What Is Shape Memory Alloy Tubing and How Does It Work

Shape memory alloy tubing lets you use metal tubes that go back to their first shape when you heat them. This special tubing, often made from Nitinol, has a special skill called the shape memory effect. You can bend or twist the tubing when it is cold. When you heat the tubing, it goes back to its set shape. Many industries use this tubing because it helps fix hard design problems. For example, companies keep making tubing better, like a patent that shows how to stop damage during making. You can find shape memory alloy tubing in medical, industrial, and consumer products. Tubing with these features gives you answers that normal metal tubes cannot give. Tubing that changes to fit your needs helps many fields in a big way.

Key Takeaways

Shape memory alloy tubing, like nitinol, can bend or twist when it is cold. When it gets hot, it goes back to its first shape. Nitinol tubing is strong and flexible. It does not rust. It is safe for use in medicine. This makes it good for things like stents and guide wires. The tubing works by changing between two forms inside the metal. It is soft martensite when cold. It is strong austenite when hot. Shape memory alloys last longer than regular metal tubing. They bend more and go back to their shape without breaking. Memory metal tubing is used in medical tools and machines. It is also in things we use every day, like eyeglasses and car parts. This helps them work better and last longer.

Shape Memory Alloy Tubing

What Is Shape Memory Alloy

You might ask why memory metal tubing is so different. Shape memory alloys are metals that can go back to their first shape. If you bend or twist these metals when cold, they keep that new shape. When you heat them, they change back to how they started. This is called the shape memory effect. You see this best in nitinol tubing. Nitinol is made from nickel and titanium. People use nitinol tubing when they need a tube that bends and then returns to its first shape with heat. This happens because the atoms inside the metal move between two phases. One phase is martensite, which is soft and easy to bend. The other is austenite, which is strong and goes back to the set shape. When nitinol tubing is cold, it is in the martensite phase. When you heat it, it changes to the austenite phase and returns to its original shape.

Common Materials in Tubing

There are a few types of shape memory alloys used for tubing, but nitinol tubing is the most common. Here are the main types:

Nitinol (nickel-titanium): Used in most memory metal tubing because it is strong, bends well, and is safe for your body.

Cu-Al-Ni (copper-aluminum-nickel): Used for jobs that need high heat.

Cu-Zn-Al (copper-zinc-aluminum): Used when you want to save money and still get good shape memory.

Nitinol tubing is popular because it can bend a lot and still go back to its shape. It also does not rust and works well inside the body. You see nitinol tubing in medical tools, airplanes, and safety gear. Other memory metal tubing, like Cu-Al-Ni and Cu-Zn-Al, is better for machines or robots that do not need as much bending or safety.

Here is a table to help you compare the main types of memory metal tubing:

Shape Memory Alloy | Main Elements | Key Features | Typical Uses |

|---|---|---|---|

Nitinol | Nickel, Titanium | Superelasticity, biocompatibility, corrosion resistance, fatigue resistance | Medical, aerospace, safety |

Cu-Al-Ni | Copper, Aluminum, Nickel | High temperature resistance | Industrial, actuators |

Cu-Zn-Al | Copper, Zinc, Aluminum | Good shape memory, cost-effective | Consumer, robotics |

