How Superelastic Nitinol Tubing Improves Blood Clot Removal Devices

Superelastic nitinol tubing for blood clot removal devices transforms patient care by delivering unmatched flexibility, safety, and reliability. Nitinol’s superelasticity enables devices to bend and recover shape, even in complex vascular networks. Devices using superelastic nitinol tubing achieve tensile strengths up to 900 MPa and withstand millions of cycles, ensuring durability in life-saving medical devices. Nitinol’s controlled transformation temperature and reduced surface roughness enhance safety and lower complications. These features help clinicians navigate vascular pathways, improve clot removal, and speed up recovery for patients.

Key Takeaways

Superelastic nitinol tubing bends easily and returns to its original shape, helping devices navigate complex blood vessels safely.

Nitinol’s shape memory lets devices expand inside the body to fit patient anatomy, improving clot removal success.

Nitinol tubing is biocompatible and resists corrosion, making it safe for long-term use in medical devices.

Devices made with nitinol show high durability and fatigue resistance, ensuring reliable performance during repeated use.

Using nitinol tubing in blood clot removal devices leads to better patient outcomes, faster recovery, and fewer complications.

Superelastic Nitinol Tubing for Blood Clot Removal Devices

Superelasticity for Enhanced Flexibility

Superelastic nitinol tubing for blood clot removal devices stands out due to its remarkable ability to undergo large deformations and return to its original shape. This superelasticity for enhanced flexibility allows devices to navigate the intricate and winding pathways of the human vascular system without permanent deformation. Researchers have shown that superelastic nitinol tubing can stretch up to 100% in uniaxial tests and up to 360% in biaxial stretching, far surpassing the limits of traditional metal alloys. Devices made from nitinol can bend from 0° to 180° during mechanical testing, demonstrating the flexibility and durability needed for challenging vascular applications.

The unique phase transformation between austenite and martensite phases in nitinol enables this superelastic behavior. Manufacturers tailor these properties through precise heat treatments, ensuring that the tubing can recover from large strains and maintain its mechanical integrity. This flexibility is essential for minimally invasive procedures, where devices must pass through narrow, curved arteries to reach and remove blood clots. The ability to compress, bend, and expand without losing shape or strength makes superelastic nitinol tubing the preferred choice for these critical applications.

A comparison of performance metrics highlights why nitinol is better than older materials. Devices using superelastic nitinol tubing achieve nearly 100% size recovery after loading, low trackability force for smooth delivery, and maintain their structure even after repeated use. These features directly translate to safer, more effective minimally invasive procedures, reducing the risk of complications and improving patient outcomes.

Measurement Type | Quantitative Value(s) | Description/Context |

|---|---|---|

Uniaxial stretching | Up to 100% strain displacement | Demonstrates stretchability without buckling |

Biaxial stretching | ~300% to ~360% strain | Mimics stent deployment in real-world applications |

Bending test | Rotation from 0° to 180° | Assesses flexibility for navigating tortuous vessels |

Fracture limit strain | 12% maximum principal strain | Indicates high durability before mechanical failure |

Shape Memory and Biocompatibility

Shape memory and flexibility are two defining characteristics of nitinol that further enhance its performance in blood clot removal devices. Shape memory allows the tubing to be compressed for delivery through microcatheters and then expand precisely to its intended shape once deployed inside the body. This property ensures that devices can adapt to the unique anatomy of each patient, providing reliable clot capture and removal during minimally invasive procedures.

Biocompatibility for safe medical applications is another critical advantage of nitinol. Experimental studies confirm that nitinol exhibits excellent biocompatibility and corrosion resistance, making it suitable for long-term implantation in neurovascular applications. In vivo studies in swine models show no thrombosis or tissue abnormalities after device implantation, supporting its safety profile. Surface treatments such as polishing and coating further enhance corrosion resistance and reduce the risk of thrombosis, ensuring that devices remain safe and effective over time.

Shape memory and flexibility work together to improve the adaptability and reliability of blood clot removal devices. Clinical studies demonstrate that nitinol devices integrate successfully into vascular tissue within 30 days, confirming both biocompatibility and durability. These properties allow devices to perform consistently under the dynamic conditions of the human body, maintaining flexibility and durability throughout their lifespan.

