5 Simple Steps to Test Polyimide Tubing

Testing polyimide tubing with chemical resistance checks its strength and reliability. You must ensure that the tubing can handle strong chemicals. It should not break or stop working when exposed to them. This is very important for industries like medical tools or airplanes. In these fields, failure can cause significant problems. Testing helps identify weak spots and ensures the tubing works for your needs.

Always test polyimide tubing with chemical resistance to make sure it functions well. Without testing, it might fail and lead to costly mistakes.

Key Takeaways

Find out which chemicals will touch the polyimide tubing. This makes sure tests match real-life use.

Cut the tubing into the right size and clean it well. This removes dirt that might change the test results.

Pick the right testing method, like soaking or exposing, to check how the tubing handles chemicals.

Watch the tubing during tests for changes like swelling or fading. These changes help judge how well it works.

Write down all results and compare them to the needed rules. This shows if the tubing is safe and works properly.

Step 1: Find Out Which Chemicals Will Touch the Polyimide Tubing

List the chemicals the tubing will come into contact with.

Before testing, figure out which chemicals the tubing will face. Polyimide tubing is used in fields like medicine, electronics, and aerospace. Each field uses different chemicals. For example, in medical tools like catheters, the tubing might touch saline, alcohol, or cleaning agents. In electronics, it could meet solvents or cleaning liquids during production.

Make a full list by thinking about where the tubing will be used. Include chemicals from cleaning, sterilizing, or daily use. This step makes sure the tests match real-life conditions.

Tip: Ask experts or check material safety data sheets (MSDS) to find possible chemical exposures.

Learn how these chemicals might affect polyimide tubing.

