How Superelastic Nitinol Tubing Enhances Medical Device Performance

Superelastic nitinol tubing has revolutionized the design and functionality of medical devices. Its unique combination of flexibility and durability allows it to adapt to the body's movements without losing shape. Nitinol’s biocompatibility ensures it integrates safely with human tissues, reducing the risk of adverse reactions. These superelastic properties make it ideal for creating devices that require precision and reliability. By enhancing device performance, nitinol tubing contributes to better patient outcomes and supports the advancement of minimally invasive procedures, which are less traumatic and promote faster recovery.

Key Takeaways

Superelastic nitinol tubing bends easily and lasts a long time. It works well for medical tools that move with the body.

It is safe to use with human tissues. This lowers the chance of bad reactions during medical treatments.

Nitinol tubing helps small surgeries by letting tools move smoothly. It avoids bending or breaking, helping patients heal faster.

This material is strong and doesn’t rust, so it lasts longer. It means fewer replacements and lower medical costs.

Doctors can design nitinol tools to fit each patient better. This makes treatments safer and works better for everyone.

Unique Properties of Superelastic Nitinol Tubing

Shape Memory and Elasticity

Superelastic nitinol tubing exhibits remarkable shape memory and elasticity, making it a cornerstone in the development of advanced medical devices. Shape memory refers to the material's ability to return to its original form after deformation. This property arises from nitinol’s unique crystalline structure, which undergoes a reversible phase transformation between austenite and martensite phases. For instance, nitinol tubing can recover a shape recovery strain of 4.16%, ensuring precision in applications requiring repeated deformation.

Elasticity in nitinol tubing is equally impressive. It can endure a superelastic strain of up to 7%, allowing it to bend and flex significantly without permanent damage. This characteristic is particularly valuable in minimally invasive procedures, where devices must navigate complex anatomical pathways. Measurements such as tensile testing and bend recovery tests confirm these properties, highlighting nitinol’s ability to maintain its structural integrity under stress.

Measurement Type | Description |

|---|---|

Tensile Testing | Measures strength, elongation, and elastic modulus, focusing on the superelastic plateau. |

Bend and Free Recovery Tests | Evaluates the ability to return to the original shape after deformation. |

These properties make nitinol tubing indispensable in medical devices like stents and catheters, where flexibility and reliability are critical.

Biocompatibility and Corrosion Resistance

Biocompatibility and corrosion resistance are essential for materials used in medical devices, and nitinol tubing excels in both areas. Its biocompatibility ensures safe integration with human tissues, minimizing adverse reactions. Clinical studies have demonstrated that nitinol-based implants maintain excellent biocompatibility profiles for over 10 years, with minimal reported complications. In vivo studies in swine models further confirm successful vascular integration within 30 days, supported by new tissue growth observed through histopathology.

Corrosion resistance in nitinol tubing is enhanced by its smooth surface finish, which reduces the risk of degradation in challenging environments like the cardiovascular system. As a passive metal alloy, nitinol forms a protective oxide layer that prevents harmful ion release. This feature is particularly important for long-term implants, where durability and safety are paramount.

Key biocompatibility evaluations include:

Cytotoxicity

Sensitization

Irritation

Systemic toxicity

Genotoxicity

The combination of biocompatibility and corrosion resistance makes nitinol tubing a reliable choice for medical devices used in diverse body locations.

