Superelastic NiTi Tubing Small Diameter Surprises for Tiny Tools

You can now see superelastic NiTi tubing small diameter changing how engineers make tiny tools. This tubing can bend and stretch, returning to its original shape, making it great for small devices. People in medical, robotics, and precision engineering use superelastic NiTi tubing small diameter for its special features.

Property | Description |

|---|---|

Shape Memory Effect | Goes back to its first shape after bending, good for flexible medical devices. |

Superelasticity | Stretches and goes back at body temperature. |

Biocompatibility | Safe for the body because of a titanium oxide layer. |

Corrosion Resistance | Lasts longer in tough places. |

Fatigue Resistance | Can move many times without breaking. |

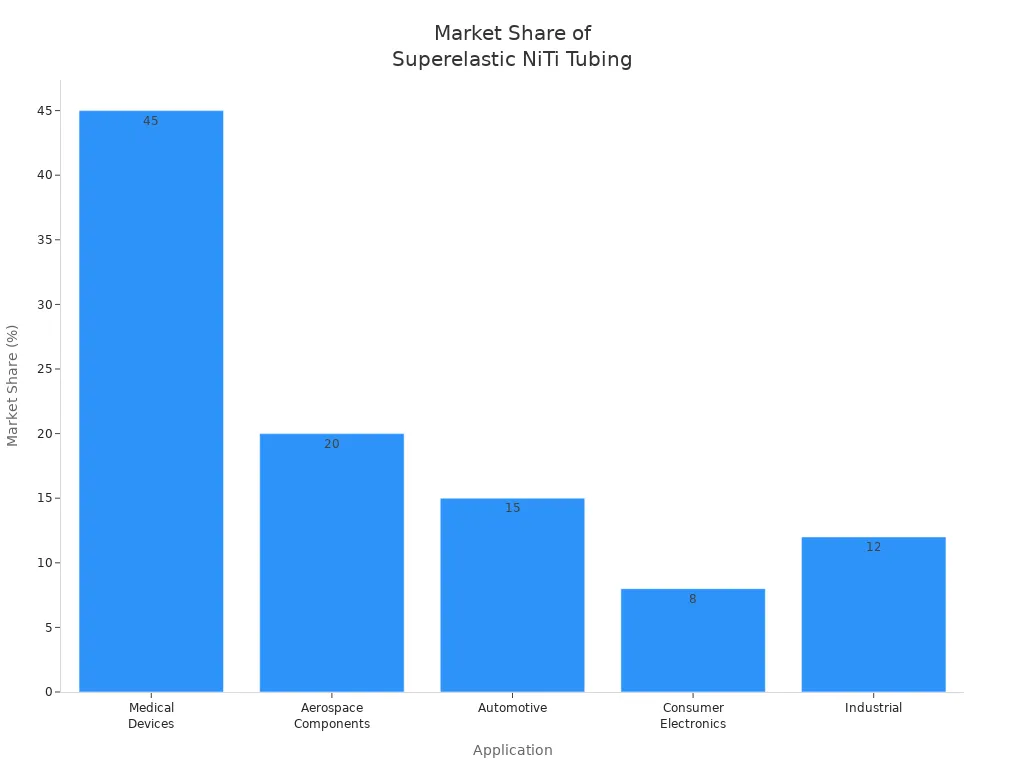

You will see the medical device field is the leader. It holds 45% of the market share for this tubing. In the last ten years, new ways to make superelastic NiTi tubing small diameter and more need for safe, bendy tools have made it grow fast. With these changes, you can expect even more cool uses for this amazing material.

Key Takeaways

Superelastic NiTi tubing can bend and go back to its shape. This makes it great for small tools in medicine and robots. This tubing is safe for the body and does not rust. It helps keep medical devices like stents and catheters safe and strong. Nitinol tubing can stretch a lot and not break. It can stretch up to 8% and still work well. This makes small tools more reliable. Engineers need to look at the nickel-titanium mix and how pure it is. This helps them pick the best nitinol tubing for their designs. Using superelastic NiTi tubing can make surgeries less invasive. It can help people heal faster and feel better after surgery.

What Is Superelastic Nitinol Tubing?

Superelasticity Explained

You may ask why superelastic nitinol tubing is so different. This tubing bends, stretches, and twists more than normal metal tubes. After you bend it, it goes back to its first shape. This happens because of a special phase change inside the tubing. The change is between austenitic and martensitic structures. This lets the tubing handle big shape changes without breaking.