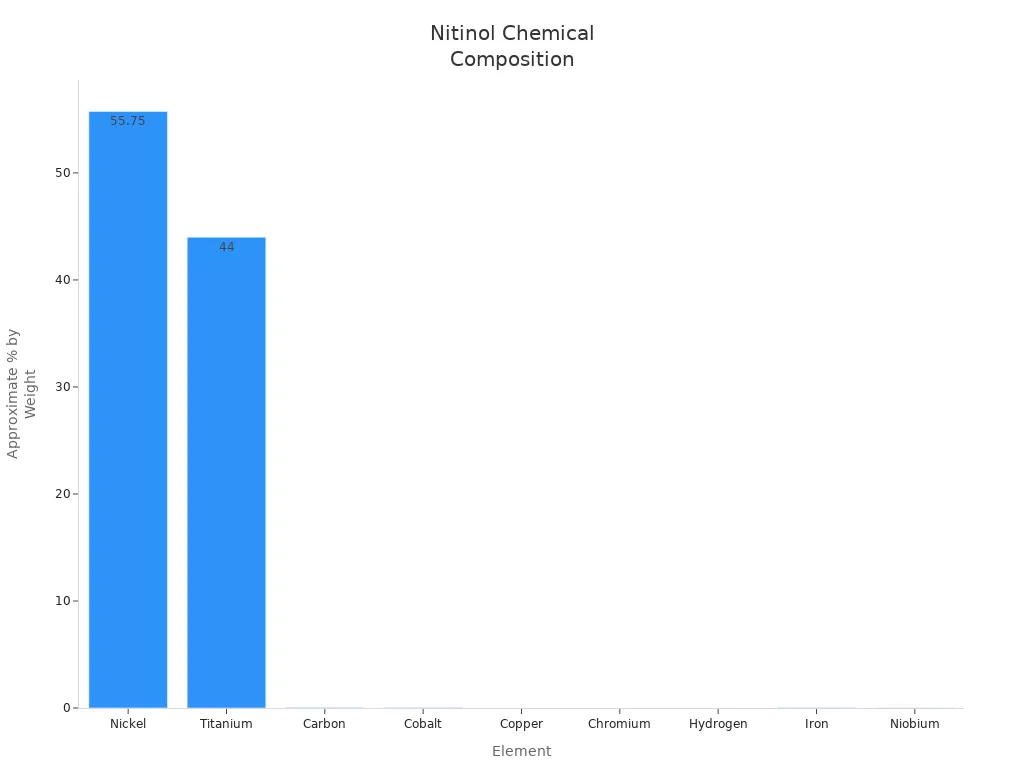

Nitinol tubing has a mix of nickel and titanium. The exact mix matters because it controls how the tubing changes shape. Here is a closer look at what is inside nitinol:

Element | Approximate Percentage Range (%) |

|---|---|

Nickel | 54.5 - 57.0 |

Titanium | Balance (approx. 43 - 45) |

Carbon | ≤ 0.040 |

Cobalt | ≤ 0.050 |

Copper | ≤ 0.010 |

Chromium | ≤ 0.010 |

Hydrogen | ≤ 0.005 |

Iron | ≤ 0.050 |

Niobium | ≤ 0.025 |

This careful mix lets nitinol tubing switch between martensite and austenite phases. You can even change the temperature where this happens by changing the nickel-titanium ratio.

Unique Properties

Memory metal tubing has features that regular metal tubes do not have. The most important things about shape memory alloys are the shape memory effect and superelasticity. When you use nitinol tubing, you get both. You can bend the tubing, and it will go back to its first shape when heated. You can also stretch or twist nitinol tubing, and it will snap back without breaking. This makes nitinol tubing great for places where you need both bending and strength.

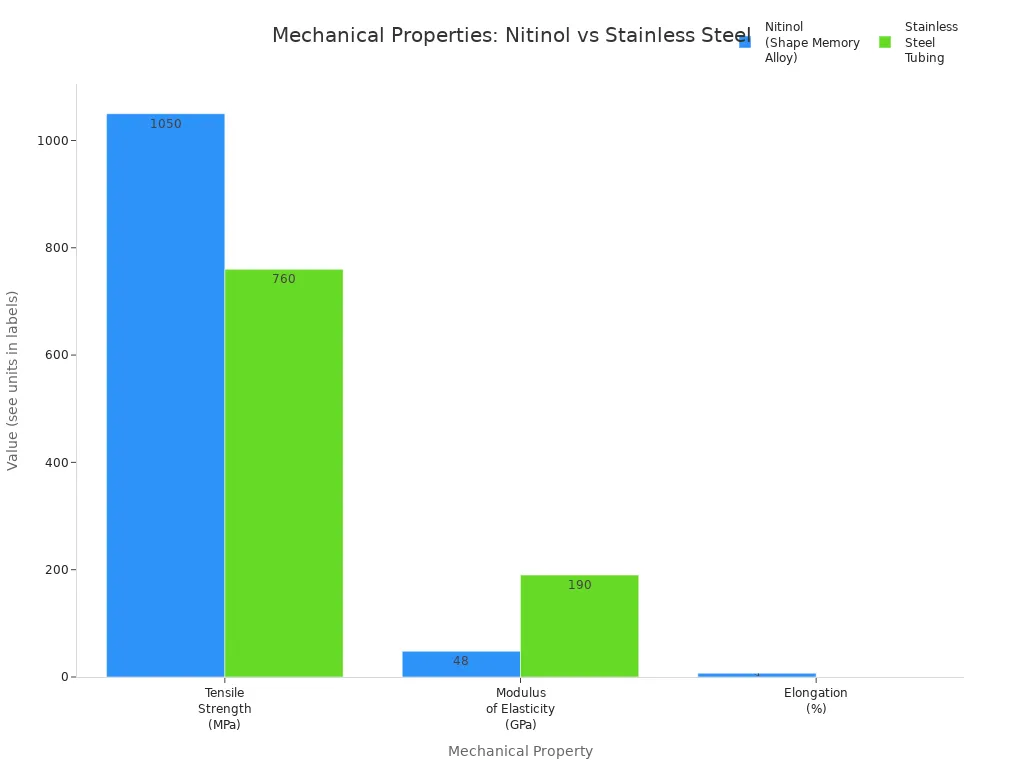

Let’s see how nitinol tubing compares to stainless steel tubing:

