What Factors Influence the Fatigue Life of Superelastic Nitinol Tubing

Fatigue in superelastic nitinol tubing plays a critical role in the safety and durability of medical devices. Many medical applications, especially those related to the heart, require tubing that can endure millions of cycles without failure. Researchers have focused on superelastic nitinol tubing fatigue life optimization, testing tubing to withstand up to 100 million cycles in medical environments. Factors such as surface inclusions, internal purity, and repeated bending significantly impact fatigue strength. Tubing with fewer inclusions prevents crack propagation, which is essential for avoiding premature device failure. Optimizing the fatigue life of superelastic nitinol tubing involves carefully controlling these factors to meet the stringent requirements of medical and cardiovascular devices.

Key Takeaways

Having fewer impurities and inclusions in nitinol tubing makes it stronger and stops cracks from forming. Using advanced manufacturing methods like TM-1 makes tubing with smaller defects. This helps the tubing last longer than tubing made with other methods. Proper heat treatment and surface finishing, like annealing and electropolishing, protect the tubing from damage. These steps also make the tubing last longer. Using the right amount of prestrain and controlling how the tubing is loaded helps it survive many bends and stretches. Careful material control, strong quality checks, and computer modeling help engineers design nitinol tubing. This makes sure the tubing is safe and works well in medical devices.

Material Purity

Inclusions

Inclusions are small bits or impurities stuck inside Nitinol tubing. These can come from the starting materials or from how the tubing is made. Studies show that inclusions, scratches, and surface problems often help cracks begin. Tests show wires with bigger inclusions do not last as long. Inclusions make stress build up and help cracks start and spread.

Bigger inclusions make fatigue strength lower.

The way inclusions look and point changes how strain builds up.

Empty spaces or broken pieces near inclusions make things worse.

The most important things for local fatigue strain are global strain amplitude, inclusion shape, direction, and mean strain.

Studies show inclusions are a main reason for fatigue failure in Nitinol tubing.

Scientists keep studying inclusions under repeated loading, but their bad effects are clear.

Tip: Making fewer inclusions during production helps the fatigue life of superelastic Nitinol tubing.

Alloy Balance

The mix of nickel and titanium in Nitinol tubing changes its superelastic properties and fatigue life. Small changes in the mix can change how the tubing acts under stress. If there is too much nickel or titanium, the tubing may lose superelasticity or get more brittle. Makers control the alloy mix to keep tubing strong and bendy. A steady alloy balance stops weak spots and keeps medical devices working well.

Cleanliness

Cleanliness means there are no unwanted bits, oils, or dirt on or inside the tubing. Good cleanliness lowers the chance of problems that can start cracks. Makers use special cleaning steps to get rid of dirt. Clean tubing fights fatigue better and lasts longer in tough places.

Factor | Fatigue Life Impact (at 10⁷ cycles) | Comparative Insight |

|---|---|---|

Tube Processing (TM-1) | 2 to 3 times greater fatigue life than TM-2 for the same Std VIM-VAR grade | TM-1 processed tubing does better than TM-2 tubing even when TM-2 uses higher purity materials (HP-VAR, PO VIM-VAR) |

Tube Processing (TM-2) | Lower fatigue life across standard and high purity grades | TM-2 processing gives worse fatigue life even if the material is purer |

Material Purity (HP-VAR, PO VIM-VAR) | Better fatigue life than standard grades but not as good as TM-1 processed Std VIM-VAR | Material purity helps fatigue life but does not beat the effect of TM-1 processing |

Microstructural Factors | Fatigue life goes down as defect size goes up | Tube processing changes microstructure and defect size, which really affects fatigue resistance |

Note: Material purity helps fatigue life, but tube processing methods matter even more for performance.

Tube Processing

Manufacturing Methods

How tubing is made changes how long it lasts. TM-1 and TM-2 are two main ways to make tubing. TM-1 uses special diamond tools and pulls the tubing once. This makes tubing with smaller inclusions and even structure. TM-1 tubing lasts much longer than TM-2 tubing. It can last two or three times longer. TM-2 uses different tools and pulls the tubing many times. This makes bigger inclusions and uneven stress. These things make TM-2 tubing break faster. Tests and studies show TM-1 tubing is better, even with the same Nitinol. Computer models say TM-1 helps close gaps and fix the inside. This makes tubing stronger. TM-1 is best for jobs that need tough tubing.