High Durability and Flexibility

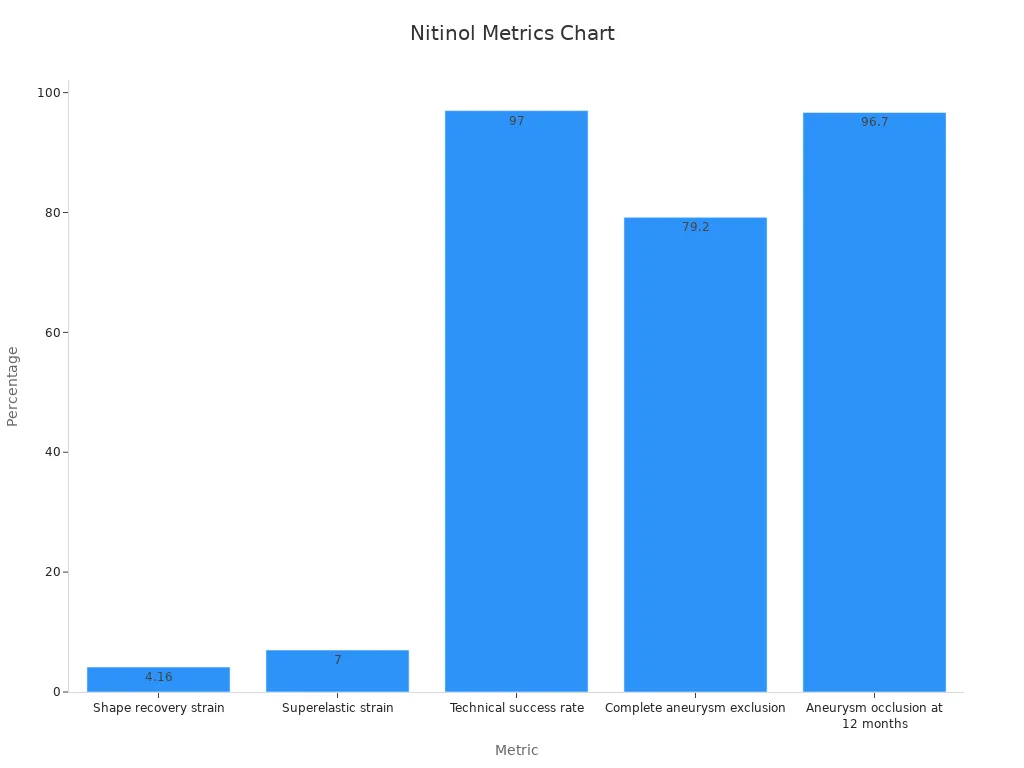

Nitinol tubing offers unmatched durability and flexibility, ensuring long-term performance in demanding medical applications. Its ability to withstand high-cycle fatigue life is crucial for devices like vascular stents, which experience constant mechanical stress. Studies show that nitinol tubing achieves a technical success rate of 97% in clinical applications, with complete aneurysm exclusion in 79.2% of cases.

Metric | Result |

|---|---|

Shape Recovery Strain | 4.16% |

Superelastic Strain | 7% |

Technical Success Rate | 97% (70 of 72 patients) |

Complete Aneurysm Exclusion | 79.2% (57 of 72 patients) |

Aneurysm Occlusion at 12 Months | 96.7% (29 of 30 patients) |

Flexibility is another hallmark of nitinol tubing. Its superelastic properties allow it to adapt to the body’s movements without compromising structural integrity. This flexibility reduces the risk of device failure and enhances patient comfort. Additionally, the material’s strength-to-weight ratio, supported by a relative material density of 99.4%, ensures that devices remain lightweight yet robust.

The combination of high durability and flexibility positions nitinol tubing as a preferred material for medical devices, enabling reliable performance and improved patient outcomes.

Applications in Medical Devices

Cardiovascular Devices (e.g., stents, heart valves)

Nitinol tubing plays a vital role in cardiovascular devices, particularly in stents and heart valves. Its shape memory and superelasticity allow these devices to adapt to the dynamic environment of the human body. For example, self-expanding stents made from nitinol tubing can compress for insertion and then expand to their original shape once deployed. This ensures precise placement and reliable performance in treating conditions like coronary artery disease.

The material's ability to withstand significant strain without permanent deformation is critical in cardiovascular applications. Experimental measurements conducted in temperature-controlled environments validate the phase transformations that enable nitinol's unique properties. These tests confirm its reliability in devices such as guidewires and advanced stents. Clinical trials further highlight the effectiveness of nitinol-based stents, demonstrating their success in improving blood flow and reducing complications.

Evidence Type | Description |

|---|---|

Shape Memory and Superelasticity | Nitinol tubing can return to its original form after deformation and withstand significant strain without permanent deformation, which is crucial in dynamic environments like the human body. |

Experimental Measurements | Tests in temperature-controlled environments validate the phase transformations that contribute to the material's unique properties, demonstrating reliability in applications like stents and guidewires. |

Clinical Trials | Self-expanding stents made from Nitinol have shown exceptional effectiveness in treating coronary artery disease, highlighting the material's performance in real-world medical applications. |

The combination of shape memory, flexibility, and biocompatibility makes nitinol tubing indispensable in cardiovascular devices. These properties enhance patient outcomes by improving device performance and reducing the risks associated with traditional materials.

