Superelastic vs Shape Memory Nitinol Tubing Key Differences You Should Know

Superelastic and shape memory Nitinol tubing differ in how they respond to stress and temperature. Superelastic tubing changes shape when bent but returns to its original form as soon as the force is removed. Shape memory tubing bends and holds its new form until heated, then it goes back to its original shape. Understanding superelastic vs shape memory Nitinol tubing differences helps engineers and designers pick the best option for their specific needs.

Key Takeaways

Superelastic Nitinol tubing bends and instantly returns to its original shape without heat, making it ideal for repeated bending and quick recovery.

Shape memory Nitinol tubing holds a new shape until heated, then returns to its original form, perfect for controlled movements triggered by temperature.

Nitinol tubing offers high strength, corrosion resistance, and durability, making it suitable for medical devices, robotics, aerospace, and consumer products.

Choosing the right tubing depends on the application’s temperature, movement needs, and cycling frequency to ensure safety and long service life.

Engineers use experimental data and models to predict tubing behavior, helping them select the best option for specific project requirements.

Nitinol Tubing Basics

Unique Properties

Nitinol tubing stands out because of its unique properties of nitinol. This material combines superelasticity, shape memory, and biocompatibility. These features make it different from stainless steel and titanium alloys. The table below compares the main properties of these materials:

Material | Tensile Strength (MPa) | Unique Properties |

|---|---|---|

Nitinol | 500 - 900 | Superelasticity, shape memory effect, biocompatibility |

Stainless Steel | 600 - 1100+ | Versatile grades, good corrosion resistance |

Titanium Alloys | 900 - 1200 | High strength, lightweight, excellent corrosion resistance |

