How Nitinol Tubing Transforms Stent Graft Performance

Stent graft nitinol tubing has revolutionized how doctors treat damaged blood vessels. The choice of nitinol tubing matters because it shapes how stent grafts perform inside the body. Nitinol brings special qualities, like shape memory and superelasticity, that help stent grafts fit vessels better and last longer. In real-world cases, patients benefit from safer procedures and fewer complications.

Clinical studies show how nitinol tubing makes a difference:

Performance Index

Grade V (Highest)

Grade IV

Other Grades

Positioning accuracy of delivery system

89% (8/9)

11% (1/9)

0%

Operational controllability

89% (8/9)

11% (1/9)

0%

Stability of delivery system

100% (9/9)

0%

0%

Supporting performance of stent-graft

100% (9/9)

0%

0%

Conformability of stent-graft

100% (9/9)

0%

0%

Attachment ability of stent-graft

100% (9/9)

0%

0%

Visibility of stent-graft marker

100% (9/9)

0%

0%

The impact of nitinol tubing reaches both the technical side of medicine and the lives of patients who need strong, flexible grafts for their vessels.

Key Takeaways

Nitinol tubing has unique shape memory and superelasticity that help stent grafts fit blood vessels better and stay strong.

Special surface treatments make nitinol tubing safe and reduce risks like blood clots and nickel release inside the body.

Nitinol stents are flexible and durable, lasting many years while adapting to twisted or curved blood vessels.

Clinical studies show nitinol stents improve patient outcomes with fewer complications and higher success rates.

New technologies like thin-film nitinol and smart stents promise even better performance and wider medical uses in the future.

Nitinol Properties

Shape Memory

Nitinol tubing stands out because of its shape memory effect. This means nitinol can return to its original shape after bending or twisting. Scientists have tested nitinol tubing in the lab by bending it many times and then heating it. The tubing always goes back to its first shape. For example, researchers used plasma electrolytic polishing on nitinol wire samples and saw that the shape memory effect stayed strong even after many cycles. They measured how much the nitinol tubing could recover its shape and found that it worked well, even after 100 cycles. This property helps stents made from nitinol tubing fit tightly inside blood vessels. Doctors can compress a stent, insert it into the body, and then let it expand to its intended shape. This makes nitinol tubing perfect for stents that need to adapt to different vessel sizes and shapes.

Aspect | Description |

|---|---|

Material | NiTi wire samples (Ti-49.9 atomic% Ni) |

Experimental Methods | Cyclic deformation and recovery tests up to 100 cycles |

Key Findings | Recovery strain measured quantitatively; conditioning improved stability of one-way shape memory effect |

Superelasticity

Superelasticity is another key feature of nitinol tubing. When doctors use stents made from nitinol, the tubing can stretch and bend much more than other metals. It does not break or lose its shape. This helps stents move with the body’s natural motions. Superelastic nitinol tubing allows stents to stay open inside blood vessels, even when the vessels twist or flex. This property is important for stents in areas that move a lot, like the legs or neck. Applications of superelastic nitinol tubes include stents for arteries that need to handle high movement. Superelasticity also means that nitinol tubing can keep blood flowing smoothly, which lowers the risk of blockages.

Biocompatibility

Nitinol tubing offers excellent biocompatibility and corrosion resistance. Before doctors use nitinol stents in patients, the tubing goes through special surface treatments. Electropolishing removes impurities and makes the surface smooth. This process lowers the risk of blood clots and stops harmful nickel ions from leaking out. Many tests check the safety of nitinol tubing, such as cytotoxicity, irritation, and hemolysis testing. These tests follow strict rules from ISO and the FDA. Clinical trials show that nitinol stents work well in real patients. For example, the DAWN Trial found that nitinol stents helped stroke patients recover better than standard care. The PARTNER 3 Trial showed that nitinol stents in heart valves led to lower death rates compared to surgery. These results prove that nitinol tubing is safe and effective for many vascular applications.

Tip: Nitinol tubing’s biocompatibility makes it a top choice for stents in sensitive areas of the body.