Orthopedic Implants and Tools

Nitinol tubing has transformed the field of orthopedics by enabling the development of advanced implants and surgical tools. Its high durability and flexibility make it ideal for devices that must endure repetitive stress, such as bone fixation plates and spinal implants. Unlike traditional materials, nitinol can adapt to the body's movements without breaking or losing its structural integrity.

Orthopedic tools made from nitinol tubing also benefit from its unique properties. For instance, surgical instruments designed for precision cutting or drilling can leverage nitinol's elasticity to navigate complex anatomical structures. This reduces the risk of tissue damage and enhances surgical accuracy. Additionally, the material's biocompatibility ensures that implants integrate seamlessly with bone and tissue, minimizing the risk of rejection or infection.

The use of nitinol in orthopedics has improved patient outcomes by reducing recovery times and enhancing the reliability of implants. Its ability to combine strength with flexibility ensures long-term performance, even in demanding applications.

Devices for Minimally Invasive Procedures

Minimally invasive procedures rely heavily on the unique properties of nitinol tubing. Its superelasticity allows medical devices to navigate narrow and complex pathways within the body, such as blood vessels or the gastrointestinal tract. For example, catheters and guidewires made from nitinol tubing can bend and flex without kinking, ensuring smooth and precise navigation.

The shape memory of nitinol tubing is particularly valuable in minimally invasive procedures. Devices can be pre-shaped for specific applications and then return to their original form once deployed. This capability enhances the precision of procedures like angioplasty or endoscopy, where accuracy is critical. The material's biocompatibility further ensures that these devices can remain in the body for extended periods without causing adverse reactions.

Minimally invasive procedures benefit from nitinol tubing's lightweight and durable nature. These characteristics reduce the risk of device failure and improve patient comfort. By enabling advanced medical techniques, nitinol tubing has revolutionized the field of minimally invasive surgery, making treatments safer and more effective.

Benefits for Patients and Healthcare Providers

Faster Recovery and Reduced Risks

Superelastic nitinol tubing significantly enhances patient recovery and minimizes risks during medical procedures. Its superelasticity supports minimally invasive procedures, allowing devices to navigate complex anatomical pathways with ease. Shape memory ensures smaller incisions and less tissue damage, reducing trauma and promoting faster healing. Biocompatibility further contributes to patient safety by minimizing adverse reactions, while corrosion resistance ensures long-term reliability in challenging environments. These properties collectively improve patient outcomes, making nitinol tubing indispensable in modern medical devices.

Property | Benefit |

|---|---|

Superelasticity | Minimally invasive procedures |

Shape memory | Smaller incisions, less tissue damage |

Biocompatibility | Reduced risk of adverse reactions |

Corrosion resistance | Enhanced patient safety |

Improved patient outcomes |

The combination of these features allows healthcare providers to perform safer and more effective treatments, ensuring better results for patients.

Improved Device Longevity and Reliability

Nitinol tubing offers exceptional durability and reliability, making it ideal for long-term medical applications. Studies highlight its ability to withstand high-cycle fatigue, ensuring consistent performance in devices like stents and implants. Low-temperature aging processes enhance nitinol’s fatigue life, further improving its longevity. Researchers emphasize the importance of simulating physiological conditions to validate nitinol’s durability, ensuring its reliability in real-world applications. These advancements reduce the need for device replacements, lowering healthcare costs and improving patient outcomes.

Nitinol cardiovascular devices demonstrate excellent fatigue behavior, supporting long-term use.

Low-temperature aging enhances fatigue life, increasing device longevity.

Advanced simulation methods validate nitinol’s durability under physiological conditions.

Healthcare providers benefit from nitinol tubing’s reliability, as it reduces device failure rates and ensures consistent performance over time.

Enhanced Precision in Medical Treatments

The unique properties of nitinol tubing enable precise navigation through complex anatomical structures, enhancing the accuracy of medical treatments. Shape memory and superelasticity allow devices to adapt to the body’s movements, ensuring smooth and controlled procedures. Nitinol guide wires facilitate minimally invasive procedures, reducing trauma and improving patient outcomes. Clinical success rates highlight the material’s effectiveness in delivering precise treatments, making it a preferred choice for advanced medical devices.

