How Thin-Wall Nitinol Tubing Shapes the Future of Stent Retrievers

Thin-Wall Nitinol Tubing for High-Flexibility Stent Retrievers sets a new standard in clot removal. Nitinol enables stent devices to combine ultra-thin walls with remarkable superelasticity. This innovation improves clot removal by allowing stent systems to flex and adapt inside blood vessels. Nitinol’s unique properties help clinicians perform minimally invasive procedures with higher success rates. Patients benefit from safer clot removal and reduced complications. Nitinol supports durability and flexibility, making each stent more effective during minimally invasive procedures and clot removal.

Key Takeaways

Thin-wall nitinol tubing offers unmatched flexibility and strength, allowing stent retrievers to navigate complex blood vessels safely and effectively.

Nitinol’s shape-memory and superelasticity let devices compress for delivery and expand precisely to remove clots, improving procedure success and patient safety.

Advanced manufacturing methods like precision tube drawing and laser microfabrication produce ultra-thin, high-quality tubing that meets strict medical standards.

Nitinol tubing’s excellent biocompatibility and corrosion resistance reduce complications and support long-term use inside the body.

Innovations in surface treatments and customization enhance nitinol tubing’s durability and performance, leading to safer, more effective vascular devices.

Nitinol Tubing Properties

Nitinol tubing stands out in medical device engineering due to its unique combination of shape-memory, superelasticity, biocompatibility, and corrosion resistance. These properties make nitinol tubing the preferred choice for stent retrievers and other advanced vascular devices. The following sections explore how these characteristics contribute to device performance and patient safety.

Shape Memory & Superelasticity

Shape-memory defines nitinol tubing’s ability to return to a pre-set shape after deformation. This property allows stent retrievers to compress for delivery through narrow vessels and then expand precisely at the target site. Shape-memory capabilities ensure that devices adapt to complex vascular anatomies, improving procedural success.

Superelasticity, another hallmark of nitinol tubing, enables the material to undergo significant deformation and recover instantly without permanent damage. Recent studies on additively manufactured nitinol report a superelastic strain recovery of 5.62% and a recovery ratio of 98%, even without post-process heat treatment. These results highlight the superior shape-memory and superelasticity of nitinol compared to conventional alloys. Devices made from nitinol tubing can flex and navigate tortuous vessels, reducing the risk of vessel injury and improving patient outcomes.

Devices with shape-memory and superelasticity adapt to patient anatomy, supporting safer and more effective interventions.

Nitinol tubing’s shape-memory capabilities also allow for patient-specific customization. Engineers can program the tubing to respond to body temperature or mechanical stress, ensuring optimal deployment and performance. This adaptability sets nitinol apart from stainless steel and other traditional materials.

Biocompatibility & Corrosion Resistance

Biocompatibility and corrosion resistance are critical for any implantable device. Nitinol tubing excels in both areas, making it highly suitable for long-term use in the human body. The following table compares nitinol’s properties with other common device materials:

Property | Nitinol | Stainless Steel | Titanium |

|---|---|---|---|

Corrosion Resistance | Excellent | Good | Excellent |

Biocompatibility | Excellent | Good | Excellent |

Nitinol tubing’s corrosion resistance benefits from advanced surface treatments such as electropolishing and magnetoelectropolishing. These processes create a nickel-free oxide layer, reducing nickel ion release and improving cellular adhesion. Scientific studies show that electropolished nitinol tubing reduces protein adsorption, enhancing hemocompatibility and minimizing adverse reactions. This combination of biocompatibility and reliability supports device longevity and patient safety.

Nitinol tubing also demonstrates a lower foreign body reaction compared to stainless steel. Its non-ferromagnetic nature ensures MRI compatibility, similar to titanium. The mechanical properties of nitinol tubing, including shape-memory and superelasticity, further enhance biomechanical compatibility with biological tissues. These advantages explain why nitinol tubing has become the standard for stent retrievers and other cardiovascular implants.