Note: The combination of superelasticity, shape memory, and biocompatibility in nitinol tubing enables the development of advanced blood clot removal devices that can safely and effectively treat patients using minimally invasive procedures. These innovations continue to set new standards for flexibility, safety, and clinical performance in vascular applications.

Nitinol Tubing for Thrombectomy Stent Performance

Navigating Tortuous Vessels

Nitinol tubing for thrombectomy stent devices plays a vital role in the effective removal of clots from the vascular system. The unique properties of nitinol, such as superelasticity and shape memory, allow stents and catheters to bend and recover their original shape. This flexibility for navigating complex vascular pathways ensures that devices can reach clots in even the most challenging vessel anatomies without breaking or deforming. Researchers have observed that nitinol tubing for thrombectomy stent applications can endure extreme deformation, sometimes up to 400-500%, while maintaining performance and durability.

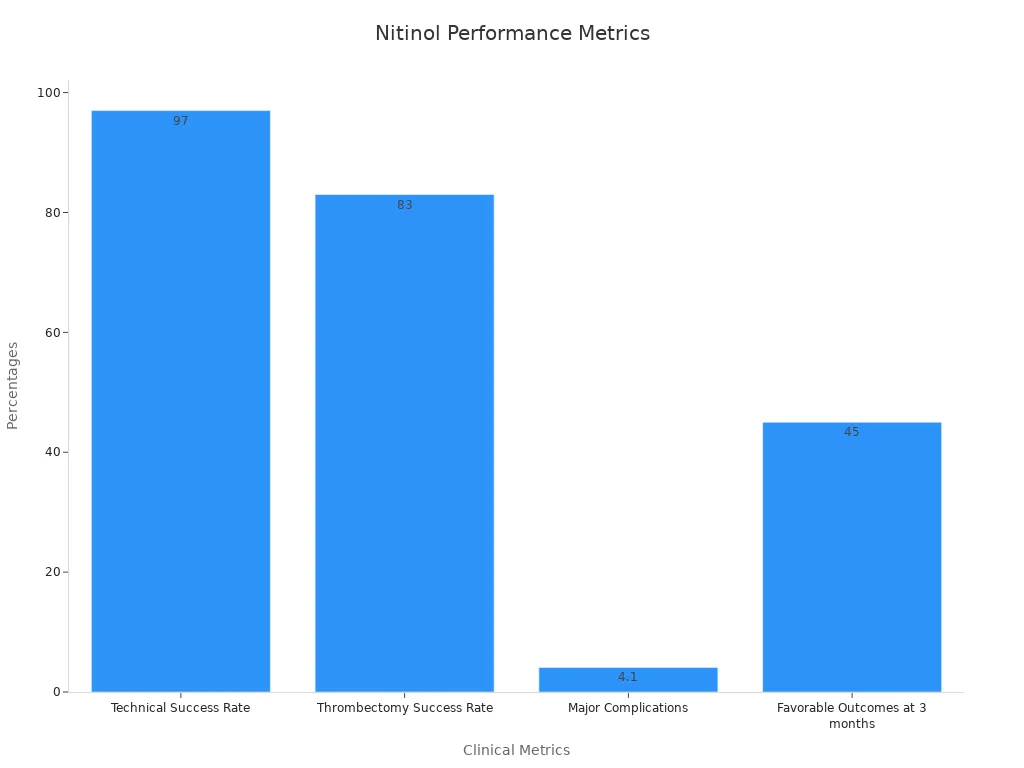

The titanium dioxide passivation layer on nitinol enhances biocompatibility and corrosion resistance, supporting long-term device integrity. Cyclic mechanical testing confirms that nitinol tubing maintains tensile strength and strain recovery, even after repeated use. The adaptability of nitinol stents to intricate vascular anatomies reduces procedural complications and improves patient outcomes. Clinical studies report a technical success rate of 97% and a thrombectomy success rate of 83% in restoring blood flow, with major complications occurring in only 4.1% of cases.

Maintaining Shape and Mechanical Integrity

Nitinol tubing for thrombectomy stent devices demonstrates high resistance to plastic deformation and consistent force application during clot retrieval. Experimental data from three-point bending tests and deployment force measurements show that nitinol stents exhibit superelasticity, allowing them to flex and recover without permanent damage. Deployment and recapture forces remain moderate, which balances ease of use and device integrity.