Property | Nitinol (Shape Memory Alloy) | Stainless Steel Tubing |

|---|---|---|

Tensile Strength (MPa) | ~1050 | ~760 |

Modulus of Elasticity (GPa) | ~48 | ~190 |

Elongation / Strain Limit | 6–8% with shape recovery | Cannot stretch and recover |

Nitinol tubing is stronger and bends more than stainless steel tubing. You can stretch nitinol tubing up to 8% and it will still go back to its shape. Stainless steel tubing cannot do this. The lower modulus of elasticity in nitinol means it bends more before breaking. This is why you see nitinol tubing in stents, guidewires, and other medical tools that move inside your body.

You also get other good things from memory metal tubing. Nitinol tubing does not rust and works well in wet or rough places. It is safe for your body, so doctors use it in implants. Superelastic alloys like nitinol tubing can bend and stretch many times without wearing out. You can trust memory metal tubing to last a long time, even in hard jobs.

Tip: If you need tubing that bends, stretches, and always goes back to its shape, pick nitinol tubing. You get the best mix of strength, bending, and safety.

How It Works

Shape Memory Effect

The shape memory effect is like a cool trick for metals. Think about a bendy straw. If you twist it, it stays twisted. Now, imagine a special straw that goes back to normal when you heat it. That is what happens with shape memory alloys in tubing. When nitinol tubing is cold, you can bend or stretch it. It will keep the new shape until you heat it up. When you heat the tubing, it remembers its first shape and returns to it. This special ability is called the shape memory effect.

Nitinol shows this effect because of changes inside the metal. The atoms move but do not break the metal’s structure. People use this effect in many ways. Doctors use nitinol tubing in stents that open up blood vessels. Engineers use it in devices that must change shape and then go back.

Note: The shape memory effect helps you make tubing that bends, moves, and returns to its shape. This makes it useful in many jobs.

Phase Transformation

The shape memory effect works because of a special phase change inside the tubing. Nitinol has two main phases: martensite and austenite. When it is cold, nitinol tubing is in the martensite phase. This phase is soft and easy to bend. When you heat the tubing, it changes to the austenite phase. Austenite is stiff and strong. This change makes the tubing snap back to its first shape.

Here is a table to show the differences between the two phases:

Aspect | Austenite Phase | Martensite Phase |

|---|---|---|

Crystal Structure | Body-Centered Cubic (BCC) | Monoclinic |

Elastic Modulus | Higher stiffness | Lower stiffness |

Phase Stability | Stable at high temp | Stable at low temp |

Transformation | Shear transformation | Lattice distortion |

Mechanical Behavior | Stiff, recovers shape | Easily deformed |

When you cool nitinol tubing, it becomes martensite and gets flexible. You can bend it without breaking it. When you heat it above a certain temperature, it turns into austenite and goes back to its set shape. This temperature is different for each type of tubing. Some nitinol tubing changes at 18°C. Others change at 81°C. You can change the temperature by changing the nickel and titanium mix.

Nitinol tubing switches between martensite (flexible) and austenite (stiff) as the temperature changes.

Four main temperatures control this: martensite start (Ms), martensite finish (Mf), austenite start (As), and austenite finish (Af).

For medical tubing, the austenite finish temperature is usually set close to body temperature (about 37°C).

The inside of nitinol tubing also changes during this process. Inside, there are layers where nickel and titanium mix together. As the tubing changes phase, small flaws and tiny shifts can form. These things affect how well the tubing works and how many times you can use the shape memory effect.

Training and Cycling

You can train shape memory alloys to remember a shape. To train them, you heat the tubing and set it into the shape you want. When you cool it, the tubing keeps this memory. Each time you bend and heat the tubing, it goes back to the trained shape. This is called cycling.

Cycling means you use the shape memory effect over and over. After many cycles, the tubing can start to wear out. Small changes happen inside, like tiny cracks or shifts in the atoms. These changes can make the tubing less able to return to its first shape. The more you use the tubing, the more these changes build up.

Using the tubing many times causes it to collect small amounts of permanent strain.

High stress or slow cycling can make the tubing wear out faster.

Bending and stretching in many directions can speed up this wear.

The tubing’s fatigue life depends on how much and how often you use the shape memory effect.

Tip: If you want your nitinol tubing to last longer, use it the right way and do not bend or stretch it too much.