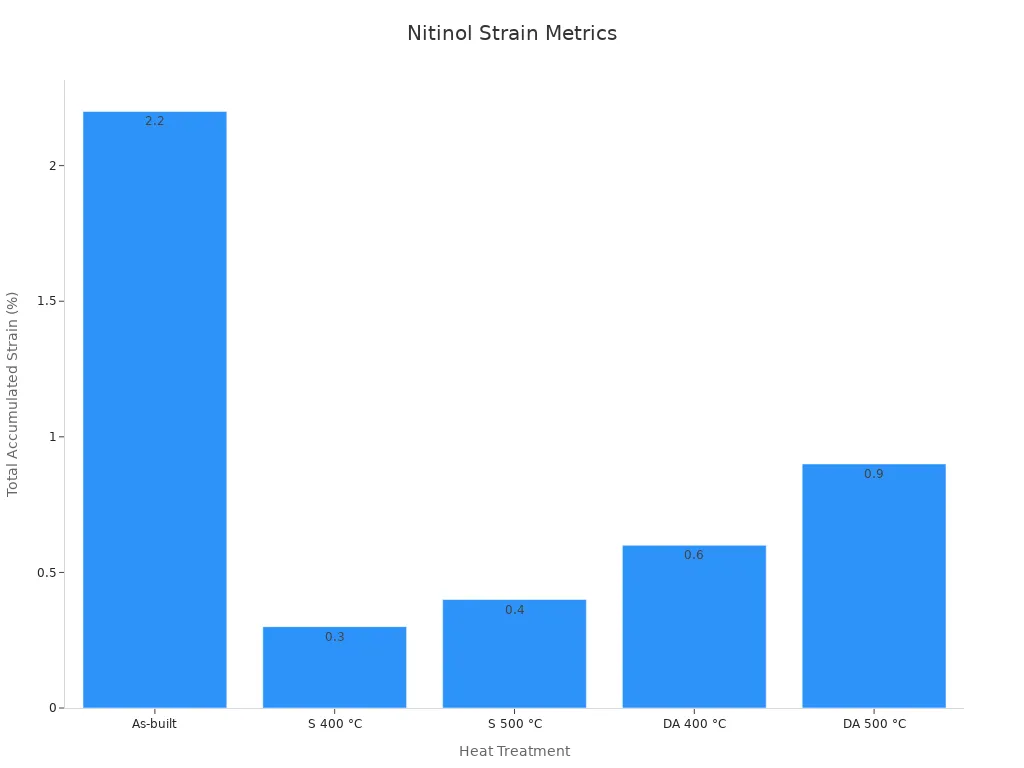

Nitinol tubing can recover from strains up to 5.5% and maintain its shape after more than 10 million cycles. The tubing also resists corrosion because of a stable titanium oxide layer. This layer prevents nickel from leaking out, which is important for safety in medical applications. Surface treatments like electropolishing improve corrosion resistance and reduce protein buildup. The chart below shows how heat treatment affects the strain of nitinol tubing:

Why Use Nitinol?

Engineers and designers choose nitinol tubing for many applications because of its strength, flexibility, and durability. Medical devices such as stents and guidewires use nitinol because it can handle up to 400 million pressure cycles. This durability means devices last longer and need fewer replacements. Nitinol tubing also works well in harsh environments, such as oil and gas wells, where it resists chemicals like hydrogen sulfide and chlorides.

The shape memory effect allows nitinol tubing to return to its original shape when heated. This property helps in robotics, where compact actuators are needed. Superelasticity lets the tubing absorb energy, which is useful in seismic protection systems. The table below highlights the main benefits for different applications:

Benefit Category | Quantified Evidence / Description |

|---|---|

Strength | Tensile strength ranges from 500 MPa to 900 MPa, comparable to stainless steel and titanium. |

Fatigue Resistance | Medical stents made from Nitinol withstand up to 400 million pressure cycles, demonstrating exceptional durability. |

Corrosion Resistance | Effective in harsh environments such as oil and gas downhole conditions with hydrogen sulfide, CO2, and chlorides. |

Superelasticity | Enables energy absorption and dissipation in seismic protection systems, improving performance over conventional materials. |

Shape Memory Effect | Allows compact, precise actuators in robotics, reducing mechanical complexity and improving efficiency. |

Nitinol tubing meets strict industry standards, making it reliable for critical applications. Over 1.5 million nitinol stents are produced each year, showing its wide use. Its long service life and ability to be customized help lower costs in many applications.

Superelastic Nitinol Tubing

How Superelasticity Works

Superelastic nitinol tubing shows a unique ability to bend and stretch far beyond what most metals can handle. This happens because of a special phase transformation inside the material. When someone bends or stretches superelastic nitinol, the crystal structure changes from austenite to martensite. This change happens at room temperature and does not need heat. As soon as the force is removed, the tubing snaps back to its original shape. This immediate recovery is a key part of the mechanism behind superelasticity.

Researchers use several experimental metrics to study this process:

Metric / Observation | Description / Value |

|---|---|

Strain rates | Range from very slow ( |

Stress level for transformation | Around 200 MPa |

Cyclic strain amplitude | About 0.5% |

Detection method | X-ray diffraction tracks phase changes during bending |

Fatigue testing | Ultrasonic fatigue tests simulate millions of cycles |

These metrics help engineers understand how superelastic nitinol performs under repeated use.

Activation Conditions

Superelasticity in nitinol tubing activates under specific conditions. The tubing must be above its transformation temperature, usually around body temperature (37 °C). When stress is applied, the tubing can stretch up to 4% strain and still return to its original shape. The following points summarize the main activation limits:

Superelastic stress plateau strain limit is about 4% at 37 °C.

Maximum mean strain reaches up to 4% with a maximum strain amplitude of 2.25%.

For process-optimized tubes, the amplitude strain limit is about 1.5% at 3% mean strain.

Alternating strain limit drops from 1.5% to 0.8% as mean strain increases from 2.5% to 4%.

Exceeding these limits can damage the superelastic properties.

Superelastic nitinol does not need heat to recover its shape. This makes it ideal for many applications where quick and reliable shape recovery is important.

Common Uses

Superelastic nitinol tubing finds use in many fields. In medicine, doctors use it for stents, guidewires, and orthodontic wires. These devices must bend and flex inside the body without breaking. Engineers also use superelastic nitinol in eyeglass frames, antennas, and robotics. The applications of superelastic nitinol include any situation where flexibility and durability matter.

