How Shape Memory Nitinol Tubing Improves Neurovascular Catheters

Shape memory nitinol tubing for neurovascular catheters transforms medical device performance by leveraging its exceptional material properties. Nitinol’s ability to undergo phase transformations between austenite and martensite enables superelasticity, ensuring flexibility and adaptability during neurovascular procedures. As strokes and aneurysms become increasingly common, effective interventions rely on advanced tubing technologies. According to the World Health Organization, one in four individuals over 25 will experience a stroke in their lifetime, highlighting the urgent need for innovations in neurovascular catheters. Nitinol's biocompatibility and durability further enhance its role in addressing these challenges, offering safer and more precise solutions for patients worldwide.

Key Takeaways

Nitinol tubing can remember shapes and bend easily, helping it fit tricky blood vessel paths while staying strong.

Nitinol is safe for the body, so it causes fewer bad reactions in catheters and stents.

It doesn’t rust, so nitinol lasts long and works well, meaning fewer surgeries are needed.

Special ways of making nitinol let doctors customize it for different medical uses.

Nitinol’s special features make surgeries safer and lower the chance of problems.

Unique Material Properties of Nitinol

Shape Memory and Superelasticity

Nitinol exhibits two remarkable properties—shape memory and superelasticity—that make it indispensable in neurovascular applications. Shape memory allows nitinol tubing to return to its original shape after deformation when exposed to a specific temperature. This property is particularly useful in neurovascular catheters, where precise control and adaptability are essential. Superelasticity, on the other hand, enables nitinol to undergo significant deformation and recover without permanent damage. This characteristic ensures that nitinol tubing can navigate the intricate and delicate pathways of the neurovascular system without compromising its structural integrity.

The performance of nitinol tubing in terms of shape memory and superelasticity is quantifiable. For instance, nitinol demonstrates a strain recovery of 5.62% and a success rate of 98% in maintaining its original form under stress.

Metric | Value |

|---|---|

Strain Recovery | 5.62% |

Success Rate | 98% |

These metrics highlight the reliability of nitinol tubing in demanding medical environments, ensuring its effectiveness in minimally invasive procedures.

Biocompatibility for Neurovascular Applications

Biocompatibility is a critical factor in the development of neurovascular catheters, and nitinol excels in this area. Its components interact safely with human tissue, minimizing adverse reactions and ensuring compatibility with the body. This makes nitinol tubing ideal for implants and devices used in neurovascular procedures.

Studies have shown that nitinol resists corrosion and fatigue, contributing to its durability and long-term performance. Additionally, highly porous, hyper-elastic TFN membranes made from nitinol support tissue growth without significant thrombosis formation or abnormalities. These findings underscore the material's suitability for neurovascular applications, where safety and reliability are paramount.

Nitinol's ability to exert a constant, gentle force against vessel walls further enhances its biocompatibility. This property minimizes trauma and promotes healing, making it a preferred choice for neurovascular catheters. Its thermal activation capabilities also allow for innovative designs that adapt to body temperature, improving procedural outcomes.

Corrosion Resistance and Durability

Corrosion resistance is another defining feature of nitinol tubing, ensuring its longevity in the challenging environment of the human body. In a canine aortic aneurysm model, nitinol stents exhibited no signs of corrosion after one month of implantation. This performance is attributed to the material's passive nature and superior surface finish, which protect it from degradation.

Nitinol's corrosion resistance is crucial for long-term exposure to bodily fluids, enhancing its performance in vascular systems. Its durability makes it suitable for use in stents, implants, and other medical devices that require consistent performance over time. Furthermore, nitinol's ability to maintain its integrity in MRI environments demonstrates its reliability and suitability for advanced medical applications.

The combination of corrosion resistance, biocompatibility, and mechanical performance solidifies nitinol's role in neurovascular catheters. These properties ensure that the tubing can withstand the rigors of medical procedures while providing safe and effective solutions for patients.

Design Advantages of Nitinol Tubing in Catheters

Flexibility for Complex Neurovascular Anatomy

Nitinol tubing offers unmatched flexibility, making it ideal for navigating the intricate pathways of the neurovascular system. Its superelasticity allows it to bend and adapt to the complex anatomy without losing structural integrity. This flexibility is especially beneficial in procedures requiring catheters and guidewires to traverse tight or tortuous vessels.

