Step-by-Step Guide to Nitinol Tubing Processing Equipment

Nitinol tubing is a special metal that can remember its shape. It needs a special process to work well. Manufacturers use Nitinol Tubing processing equipment at every step to make sure it works great. The main steps are:

Melting and mixing nickel and titanium with vacuum technology to keep it pure.

Making tubing by gun drilling, extrusion, and die drawing.

Using heat treatment to give it shape memory and superelasticity.

Finishing and testing to check the surface and size.

Careful control at each step helps nitinol tubing meet strict rules for medical and aerospace devices. These devices need to be reliable and strong.

Key Takeaways

Nitinol tubing is made by melting and shaping it. Heat treating and finishing help keep its special shape memory and strength.

The metal must stay pure. Advanced machines control each step. This helps the tubing meet strict medical and aerospace rules.

Gun-drilling, precision die drawing, and cold drawing shape the tubing. These steps keep the tubing strong and flexible.

Surface finishing uses electropolishing and passivation. This makes the tubing smooth and safe. It also helps stop rust for a long time.

Automation and quality checks like ultrasonic inspection are used. These help make nitinol tubing faster and safer. They also make it more reliable for medical and aerospace devices.

Raw Material

Alloy Melting

Nitinol alloy tubes start with very pure nickel and titanium. These metals are chosen because they have special features. The usual mix is about 55% nickel and 45% titanium. This mix is important for nitinol’s shape memory and superelasticity. Special machines melt the metals to keep them pure and even.

Melting Method | Description |

|---|---|

Vacuum Induction Melting (VIM) | Melts metals in a vacuum to stop dirt from getting in and keeps the metal very pure. This is good for medical and aerospace uses. |

Vacuum Arc Remelting (VAR) | Melts the alloy again in a vacuum to make it cleaner and more even. |

Electric Arc Melting (EAM) | Uses electric arcs to melt metals. This works well for big projects. |

Electroslag Remelting (ESR) | Cleans the melted metal more to make it stronger and better quality. |

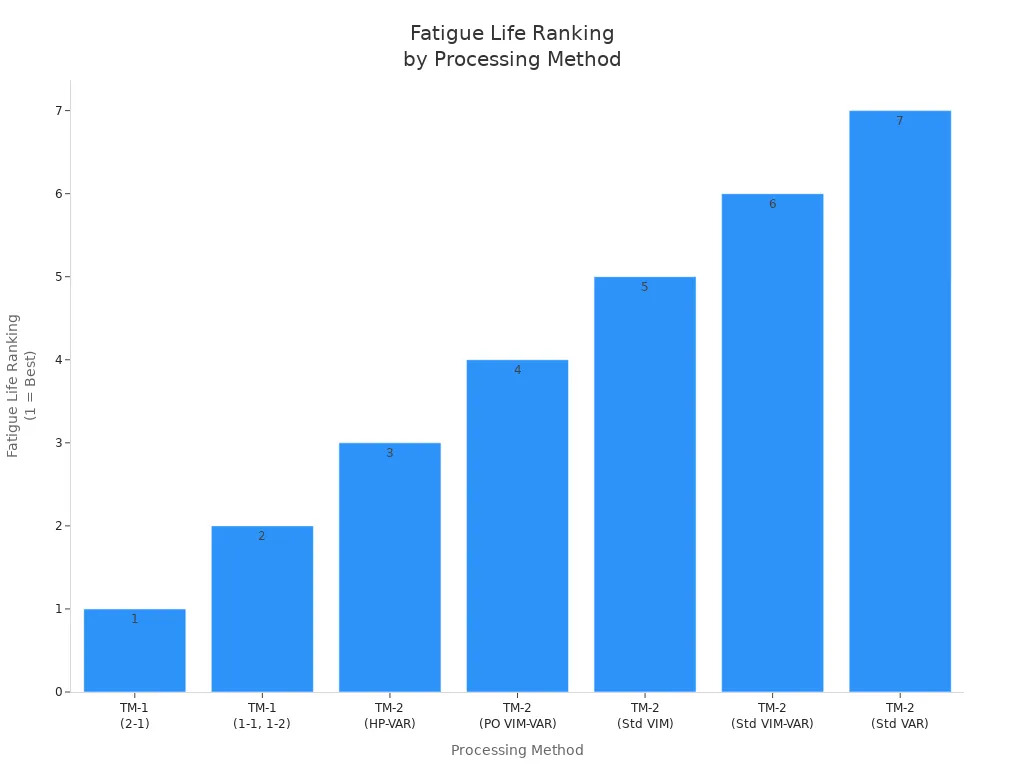

Vacuum induction melting and vacuum arc remelting are used most often for nitinol alloy tubes. These methods use a vacuum to stop dirt from mixing in. They also help keep the nickel and titanium mix just right. Sometimes, both VIM and VAR are used together. This makes the nitinol alloy very even and free of problems. The melted alloy is poured into molds and cooled slowly. This helps the inside of the metal stay the same everywhere, which is very important for nitinol alloy tubes.