Test Type | Methodology | Key Findings |

|---|---|---|

Three-point bending test | Micro-Universal Testing Machine measures force-displacement. | High flexibility and resistance to deformation. |

Deployment force | Pushing stent out of catheter. | Moderate force (0.32-0.42 N) ensures device integrity. |

Recapture force | Retracting stent into catheter. | Intermediate force (0.035-0.45 N) allows repositioning without damage. |

In vitro thrombus retrieval rate | Tested in artificial vessels with clots. | High retrieval rates (>95%) during clot removal. |

Accelerated fatigue testing under clinical conditions shows that nitinol tubing can withstand millions of cycles without failure. This durability and flexibility and durability make nitinol the preferred material for thrombectomy stent performance, ensuring reliable removal of clots and long-term vascular health.

Manufacturing and Customization of Superelastic Nitinol Tubing

Heat Treatment and Shape Setting

Manufacturers use advanced processes to create superelastic nitinol tubing for medical applications. The journey begins with precise melting of nickel and titanium using vacuum induction or arc remelting. This step ensures the alloy remains pure and homogeneous, which is essential for all applications of nitinol tubing. After melting, hot working methods like forging and extrusion break down the cast structure and improve mechanical properties. Cold drawing then reduces the tubing diameter and increases strength, while intermediate annealing restores ductility.

Heat treatment and shape setting play a crucial role in imparting superelastic properties to nitinol. Multiple heat treatment trials, with careful control of time and temperature, help optimize the tubing’s performance. Specialized equipment such as salt bath and fluidized bed furnaces provide high heat transfer rates and precise temperature control, but these methods can be expensive and hazardous. Box furnaces are more common in laboratory settings, though they offer less repeatability. Manufacturers must balance shape accuracy with the retention of superelasticity, often relying on trade secrets and experience.

Nitinol ingots are produced by vacuum induction melting and vacuum arc remelting.

Hot working and cold drawing shape the tubing and enhance its properties.

Annealing prevents premature failure from work hardening.

Heat treatment at 400–500°C with controlled dwell times sets the final shape and superelasticity.

Surface finishing, such as electropolishing and passivation, improves corrosion resistance and biocompatibility.

Tailoring Tubing for Procedures

Customization of nitinol tubing allows device designers to meet the unique demands of different blood clot removal procedures. By adjusting the tubing’s diameter, wall thickness, and shape, manufacturers can create devices that fit specific vascular anatomies. For example, some applications require tubing with higher stiffness to navigate challenging vessels, while others need more flexibility for delicate pathways.

A comparison of nitinol and plastic tubing highlights the benefits and limitations of customization:

Aspect | Nitinol Tubing | Plastic (Nylon) Tubing | Notes |

|---|---|---|---|

Bending Force to Straighten | 111.84 N | 4.96 N (insufficient stiffness) | Larger diameter nylon tube needed to match stiffness (107.44 N) |

MR Imaging Artifact Increase | 440% increase over tube diameter | 6.07% increase | Nitinol causes significant MRI artifacts, limiting MR-guided use |

Robotic Targeting Accuracy (RMSE) | Comparable to metallic tubes (~1.26 mm) | 0.85 ± 0.16 mm (2D MRI), 1.39 ± 0.54 mm (3D EM tracking) | Plastic tubes allow patient-specific customization based on pre-op scans |

Customization Method | Limited due to high stiffness | Heat-setting at 350°C for 30s with fixture | Plastic tubing enables patient-specific curvature |

Nitinol tubing offers unmatched mechanical strength and durability for demanding applications. However, its high stiffness and the complexity of heat-setting limit patient-specific customization. Despite this, nitinol remains the preferred choice for most blood clot removal devices due to its superelasticity, biocompatibility, and reliability in critical applications.

Real-World Benefits of Superelasticity

Improved Patient Outcomes

Superelastic nitinol tubing in blood clot removal devices has transformed patient care by improving safety, durability, and clinical performance. Patients benefit from devices that adapt to the body’s complex vascular pathways, which reduces trauma during minimally invasive procedures. Nitinol’s unique superelasticity and shape memory allow thrombectomy stents to reach and remove clots in challenging locations, leading to higher rates of successful clot removal and restored blood flow.