Shape memory and superelasticity ensure precise navigation through anatomical pathways.

Patients experience reduced trauma and faster recovery, improving treatment success rates.

Nitinol guide wires support minimally invasive procedures, enhancing accuracy and outcomes.

By enabling precision and reliability, nitinol tubing transforms medical treatments, benefiting both patients and healthcare providers.

Innovations and Future Trends in Nitinol Tubing

Advances in Manufacturing and Design

Recent advancements in manufacturing techniques have significantly improved the performance and reliability of superelastic nitinol tubing. Methods like electropolishing and micro-electrical-polishing (MEP) have enhanced the material's surface properties. For instance, studies show that MEP-treated nitinol exhibits high resistance to pitting corrosion, increasing the longevity of medical devices. Additionally, coatings such as Titanium Nitride (TiN) have reduced corrosion rates by 50%, though maintaining coating integrity remains a challenge.

Study | Findings | Implications |

|---|---|---|

Chu et al. | TiO2 layer from electropolishing suppressed nickel leaching. | Enhanced corrosion resistance and biocompatibility. |

Zhang et al. | TiN coating reduced corrosion rate by 50%. | Improved corrosion resistance. |

Dharam et al. | MEP improved cellular adhesion and endothelialization. | Better integration with biological tissues. |

Haider et al. | MEP-treated nitinol showed high resistance to pitting corrosion. | Increased longevity and safety of implants. |

Industry reports highlight the growing use of nitinol tubing in catheter systems and complex medical devices. These advancements have also improved production efficiency, making nitinol more accessible for various applications. The role of oxide layer thickness and composition in corrosion behavior has further refined the design of laser-cut nitinol stents, ensuring better performance in minimally invasive procedures.

Customization for Patient-Specific Applications

Customization has become a cornerstone in the development of patient-specific solutions using nitinol tubing. Advanced manufacturing techniques now allow for tailored designs that meet individual anatomical and procedural requirements. For example, nitinol stents can be customized to fit specific vascular geometries, ensuring optimal performance and reducing complications.

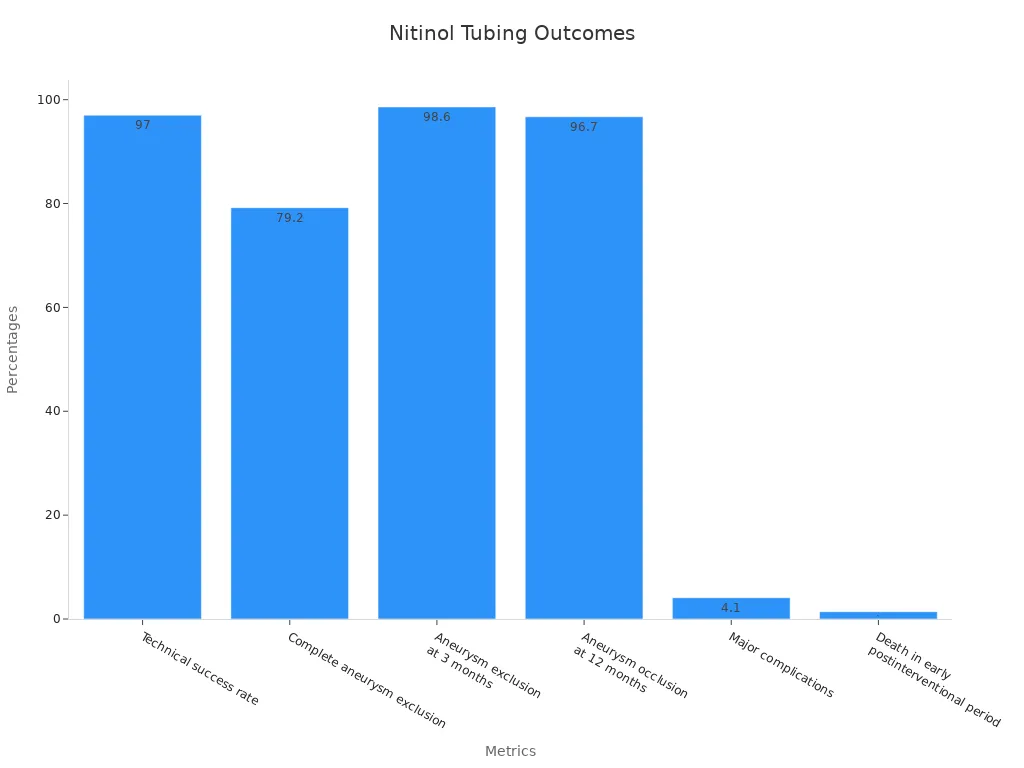

Clinical data underscores the success of these patient-specific solutions. Aneurysm exclusion rates at three months reached 98.6%, while occlusion rates at 12 months stood at 96.7%. Major complications occurred in only 4.1% of cases, demonstrating the reliability of customized nitinol devices.