Stent Graft Nitinol Tubing

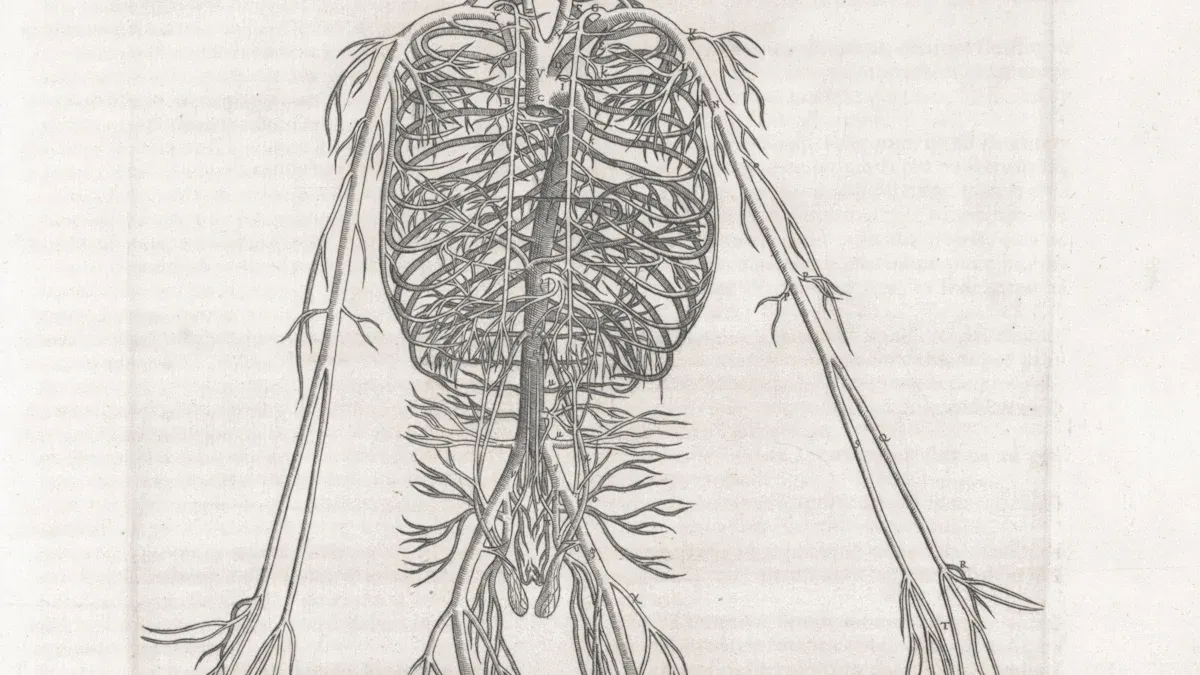

Structural Backbone

Stent graft nitinol tubing forms the main support for many modern stents and grafts. This tubing gives stent grafts their shape and strength. Nitinol tubing for vascular grafts stands out because it can bend and return to its original form. Doctors rely on this property when they place stents in blood vessels that twist or move. The superelasticity of nitinol tubing lets stent grafts handle large changes in shape without breaking. Industry reports show that nitinol tubing acts as a reliable backbone because it resists corrosion and keeps nickel ions from leaking. Special surface treatments, such as mechanical polishing and oxidation, help make nitinol tubing safe for long-term use in the body. These steps protect patients from harmful reactions and help stent grafts last longer.

Nitinol tubing supports the structure of stent grafts.

Surface processing improves biocompatibility and durability.

The oxide layer on nitinol tubing prevents nickel ion release.

Manufacturing Techniques

Laser-cut nitinol tube stents use advanced manufacturing steps to achieve their unique shapes. Laser cutting allows engineers to create detailed patterns in nitinol tubing for vascular grafts. This process helps stents fit different vessel sizes and shapes. After laser cutting, heat treatment sets the shape memory of the nitinol tubing. Workers heat the tubing to high temperatures, then cool it to lock in the desired form. Cold drawing and extrusion shape the tubing to exact sizes. Quality control tools, such as laser micrometers and bore gauges, check that each laser-cut nitinol tube stent meets strict standards. Every step ensures that stent graft nitinol tubing performs well inside the body.