Superelastic nitinol tubing can bounce back from 5-10% shape changes.

The tubing does not use regular metal bending. It uses a reversible crystal change instead.

You check superelasticity by looking at the superelastic ratio. This ratio comes from the slope of the unloading curve in a force/displacement graph.

If you look at superelastic nitinol tubing and regular metal tubing, you see big differences. Superelastic nitinol tubing stretches up to 13% and returns to its shape. Stainless steel tubing stays stiff and does not bounce back as well. You can see the differences in the table below:

Property | Nitinol Tubing | Stainless Steel Tubing |

|---|---|---|

Tensile Strength Range | 500–900 MPa | 600–1100+ MPa |

Fatigue Resistance | Excellent; millions of cycles | Lower; better for static |

Flexibility | Up to 13% strain recovery | High rigidity |

Durability in Medical Devices | Best for rigid devices |

Material Properties for Small Diameters

When you pick superelastic nitinol tubing for tiny tools, you get many good things. This tubing keeps its shape even when it is very small. You can use it in medical devices, robotics, and other places where you need precision.

Property | Description |

|---|---|

Superelasticity | Tubing goes back to its shape after you bend it. |

Shape Memory | Tubing remembers its shape, helping with exact movements. |

High Durability | Tubing takes lots of stress and keeps working in small devices. |

Biocompatibility | Tubing is safe for the body and meets ISO 10993 rules. |

You find superelastic nitinol tubing in catheters, stents, and tiny robotic arms. The tubing lasts a long time, so you can trust it for millions of uses. Superelastic nitinol tubing also works well in tough places. This makes it a great pick for engineers and doctors. You get tubing that is bendy, strong, and safe for many jobs.

Superelastic NiTi Tubing Small Diameter Advantages

Flexibility and Kink Resistance

Tiny tools need to move without getting stuck or bent. Superelastic niti tubing small diameter helps tools bend and not kink. Nitinol tubing bends and stretches more than other tubes. It works better in small, tight places. Other tubes might break or kink, but nitinol does not.

Here is a table that shows how nitinol stands out:

Parameter | Value/Description |

|---|---|

Deformation Strain Recovery | Up to 13% |

Flexibility Increase | 32% to 40% over thicker needles |

Positional Accuracy | ±2.5 microns |

Wall Thickness Tolerance | ±0.005 mm |

Superelastic niti tubing small diameter gives you more control. It keeps its shape after you bend it many times. You can use it for medical tools, robots, and other small devices. Nitinol is flexible and strong, so your tools last longer and work better.

Tip: If you need a tube that bends but does not kink, nitinol is your best choice for small diameter applications.

Corrosion Resistance and Durability

You want tubing that lasts in hard places. Superelastic niti tubing small diameter does not rust or get damaged easily. Nitinol has a titanium oxide layer that keeps it safe. This layer protects the tubing for a long time.

Look at the corrosion resistance values for nitinol in different tests:

Sample Type | Breakdown Potential (mV) | Standard Deviation (mV) |

|---|---|---|

CE | 649.3 | 222.3 |

AO | 520.4 | 102.4 |

BO | 442.0 | 62.37 |

Nitinol stays strong even in tough places. Superelastic niti tubing small diameter is also very durable. Capillary nickel titanium tubes keep their shape in twisty paths. These tubes do not break or wear out as fast as other tubes. You can use them in tools that move a lot, like catheters or robot arms.

Capillary nickel titanium tubes keep their structure in tough pathways.

Nitinol shows higher fatigue resistance than stainless steel or polymers.

The shape memory effect helps nitinol last longer in cyclic loading.

Nitinol tubing stays safe and strong after many uses. Its durability makes it a great pick for tiny tools that must work every time.

High Strain Recovery

You want tubing that can stretch and go back to its shape. Superelastic niti tubing small diameter does this well. Nitinol can stretch up to 8% and return to its first shape. This helps you make small tools that move and bend without breaking.

Nitinol tubing stretches up to 8% and returns to its shape.

You can use this property in orthodontics, where gentle pressure moves teeth.

High strain recovery means your tiny tools stay accurate and reliable.