Manufacturing parameters, such as heat input, travel speed, and wire feed speed, influence the performance of nitinol tubing. Predictive models based on thermal histories help engineers optimize mechanical properties like ultimate tensile strength, reducing variability and ensuring consistent device quality. Surface modifications, including plasma treatments, protect against wear and improve long-term durability.

Thin-Wall Nitinol Tubing for High-Flexibility Stent Retrievers

Wall Thickness & Mechanical Stability

Thin-wall nitinol tubing for high-flexibility stent retrievers achieves a delicate balance between flexibility and mechanical stability. Engineers select wall thickness with precision to ensure that nitinol tubing can withstand the forces encountered during clot retrieval. Computational simulations and mechanical tests confirm that a wall thickness of 0.08 mm provides optimal elasticity and adaptability under bending and compression.

Mechanical stability depends on several parameters. Increasing the wall thickness or wire diameter enhances the radial force, which helps the stent maintain its shape and position inside the vessel. The following table summarizes how different design factors influence mechanical stability:

Parameter Tested | Values Tested | Effect on Radial Force / Mechanical Stability |

|---|---|---|

Nitinol wire diameter (tube thickness) | 0.009", 0.0120", 0.0140", 0.0155" | Radial force increases with larger wire diameter (thicker tubing) |

Distance between welds | 17 mm, 23 mm, 30 mm | Radial force increases as welding distance decreases (shorter weld distance = higher stiffness) |

Deployed stent diameter | 15 mm, 20 mm, 25 mm | Larger deployed diameter stents exert higher radial force at the same crimping percentage |

Heat treatment | Annealing times and temperatures | Higher annealing temperature increases radial force; optimal annealing time needed for best mechanical properties |

Careful control of these factors ensures that thin-wall nitinol tubing for high-flexibility stent retrievers delivers both strength and adaptability. This approach supports device reliability and patient safety.

Flexibility & Kink Resistance

Flexibility and kink resistance define the performance of thin-wall nitinol tubing for high-flexibility stent retrievers. Nitinol tubing exhibits superelasticity and shape memory, allowing it to bend through complex vascular pathways without permanent deformation or kinking. This property is essential for stent navigation in tortuous brain vessels.

Research shows that thin-walled nitinol tubing enhances maneuverability and kink resistance, which improves outcomes in minimally invasive procedures. Flexibility tests, such as those performed on Solitaire FR stents, demonstrate superior flexibility compared to other designs. The tubing’s elastic modulus and tensile strength confirm its ability to withstand physiological stresses.

Thin-wall nitinol tubing for high-flexibility stent retrievers enables rapid clot removal and reduces the risk of vessel injury.