Purity Control

Keeping nitinol alloy tubes very pure is very important, especially for medical and aerospace jobs. Even tiny bits of dirt can change how nitinol bends and remembers its shape. Manufacturers use many ways to keep the metal pure:

Only very pure metals are used to meet medical rules.

Cleaning and checking remove any dirt you can see.

Spectroscopy checks what metals are in the mix.

Melting in a vacuum stops air and dirt from getting in.

Careful testing and checking happen at every step.

Special math and Six Sigma help find and fix mistakes.

X-ray diffraction and electron microscopy check the size of grains and the inside of the metal.

These steps help nitinol alloy tubes stay strong, bendy, and safe for tough jobs. Quality checks, like looking at the tubes and testing for nickel, make sure every batch is good enough for the rules.

Shaping

Forging and Rolling

Engineers start by heating nitinol rods until they are very hot. They use machines to press and stretch the metal. This makes the metal soft and easy to shape. The temperature is usually between 750°C and 900°C. Operators watch how fast the metal is pressed. This speed can be very slow or very fast. They do this to stop problems and keep the metal strong.

Shaping Process | Description | Impact on Material Properties |

|---|---|---|

Hot Working (Forging, Rolling) | Heating nitinol until it is soft and shaping it into tubes. | Makes the inside grains better, makes the metal stronger, and keeps it even. |

Extrusion | Pushing hot nitinol through a mold to make tubes with the right size. | Keeps the metal even and gets it ready for more steps. |

During this step, the inside of the metal changes and gets stronger. The right heat and speed stop problems and keep the grains small. Forging and rolling also help make the first size and shape of the tubing.

Tip: Watching the heat and speed during forging and rolling helps the tubing stay strong and bendy for medical and aerospace jobs.

Gun-Drilling

After forging and rolling, workers use gun-drilling to make a hole in the nitinol rod. This step drills a straight hole down the middle. It makes a thick tube but keeps nitinol’s special features.

Gun-drilling uses deep drills, like the ones for gun barrels.

The tube hollowing step must stop mistakes and keep the tube smooth.

After gun-drilling, the tube is pulled through smaller molds. A rod inside keeps the hole the same size while the outside gets thinner.

The tube is polished and cleaned to remove rough spots and meet size rules.

Cleaning, like using sound waves, gets rid of dirt and metal bits.

Checks, like using sound tests and measuring, make sure the tube is ready for the next step.

Gun-drilling is very important for shaping nitinol tubing. It helps make strong and exact tubes for tough jobs.

Nitinol Tubing Manufacturing

Precision Die Drawing

Precision die drawing is a very important step. After gun-drilling, workers pull nitinol through special dies. Each die makes the tubing smaller and shapes it just right. This helps the tubing fit exact sizes for things like stents and implants. Machines with high-precision dies and monitors help control this step. They keep the tubing’s size very close to what is needed. The tubing walls stay even all around. This step helps the tubing remember its shape and stay strong for a long time.

Note: Precision die drawing lets companies control the tubing from start to finish. This is important for making tubing that meets tough rules for medical and aerospace use.

Cold Drawing

Cold drawing comes after precision die drawing. Workers pull the tubing through dies at room temperature or a little warmer. This uses nitinol’s ability to bend and get stronger as it is shaped. The tubing gets harder and stronger as it goes through the dies. This makes the tubing both strong and flexible. Cold drawing also changes the inside of the tubing. It helps the tubing show superelastic behavior over a bigger range. Some cold drawing uses sensors and controllers to change speed and force. This can make the tubing’s size almost perfect along its length.

Tip: Cold drawing and extrusion work together to shape nitinol tubing. Using both steps helps make tubing with great shape memory and strength.

