Nitinol stents need very exact cuts because they have thin strands. Micro-laser cutting makes tiny features and hard shapes. It works for making one part or many parts. This makes it perfect for new medical devices.

Note: Micro-laser cutting has helped make medical parts since the 1960s. Today, it is still the best way to make laser cut nitinol tubing for stents and other medical devices.

Quality of Laser Cut Nitinol Tubing

Clean Edges and Minimal Damage

Laser cut nitinol tubing makes very smooth and clean edges. The laser uses careful energy to cut, so heat does not spread much. This keeps nitinol’s special features safe, like shape memory and superelasticity. The laser does not touch the tubing, so there are no scratches or dents. This is important for medical devices. Even small marks can cause trouble in the body.

Laser cut nitinol tubing keeps its superelastic and shape memory features. These are very important for medical tools, like stents and guidewires. The way it is made stops dirt from getting on the tubing. It also means less extra work, like polishing or removing rough spots. This helps keep the tubing strong and safe for medical use.

Clean edges and little heat damage help nitinol stents work better and last longer in the body.

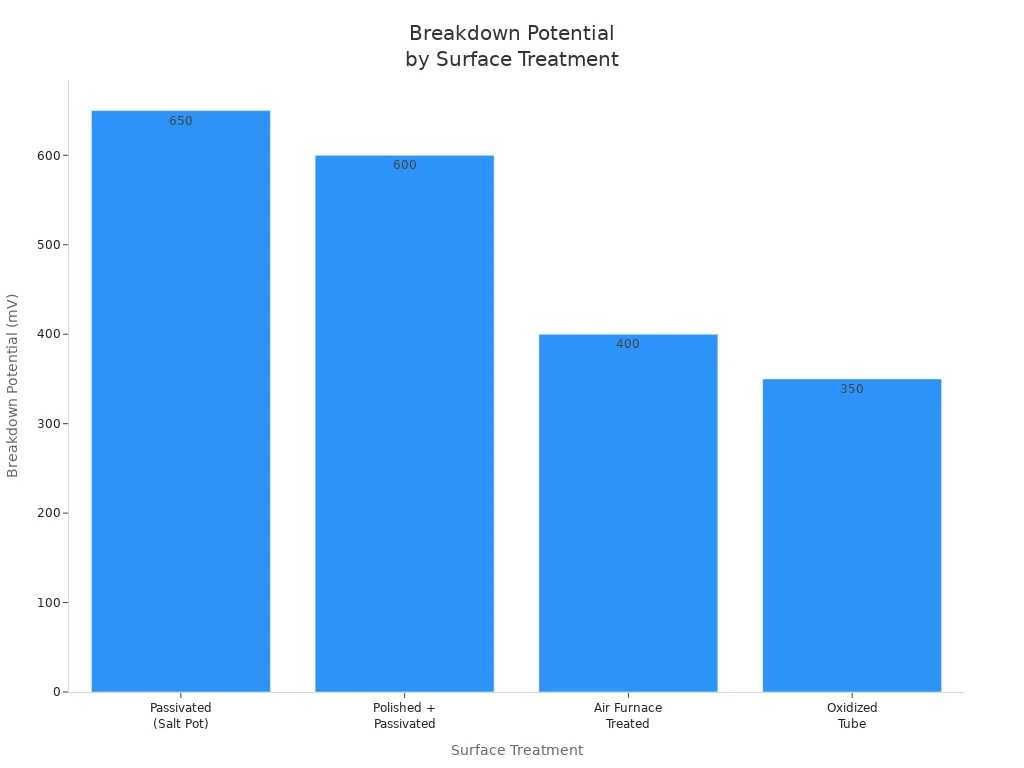

Wet laser cutting and electropolishing make the tubing’s surface even better. Wet laser cutting uses liquid to cool the tubing while cutting. This lowers heat and stops rust from forming. Electropolishing makes the surface smooth and removes tiny flaws. It also adds a thin, strong layer that protects the tubing. This makes the tubing resist rust and lets out less nickel, which is safer for implants.

Surface Treatment Method | Surface Roughness (Ra) | Corrosion Resistance | Nickel Ion Release | Fatigue Life & Other Notes |

|---|---|---|---|---|

Mechanical Polishing | Rough surface with grooves and flaws | Lower corrosion resistance; more corrosion sites | Higher nickel ion release | Flaws remain; weaker fatigue resistance |

Electropolishing | Very smooth surface; Ra below 0.5 µm (down to 0.1 µm) | High corrosion resistance; fewer corrosion sites | Reduced nickel ion release; safer for implants | Removes surface flaws and cracks; improves fatigue life and biocompatibility |

Laser cut nitinol tubing that is electropolished meets strict rules for safety and quality. This process also helps stop tissue irritation. It makes the tubing last longer and work better in the body.

The chart above shows that electropolished tubing is stronger against rust. This means it is safer and has fewer problems in the body.