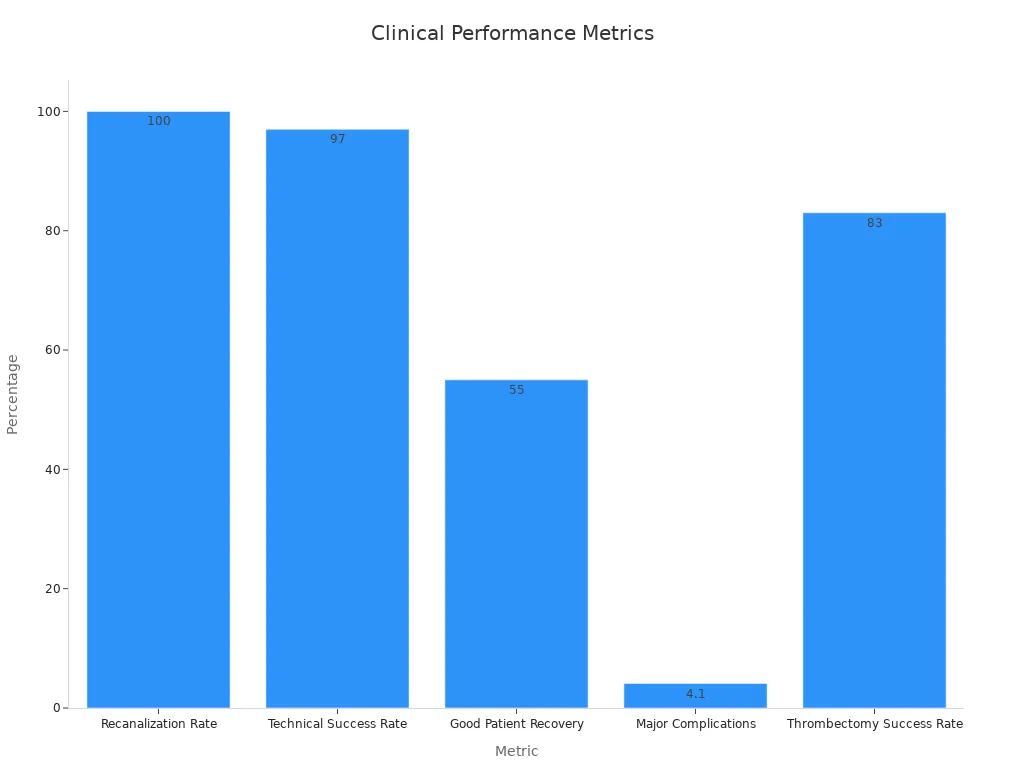

Clinical data further highlight the benefits of nitinol tubing. Devices made from thin-wall nitinol tubing for high-flexibility stent retrievers achieve up to 100% recanalization rates and 97% technical success rates, with low complication rates. The chart below illustrates these performance metrics:

Customization techniques, such as heat treatment and surface modifications, further improve flexibility, durability, and biocompatibility. These advances ensure that nitinol tubing continues to set new standards for stent performance and patient outcomes.

Manufacturing Ultra-Thin Nitinol Tubing

Producing ultra-thin nitinol tubing for medical devices demands advanced manufacturing techniques and strict quality control. Engineers use a combination of precision tube drawing and laser microfabrication to achieve the thin walls, tight tolerances, and surface quality required for stent retrievers.