TM-1: Smaller inclusions, higher fatigue life, better durability.

TM-2: Larger inclusions, lower fatigue life, reduced durability.

Surface Finish

How smooth the tubing is matters a lot. Rough spots and inclusions can start cracks. Cracks often begin at inclusions where stress builds up. Tests show rough areas grow near these spots and cause early breaks. Smoother tubing with fewer inclusions stops cracks from growing fast. The outside layer also helps. Electropolished tubing gets a thin TiO2 layer. Heat-treated tubing gets a thicker oxide layer. Both layers help stop rust and make tubing last longer. Good surface finish protects tubing from damage and helps it work better.

Smoother surfaces = higher fatigue resistance and durability.

Thicker oxide layers can improve corrosion resistance and fatigue life.

Annealing

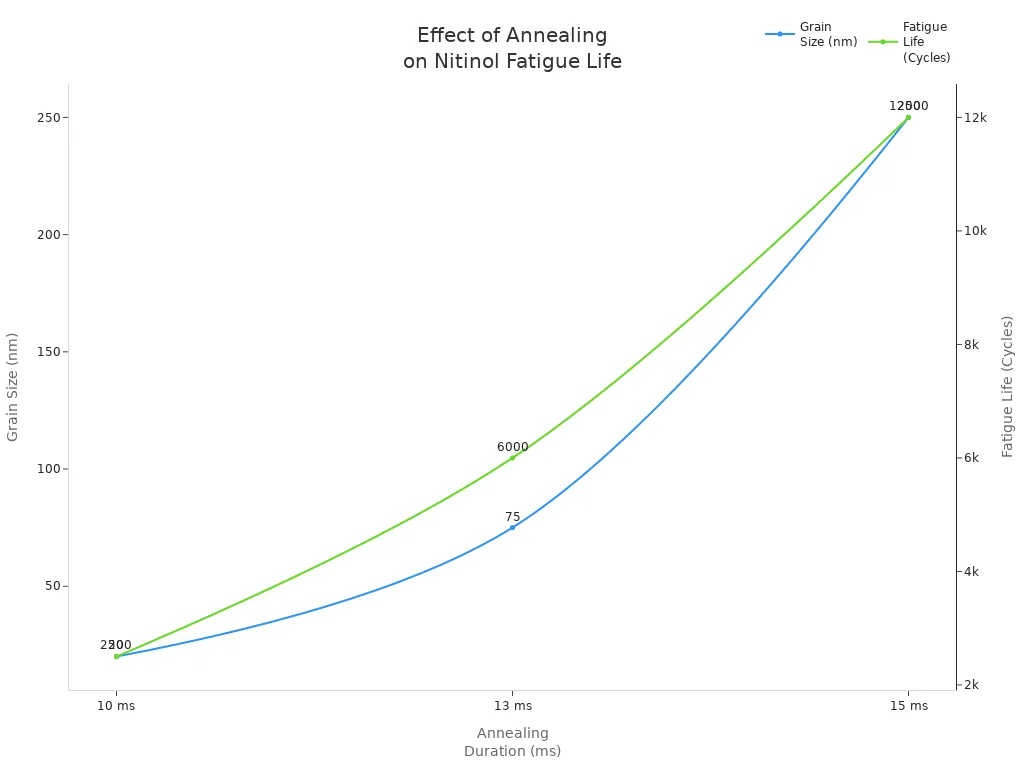

Annealing uses heat to change the inside of tubing. Heating between 400°C and 550°C sets the tubing’s shape and strength. Good annealing stops the tubing from getting too hard and brittle. Cold working makes the inside crowded and grains smaller. This can make tubing strong but also easy to break if not heated right. Using the right heat brings back superelasticity and keeps tubing strong.