Tube Sizing

Tube sizing is the last step before heat treatment and finishing. This step makes sure the tubing is the right size and shape. Workers use multi-pass drawing, pulling the tubing through many dies. Each die makes small changes to the size. They watch the pulling force and speed to keep the tubing accurate. Special tools check the tubing’s size. Laser micrometers, ultrasound, and CMMs measure the tubing. These tools can find very small changes in size. Real-time checks help fix problems fast.

Tube sizing steps include:

Multi-pass drawing to slowly make the tubing smaller.

Heat treatment between steps to keep strength and shape memory.

Surface finishing, like electropolishing, to smooth the tubing and keep the right size.

Micromachining, such as laser cutting, for detailed shapes.

Tools for checking size:

Laser micrometers and ultrasound for diameter and wall thickness.

Optical comparators and imaging for design checks.

Bore gauges for inside diameter.

CMM and diffraction tools for very accurate checks.

Automated inspection with AI for real-time checks.

Tube sizing makes sure superelastic nitinol tubing meets strict rules for medical and aerospace jobs. By following these steps, companies make tubing that is strong, the right size, and works well every time.

Heat Treatment

Salt Bath Ovens

Salt bath heat treating is very important for nitinol tubing. Workers put the tubing in hot, melted salt. This heats the metal fast and evenly. The salt keeps nitinol safe from rust and damage. It helps the tubing keep its shape memory. The salt covers the tubing and heats it all over. Inside the bath, moving currents keep the heat the same everywhere. New salt bath machines use different salts for each job. This helps control the heat for every process. It also makes the tubing resist rust better. The electric charge stays steady, which is needed for medical tools. Some baths use aluminum oxide instead of salt. These fluidized baths give even and steady heat. They lower the chance of rust and cut out extra cleaning.

Shape Setting

Shape setting lets nitinol tubing remember a special shape. Workers put the tubing on a strong mold or rod. This holds the tubing in the right shape. They heat the tubing and mold together. The heat is usually between 455°C and 565°C. Small pieces need only a few minutes. Big pieces may need up to 20 minutes. After heating, they cool the tubing in water fast. This locks the shape in place. The tubing can now work well in tough places. Shape setting is needed for things like stents and implants. These need tubing with exact shapes.

Mandrels and Fixtures

Mandrels and fixtures help shape nitinol tubing during heat treatment. Metal fixtures can handle high heat and pressure. They hold the tubing still as it sets. Some fixtures use pins and plates. Others use ceramic or 3D-printed molds for hard shapes. Mandrels that get bigger help stretch the tubing in steps. This controls the final size and shape. The way these tools are made changes how exact the tubing will be. Picking the right mandrels and fixtures is important. It helps nitinol tubing get the right shape memory and strength.

Surface Finishing

Surface finishing makes nitinol tubing smooth and clean. This is needed for medical and aerospace jobs. These steps take away flaws and help stop rust. They also make the tubing safe for the body.

Electropolishing

Electropolishing uses electricity and chemicals to take off a thin layer from the tubing’s surface. This step makes the tubing smoother and removes tiny cracks. It also lowers how much nickel is on the outside. Workers use special machines to run this process. They watch the chemicals, heat, and electric power to get good results.

Process Parameter | Recommended Range/Value | Effect on Surface Quality |

|---|---|---|

Electrolyte Composition | 0.2 M NaNO3 ozonated electrolyte | Smooths surface, supports Ra < 0.2 µm |

Temperature | 20°C - 30°C | Prevents pitting, ensures even material removal |

Current Density | 0.1 - 0.3 A/cm² | Balances polishing and surface integrity |

Timing | 2 - 5 minutes | Prevents over-polishing |

Agitation | Gentle, continuous stirring | Ensures uniform polishing |

Before electropolishing, workers grind and polish the tubing to get it ready. After electropolishing, they rinse and dry the tubing to stop stains. They check how rough the surface is with special tools. A very smooth finish helps the tubing last longer and work better in the body.

Electropolishing makes nitinol tubing shiny. It also helps the tubing last longer and be safe for the body. This step is very important for stents and other implants.

Cleaning and Passivation

Cleaning and passivation take away dirt, iron, and other things from the tubing. These steps help make a thin layer that stops rust and keeps the tubing safe. Workers use machines with sound waves and other tools to wash the tubing before passivation.