Laser cutting creates precise stent designs.

Heat treatment gives nitinol tubing its shape memory.

Quality checks keep laser-cut nitinol tube stents accurate.

Radial Stiffness

Radial stiffness measures how well a stent resists being squeezed. Laser-cut nitinol tube stents show high radial stiffness, which helps them stay open in blood vessels. Engineers test radial force by crimping the stent and measuring how much it pushes back. Thicker nitinol tubing increases radial stiffness, making the stent stronger. The distance between welds and the heat treatment process also affect stiffness. When stent graft nitinol tubing has the right stiffness, it prevents the stent from moving or leaking. Studies in animals show that strong and long-lasting nitinol tubing helps stent grafts work better and last longer. Oversizing the stent backbone can make it too stiff, so engineers balance strength and safety. The design of laser-cut nitinol tube stents ensures that they support blood flow and resist damage over time.

Note: Radial stiffness is key for the performance and durability of stent grafts in complex blood vessels.

Performance in Vascular Grafts

Flexible and Adjustable for Blood Vessels

Nitinol tubing for vascular grafts gives stents the ability to be flexible and adjustable for blood vessels. Doctors often face challenges when placing stents in vessels that twist, curve, or branch. Nitinol tubing bends and returns to its original shape, which helps stents fit inside many types of vessels. This flexibility means that stents can move with the body and keep blood flowing smoothly. Nitinol tubing allows stents to expand and press gently against vessel walls, reducing the risk of injury. The superelastic nature of nitinol helps stents recover their shape after being compressed or bent. This property supports reliable performance in many clinical applications, especially in vessels that experience constant movement. Patients benefit because the stents adapt to their unique anatomy, which lowers the chance of complications and improves outcomes.

Performance Metric | Benefit |

|---|---|

Superelasticity | Enables self-expanding stents to recover shape and conform to complex vessel anatomy |

Flexibility | Allows guidewires and stents to navigate natural vessel contours, reducing trauma |

Fatigue Resistance | Maintains structural integrity under repeated stress |

Biocompatibility | Ensures safe integration with human tissue, minimizing adverse reactions |

Clinical Outcomes | Higher procedural success rates in cardiovascular treatments |

Durability Over Time

Nitinol tubing stands out for its long-term durability in vascular grafts. Engineers have tested nitinol stents under conditions that mimic the human body. They used displacement-controlled fatigue tests and simulated 10 million cycles of pulsatile loading, which equals about 10 years inside the body. These tests showed that nitinol stents do not break or lose strength, even after years of use. Finite element analyses confirmed that nitinol materials stay within safe fatigue-life zones under normal blood pressure. No fatigue fractures appeared in stent-graft combinations exposed to radial stresses between 50 and 150 mmHg. This means nitinol tubing provides reliable performance for patients with aneurysm repairs and other vascular conditions.

Nitinol stents passed fatigue tests that simulate a decade of use.

Fatigue safety factors showed high resistance to cracking and breaking.

Compliance with international standards ensures that durability matches real-life needs.

Nitinol’s fatigue life improves with higher mean strain, which helps stents last longer.

Thin-walled nitinol tubing used in stents showed strong fatigue thresholds and slow crack growth.

These results prove that nitinol tubing supports reliable performance and long-lasting grafts in many blood vessel applications.