The advantages and limitations of superelastic nitinol depend on the application. It offers high fatigue resistance and immediate shape recovery, but it can lose its superelasticity if strained too much. Designers must consider these factors when choosing materials.

Tip: Superelastic nitinol works best in environments where repeated bending and quick shape recovery are needed.

Shape Memory Nitinol Tubing

How Shape Memory Works

Shape memory nitinol tubing shows a unique ability to "remember" its original shape. When someone bends or twists the tubing at low temperatures, it stays in the new shape. This happens because the material enters the martensite phase, which is soft and easy to form. When heated above a certain temperature, the tubing returns to its original shape. Scientists call this the shape memory effect. The shape memory effect explained: the tubing changes between two crystal structures, martensite and austenite, depending on temperature. This reversible phase transformation allows the tubing to recover its shape after deformation. Researchers have used molecular dynamics simulations to study how atoms move during this process. These studies show that the transformation does not need atoms to move far, making the change quick and reliable. The shape memory nitinol tubing can be shaped, set, and then activated by heat many times.

Activation by Temperature

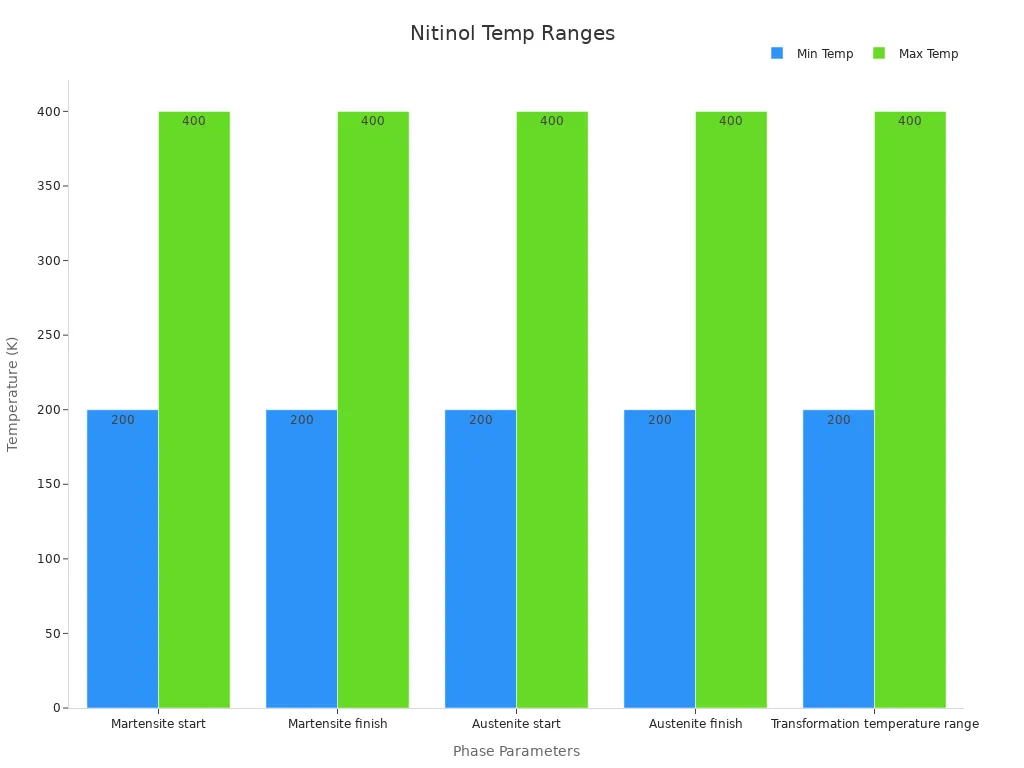

The shape memory effect in nitinol tubing depends on specific temperatures. Four key temperatures control the process: martensite start (Ms), martensite finish (Mf), austenite start (As), and austenite finish (Af). When the tubing cools below Ms, it starts to become martensite. Below Mf, the transformation finishes. When heated above As, the tubing begins to change back to austenite. Above Af, the tubing fully returns to its original shape. The typical range for these temperatures is about 200 K to 400 K, depending on the nickel content and processing. The chart below shows the lower and upper temperature ranges for these phase transitions:

Shape memory nitinol tubing can be customized for different applications by adjusting these transformation temperatures. Heat treatment, such as shape setting at 400°C to 550°C, helps set the desired shape and ensures stable performance.