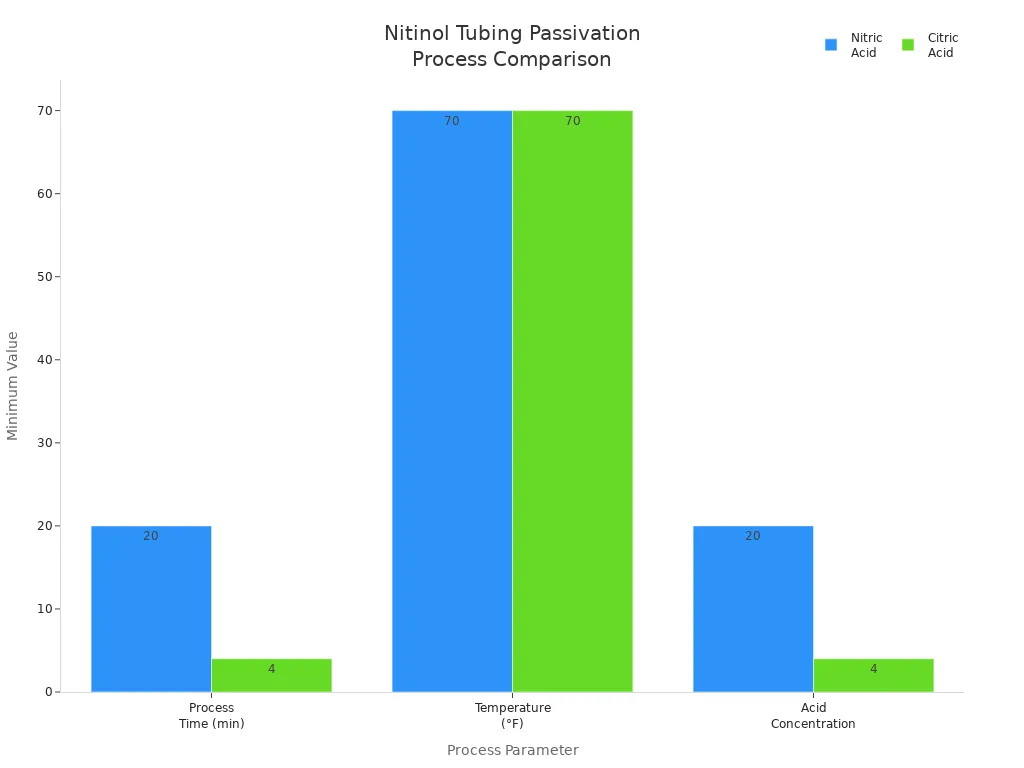

There are two main ways to do passivation:

Aspect | Nitric Acid Passivation | Citric Acid Passivation |

|---|---|---|

Description | Removes free iron to prevent corrosion | Uses citrus-based chemicals, safer for workers |

Safety | Needs careful handling, gives off fumes | Safer, no toxic fumes |

Environmental Impact | Can harm the environment | Environmentally friendly |

Process Time | 20 minutes or more | As short as 4 minutes |

Temperature | 70-140 °F | 70-160 °F or room temperature |

Standards | ASTM A967, AMS 2700, ASTM F86 | ASTM A967, AMS 2700 |

Citric acid passivation is getting more popular because it is safer and better for nature. Both ways follow strict rules like ASTM A967 and AMS 2700. After passivation, workers rinse and dry the tubing. They use cameras and microscopes to check if the tubing is clean and smooth.

Good cleaning and passivation help nitinol tubing fight rust. They also help the tubing meet tough rules for medical and aerospace use.

Quality Control

Ultrasonic Inspection

Manufacturers use ultrasonic inspection to find hidden problems in nitinol tubing. A transducer sends high-frequency sound waves through the tubing. If there is a flaw, the waves bounce back. The machine shows these signals on a screen. Operators look for cracks or other issues inside the tubing. The BenchLinc UT system is often used for this job. It checks wall thickness and concentricity with ultrasonic sensors. Laser micrometers measure the outer and inner diameters. An encoder matches measurements to the tubing’s length. This setup lets workers check the whole tube. They can spot tubing that does not meet the rules before it leaves the factory.

Ultrasonic inspection helps companies follow strict quality rules. It finds both surface and inside problems, making sure the tubing is safe for medical and aerospace jobs.

Dimensional Testing

Dimensional testing checks if nitinol tubing is the right size. Workers use laser micrometers and measuring machines for this. They measure the outer diameter, inner diameter, and wall thickness. These tools give accurate and repeatable results. Using the same way to measure helps get reliable tensile strength tests. Tensile testing machines use special grips and load cells. They stretch the tubing and measure how much it can take before breaking. Marking the gauge length on each sample helps measure how much it stretches and other features.