Annealing Duration (ms) | Grain Size (nm) | Fatigue Life (Cycles) | Microstructural Effects |

|---|---|---|---|

10 | ~20 | < 2,500 | High defects, low fatigue life |

13 | ~75 | Intermediate | Moderate grain size, better fatigue properties |

15 | ~250 | ~12,000 | Largest grains, highest fatigue life |

Heating at 400°C for two hours makes Ni4Ti3 bits inside the tubing. These bits make the tubing stronger and change how it acts. This helps tubing last longer and work better in tough places.

Tip: Careful steps in making, finishing, and heating tubing help it last longer and work better.

Microstructure

Grain Size

Grain size is important for how Nitinol tubing works. It changes how the tubing handles being bent over and over. Studies show grain size affects stress at grain edges. If grains are too big or too small, stress builds up there. This stress can change the tubing and cause cracks. Cracks make the tubing weaker and lower its fatigue strength. The right grain size helps stop these stress points. Small or well-controlled grains help the tubing last longer. They stop changes that can hurt the tubing. Engineers change grain size during making to help the tubing stay strong.

Phase Composition

The phases inside Nitinol tubing change how it acts under stress. Different phase mixes change how the tubing bends and stretches many times. The table below shows how each part of phase mix changes fatigue life:

Phase Composition Aspect | Influence on Fatigue Performance |

|---|---|

Martensitic mechanism (εcr parameter) | Increases recoverable strain and boosts low-cycle fatigue resistance. |

σM/σslip ratio | Lower ratio means better fatigue resistance by favoring martensite movement. |

Nanoscale Ni-rich precipitates | Strengthen the microstructure and improve high-cycle fatigue performance. |

Increased dislocation density | Helps the tubing resist fatigue in high-cycle conditions. |

Reduced Ti4Ni2Ox volume fraction | Less harmful oxide means better fatigue behavior. |

Thermo-mechanical processing & heat treatment | Change phase composition and microstructure, affecting fatigue behavior. |

Complex interplay of phases and environment | Makes fatigue behavior hard to predict. |

When more martensite forms at high-stress spots, tubing lasts longer. This happens when mean strain is about 1.5%. Grains lined up in the (111) direction help this change. This makes the tubing stronger and last longer.

Defects

Defects in the tubing can make it weaker. Nonmetallic inclusions like carbides and oxides start cracks. These weak spots collect stress and help cracks grow. More and bigger inclusions mean the tubing is weaker. Stress around these defects makes things worse. Surface carbides are where cracks often start. High purity Nitinol has fewer bad inclusions. It is made with vacuum arc remelting. This makes the tubing stronger and last longer. Controlling defects is very important for good fatigue life.

Loading Conditions

Strain Amplitude

Strain amplitude means how much the tubing stretches or squeezes each time. If strain amplitude is higher, cracks grow faster. This makes the tubing break sooner. When engineers add more prestrain, tubing can stretch more before breaking. The table below shows how prestrain and strain amplitude change fatigue life:

Aspect | Observation | Effect on Fatigue Life |

|---|---|---|

Prestrain level | Raised from 4% to 9% in tension–tension fatigue tests | Fatigue limit doubled at 9% prestrain |

Strain amplitude | Tested at different levels after prestraining | More prestrain lets tubing handle bigger strain |

Loading mode | Tension–tension vs. rotary bending fatigue | Prestrain helps most in tension–tension fatigue |

Residual stresses | Compressive at tension-exposed spots | Makes fatigue life better |

Residual stresses | Tensile at tension-exposed spots | Makes fatigue life worse |

Microstructural changes | Strains up to 8-9% make helpful microstructures | Fatigue life gets better |

Tubing with more prestrain lasts longer and is stronger, especially in tension–tension loading.

Mean Stress

Mean stress is the average force on tubing when loaded again and again. If mean strain goes up, tubing cannot stretch as much before breaking. For example, at zero mean strain, tubing lasts 400 million cycles at 0.55% strain amplitude. If mean strain is 3% or more, tubing only lasts at about 0.16% strain amplitude. Higher mean stress makes tubing weaker and less durable. Between 3% and 7% mean strain, the strain amplitude limit stays about the same. So, more mean stress does not help fatigue life. Engineers need to think about mean stress when designing tubing to last a long time.