Consistent Results

Thin-wall nitinol tubing micro-laser cutting gives the same good results every time. Machines and robots help control each step. This makes sure every piece of tubing is made the same way. For medical devices, this is very important. Nitinol stents and other parts must always work the same to keep people safe.

Makers use special tools to check the tubing’s smoothness and thickness. These tools help make sure the tubing is right for medical use. They also test groups of tubing for things like strength and how long they last. This testing helps make sure nitinol stents and other parts will work well in the body.

Rules are very important when making laser cut nitinol tubing for medical devices. Companies must follow strict rules to keep tubing safe and strong. Some important things are:

Vertically integrated suppliers control all steps of nitinol processing, so quality stays high.

Suppliers with ISO 13485 and FDA experience meet medical device rules.

Advanced options, like laser cutting and coatings, help make strong nitinol parts.

Good records and tracking help get approval from regulators.

Special machines and robots help make more tubing and keep quality steady.

Supplier skill with nitinol’s features lowers mistakes and helps devices work well.

Laser cut nitinol tubing fits what modern medical makers need. The process helps make superelastic nitinol tubing and shape memory alloy parts for new medical devices. Good quality and strong testing help make sure every tube is ready for important medical jobs.

Efficiency in Ultra-Thin Nitinol Tubing

Fast Production

Thin-wall nitinol tubing micro-laser cutting lets companies make tubing fast. The laser moves over the tubing but never touches it. This keeps the tubing safe from harm. Machines help guide the laser quickly and with great care. Workers can set up the machines for many tubing types. Each piece is cut with the same care every time.

Laser cut nitinol tubing helps make lots of tubing fast for medical and industrial use. CNC and robots move the tubing and laser together. This lets the laser cut in many directions. Companies can make hundreds or thousands of tubes quickly. The laser does not slow down because it does not wear out like other tools. Every tube comes out the same size and shape.

Tip: Fast production helps companies send nitinol tubing for new devices quickly. This means doctors and engineers get the parts they need faster.

Reduced Deformation

Ultra-thin nitinol tubing can break or bend easily. Laser cut nitinol tubing keeps the tubing from bending or breaking. The laser uses energy to cut without pushing or pulling. This keeps the tubing straight and strong. The process does not make too much heat that could change the tubing’s shape. Special lasers keep the heat low and stop damage.

Laser cut nitinol tubing keeps superelastic nitinol tubing features safe. The process does not make stress or cracks in the tubing. Medical devices need tubing that stays strong and bends easily. The process helps keep nitinol’s shape memory and superelasticity. Machines check each tube to make sure they are all the same. The process makes tubing with little difference from one to the next. This is important for medical devices that need exact sizes and shapes.

Making nitinol tubing with lasers makes less waste. The process makes smooth cuts and keeps the tubing’s surface nice. Companies know each tube will work well in medical or industrial jobs. The process helps make high-quality nitinol tubing.

Laser cutting does not touch the tubing or wear out.

Machines make sure cuts are always the same.

The process keeps tubing strong and even.

Cost and Innovation in Thin-Wall Nitinol Tubing Micro-Laser Cutting

Lower Waste and Tooling Costs

When companies use micro-laser cutting, they save money. The laser cuts nitinol tubing very accurately, so less material is wasted. Machines help the process go fast and smooth. Companies do not need many tools because the laser does not get dull. This means they spend less on new tools and repairs.

Machines help make tubing faster and keep quality high.

The process makes less waste by cutting exact shapes and sizes.

Fewer errors mean less fixing and lower work costs.

Fast work helps companies fill orders quickly and store less tubing.

Engineers can test new tubing designs without spending a lot.

Laser cut nitinol tubing uses less material and saves money. The process lets companies make small or big batches with the same care. This makes nitinol tubing cheaper for medical and industrial jobs.

Latest Technology

In 2025, new machines change how nitinol tubing is made. Femtosecond lasers cut with great accuracy. These lasers do not heat the tubing, so nitinol keeps its special features. Fiber lasers help make thin-wall tubing quickly and for less money. Robots move tubing and check each piece.

Laser interferometry correction helps machines cut with tiny accuracy. This technology finds and fixes small mistakes in movement. Smart cameras and sensors check every piece of tubing for problems. They make sure each one meets strict rules.

AI helps watch the process and find problems. AI vision spots defects in nitinol tubing. Robots move materials and keep things running well. Big data helps engineers pick the best laser settings for each job. These new ideas make laser cut nitinol tubing safer and more dependable.

Note: New machines in micro-laser cutting help companies make nitinol tubing with better quality and lower costs. The process allows for tricky shapes and keeps nitinol strong for medical devices.