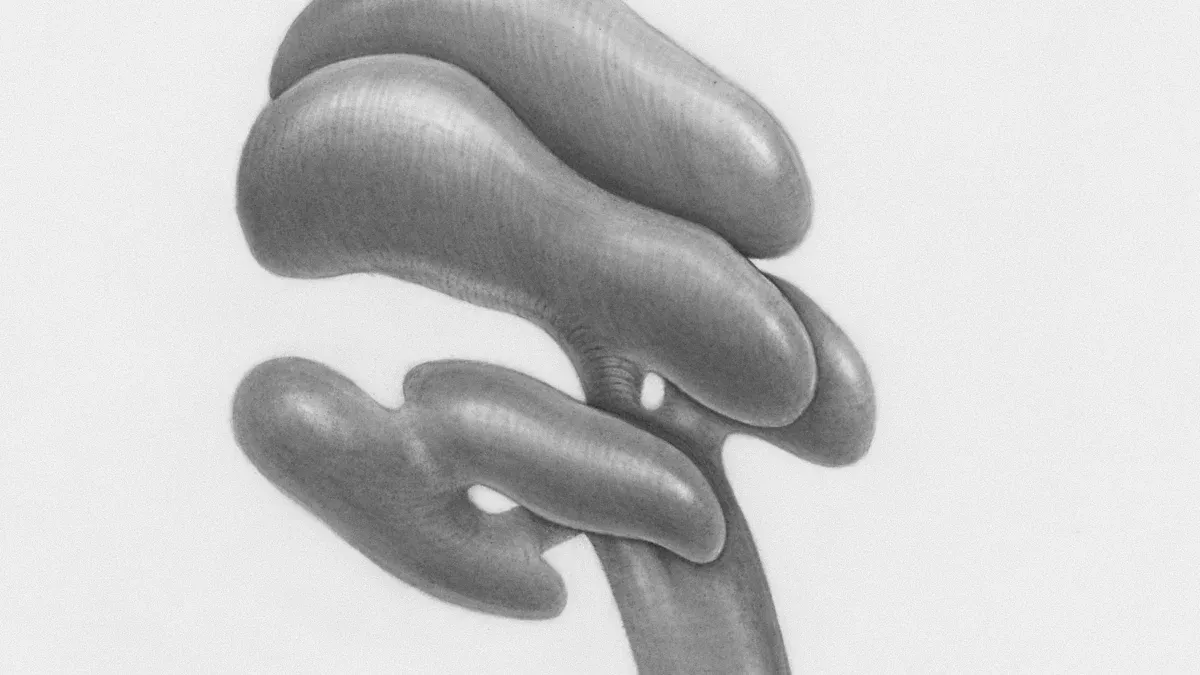

Adaptation to Complex Anatomy

Doctors often treat patients with vessels that have unusual shapes or curves, especially in aneurysm cases. Nitinol tubing helps stents adapt to these complex anatomies. The superelastic and flexible properties of nitinol tubing allow stents to conform to the vessel’s natural shape. This reduces the risk of gaps or leaks and helps the stent stay in place. Clinical studies, such as the SUPERB trial, show that nitinol stents maintain vessel patency and structural integrity over time. The trial found a primary patency rate of 86.3% at 12 months and a stent fracture rate of 0%. Most patients showed clinical improvement, with 88.7% improving by at least one Rutherford–Becker category. Interwoven nitinol wires in the stent design provide both radial strength and flexibility, which are important for reliable performance in challenging anatomies.

Aspect | Evidence |

|---|---|

Primary Patency Rate | 86.3% at 12 months (Kaplan–Meier analysis) |

Stent Fracture Rate | 0% at 12 months (independent core lab analysis) |

Clinical Improvement | 88.7% improved by ≥1 Rutherford–Becker category at 12 months |

Stent Design | Interwoven nitinol wires providing radial strength, flexibility, and fracture resistance |

Nitinol tubing allows stents and grafts to work in many applications, including those with complex vessel shapes. This adaptability leads to better outcomes for patients with aneurysm and other vascular diseases. Doctors trust nitinol tubing to deliver reliable performance in even the most difficult cases.

Clinical Use and Outcomes

Abdominal Aortic Aneurysms

Doctors use nitinol stents and grafts to treat abdominal aortic aneurysms. These aneurysms form when the wall of the main blood vessel in the abdomen weakens and bulges. Nitinol medical stents help support the vessel and prevent rupture. In one study, 53 patients received nitinol-based self-expandable stent-grafts covered with polyester fabric. The initial technical success rate reached 87%. Perioperative mortality was very low at 0.6%. Minor complications occurred in 8% of cases, while major complications appeared in only 2%. No aneurysm growth was seen during follow-up, and many patients showed shrinkage of the aneurysm after complete exclusion of the aneurysm. Technical failures, such as leaks or device movement, were managed successfully, leading to a secondary success rate of 97%. Another group of 40 patients treated with custom-made nitinol–ePTFE stent-grafts had a technical success rate of 97.5%. Early mortality was 2.5%, and survival rates at one and two years were about 84.2%. These results show that nitinol stents and grafts offer a safe and effective option for the treatment of aaas, especially for patients who cannot have open surgery.