Precision Tube Drawing

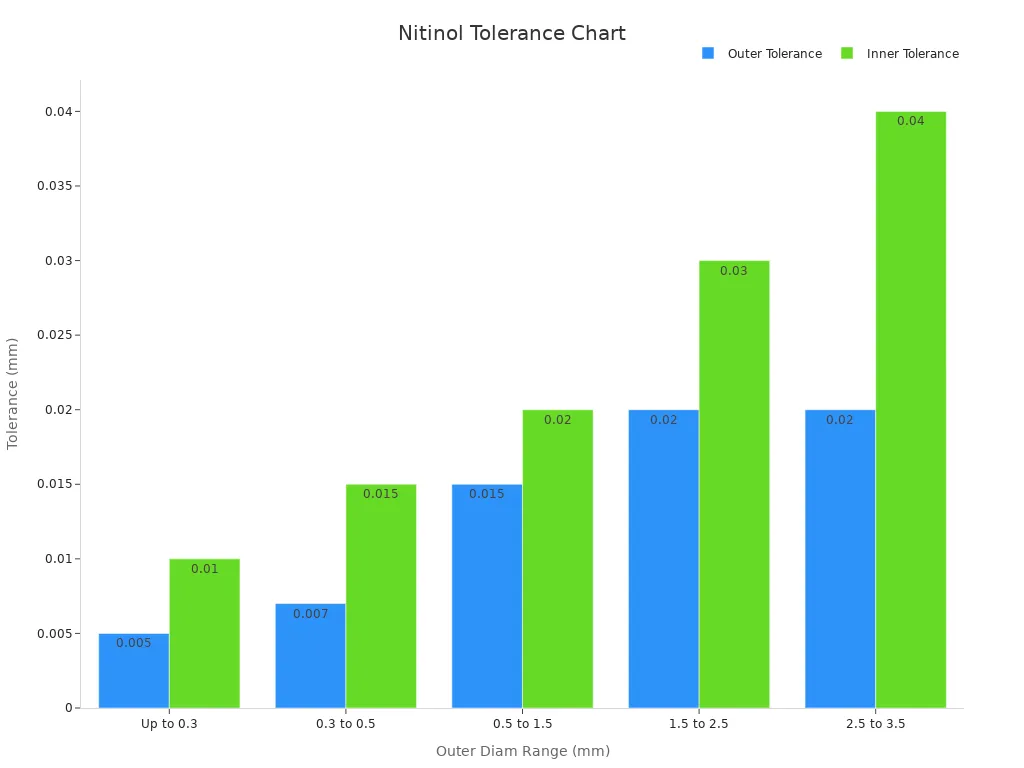

Precision tube drawing shapes nitinol tubing by pulling the alloy through a series of dies. This process gradually reduces the diameter and wall thickness while preserving the material’s superelastic properties. Manufacturers monitor each step to ensure the tubing meets strict dimensional standards. The following table shows typical tolerances for outer and inner diameters:

Outer Diameter Range (mm) | Typical Outer Diameter Tolerance (mm) | Typical Inner Diameter Tolerance (mm) |

|---|---|---|

Up to 0.3 | ±0.005 | ±0.010 |

0.3 to 0.5 | ±0.007 | ±0.015 |

0.5 to 1.5 | ±0.015 | ±0.020 |

1.5 to 2.5 | ±0.020 | ±0.030 |

2.5 to 3.5 | ±0.020 | ±0.040 |

Seamless tube drawing ensures that ultra-thin nitinol tubing maintains uniform wall thickness and high strength. Real-time imaging systems detect any deviations in diameter or surface finish, allowing for immediate corrections. Manufacturers also control cold work levels and temperature to enhance fatigue resistance and durability.

Consistent dimensional accuracy and surface quality are essential for the safety and performance of nitinol tubing in medical applications.

Laser Cutting & Microfabrication

Laser cutting and microfabrication allow engineers to create complex patterns and precise features in nitinol tubing. These techniques use focused laser beams to cut or ablate the material with micron-level accuracy. Researchers have found that:

Fiber laser cutting offers fast processing but can cause heat-affected zones and recast slag, which require extra finishing.

Femtosecond lasers produce cleaner cuts with minimal thermal damage, making them ideal for ultra-thin nitinol tubing.

Microfabrication enables the creation of intricate 3D geometries and fine struts, improving device flexibility and performance.

Post-processing steps such as electropolishing and oxide removal further enhance biocompatibility and surface smoothness.

Manufacturers rely on advanced finishing methods like mechanical polishing, lapping, and abrasive cutting to achieve surface roughness values as low as Ra 0.1 μm. Real-time monitoring ensures that each piece of nitinol tubing meets the strict requirements for medical use.

The combination of precision tube drawing and laser microfabrication enables the production of ultra-thin nitinol tubing with the strength, flexibility, and surface quality needed for next-generation stent retrievers.

Superelastic Nitinol Tubing in Device Performance

Flexibility & Navigation

Superelastic nitinol tubing transforms the way clinicians perform thrombectomy and other vascular interventions. The superelasticity of nitinol allows stent retrievers to recover their original shape after significant deformation. This property enables the device to move through complex vessel anatomy without losing its structure. Nitinol tubing provides flexibility that lets guidewires and catheters conform to the natural curves of blood vessels. This reduces the risk of vessel damage and improves the safety of minimally invasive procedures.