Technology Feature | Benefit for Nitinol Tubing |

|---|---|

Femtosecond Laser | No heat damage, ultra-precise cuts |

Fiber Laser | Fast, cost-effective production |

Laser Interferometry Correction | Micrometer-level accuracy |

AI Vision Inspection | Defect detection, quality control |

Robotic Material Handling | Consistent process, less error |

Alternatives to Laser Cut Nitinol Tubing

Mechanical vs. Laser Cutting

Mechanical cutting uses tools to shape nitinol tubing. These tools cut away material by touching the tubing. This makes a lot of heat. The heat can bend the tubing and cause tiny cracks. Nitinol’s shape memory and superelasticity can get damaged. The edges are often rough and have burrs. Burrs need extra work to remove.

Laser cutting is a newer way to cut nitinol tubing. The laser makes clean cuts and does not waste much material. The edges are smooth and need little extra work. Laser cutting can be very exact, down to ±0.0005 inches. This is important for medical nitinol devices. Special lasers, like femtosecond and fiber lasers, keep heat low. This helps nitinol keep its special features. Using gases like argon stops rust and keeps tubing clean. Laser cutting can make small holes and tricky shapes. Tests check that the tubing is the right size and strong.

Mechanical cutting makes more heat and bends tubing.

Laser cutting is more exact and makes smoother edges.

Laser cutting keeps nitinol’s shape memory and superelasticity better.

Cutting Method | Edge Quality | Dimensional Accuracy | Impact on Nitinol Properties | Suitability for Thin-Wall Tubing |

|---|---|---|---|---|

Mechanical Cutting | Rough, burrs | Lower | Can degrade properties | Poor |

Laser Cutting | Smooth, clean | Very high | Preserves properties | Excellent |

Laser cutting is best for nitinol tubing when smooth edges and exact cuts matter most.

EDM and Chemical Etching

EDM uses electric sparks to cut nitinol tubing. It is very exact and good for making hard shapes. EDM can have problems at the start, like short circuits. These problems slow down making thin nitinol tubing. After the first layer, the tool does not wear out much. But EDM is slower than laser cutting.

Chemical etching uses liquids or gases to take away material. It works well for making lots of parts and tiny shapes. Chemical etching is very exact, about ±0.01mm. It is good for thin nitinol tubing and small parts. Chemical etching does not push or heat the tubing. This makes it safe for delicate nitinol. It is fast for testing new designs and making parts quickly. Burrs and extra work are not needed much.

Laser cutting is flexible and very exact for nitinol tubing. It lets makers control heat and make tricky shapes. Sometimes, laser cutting needs many passes and careful settings. This can slow down making lots of tubing. Chemical etching is faster and cheaper for thin nitinol tubing. EDM and laser cutting are best for exact cuts but can cost more or be slower.

Chemical etching is best for thin nitinol tubing when speed and no stress are needed. Laser cutting is still the best for exact cuts and hard shapes.

Micro-laser cutting is the best way to cut thin-wall nitinol tubing in 2025. This method gives very exact cuts, good quality, and quick results. Companies waste less material and save money. They can change laser settings to get better nitinol and fewer mistakes.

Micro-laser cutting is good for nitinol because old ways do not work well with its special features.

Femtosecond lasers cut nitinol without making it hot, so the edges are smooth and more tubes turn out right.

New machines and robots help make nitinol tubing faster and with fewer problems.

More companies now use micro-laser cutting for new nitinol tubing, especially for medical tools.

Companies should pick micro-laser cutting to keep up with the need for better nitinol tubing. In the future, AI and new lasers will help make nitinol tubing even stronger and support new ideas in medicine and industry.

FAQ

What makes nitinol tubing special for medical devices?

Nitinol tubing can bend a lot and snap back to shape. These features help medical devices move and fit inside the body. Doctors use nitinol for stents and guidewires because it works well in the body and stays strong.

How does micro-laser cutting protect nitinol’s properties?

Micro-laser cutting uses a focused beam of energy. This keeps nitinol cool and stops damage. The tubing keeps its superelasticity and shape memory. The process also makes the edges smooth, so nitinol works better in medical tools.

Can micro-laser cutting handle very thin nitinol tubing?

Yes, micro-laser cutting works great for very thin nitinol tubing. The laser makes tiny, exact cuts and never touches the tubing. This keeps the tubing from bending or breaking. Makers use this for thin nitinol in new medical devices.

Why do companies choose laser cutting over other methods for nitinol?

Laser cutting gives smooth, exact cuts on nitinol tubing. Other ways can leave rough edges or cause damage. Laser cutting is also faster and wastes less material. Companies use this method to keep nitinol’s special features safe.

Is laser cut nitinol tubing safe for implants?

Laser cut nitinol tubing follows strict safety rules. The process removes rough spots and keeps the surface smooth. Extra steps like electropolishing make nitinol tubing even safer for use in the body.

See Also

Innovations Driving Laser-Cut Hypotube Tech In 2025

Latest Developments In Laser Cutting For Nickel-Titanium Tubes

The Process Behind Manufacturing Nitinol Tubing For Medicine

Choosing The Right Nitinol Tubing Supplier For Your Requirements