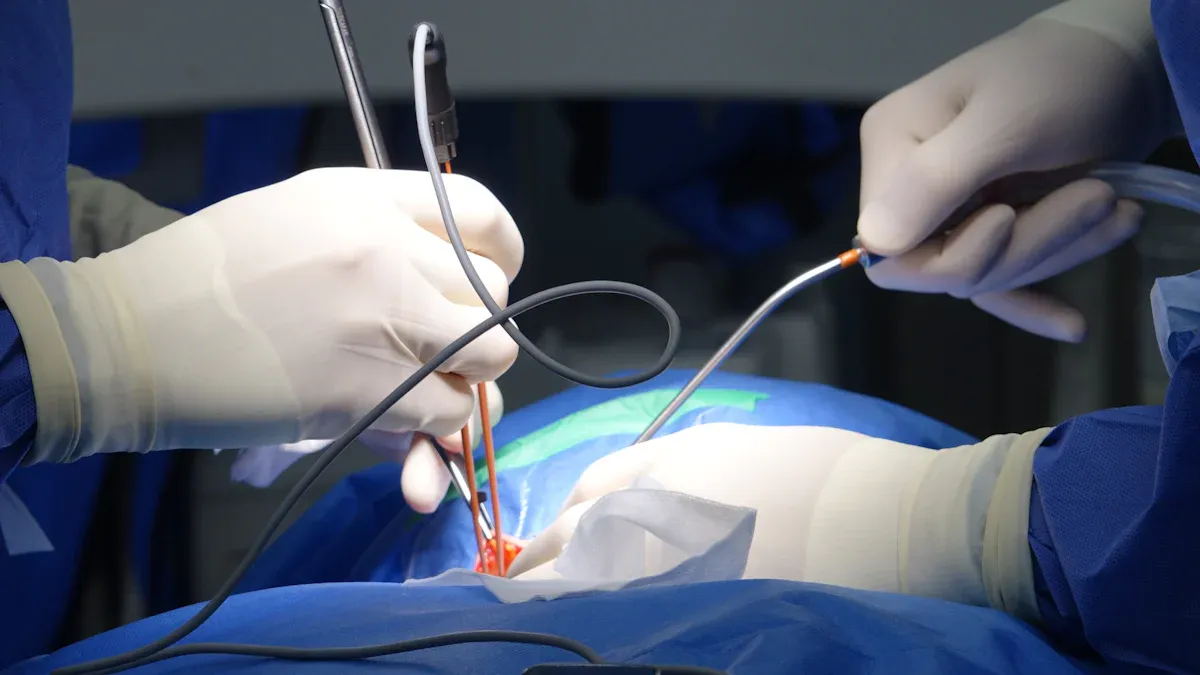

Steerable catheters made from nitinol tubing have demonstrated significant advantages in clinical settings:

They reduce procedure time compared to non-steerable alternatives.

They enhance patient safety by minimizing the risk of vessel damage.

They enable precise positioning of implants, allowing successful treatments for patients who might otherwise be ineligible for minimally invasive surgery.

These benefits highlight the critical role of nitinol tubing in improving surgical accuracy and patient outcomes in neurovascular procedures.

Precision in Minimally Invasive Procedures

High-precision nitinol tubing plays a pivotal role in minimally invasive surgery. Its unique properties, such as shape memory and superelasticity, contribute to exceptional accuracy during procedures. For example:

Property | Contribution to Precision |

|---|---|

Superelasticity | Allows devices to navigate complex pathways, reducing errors. |

Shape Memory | Enables devices to return to a predetermined shape, enhancing control. |

Exceptional Flexibility | Improves performance in tight spaces while maintaining stability. |

Nitinol's precision in manufacturing further enhances its effectiveness. The ability to create intricate components with tight tolerances ensures reliable performance. Additionally, braided nitinol tubing combines strength and flexibility, providing surgeons with precise control during interventions. These features make nitinol tubing indispensable in neurovascular applications requiring high levels of accuracy.

Structural Integrity and Long-Term Performance

Nitinol tubing excels in maintaining structural integrity and durability over time. Its corrosion resistance ensures that it withstands prolonged exposure to bodily fluids without degradation. This property is vital for neurovascular devices, which must perform reliably in challenging environments.

Reliability tests confirm nitinol's long-term performance:

Minimal tissue reactions post-implantation, with histological scores ranging from 0 to 1.

Sustained 30% reduction in intraocular pressure over six months.

No significant inflammatory responses in examined tissues.

Design factors such as wire diameter, braiding angle, and the number of PET strips also influence the performance of nitinol tubing. For instance:

Design Factor | Impact on Performance |

|---|---|

Nitinol Wire Diameter | Larger diameter increases radial strength but decreases flexibility. |

Braiding Angle | Larger angle enhances radial strength and flexibility but diminishes with large deformation. |

Number of PET Strips | Significantly affects surface coverage. |

These attributes ensure that nitinol tubing maintains its functionality and structural integrity, making it a reliable choice for neurovascular catheters and guidewires.