Performance Aspect | Contribution to Flexibility and Navigation |

|---|---|

Superelasticity | Enables stents to recover shape after deformation, allowing navigation through complex vessel anatomy |

Flexibility | Allows guidewires and catheters to conform to natural vessel contours, reducing vessel damage risk |

Fatigue Resistance | Maintains device integrity under repeated stress, ensuring durability during navigation |

Clinical Outcomes | Demonstrated improved success rates in cardiovascular treatments using nitinol stents |

Nitinol’s superelasticity and shape memory support precise navigation through narrow, tortuous pathways. Clinical studies show that devices using superelastic nitinol tubing achieve higher success rates and fewer complications in thrombectomy. The adoption of nitinol since the early 1990s has enabled minimally invasive procedures to become safer and more efficient. Robotic-assisted systems and AI models now use nitinol’s flexibility to further improve navigation and reduce trauma during thrombectomy.

Superelastic nitinol tubing enables clinicians to reach and remove clots in challenging locations, making thrombectomy more effective and less traumatic for patients.

Fatigue Resistance & Durability

Durability is a critical factor in the performance of stent retrievers and other devices made from superelastic nitinol tubing. Nitinol’s unique microstructure allows it to withstand millions of loading cycles without failure. Researchers have measured fatigue resistance and durability using diamond-shaped specimens that simulate clinical loading conditions. Tensile tests and finite element analysis confirm that nitinol tubing maintains its properties even after repeated use.

Fatigue resistance and durability of superelastic nitinol tubing were measured using diamond-shaped specimens simulating clinical device loading conditions.

Tensile tests followed ASTM F2516 standards, and finite element analysis (FEA) was used to determine strain inputs.

Two tube manufacturing techniques (TM-1 and TM-2) were compared, showing TM-1 tubing has 2 to 3 times greater fatigue endurance limits at 10^7 cycles than TM-2.

Fatigue life inversely correlates with the size of non-metallic inclusions (NMI), with smaller inclusions leading to improved fatigue resistance.

TM-1 processed tubing exhibited matrix healing phenomena (void closures) that enhance fatigue life.

Probabilistic fatigue endurance limits (εaP) at 10^7 cycles for TM-1 standard VIM-VAR grade tubing are significantly higher than TM-2 processed tubing.

The fatigue behavior of TM-1 tubing is comparable to cleaner, high-purity grades processed by TM-2.

The studies simulate cardiovascular implant conditions, providing relevant data for clinical applications despite being based on surrogate samples and lab testing.

The research suggests manufacturing process and microstructure critically influence fatigue durability of nitinol tubing used in clinical devices.

A quantitative study on superelastic nitinol tubing found that moderate tensile pre-strains improve fatigue life by inducing beneficial defect structures. These structures help the material transform between phases, which is essential for long-term durability. However, excessive pre-strains can degrade performance by creating microstructures that inhibit transformation. The study used in situ neutron diffraction to reveal how different strain levels affect residual stress and transformation behavior. These findings directly apply to thrombectomy devices, where pre-strain from crimping and deployment impacts durability and performance.

Nitinol’s durability ensures that stent retrievers can perform multiple thrombectomy procedures without losing effectiveness. The manufacturing process and microstructure play a key role in determining the fatigue resistance of nitinol tubing. Devices made from high-quality nitinol tubing provide reliable performance and long service life, supporting better patient outcomes.

Patient Safety

Patient safety remains the top priority in the design and use of superelastic nitinol tubing for stent retrievers. The material’s superelasticity and shape-memory effects allow the device to be delivered through microcatheters and then expand to its original shape inside blood vessels. This expansion creates a gentle, chronic outward force that engages and integrates the clot, making thrombectomy more effective.

Superelastic nitinol tubing used in stent retrievers exhibits unique material properties such as superelasticity and shape-memory effects, allowing the device to be delivered through microcatheters and then expand to its original shape inside vessels.

This expansion exerts a chronic outward force that engages and integrates the clot, facilitating effective clot retrieval.

Computational and finite element analyses confirm that the material properties of nitinol dominate the stent's mechanical behavior, ensuring device reliability and safety.