Reduced Complications

Nitinol stents lower the risk of complications in patients with abdominal aortic aneurysms. Medical stents made from nitinol show strong results in clinical studies. The table below highlights outcomes for different nitinol stent designs:

Stent Graft | Material & Design Features | Clinical Outcomes & Complication Rates |

|---|---|---|

Anaconda | Independent nitinol circular stents, woven polyester graft | 5.1% secondary intervention for limb thrombosis/stenosis (177 patients, 33 months); 1.4% graft limb occlusion (29 months) |

Aorfix | Continuous nitinol wire in ring stent configuration, woven polyester | 0% iliac thrombosis in 30 patients (27 months); 0% limb thrombosis in highly angulated iliac anatomy after adoption (vs 6.2% before) |

Endurant | M-shaped nitinol stents with polyester | 3.4% graft limb occlusion (ENGAGE registry, 1,143 patients, 2 years); 3.7% occlusion (273 patients, 42 months) |

Excluder | ePTFE with outer self-expanding nitinol support | 1.1% graft limb thrombosis (872 patients, 20.6 months); 2% reintervention for limb occlusion (GREAT registry, 16 months) |

Ovation | Highly flexible nitinol stents embedded in PTFE | 1.8% reintervention for limb stenosis/occlusion (161 patients, 1 year); 0% limb occlusion (36 patients, 2 years); 0% occlusion in hostile iliac anatomy (42 patients) |

Zenith | Gianturco Z-stents with polyester | 2.6% cumulative limb occlusion risk (5 years); 5.6% occlusion (Mertens et al); New design with nitinol spiral stent showed 0% occlusion (100 limbs, 6 months) |

Doctors see fewer cases of limb thrombosis, occlusion, and other problems when using nitinol stents. In a study of the Ovation Iliac Stent Graft, technical success reached 100%, with a 30-day major adverse event rate of only 2.5%. At one year, the reintervention rate for iliac limb stenosis or occlusion was just 1.8%. No stent migration or major endoleaks were reported. These results show that nitinol stents help reduce complications in minimally invasive cardiovascular procedures.

Improved Patency

Nitinol stents improve patency rates for patients with abdominal aortic aneurysms and peripheral arterial disease. Patency means the stent or graft keeps the blood vessel open over time. In the SUPER-SL randomized controlled trial, two self-expanding nitinol stents were compared. The newer COMPLETE-SE stent showed a one-year primary patency rate of 80%, while the SMART CONTROL stent had a rate of 65%. Other clinical trials report patency rates for nitinol stents between 57.7% and 90.7% at 12 months. The table below shows results from several devices:

Device (Trial) | 12-month Primary Patency Rate (%) | Year |

|---|---|---|

Luminexx Bard (FAST) | 68.3 | 2007 |

Absolute Abbott (ASSESS) | 90.7 (at 1 month) | 2007 |

Zilver PTX Cook Medical | 77.6–86.2 | 2011 |

LifeStent Bard (RESILIENT) | 81–81.5 | 2012, 2015 |

Maris Medtronic (DEBATE SFA) | 57.7 | 2013 |

Doctors rely on nitinol stents and medical stents to keep blood flowing through vessels. These devices help prevent blockages and support long-term success in the treatment of aaas and peripheral arterial disease. Nitinol tubing in endovascular stent-grafts provides the flexibility and strength needed for complete exclusion of the aneurysm and improved patient outcomes.