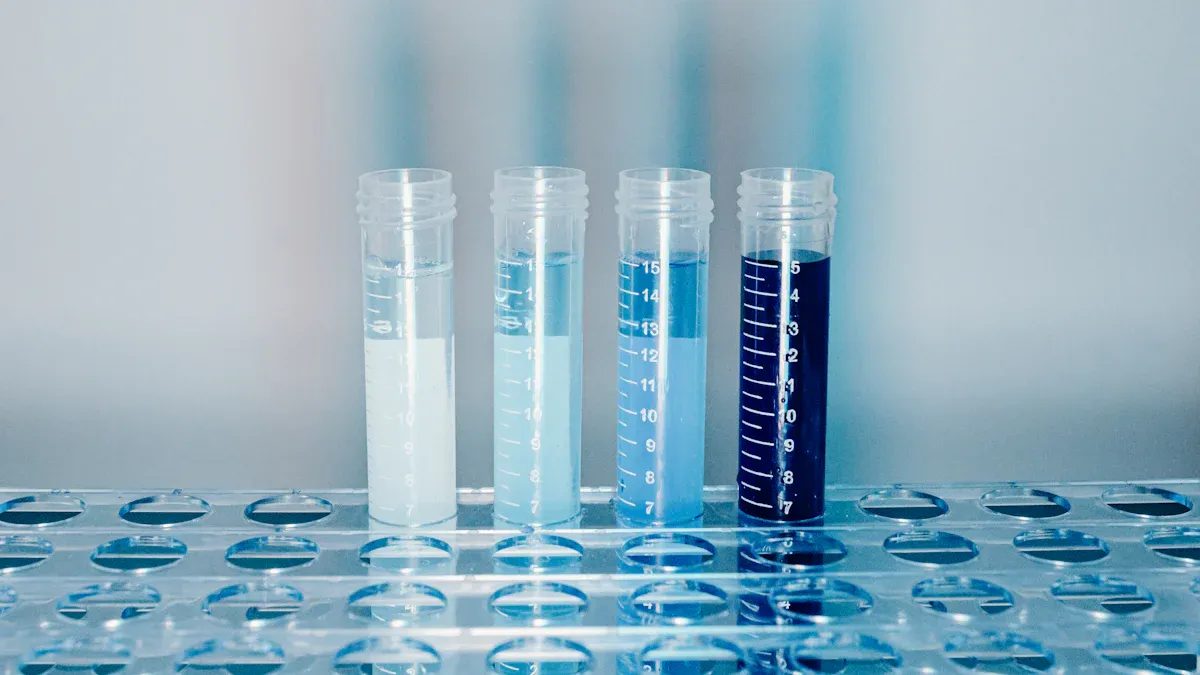

After listing the chemicals, study how they interact with polyimide. Polyimide resists many chemicals, but not all affect it the same way. For instance, polyimide blends stay strong with 10% potassium hydroxide (KOH) or 37% hydrochloric acid (HCl) for 24 hours. However, HCl vapors might cause slight fading over time, shown in UV-Vis spectrum changes.

The tubing's strength also matters for its performance. Tensile tests show polyimide blends are strong, with values between 49.96 and 91.45 MPa. Some blends stretch more before breaking, making them tougher under pressure. Knowing these details helps you see how the tubing will work in its job.

By studying chemical effects and tubing properties, you can plan tests to ensure the tubing works well in its environment.

Step 2: Get Polyimide Tubing Samples Ready for Testing

Cut the tubing into the right sizes.

First, cut the polyimide tubing into smaller pieces. These pieces should match how the tubing will be used. Use a sharp tool like a blade or cutter for smooth edges. Uneven cuts can create weak spots and affect the test results.

Think about the tubing's purpose when choosing the size. For medical tools, smaller pieces might work. For industrial uses, larger pieces may be needed to mimic real conditions. Keep all pieces the same size for accurate testing.

Tip: Mark each piece to track its test details and results.

Clean the tubing to remove dirt or oils.

Before testing, clean the tubing well. Dust, oil, or leftover materials can change how the tubing reacts to chemicals. Use a gentle cleaner or rubbing alcohol to wipe each piece. Stay away from strong cleaners that might damage the tubing.

Rinse the tubing with distilled water to wash off the cleaner. Let the pieces dry in a clean place. This step makes sure the tubing is ready for testing without any impurities.

Note: Wear gloves to avoid getting dirt or oil from your hands on the tubing.

By cutting and cleaning the tubing correctly, you prepare for good testing. These steps help check if the tubing works well for its job.

Step 3: Prepare the Testing Setup for Polyimide Tubing

Pick the right testing method (like soaking or exposure)

Choosing the correct test method gives accurate results for polyimide tubing. Two common methods are soaking and exposure. Soaking means putting the tubing in liquids. This checks how it reacts to chemicals at different temperatures. Measure the tubing's size before and after soaking to see if it swells or shrinks. Afterward, bending tests or voltage tests can show if the tubing stays strong.

Exposure testing copies real-life conditions. For example, forced hydrolysis mimics heat and moisture over time. This test is important for wiring, where polyimide must resist breaking down. Knowing how polyimide acts in these situations helps ensure it works as needed.

Tip: Choose a test method that matches how the tubing will be used.

Manage factors like temperature and testing time

Temperature and time are important for testing polyimide tubing. Heat changes how polyimide reacts to chemicals. High heat speeds up chemical reactions and shows weak spots. Set the temperature based on where the tubing will be used. For example, if it's for airplanes, test it with extreme heat.

Time also matters. Longer tests show slow changes like fading or losing strength. For soaking tests, leave the tubing in liquid for 24 hours or more. For exposure tests, think about how long the tubing will last and adjust the test time.

Note: Keep all test conditions the same to get reliable results.

By picking the right test and controlling conditions, you can check how polyimide tubing performs in real-world situations. This step makes sure the tubing works for its job.

Step 4: Perform the Chemical Resistance Test on Polyimide Tubing

Soak or expose the tubing to chosen chemicals.

Start by soaking or exposing the polyimide tubing to the chemicals. Use a clean container for soaking tests and fully submerge the tubing. For exposure tests, place the tubing where it can meet chemical vapors or droplets. This helps mimic real-life conditions and shows how the tubing reacts.

Use a timer to track how long the test lasts. Short tests might take hours, while long ones could last days. Keep the temperature and humidity steady during the test. These factors affect how the tubing handles the chemicals.