Animal and patient data demonstrate that embolus removal with nitinol stent retrievers improves blood flow and parenchymal reperfusion, indicating positive patient safety outcomes.

Although explicit patient safety metrics (e.g., adverse event rates) are not directly reported, the mechanical advantages of nitinol underpin the clinical efficacy and safety of stent retrievers.

The stent’s gentle chronic outward force minimizes vessel trauma while providing sufficient radial resistive force to prevent elastic recoil, supporting procedural safety.

Nitinol’s superelasticity ensures that the stent can adapt to the vessel wall without causing excessive pressure or trauma. This property reduces the risk of vessel injury during thrombectomy. The chronic outward force provided by the stent helps maintain vessel patency and prevents elastic recoil, which is crucial for successful clot removal. Animal and patient studies show that nitinol stent retrievers improve blood flow and tissue reperfusion, supporting positive safety outcomes.

Superelastic nitinol tubing combines flexibility, durability, and safety, making it the material of choice for next-generation thrombectomy devices.

Applications of Superelastic Nitinol Tubing

Stent Retrievers in Stroke Treatment

Stent retrievers made with superelastic nitinol tubing have transformed the approach to acute ischemic stroke. Clinicians use these devices for thrombectomy, a procedure that removes blood clots from blocked vessels in the brain. The superelasticity of nitinol allows the thrombectomy stent to compress for delivery and then expand to engage the clot. This property supports precise clot removal, even in tortuous vessels.

Clinical studies show that mechanical thrombectomy with nitinol-based stent retrievers achieves faster and more effective recanalization than drug-based treatments. In animal models, repeated use of thin-wall nitinol tubing in thrombectomy stent devices caused only minor, manageable vessel changes. No significant increase in arterial damage occurred, even after multiple clot removal attempts. These findings support the safety and reliability of nitinol in stroke care.

Nitinol’s flexibility and durability help clinicians reach challenging clots, improving patient outcomes and reducing complications.

Other Vascular Devices

The applications of superelastic nitinol tubing extend far beyond stroke treatment. Cardiovascular and orthopedic devices benefit most from nitinol’s unique properties. The table below summarizes clinical research-supported uses and key benefits:

Application Area | Clinical Research Supported Uses | Key Benefits from Nitinol Tubing Properties |

|---|---|---|

Stents, Guidewires, Heart Valve Frames, Occlusion Devices | Flexibility, durability, biocompatibility | |

Orthopedic Devices | Implants, Fixation Devices, Spinal Devices | Shape memory, long-term strength, reduced tissue stress |

Clinical trials such as the DAWN and PARTNER 3 Trials highlight nitinol’s effectiveness in vascular implants. For example, nitinol-based tools in the DAWN Trial achieved 49% functional independence at 90 days, compared to 13% with standard care. The PARTNER 3 Trial reported lower mortality rates for nitinol-assisted procedures than open-heart surgery. Nitinol stents in peripheral arteries also show high durability and fatigue resistance, supporting long-term vessel patency.

Nitinol’s superelasticity allows devices to bend and return to shape, which is crucial for dynamic environments like blood vessels and joints. Its biocompatibility and corrosion resistance ensure safety for long-term implants. These features make nitinol essential for thrombectomy stent systems, guidewires, and other devices that require repeated movement and reliable clot removal.

Innovations & Future Trends

Advanced Surface Treatments

Researchers continue to develop new surface treatments that improve the performance and safety of nitinol tubing. These treatments address challenges such as corrosion, biocompatibility, and device longevity. Recent studies show that advanced coatings and finishing methods can significantly enhance nitinol’s properties.