Future of Nitinol Tubing for Vascular Grafts

Thin-Film Nitinol

Thin-film nitinol is changing how doctors think about vascular grafts. This material is less than 10 microns thick but keeps the superelastic and shape memory properties of regular nitinol tubing. Researchers found that thin-film nitinol has a much smoother surface than traditional stents, which helps lower the risk of blood clots. The smoothness also means less irritation for blood vessels. Thin-film nitinol can fit into very small delivery catheters, making it easier for doctors to treat hard-to-reach or narrow vessels. In tests, thin-film nitinol showed better hemocompatibility than ePTFE, a common graft material. Its thinness and flexibility allow it to work well in small or twisted blood vessels, where other materials might fail. Doctors see this as a big step forward for the future of vascular grafts.

Smart Stents

Smart stents use nitinol tubing to do more than just hold blood vessels open. These stents can now include sensors that measure pressure or temperature inside the vessel. The superelasticity and shape memory of nitinol tubing help these stents expand exactly where needed. Surface treatments like electropolishing make the tubing even safer by reducing nickel release and helping cells stick better. Smart stents can send real-time data to doctors, which helps them make quick decisions during surgery. New manufacturing methods, such as 3D printing and laser cutting, let engineers create stents that fit each patient’s body. These smart stents also show high strength and can last through millions of heartbeats without breaking. As technology grows, smart stents will help doctors treat patients with more accuracy and fewer risks.

Expanded Applications

The applications of nitinol tubing keep growing. Doctors now use nitinol tubing in many fields besides vascular grafts. Some new uses include guidewires, surgical tools, and even devices for the brain and heart. Companies are building new factories to make more nitinol products, showing strong market growth. The FDA has approved new devices that use nitinol tubing, such as drug-eluting stents for hard-to-treat arteries. Engineers also combine nitinol tubing with other materials, like polymers, to make devices that dissolve after healing. These expanded applications of nitinol tubing help patients in cardiology, orthopedics, neurology, and more. As research continues, the future will bring even more ways to use nitinol tubing to improve patient care.

Note: The future of nitinol tubing includes AI-driven designs, robotic-assisted surgeries, and new surface treatments that make devices safer and more effective.

Nitinol tubing has changed how stents work in blood vessels. Clinical studies show high success rates and strong vessel patency. The table below highlights key results:

Study/Metric | Description | Outcome/Value |

|---|---|---|

Mewissen (2004) | 137 legs treated with SMART nitinol stents | 98% procedural success, 92% vessel patency at 6 months |

Zeller et al. (2008) | 110 patients with artery issues | 96% success, 23.3% restenosis at 1 year |

Kickuth et al. (2007) | 35 patients with leg pain | 82% vessel patency at 6 months, 100% limb salvage |

Stents made from nitinol tubing offer flexibility, durability, and safety. New stents use better alloys and smart designs. These advances help more people with vascular disease. Stents will keep improving as technology grows.

FAQ

What makes nitinol tubing special for stent grafts?

Nitinol tubing has shape memory and superelasticity. These features help stent grafts fit blood vessels well and stay strong. Doctors trust nitinol because it bends and returns to its original shape.

How does nitinol tubing improve patient safety?

Nitinol tubing resists corrosion and does not release harmful nickel ions after special treatments. This makes it safe for long-term use inside the body. Patients have fewer complications with nitinol stents.

Can nitinol stents work in twisted or curved blood vessels?

Yes. Nitinol stents bend easily and recover their shape. This flexibility helps them fit into vessels with many curves or branches. Doctors use nitinol stents for complex vessel shapes.

How long do nitinol stent grafts last?

Tests show nitinol stents can last for many years. They resist breaking and keep blood vessels open. Many clinical studies report high success rates and long-term durability.

Are there new uses for nitinol tubing in medicine?

Researchers keep finding new ways to use nitinol tubing. Doctors now use it in guidewires, smart stents, and even brain devices. The future may bring more advanced nitinol-based tools for patient care.

See Also

Ways Nickel-Titanium Tubing Improves Catheter And Implant Efficiency

Nitinol Tubing Versus Stainless Steel Tensile Strength Comparison

Complete Guide To Manufacturing Nitinol Microtubing For Neurovascular Use

Finding The Most Cost-Effective Supplier For 2mm Nitinol Tubing