Functional Benefits of Shape Memory Nitinol Tubing

Enhanced Adaptability to Vascular Environments

Shape memory nitinol tubing demonstrates exceptional adaptability to the dynamic and complex environments of the neurovascular system. Its superelasticity allows it to conform to varying vessel diameters and intricate pathways without losing structural integrity. This adaptability is critical for neurovascular stents, which must navigate tortuous vessels while maintaining precise positioning.

Studies reveal that the mechanical performance of nitinol tubing depends on factors such as the initial braiding angle and nitinol diameter. For instance:

Factor | Sensitivity at 60° | |

|---|---|---|

Initial Braiding Angle | 36% | 27% |

Nitinol Diameter | 25% | 33% |

A larger braiding angle enhances flexibility, while a smaller nitinol diameter improves adaptability. These properties ensure that nitinol tubing meets the performance requirements for neurovascular stents, enabling it to conform to diverse vascular anatomies.

Additionally, nitinol tubing exhibits superior flexibility compared to other alloys, making it ideal for neurovascular applications. Its ability to expand precisely within arteries ensures compatibility with neurovascular procedures, reducing the risk of complications. This adaptability enhances the overall success rate of minimally invasive interventions.

Improved Safety and Reduced Complications

Nitinol tubing significantly improves safety during neurovascular procedures by minimizing complications. Its biocompatibility ensures that it interacts safely with human tissue, reducing the likelihood of adverse reactions. This property is particularly important for neurovascular stents, which remain in the body for extended periods.

The corrosion resistance of nitinol tubing further enhances its safety profile. Long-term studies indicate that nitinol stents remain intact within the body, minimizing the risk of material degradation. This durability ensures that the tubing performs reliably over time, reducing the need for repeat interventions.

Innovative surface treatments, such as electropolishing and drug-eluting coatings, enhance the safety of nitinol tubing. These techniques improve corrosion resistance and reduce the risk of restenosis, a condition where blood vessels narrow again after treatment. The development of new nitinol alloys with improved fatigue resistance and durability also contributes to safer neurovascular procedures.

Advancement Type | Description |

|---|---|

Innovative Surface Treatments | Techniques like electropolishing improve corrosion resistance and safety. |

Additive Manufacturing | 3D printing enables patient-specific designs, enhancing safety and precision. |

New Nitinol Alloys | Improved fatigue resistance optimizes performance in challenging environments. |

These advancements ensure that nitinol tubing meets the stringent safety requirements of neurovascular applications, providing reliable solutions for patients.

Better Responsiveness During Procedures

The responsiveness of shape memory nitinol tubing plays a crucial role in the success of neurovascular interventions. Its ability to recover its original shape after deformation ensures precise deployment and control during procedures. This property is particularly beneficial for neurovascular stents, which must adapt to the dynamic conditions of the vascular system.

Experimental data highlights the responsiveness of nitinol tubing under different conditions:

Experiment Type | Temperature (°C) | Response Description |

|---|---|---|

Constant Temperature Experiment | 81 | Exhibited elastic almost linear behavior in austenite phase. |

Constant Temperature Experiment | 18 | Stretched due to detwinning and elastic deformation in martensite phase. |

History Dependence Experiment | N/A | Response varied under similar loading conditions in martensite phase, demonstrating history dependence. |

Recovery Experiment | N/A | Constant force response recovered after heating above transition temperature and cooling back. |

These findings demonstrate the ability of nitinol tubing to respond effectively to changes in temperature and mechanical stress. Its shape memory and superelasticity enable it to adapt to varying conditions, ensuring precise performance during procedures.

Nitinol tubing also exhibits excellent fatigue resistance and durability, allowing it to withstand repeated cycles of deformation without losing functionality. This property is essential for neurovascular stents, which must endure the mechanical stresses of the vascular system. By combining responsiveness with durability, nitinol tubing ensures optimal outcomes for patients undergoing neurovascular procedures.

Manufacturing and Customization of Nitinol Tubing

Advanced Fabrication Techniques

Advanced fabrication techniques play a pivotal role in producing high-quality nitinol tubing for neurovascular applications. Additive manufacturing technologies, such as 3D printing, enable the creation of complex geometries and customized designs. These innovations enhance production efficiency and allow for precise tailoring of tubing to meet specific medical needs.

The unique properties of nitinol, including its shape memory and superelasticity, further support customization. Heat treatment processes adjust the material's transformation temperatures, ensuring optimal performance in neurovascular environments. For example, cyclic testing has shown that nitinol tubing achieves a recovery ratio of over 90% and a stable recoverable strain of 6.52% after ten cycles.

Metric | Value |

|---|---|

Af temperature (initial) | 2.1°C |

Af temperature (after heat treatment) | 30.2°C |

Recovery ratio (2nd cycle) | > 90% |

Stable recoverable strain (10th cycle) | 6.52% |

Recovery ratio (10th cycle) | 96% |

These results highlight the precision and reliability of advanced fabrication methods in producing nitinol tubing for neurovascular applications.