Tip: Mark each sample and note the chemical and test details.

Watch for changes like swelling, color fading, or damage.

During the test, check the tubing for any visible changes. Swelling may mean the tubing is soaking up the chemical. Fading colors could show a reaction on the tubing's surface. Look for cracks, soft spots, or other damage that might weaken the tubing.

Measure the tubing with tools like calipers to check size changes. Use a microscope to spot tiny surface damage you can’t see with your eyes. Take photos and write notes about what you find. This helps decide if the tubing works as needed.

Note: Watching closely helps you notice small changes that matter.

By soaking or exposing the tubing and checking for changes, you can test its chemical resistance. This step ensures the tubing works well for its job.

Step 5: Study and Write Down Results of Polyimide Tubing Tests

Write down what you see and measure about the tubing.

After testing, write down all changes in the polyimide tubing. Look for swelling, color changes, or surface damage. Use tools like rulers or calipers to measure size changes. Check the length, width, or thickness of the tubing. These details show how the tubing reacts to chemicals.

For deeper study, use advanced tools to check the tubing’s properties. One key property is the level of imidization, which affects strength and durability. A tool like laser-induced breakdown spectroscopy (LIBS) can measure this accurately. LIBS uses signals to find imidization levels and gives exact results. This method is proven to work well compared to older techniques like FT-IR. Using these tools helps you collect clear data about the tubing’s performance.

Tip: Take notes and photos of each sample for better records.

Match your results to the needed standards or uses.

After gathering data, compare it to the required standards. See if the polyimide tubing meets the needed strength, durability, and chemical resistance. For example, medical tubing must handle cleaning agents without breaking down. Tubing for airplanes must resist heat and chemicals.

Make a chart or table to organize your findings. This helps you see if the tubing meets the benchmarks. If it fails, you might need to change the material or test setup. If it passes, you can trust it for its job.

Note: Comparing results to standards ensures the tubing is safe and works well.

By studying and recording the results, you can decide if the polyimide tubing is ready for its job. This step makes sure the tubing works as expected in real-life situations.

Testing polyimide tubing checks if it works in its environment. Follow five steps: list the chemicals, get tubing samples ready, prepare the test setup, do the chemical resistance test, and study the results. These steps help you see how strong and reliable the tubing is.

Remember: Careful testing stops problems and keeps things safe in important uses like medical tools or airplanes. By doing these steps, you can be sure the tubing fits your needs.

FAQ

What is polyimide tubing used for?

Polyimide tubing is used in fields like medicine, aerospace, and electronics. It is great for catheters, wire coverings, and hot environments. Its strength and resistance to chemicals make it perfect for tough jobs.

Tip: Pick tubing that fits your specific job needs.

How do you know if polyimide tubing is chemically resistant?

Test its resistance by exposing it to the chemicals it will face. Look for changes like swelling, color fading, or cracks. If it stays strong and works well, it is resistant.

Note: Testing makes sure the tubing is safe and works properly.

Can you reuse polyimide tubing after testing?

No, tested tubing should not be reused. Chemicals might weaken it or change its properties. Always use new tubing for important tasks to keep things safe and reliable.

What tools do you need to test polyimide tubing?

You need tools like rulers to measure size changes, containers for soaking, and microscopes to check for damage. Advanced tools like LIBS can study chemical effects on the tubing.

Tip: Use clean tools to get accurate test results.

Why is cleaning the tubing before testing important?

Cleaning removes dirt, oil, or leftover materials that could affect the test. These things might react with chemicals and give wrong results. Clean tubing helps ensure accurate and fair testing.

Reminder: Wear gloves and use gentle cleaners to avoid adding dirt.

See Also

Key Guidelines for Effectively Utilizing FEP Heat Shrink Tubing

Comprehensive Instructions for Selecting Proper Heat Shrink Tubing Size

Advice on Choosing FEP Autoclavable Heat Shrink Tubing

Important Considerations for Selecting FEP Shrink Tubing

Essential Information Regarding PET Heat Shrink Tubing for Electronics