Clinical studies highlight the impact of nitinol in life-saving medical devices. For example, systematic reviews of nitinol prostheses in stapes surgery show significant improvements in hearing and patient safety. These studies report reliable device function and fewer complications, which demonstrates the value of superelasticity in real-world applications. Mechanical testing of nitinol staples for sternal closure also reveals constant clamping pressure and fast recovery, outperforming traditional materials. Patients experience shorter hospital stays and faster recovery times due to the biocompatibility and durability of nitinol devices.

Note: The combination of biocompatibility, durability, and safety in nitinol devices leads to fewer complications and better long-term outcomes for patients.

Advantages for Clinicians

Clinicians rely on nitinol-based devices for their flexibility, efficiency, and consistent performance in minimally invasive procedures. The superelastic properties of nitinol stents and thrombectomy devices enable precise navigation through tortuous vessels, which increases procedural success and reduces the risk of device failure. Enhanced biocompatibility and durability support long-term use and minimize the need for repeat interventions.

Key advantages for clinicians include:

Improved efficiency in mechanical thrombectomy procedures due to reliable device deployment and retrieval.

Devices conform to complex anatomies, reducing trauma and improving safety.

Fatigue resistance and strength retention ensure durability and reduced risk of complications.

Technological advancements in nitinol processing, such as laser cutting and electropolishing, enhance device performance and lifespan.

Broader adoption of nitinol devices in cardiovascular, neurological, and urological applications supports better patient care.

Experts recognize nitinol’s role in enabling minimally invasive procedures, reducing hospital stays, and supporting value-based healthcare. The growing demand for nitinol devices reflects their proven performance, safety, and adaptability in life-saving medical devices.

Superelastic nitinol tubing has changed the way blood clot removal devices work. Nitinol gives devices the flexibility to move through complex vessels and the safety needed for patient care. Devices made with nitinol show high fatigue resistance, strong shape memory, and excellent biocompatibility. Recent innovations in nitinol include advanced coatings and alloying methods that improve corrosion resistance and device durability. These advances help devices perform better and last longer.

Development of gold and platinum coatings on nitinol increases corrosion resistance and reduces nickel ion release.

Bioactive coatings on nitinol devices promote tissue integration and lower infection risk.

Ultrasonic-assisted electroplating on nitinol ensures even coatings for flexible devices.

Property/Aspect | Description/Impact |

|---|---|

Superelasticity | Nitinol allows devices to deform and recover shape without damage. |

Shape Memory Effect | Nitinol devices return to their original shape after deployment. |

Fatigue Resistance | Nitinol devices last longer under repeated use. |

Biocompatibility | Nitinol reduces tissue reactions compared to other metals. |

Corrosion Resistance | Nitinol coatings keep devices safe and reliable in the body. |

Nitinol continues to drive progress in minimally invasive vascular procedures. Devices using nitinol improve patient outcomes and support safer, faster recovery. Material science, especially nitinol, plays a vital role in the future of medical devices and patient care.

FAQ

What makes superelastic nitinol tubing different from other metals?

Superelastic nitinol tubing bends and returns to its original shape. Other metals often deform or break under stress. Nitinol’s unique atomic structure gives it both flexibility and strength, making it ideal for medical devices.

Is nitinol safe for use inside the human body?

Nitinol shows excellent biocompatibility. Medical studies confirm that nitinol rarely causes allergic reactions or tissue damage. Surface treatments, such as electropolishing, further improve its safety for long-term use in blood vessels.

How does nitinol improve blood clot removal procedures?

Nitinol tubing allows devices to reach clots in narrow, winding vessels. Its flexibility reduces trauma to blood vessels. Devices made with nitinol often lead to faster recovery and fewer complications for patients.

Can nitinol tubing be customized for different procedures?

Manufacturers can adjust nitinol tubing’s diameter, wall thickness, and shape. This customization helps create devices for specific patient needs and different types of blood clot removal procedures.

Does nitinol tubing affect MRI scans?

Nitinol can cause artifacts in MRI images. These artifacts may limit its use in some MRI-guided procedures. However, most blood clot removal devices work safely with standard imaging techniques.

See Also

Transforming Medical Devices Through Innovative Nitinol Tubing Use

Nitinol Tubing’s Impact On Progress In Medical Technology

A Deep Dive Into Nitinol Tubing Applications In Healthcare

The Importance Of Nitinol Tubing In Cutting-Edge Medical Fields

Nitinol Tubing’s Crucial Role In Minimally Invasive Surgeries