Prestrain

Prestrain means stretching tubing before it is used. Prestrain helps the inside structure stay stable and makes tubing last longer. Tests show prestrain stops cracks from starting and helps phase changes that lower stress. Hourglass-shaped samples stop strain from building up in one spot, so tests are fair. The R-phase transformation helps relieve stress and makes tubing last longer at higher strains. Prestrain levels of 6% and 10% make fatigue life better and keep the elastocaloric effect steady during use. Tubing with the right prestrain stays strong for a long time.

Prestrain keeps phase changes steady.

Prestrain stops damage from repeated loading.

Prestrain helps fatigue life at some strain amplitudes.

Environment

Things like temperature and corrosion affect how tubing lasts. Nitinol tubing works best in certain temperature ranges. High temperatures can hurt phase changes, making shape memory and superelasticity worse. Staying above the austenite finish temperature for a long time lowers fatigue resistance and strength. Corrosion from water or body fluids breaks the surface oxide and causes hydrogen embrittlement, which makes tubing weaker. Slower test speeds let more hydrogen in, causing more damage. Protective surface treatments help stop corrosion and make tubing last longer. Real-world use is often tougher than lab tests, with more types of stress and changing amplitudes. Engineers need to test tubing in these real conditions to know how long it will last and make sure devices stay strong.

Tip: Testing tubing in real environments helps engineers learn how it really lasts and stays strong.

Superelastic Nitinol Tubing Fatigue Life Optimization

Fatigue Life Drivers

Engineers and scientists look at many things to make superelastic nitinol tubing fatigue life optimization better. They pick materials with the right chemical mix. Nickel is kept between 54.5% and 57.0%. They try to keep out impurities like oxygen, carbon, and iron. This helps stop inclusions that can make tubing weak. Makers follow ASTM F2063 rules to keep mechanical properties steady. These rules help with tensile strength and superelastic strain. They use vacuum arc remelting and vacuum induction melting. These methods help control the inside structure and make tubing stronger.

Surface finishing like electropolishing and passivation helps stop corrosion. It also lowers nickel ion release. These steps make medical devices safer and last longer. If the inside is pure and inclusions are small, tubing is stronger. Smaller inclusions mean tubing lasts longer. Makers use heat treatment and annealing. These steps keep superelastic properties steady and help with fatigue.

Quality control is very important. Makers check chemical mix at many steps. They keep track of products to make sure quality stays the same. New ideas like keeping non-metallic inclusions under 5.4 μm help a lot. They also make surface roughness less than Ra ≤ 0.1 μm. This makes tubing last longer. They test tubing with high-cycle fatigue tests and corrosion tests. These tests show if tubing is strong enough for medical use.

Tip: Makers should use strict material choices, good processing, and strong testing to make medical devices last longer and work better.

Key Steps for Fatigue Life Optimization:

Control chemical mix and keep out impurities.

Use special melting and finishing steps.

Heat treat and anneal for steady properties.

Test tubing with high-cycle fatigue and check the inside.

Keep quality control and track products.

Optimization Step | Impact on Fatigue Life and Durability | Importance for Medical Devices |

|---|---|---|

Precise composition control | Cuts inclusions, makes fatigue life better | Keeps devices safe and steady |

Advanced melting processes | Controls inside structure, makes tubing last | Stops devices from breaking |

Surface finishing | Stops corrosion, helps biocompatibility | Makes devices last longer |

Rigorous fatigue testing | Checks strength under repeated use | Meets medical rules |

Quality control | Keeps product working the same every time | Protects patient health |

Prediction Methods

New computer models and data tools help predict how long superelastic nitinol tubing will last. Researchers use high-resolution X-ray computed tomography (XCT). This maps where inclusions and empty spaces are inside tubing. They use this data with finite element analysis (FEA). FEA finds places inside tubing where strain is high. By checking where impurities and high strain overlap, they use a volumetric hazard probability metric. This metric shows the risk of tubing breaking from fatigue. It measures the chance of finding a particle-void group near a high strain spot. Custom Python scripts help report stress, strain, and the size and shape of these spots.