Common Uses

Many industries use shape memory nitinol tubing because of its special properties. In medicine, doctors use it for stents, bone anchors, and surgical tools that need to change shape inside the body. Engineers use shape memory nitinol in actuators for robotics, where parts must move or return to a set position when heated. Aerospace designers use it for couplings and fasteners that need to lock or unlock with temperature changes. The shape memory effect makes these applications possible. The tubing is malleable below its transformation temperature, so workers can shape it easily before activation. The applications of shape memory nitinol include any situation where thermal activation and precise movement are important. Shape memory nitinol tubing offers reliable performance, long life, and adaptability for many applications.

Note: Shape memory nitinol tubing is best for applications that need controlled shape changes with heat, not just flexibility.

Superelastic vs Shape Memory Nitinol Tubing Differences

Key Differences in Behavior

Superelastic vs shape memory nitinol tubing differences start with how each type reacts to stress and temperature. Superelastic nitinol shows a unique behavior when bent or stretched. It returns to its original shape as soon as the force is gone. This happens because of a special mechanism inside the metal. The tubing changes its crystal structure under stress, but it does not need heat to recover. This behavior makes superelastic nitinol act like a spring.

Shape memory nitinol tubing behaves differently. When someone bends or twists it at a low temperature, it keeps the new shape. The tubing only returns to its original form when heated above a certain point. This shape memory behavior depends on temperature, not just force. The tubing stays soft and easy to shape until it gets warm enough to "remember" its set form. This key differences in behavior helps engineers decide which tubing to use for each job.

Comparing Superelastic and Shape Memory Nitinol

Comparing superelastic and shape memory nitinol shows clear differences in mechanism, activation, and use. The table below highlights these superelastic vs shape memory nitinol tubing differences:

Feature | Superelastic Nitinol Tubing | Shape Memory Nitinol Tubing |

|---|---|---|

Main Mechanism | Stress-induced phase change | Temperature-induced phase change |

Behavior | Returns to shape after bending (no heat) | Holds new shape until heated |

Activation | Needs only force above transformation temp | Needs heating above set temperature |

Recovery Speed | Immediate | Delayed (after heating) |

Typical Strain Limit | Up to 4% | Up to 8% (after heating) |

Malleability | Not malleable at room temperature | Malleable below transformation temperature |

Fatigue Resistance | Very high | High, but depends on cycling and heating |

Common Applications | Stents, guidewires, eyeglass frames | Actuators, couplings, surgical tools |

Note: Superelastic nitinol works best where quick recovery is needed. Shape memory nitinol is better for controlled shape changes with heat.

Application Suitability

Superelastic vs shape memory nitinol tubing differences affect which tubing works best for certain applications. Superelastic nitinol fits jobs that need repeated bending and fast recovery. Medical stents and orthodontic wires use this tubing because it can flex many times without losing its shape. Eyeglass frames also use superelastic nitinol for durability.

Shape memory nitinol tubing suits applications that need a part to change shape only when heated. Engineers use shape memory nitinol in robotics for actuators that move when warmed. Aerospace designers use it for fasteners that lock or unlock with temperature changes. Shape memory nitinol also helps in surgical tools that must change shape inside the body.

The behavior of each tubing type matches different needs. Superelastic nitinol gives instant recovery and high fatigue resistance. Shape memory nitinol offers easy shaping at low temperatures and precise movement when heated. Knowing these superelastic vs shape memory nitinol tubing differences helps engineers and designers pick the right tubing for their projects.