Nitinol tubing must meet very tight size limits. For example, outer diameter limits can be as small as ±0.025 mm for thin tubing. Wall thickness must stay even to keep the tubing strong and bendy. Advanced steps like electropolishing help keep the tubing smooth and correct. Companies also cut tubing to different lengths and set shapes for different medical devices.

Quality Control Measure | Description |

|---|---|

ISO 13485 certification | Makes sure companies follow world medical device quality rules. |

FDA QSR compliance | Follows FDA rules for making medical devices. |

Real-time SPC | Watches production all the time to keep quality high. |

PFMEA | Finds and fixes possible process problems early. |

DOE | Uses planned tests to make production and quality better. |

Careful quality control, like dimensional testing and ultrasonic inspection, makes sure every tubing batch is safe and works well.

Nitinol Tubing Processing Equipment

Key Machines

Nitinol tubing processing equipment is used from start to finish. Each machine has a special job in making the tubing. Melting furnaces, like vacuum induction and arc remelting units, melt nickel and titanium together. This makes a pure alloy. Gun-drilling machines use strong drills to make holes in the tubing. Drawing benches and die drawing machines pull the tubing through dies. This shapes the tubing to the right size. Salt bath ovens and fluidized bed furnaces heat the tubing. This helps set its shape and memory. Electropolishing units make the tubing smooth and help stop rust. Ultrasonic and eddy current testing machines look for hidden problems inside the tubing. Laser micrometers and coordinate measuring machines check the tubing’s size and wall thickness. All these machines help make sure the tubing is safe for medical and aerospace jobs.

Operators pick the best equipment for each step. This keeps the tubing strong, bendy, and safe.

Automation

Modern nitinol tubing processing equipment uses automation and new technology. This helps make the tubing better and faster. Automated systems watch every step of making the tubing. AI controls can change machine settings right away. This lowers mistakes and finds problems early. Automated ultrasonic and eddy current tests find flaws without hurting the tubing. These systems help keep the process the same and save money.

Many factories use new technology to improve tubing:

Additive manufacturing makes custom tubing shapes.

Laser cutting shapes tubing very exactly.

Cryogenic machining uses cold liquid nitrogen to keep tools sharp and protect the tubing.

Surface finishing, like magnetoelectropolishing, helps stop rust.

Sensors inside tubing give real-time feedback to doctors and engineers.

Automation in nitinol tubing processing equipment makes everything quicker and safer. Factories can make high-quality tubing for important medical and aerospace uses.