You see this in medical tools, robots, and other small devices. Superelastic niti tubing small diameter lets you make tools for tight spaces and repeated moves. Nitinol’s flexibility and strength help your tools last and work well.

Note: High strain recovery in nitinol tubing means fewer failures and better results for your miniature designs.

Applications in Tiny Tools

Medical Devices and Stents

Nitinol is changing how doctors use medical tools. In medicine, nitinol tubing helps make self-expanding stents. These stents travel through small blood vessels and open up at the right place. Nitinol is used for endovascular devices, bone repair systems, and spinal implants. Shape memory lets stents go back to their size when warmed by the body. Pseudoelasticity helps these tools bend a lot without snapping. You see nitinol in heart implants, ablation catheters, and bone implants. These tools are good for less invasive surgeries and help keep patients safe.

Tip: Self-expanding stents made with nitinol can reach hard spots and open up without losing their shape.

Here is a table that lists common uses for superelastic nitinol tubing:

Industry | Applications |

|---|---|

Robotics | Motion control systems, tactile sensors, adaptive gripping mechanisms |

Sensor Technology | Temperature sensors, pressure transducers, flow meters for extreme conditions |

Medical Devices | Stents, catheters, and implants for interventional cardiology and minimally invasive procedures |

Micro-Robotics and Automation

Nitinol is used in micro-robotics to make flexible, strong tools. The tubing gives you small actuation systems that work better than hydraulic or air-powered ones. In soft robotics, nitinol lets arms move in tight spaces and hold fragile things. Robots last longer because nitinol resists wearing out. Nitinol keeps working well even when forces change. It also stays stable with heat and does not rust, so robots work in tough places.

Nitinol helps robots move light parts with accuracy.

You can use nitinol for gripping and touch sensors.

Robots with nitinol tubing work well in factories and labs.

Catheters and Guidewires

Doctors use nitinol for catheters and guidewires in medical tools. Nitinol guidewires are flexible and move through tricky blood vessels. Shape memory lets the wire go back to its shape after bending. Superelasticity lets the wire stretch and bend without breaking. Nitinol is safe for the body, so it can stay inside for a long time. Nitinol is strong, so guidewires and catheters handle outside pressure during use, making them safer and more comfortable.

Nitinol guidewires move easily through hard paths.

Shape memory and superelasticity keep tools working well.

Nitinol is used in catheters for ablation and nerve treatments.

Note: Nitinol tubing in medical tools gives you safer and better tools for special procedures.

Design Tips for Superelastic Nitinol Tubing

Selecting Tubing for Small Diameters

When you pick nitinol tubing for tiny tools, you must think about a few key things. The nickel-titanium ratio and how pure the tubing is will change how it acts. If the nitinol is very pure, it works better, especially in medical tools. You also need to know the transformation temperatures. These temperatures tell you when the tubing will change shape and go back to normal. It is important to look at how strong and tough the tubing is. Strong tubing will last longer and not bend or break easily.

Criteria | Description |

|---|---|

Material Properties and Composition | The nickel-titanium ratio and purity levels are crucial, as they affect the alloy's properties and behavior. High-purity NiTi is essential for consistent performance, especially in medical applications. |

Transformation Temperatures | These temperatures determine the phase transitions of the material, which are critical for applications requiring specific shape memory or superelastic behaviors. |

Mechanical Strength and Durability | The tensile strength and fatigue resistance of NiTi are vital for ensuring the material can withstand operational demands without permanent deformation. |

Tip: Always check for ISO 10993-1 and ASTM F2063 standards when you pick nitinol tubing for medical jobs.

Manufacturing and Handling

You need to watch the manufacturing steps to keep nitinol tubing superelastic. The mix of metals must be just right. Even small changes can make the tubing act differently. Makers use special vacuum melting to take out bad stuff and make pure nitinol. They also heat and shape the tubing to get the right crystal form. When you touch small gage hypotubes, use soft tools and do not bend them sharply. This keeps the tubing strong and bendy.

Note: Every batch of medical nitinol tubing comes with a paper that shows it meets strict rules.

Performance Optimization

You can help nitinol tubing last longer in small devices by doing a few things:

Use superelastic nitinol wire for high fatigue resistance in places that move a lot.

Pick tubing that can handle many cycles at the stress levels found in medical tools.

Change nitinol tubing to fit what your tiny tool needs.