Choosing the Right Tubing

Difference Between Superelastic and Shape Memory Nitinol

Selecting the right tubing starts with understanding the difference between superelastic and shape memory nitinol. Superelastic tubing bends and returns to its original shape as soon as the force is gone. Shape memory tubing holds a new shape until heated, then returns to its original form. This difference between superelastic and shape memory nitinol comes from how each type reacts to stress and temperature.

Engineers look at several factors before making a choice. They consider the operating temperature, the amount of force needed, and how often the tubing will bend or change shape. Superelastic tubing works best in places where the temperature stays above the transformation point and where quick, repeated bending happens. Shape memory tubing fits jobs where a part must change shape only when heated. Many industries use shape memory for actuators, medical devices, and robotics. The shape memory effect allows for precise movement and control.

Researchers have developed models to predict how both types of tubing behave. These models use experimental data to show how the tubing will perform under different loads and temperatures. Some models focus on how the tubing changes shape, while others look at how it handles repeated use. These tools help engineers choose the best tubing for each job.

Selection Tips

Choosing between superelastic and shape memory tubing depends on the needs of the project. Here are some tips to help with selection:

Check the operating temperature. Superelastic tubing needs temperatures above its transformation point. Shape memory tubing needs heating to trigger the shape change.

Think about the type of movement needed. Superelastic tubing gives instant recovery after bending. Shape memory tubing holds its new shape until heated.

Consider how often the tubing will cycle. Superelastic tubing handles many cycles without losing performance. Shape memory tubing works well for fewer, controlled changes.

Use decision-making frameworks based on experimental and numerical data. These frameworks help predict how the tubing will behave in real-world conditions.

Review the mechanical properties and fatigue resistance. Shape memory nitinol offers reliable performance when thermal activation is needed.

Tip: For applications needing precise, temperature-driven movement, shape memory tubing is the best choice. For repeated, reversible bending, superelastic tubing works better.

Understanding the difference between superelastic and shape memory nitinol helps engineers and designers make informed choices. The right tubing ensures safety, reliability, and long service life.

Superelastic and shape memory Nitinol tubing show clear differences in how they respond to stress and temperature. Superelastic tubing recovers shape instantly after bending, while shape memory tubing needs heat to return to its original form. Choosing the right type depends on the application’s need for quick recovery or controlled movement. The table below shows how fatigue life changes with strain, highlighting why careful selection matters for medical devices:

Parameter | Value/Description |

|---|---|

Fatigue Life (0% mean strain) | 400 million cycles at 0.55% strain amplitude |

Fatigue Life (≥3% mean strain) | 400 million cycles at ~0.16% strain amplitude |

Understanding these mechanisms helps engineers select tubing that ensures safety and long service life.

FAQ

What is the main difference between superelastic and shape memory Nitinol tubing?

Superelastic tubing returns to its original shape after bending without heat. Shape memory tubing holds a new shape until heated, then returns to its original form. The key difference lies in how each type responds to stress and temperature.

Can Nitinol tubing be used in the human body?

Yes. Nitinol tubing is biocompatible and resists corrosion. Medical devices like stents and guidewires often use Nitinol because it is safe and durable inside the body.

How do engineers choose between superelastic and shape memory tubing?

Engineers look at the application’s needs. Superelastic tubing works best for repeated bending and quick recovery. Shape memory tubing fits jobs that need controlled shape changes with heat.

What are some common industries that use Nitinol tubing?

Industry | Example Applications |

|---|---|

Medical | Stents, guidewires |

Robotics | Actuators |

Aerospace | Couplings, fasteners |

Consumer | Eyeglass frames |

Nitinol tubing serves many fields because of its unique properties.

See Also

Understanding How Nitinol Exhibits Shape Memory And Elasticity

The Importance Of Nitinol Tubing In Modern Medical Use

The Process Behind Producing Nitinol Tubing For Healthcare

Nitinol Tubing’s Contribution To Progress In Medical Technology

Evaluating Tensile Strength Between Nitinol And Stainless Steel Tubing