Study | Key Findings | Performance Improvement |

|---|---|---|

Chu et al. | Formation of TiO2 layer via electropolishing prevented nickel ion leakage | Enhanced safety and corrosion resistance |

Zhang et al. | TiN coating reduced rust formation by up to 50% | Significant reduction in corrosion over time |

Dharam et al. | Micro-electropolishing (MEP) improved cell adhesion and healing | Better tissue integration and biocompatibility |

Haider et al. | MEP-treated tubing resisted deep rusting | Increased implant longevity and durability |

These findings demonstrate that surface treatments like electropolishing and titanium nitride coatings help nitinol tubing resist corrosion and improve tissue compatibility. As a result, implants last longer and remain safer for patients.

Emerging trends in surface treatments include the use of nanomaterial-based smart coatings. These coatings enable real-time structural health monitoring and support flexible electronics. E-skin technology, which integrates energy-harvesting features, further enhances the functionality of wearable medical devices. Sustainability in smart coating formulations has become a priority, reflecting a shift toward environmentally friendly solutions. Researchers also use AI and machine learning to optimize smart coatings, which accelerates both commercialization and functional performance.

Advanced surface treatments for nitinol tubing continue to set new standards for safety, durability, and device integration.

Automation & Customization

Automation and customization play a growing role in the future of nitinol medical devices. Manufacturers now use automated systems to control every step of the production process. These systems ensure that nitinol tubing meets strict quality standards and maintains consistent properties. Automation also reduces human error and increases production speed.

Customization allows engineers to design nitinol tubing for specific clinical needs. They can adjust wall thickness, diameter, and surface features to match patient anatomy or procedural requirements. AI-driven design tools help create patient-specific devices, improving outcomes and reducing complications. Innovations in nitinol tubing manufacturing now include smart coatings and flexible electronics, which support real-time monitoring and adaptive performance.

Automated manufacturing improves consistency and reliability.

Customization enables patient-specific solutions.

AI and machine learning drive rapid innovation in device design.

Nitinol remains at the center of these advances. Its unique properties, combined with new manufacturing techniques, ensure that future stent retrievers and vascular devices will be safer, more effective, and more adaptable than ever before.

Thin-wall nitinol tubing sets a new benchmark for stent retriever design and performance. Devices using nitinol offer unmatched flexibility and durability, which leads to better patient outcomes. Nitinol enables easier navigation through vessels and reduces complications during minimally invasive procedures. Recent innovations include tubing with ultra-thin walls, improved surface finishes, and integrated electrical capabilities. These advances support safer, more effective minimally invasive procedures. As nitinol technology evolves, clinicians and patients can expect even greater success in vascular interventions.

Nitinol tubing allows for smaller, more functional devices.

Advanced inspection and customization ensure high-quality, reliable products.

FAQ

What makes thin-wall nitinol tubing ideal for stent retrievers?

Thin-wall nitinol tubing offers superelasticity and shape memory. These properties help stent retrievers flex and return to their original shape. This flexibility supports safe navigation through blood vessels.

How does nitinol tubing improve patient safety during procedures?

Nitinol tubing adapts to vessel walls and reduces the risk of injury. Its biocompatibility lowers the chance of adverse reactions. Patients experience fewer complications and better outcomes.

Can nitinol tubing withstand repeated use in medical devices?

Nitinol tubing resists fatigue and maintains strength after many cycles. Studies show it performs well under repeated stress. This durability ensures reliable device performance.

What manufacturing techniques create ultra-thin nitinol tubing?

Manufacturers use precision tube drawing and laser microfabrication. These methods produce tubing with tight tolerances and smooth surfaces. Quality control ensures each tube meets strict standards.

Are nitinol stent retrievers compatible with MRI scans?

Nitinol is non-ferromagnetic. Devices made from nitinol tubing do not interfere with MRI scans. Patients can safely undergo imaging after treatment.

See Also

The Importance Of Nitinol Tubing In Minimally Invasive Surgery

Ways Nitinol Tubing Is Transforming Modern Medical Equipment

Nitinol Tubing’s Contribution To Progress In Medical Technology

Nitinol Tubes Leading The Future Of Medical Devices By 2025

The Critical Role Of Nitinol Tubing In Advanced Medical Uses