If you look at other materials, nitinol does better than steel and brass for wear. Ceramics can work well but might break if bent too much.

Material Type | Wear Characteristics | Performance Notes |

|---|---|---|

Oilon | Minimal wear | Best overall performance, maintains buckling integrity |

Steel | High wear | Highly fit-dependent, causes significant wear |

Brass/Bronze | Excessive wear | Not suitable for long-term use |

Ceramics | Promising but brittle | Limited by brittleness under high strain conditions |

Tip: Changing nitinol tubing helps you meet special needs for your small devices.

Success Stories

Minimally Invasive Surgery

Superelastic NiTi tubing helps doctors do less invasive surgery. Stent delivery systems can fold up to go in easily. They then open up inside the body. This helps doctors reach twisty blood vessels and keeps patients safer. Catheters and guidewires made from NiTi give doctors more control. They help doctors get to hard spots in the body. In brain surgery, nitinol catheters worked every time. Patients heal about 20% faster and feel less pain with nitinol tools.

Self-expanding stents fit vessel shapes and lower risks.

Nitinol suture threaders snap back to shape, making stitches easier.

Devices go in through small cuts, so there is less scarring and faster healing.

Nitinol’s biocompatibility and strength help you feel better during surgery.

Microcatheters and Graspers

Microcatheters and graspers use superelastic NiTi tubing to help doctors. These tools bend and stretch but do not lose their shape. Doctors trust them for high success and shorter surgeries. The tubing’s strain recovery rate is 99.5%, so tools stay correct.

Metric | Value |

|---|---|

Strain recovery rate | 99.5% |

Single retrieval success rate | >90% |

Procedure time (URSL) | 25 minutes (vs. 40 minutes) |

Post-operative residual stone rate | <5% |

Diameter of microcatheter | 0.015-0.021 inches |

Doctors do fewer repeat surgeries and patients do better. Packing density and recurrence rates also get better, so these tools are trusted by doctors and patients.

Advanced Micro-Actuators

Advanced micro-actuators use superelastic NiTi tubing in space and medical fields. These actuators move with great accuracy and stay strong under stress. In space, sensors made from NiTi alloys measure well even in hard places. In medical devices, actuators use shape-memory to make complex moves.

Application Area | Benefit | Description |

|---|---|---|

Aerospace | Precision | Sensors made from NiTi alloys give accurate readings in tough spots. |

Biomedical | Reliability | Actuators use shape-memory for complex moves and steady work. |

Superelastic NiTi tubing lets you make tiny tools that work better, last longer, and help people.

You notice superelastic NiTi tubing is changing tiny tool design. New research shows these tubes can change shape in special ways. This makes them both strong and bendy for lots of jobs. In medicine and precision work, NiTi tubing is safe and lasts a long time. It also goes back to its shape after bending.

Feature | Benefit |

|---|---|

Biocompatibility | Safe for medical devices |

Superelasticity | Reliable in dynamic settings |

Recyclability | Good for the environment |

The NiTi tubing market is getting bigger.

New tech lets tubes be even smaller.

NiTi tubing can help with future tiny tool ideas.

You can find more ways to use NiTi tubing and make tiny tools safer and better.

FAQ

What makes superelastic NiTi tubing special for tiny tools?

This tubing bends and goes back to its shape. It helps tools fit into small spaces. NiTi tubing does not kink and lasts longer than most metals.

Can you use superelastic NiTi tubing in the human body?

Yes, you can use it. NiTi tubing has a titanium oxide layer. This layer keeps it safe for medical tools. Doctors use it in stents, catheters, and implants.

How do you handle small diameter NiTi tubing?

Be gentle with NiTi tubing. Use soft tools and do not bend it sharply. This helps the tubing stay strong and flexible. Always look for damage before using it.

Does NiTi tubing rust or corrode easily?

No, it does not rust. The titanium oxide layer keeps it safe from rust and corrosion. You can use it in wet or tough places without worry.

What industries use superelastic NiTi tubing the most?

You see NiTi tubing in medical, robotics, and sensor fields. Medical devices use it the most. Robotics and automation also use it for its bendy and strong features.

See Also

Investigating Nitinol Tubing Uses in Medical Equipment

The Impact of Nitinol Tubing on Medical Innovations

The Importance of Nitinol Tubing in Minimally Invasive Surgery