Applications in Medical and Aerospace Fields

Medical Devices

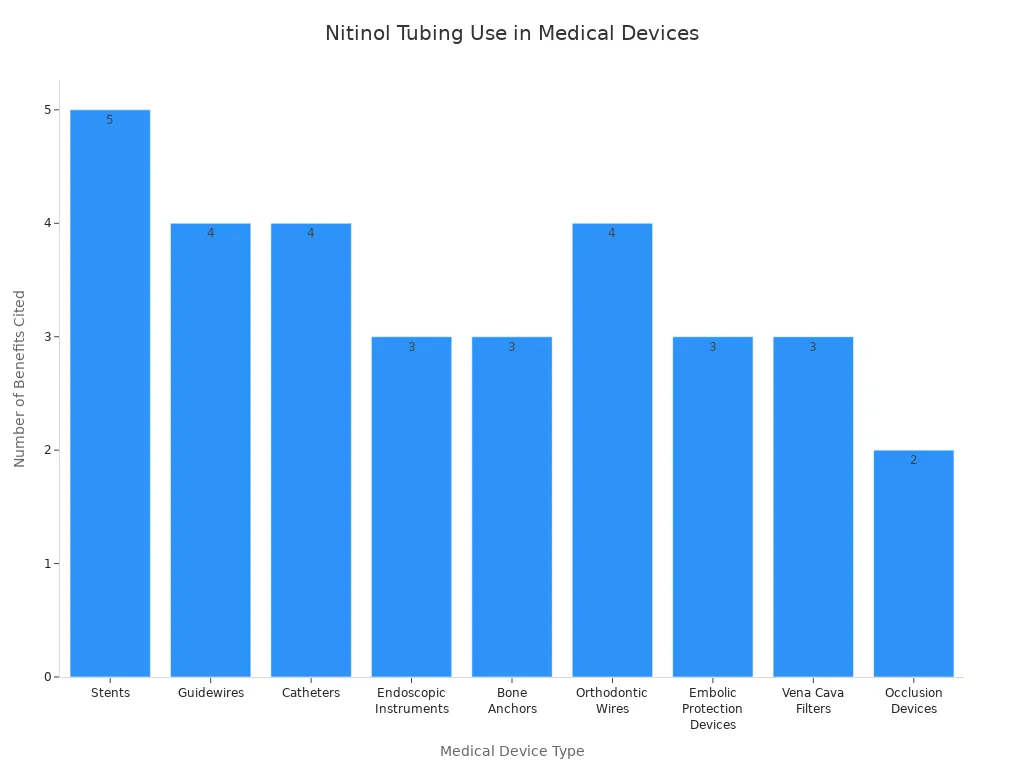

Many companies use superelastic nitinol tubing for medical devices. Hospitals and clinics need this tubing for heart surgeries and bone implants. It is also used in special surgical tools. The tubing can stretch and bend to fit the body’s shape. This makes it perfect for stents, guidewires, and catheters. Doctors like these devices because they bend without breaking. They also go back to their original shape.

Application Area | Description & Performance Requirements |

|---|---|

Cardiovascular Interventions | Used in self-expanding stents and vascular implants; needs superelasticity and shape memory to fit vessels. |

Orthopedic Implants | Used for bone fixation and spinal implants; must have strength and biocompatibility. |

Guidewires and Catheters | Require flexibility, kink resistance, and durability for complex anatomy. |

Neurosurgery Tools | Used in microcatheters and stents; need high strength-to-weight ratio and surface treatments for safety. |

Nitinol tubing must be safe for the body and not rust. Special surface treatments help stop nickel from coming out. This makes the tubing safe for long-term use. Studies show that nitinol tubing in stents helps patients heal faster. It also lowers the chance of hurting blood vessels. The chart below shows how nitinol tubing helps different medical devices:

Doctors and engineers like the tubing’s bendiness and strength. It can return to its shape after bending. These features help make new tools and implants for different jobs.

Aerospace Components

Aerospace companies use superelastic nitinol tubing for important parts. Airplanes and spaceships need this tubing for actuators, sensors, and cooling systems. The tubing can return to its shape after being bent. This is important for moving parts like flaps and landing gear.

Main aerospace uses include:

Actuators for controlling flight surfaces and landing gear

Sensors for monitoring structural health

Vibration dampers to absorb mechanical energy

Tubing for heat exchangers and cooling systems

Nitinol tubing does not rust or get tired, even in tough places. Its high strength and low weight help make planes lighter. This saves fuel and makes flying better. The tubing works well in very hot or cold places. This makes it good for space missions and high flights. These features make nitinol tubing a great choice for jobs that need safety and strength.

Every step in making nitinol tubing uses special machines. These machines help the tubing remember its shape and stretch without breaking. The last heat treatment makes sure these features stay in the tubing. Careful tests check that the tubing is strong for tough jobs. Studies show that using pure metals and new ways to make tubing helps it last longer. You can see this in the chart below.

Picking the right machines and following strict rules helps companies make tubing that fits exact sizes. This also keeps the tubing safe for use in medical and aerospace jobs.

FAQ

What makes nitinol tubing special for medical devices?

Nitinol tubing can remember its shape and stretch a lot. These features let devices bend and go back to their shape. Doctors use nitinol tubing in stents, guidewires, and implants. It is strong, bends easily, and is safe for people.

Which equipment ensures nitinol tubing purity?

Vacuum induction melting and vacuum arc remelting keep nitinol pure. These machines take out things that should not be there. They help makers follow strict rules for medical and aerospace jobs.

How do manufacturers check nitinol tubing quality?

Manufacturers use ultrasonic inspection and laser micrometers. These tools find cracks and check the tube’s size. Quality checks happen all the time to keep tubing safe and working well.

Why is electropolishing important for nitinol tubing?

Electropolishing makes the tubing surface smooth and takes away tiny flaws. This step lowers nickel on the outside and helps stop rust. It also helps the tubing work better in medical and aerospace jobs.

Can automation improve nitinol tubing production?

Automation makes work faster and more exact. Machines watch every step and change settings right away. Automated checks find problems early, so making tubing is safer and quicker.

See Also

How To Choose The Perfect Nitinol Tubing Easily

Detailed Process For Creating Nitinol Microtubing In Neurovascular Use

Comprehensive Overview Of Nitinol Parts And Production Methods

Medical Nitinol Tubing: Manufacturing Process Explained Step-By-Step