Metric | Result |

|---|---|

Technical success rate | 97% (70 of 72 patients) |

Complete aneurysm exclusion | 79.2% (57 of 72 patients) |

Aneurysm exclusion at 3 months | 98.6% (70 of 71 patients) |

Aneurysm occlusion at 12 months | 96.7% (29 of 30 patients) |

Major complications | 4.1% (3 patients) |

This level of customization not only enhances device performance but also improves patient outcomes by addressing unique medical needs.

Emerging Uses in New Medical Fields

The versatility of nitinol tubing continues to drive its adoption in emerging medical fields. Transcatheter heart valves represent one such application, where rigorous fatigue analysis ensures reliability in critical procedures. Thin-film nitinol and porous nitinol are also gaining attention for their potential in advanced implants and scaffolds.

Ongoing research explores the integration of micro-electrical-mechanical systems (MEMS) with nitinol tubing. This innovation could lead to active medical implants capable of real-time monitoring and intervention. Additionally, new nitinol alloys with enhanced properties are being developed to meet the demands of minimally invasive procedures.

Nitinol is essential for less invasive medical procedures, with studies focusing on its fatigue performance and corrosion behavior.

Emerging applications include thin-film nitinol, porous nitinol, and MEMS-integrated devices.

Research into new alloys aims to further enhance the material's properties for advanced medical applications.

These advancements highlight the expanding role of nitinol tubing in transforming medical devices and improving healthcare outcomes.

Superelastic nitinol tubing has redefined the capabilities of medical devices by combining shape memory, flexibility, and biocompatibility. Its applications span cardiovascular devices, orthopedic tools, and minimally invasive procedures, showcasing its versatility. Patients benefit from faster recovery and improved outcomes, while healthcare providers gain access to reliable and durable solutions. Nitinol continues to drive innovation, enabling advanced treatments and transforming healthcare delivery. Its role in improving medical technology underscores its importance in shaping the future of patient care.

FAQ

What makes superelastic Nitinol tubing unique compared to other materials?

Superelastic Nitinol tubing stands out due to its shape memory, elasticity, and biocompatibility. It can return to its original shape after deformation and endure significant strain without damage. These properties make it ideal for medical devices requiring flexibility, durability, and safe integration with human tissues.

How does Nitinol tubing improve minimally invasive procedures?

Nitinol tubing enhances minimally invasive procedures by offering exceptional flexibility and shape memory. Devices made from Nitinol can navigate complex anatomical pathways without kinking or breaking. Its biocompatibility ensures safe, long-term use, while its lightweight nature improves patient comfort during and after procedures.

Is Nitinol tubing safe for long-term implants?

Yes, Nitinol tubing is safe for long-term implants. Its biocompatibility minimizes adverse reactions, and its corrosion resistance prevents degradation in the body. Clinical studies confirm its reliability and safety, making it a trusted material for implants like stents and orthopedic devices.

Can Nitinol tubing be customized for specific medical needs?

Nitinol tubing can be customized for patient-specific applications. Advanced manufacturing techniques allow precise tailoring to fit unique anatomical structures. This customization improves device performance and reduces complications, ensuring better outcomes for patients with specialized medical requirements.

What are the future trends in Nitinol tubing technology?

Future trends include integrating micro-electrical-mechanical systems (MEMS) for real-time monitoring, developing new Nitinol alloys for enhanced properties, and expanding its use in emerging fields like transcatheter heart valves. These innovations aim to improve device performance and broaden its medical applications.

See Also

Nitinol Tubing's Impact on Modern Medical Device Innovation

Nitinol Tubing's Contribution to Progress in Medical Technology

Understanding Nitinol Tubing Uses in Healthcare Innovations