Tailored Designs for Neurovascular Applications

Customization for neurovascular applications ensures that nitinol tubing meets the unique demands of intricate anatomical structures. Adjustments to dimensions, such as wall thickness, enhance the tubing's strength, flexibility, and fatigue resistance. These modifications improve the performance and reliability of neurovascular catheters, ensuring compatibility with complex vascular pathways.

Advanced manufacturing techniques, including laser cutting and surface treatments, further refine the tubing. Polished and coated surfaces enhance biocompatibility, reducing the risk of complications when interacting with surrounding tissues. Additionally, the durability of nitinol stents allows them to withstand millions of stress cycles, making them ideal for high-stress environments like the neurovascular system.

Tailored designs not only improve the structural integrity of nitinol tubing but also optimize its adaptability, ensuring safer and more effective neurovascular procedures.

Quality Assurance for Consistency and Reliability

Quality assurance processes ensure that nitinol tubing meets the stringent requirements of neurovascular applications. Dimensional tolerances, microstructure optimization, and surface finishes are critical factors in achieving consistent performance. For instance, nitinol tubing achieves over 98% concentricity, which is essential for precise device functionality.

Metric | Description |

|---|---|

Dimensional Tolerances | Ultra-tight tolerances critical for precision applications. |

Microstructure Optimization | Enhancements to the microstructure that improve material properties and performance. |

Surface Finishes | Pristine finishes necessary for biocompatibility and functionality in medical devices. |

Concentricity | Achieved >98% concentricity, essential for device performance. |

Fatigue Durability | Demonstrated twofold improvement in durability through microstructural refinement. |

Testing at every stage of production ensures reliability. Raw materials undergo rigorous evaluation to meet industry standards. Component and finished product testing confirm that each piece performs reliably under real-world conditions. These measures guarantee that nitinol tubing delivers consistent results, enhancing its role in neurovascular applications.

Shape memory nitinol tubing has transformed the landscape of neurovascular catheter design. Its unique properties, such as superelasticity and shape memory, have enabled safer and more precise procedures. Over 60% of stent delivery systems now rely on nitinol tubing, which improves maneuverability in complex vasculature. A 2023 study revealed that nitinol-based tubing reduces procedural complications by 12% compared to traditional materials, further solidifying its role in advancing neurovascular interventions.

Future trends indicate continued growth in the adoption of nitinol tubing for medical devices. The Global Nitinol Tube Market, valued at USD 1.67 billion in 2024, is projected to grow at a rate of 9.68% annually through 2033. Manufacturers are also enhancing material purity to improve durability and performance. These advancements ensure that nitinol tubing will remain integral to the evolution of neurovascular medical devices, offering better outcomes for patients worldwide.

FAQ

What makes nitinol tubing ideal for neurovascular catheters?

Nitinol tubing offers shape memory, superelasticity, and biocompatibility. These properties allow it to adapt to complex vascular pathways, maintain structural integrity, and interact safely with human tissue. Its corrosion resistance ensures durability, making it a reliable choice for neurovascular applications.

How does nitinol tubing improve patient safety?

Nitinol tubing minimizes complications through its biocompatibility and corrosion resistance. Its gentle, constant force reduces vessel trauma, while advanced surface treatments, like electropolishing, enhance safety by preventing restenosis and material degradation. These features ensure safer neurovascular procedures.

Can nitinol tubing be customized for specific medical needs?

Yes, manufacturers can tailor nitinol tubing by adjusting dimensions, heat treatments, and surface finishes. These customizations optimize strength, flexibility, and fatigue resistance, ensuring compatibility with intricate neurovascular anatomies and improving procedural outcomes.

Is nitinol tubing compatible with MRI environments?

Nitinol tubing is MRI-compatible due to its non-magnetic properties. It maintains structural integrity and functionality during MRI scans, making it suitable for long-term implants and neurovascular devices used in imaging-intensive treatments.

What advancements are shaping the future of nitinol tubing?

Innovations like additive manufacturing, improved material purity, and new nitinol alloys enhance tubing performance. These advancements increase durability, precision, and adaptability, ensuring nitinol tubing remains integral to evolving neurovascular medical devices.

Tip: For more information on nitinol tubing's role in neurovascular catheters, consult your healthcare provider or device manufacturer.

See Also

Nitinol Tubing's Impact on Modern Medical Innovations

The Importance of Nitinol Tubing in Healthcare Solutions

Nitinol Tubing's Transformative Effect on Medical Equipment

The Crucial Role of Nitinol Tubing in Minimally Invasive Surgery

Investigating Nitinol Tubing Uses in Medical Device Technology