Numerical models of finite-strain superelastic behavior help simulate how Nitinol acts. This way, engineers can predict fatigue life using both the inside structure and how tubing is loaded. This makes predictions more accurate.

Data modeling also helps predictions. Tests on thin-walled tubing under twisting and other loads showed old models do not always work. By normalizing strain data, researchers made a new Coffin-Manson model. This model links cycles to failure with alternating transformation strain. It fixes problems with older ways.

Statistical tools like R programming help calculate strain amplitudes and fracture chances. Probabilistic models like log-normal and Weibull functions fit fatigue data better. This is true for low fracture probabilities. Mechanistic modeling uses stressed-volume based probabilistic fatigue models. These models need less real-life testing and can predict at higher cycle counts. Microstructural correlation, like linking defect size to fatigue strength, makes predictions better. Differences in tube processing, like TM-1 and TM-2, change fatigue behavior and help set model inputs.

Aspect | Description | Contribution to Fatigue Life Prediction Accuracy |

|---|---|---|

Statistical Tools | R programming for stats | Calculates strain amplitudes and chances |

Probabilistic Models | Log-normal and Weibull functions | Fit fatigue data better, especially for low chances |

Mechanistic Modeling | Stressed-volume based fatigue model | Predicts fatigue life with less testing |

Microstructural Correlation | Defect size data (inclusions) | Links inside structure to strength, helps reliability |

Manufacturing Effects | Tube processing differences (TM-1 vs TM-2) | Sets model inputs, shows how making tubing matters |

Testing tubing under real-life loading is still needed. These tests find things like environment and inclusions that start cracks. Checking the inside shows defects from making can lower fatigue resistance. Testing helps predict how long tubing will stay strong. This is very important for medical devices that must last a long time.

Note: Using computer models, data tools, and strong testing helps engineers make superelastic nitinol tubing last longer for medical use.

How well superelastic nitinol tubing works depends on purity, how it is made, its inside structure, and how it is used. To make medical devices last longer, engineers make the tubing purer, improve how it is made, and use computer models to predict how it will act. Many groups work together to make better medical tubing.

AccuPath and its partners look at ways to machine tubing, check quality, and try new materials to make tubing stronger.

Teams test stretching and heating steps to help medical implants last longer.

New ways to machine and cool tubing help stop damage and make tubing more reliable.

Working together helps make medical devices safer and last longer.

FAQ

What is superelastic nitinol tubing used for?

Superelastic nitinol tubing is used to make medical devices. Doctors and engineers use it for stents, guidewires, and surgical tools. The tubing can bend a lot and go back to its shape. This makes it safe for use in the human body.

Tip: Superelastic nitinol tubing is good where both flexibility and strength are needed.

How do inclusions affect fatigue life?

Inclusions are weak spots inside the tubing. They help cracks start and grow faster. Tubing with fewer inclusions lasts longer and stays strong after many bends.

Inclusions | Fatigue Life Impact |

|---|---|

Few | High |

Many | Low |

Why does surface finish matter for nitinol tubing?

A smooth surface helps stop cracks from starting. Rough or scratched tubing can break sooner. Engineers polish the tubing to make it stronger and help it last longer.

Can temperature change the performance of nitinol tubing?

Temperature changes how nitinol tubing bends and stretches. High temperatures can make it lose its special features. Tubing works best at body temperature in medical devices.

Note: Testing tubing at different temperatures helps engineers pick the right material for each job.

See Also

Evaluating The Effect Of Cyclic Testing On NiTi Durability

Understanding The Mechanisms Of Nitinol’s Shape Memory And Flexibility

Analyzing Tensile Strength Differences Between Nitinol And Stainless Steel

The Importance Of Nitinol Tubing In Cutting-Edge Medical Uses

A Detailed Look At The Production Of Medical-Grade Nitinol Tubing