The reason for the shape memory effect in tubing comes from how the atoms move during phase changes. This movement does not break the metal but lets it recover its shape again and again. Shape memory alloys like nitinol use this to give you tubing that is strong, flexible, and reliable.

SMA vs. Regular Tubing

Key Differences

When you look at shape memory alloys and regular tubing, you see big differences. Shape memory alloys can bend, twist, or stretch and then go back to their first shape when heated. Regular tubing, like stainless steel or plastic, cannot do this. If you bend regular tubing, it stays bent or might break. Memory metal tubing, such as nitinol tubing, uses the shape memory effect and superelasticity to return to its shape many times.

Shape memory alloys are more flexible than regular tubing. Memory metal tubing can bend and stretch over and over without getting ruined. Regular tubing can kink or get weak after a few bends. Nitinol tubing also does not rust and works well in wet or rough places. This makes it great for medical tools and other hard jobs. The inside of shape memory alloys stays the same, so they work well every time.

Tip: If you want tubing that can move, bend, and always go back to its shape, memory metal tubing is your best pick.

Advantages and Limitations

There are many good things about using shape memory alloys in tubing. Some main benefits are:

Memory metal tubing bends, stretches, and goes back to its first shape, even after many uses.

Shape memory alloys have superelasticity, so you can use them in small or moving spaces.

Nitinol tubing lasts longer than regular tubing because it does not kink or change shape easily.

Shape memory alloys do not rust and are safe to use inside the body.

New ways to make memory metal tubing give it exact shapes and smooth surfaces.

But there are also some things to watch out for with shape memory alloys. Memory metal tubing costs more to make because it needs special machines and careful mixing of nickel and titanium. Cutting nitinol tubing is hard, and you need special tools. Quality checks are strict, since even tiny problems can cause trouble. Shape memory alloys can lose their special skills if they get too hot for too long. If you bend the tubing too much or too often, it can get tired and break.

Here is a table to help you see the main limits:

Limitation Category | Description |

|---|---|

High Manufacturing Costs | Needs careful nickel-titanium mix and special heat, so memory metal tubing costs more. |

Complex Machining Challenges | Gets harder when cut and needs special tools, which adds cost. |

Strict Quality Control | Tiny problems can hurt how it works, so testing is very important. |

Environmental Sensitivities | Can rust in salty places unless treated. |

Temperature-Dependent Performance | Shape memory effect can change if it gets too hot or cold. |

Too much bending or stress can make cracks over time. | |

Design and Customization Constraints | Hard to control the exact temperatures and sizes you want. |

Shape memory alloys give you special benefits, but you have to think about the higher price and extra care they need. If you want tubing that lasts, bends, and stays strong, memory metal tubing is a great choice. The good things about shape memory alloys make them best for many tough jobs, but you should always think about the limits before you pick them.

Properties and Benefits

Flexibility and Durability

Shape memory alloys make tubing very flexible. Nitinol tubing bends more than regular metals. You can twist or stretch it, and it goes back to its shape. This happens because of superelasticity and the shape memory effect. Nitinol tubing can handle strains up to 6%. Regular metal tubing cannot do this. It would bend or break and not recover. These features make shape memory alloys great for medical devices that move a lot.

Durability is also a big benefit. Fatigue tests show nitinol tubing lasts through many bends. If you keep strain under 1.3%, most samples last at least 10 million cycles. Even with more strain, many samples last over 100,000 cycles. This means you can trust shape memory alloys in tough places, like inside the body or in planes.

Tip: If you need tubing that stays strong and flexible after many uses, shape memory alloys are the best choice.

Biocompatibility

You want tubing that is safe inside the body. Shape memory alloys, especially medical nitinol, are very safe. Studies show almost no tissue reaction after putting in nitinol tubing. The special features, like superelasticity and shape memory, help them work well in medical devices. Smooth surfaces on nitinol tubing lower protein buildup and reduce blood clots.

In animal tests, nitinol bone plates did not rust or hurt tissue after 17 months. No bad metals were found in organs, unlike with other alloys. This shows shape memory alloys are safe for long-term use in the body. You can trust their safety and rust resistance for important medical jobs.

Corrosion Resistance

Corrosion resistance is very important for tubing in medical and industrial jobs. Shape memory alloys make a strong oxide layer that stops rust and chemical damage. Nitinol tubing resists rust as well as or better than stainless steel in body fluids. The thin film on nitinol, made of titanium oxide, keeps nickel from leaking out. This helps keep people safe and makes the tubing work better.

Here is a table comparing corrosion resistance:

Material | Corrosion Resistance | Passive Film Composition | Notes on Biocompatibility |

|---|---|---|---|

NiTi Shape Memory Alloy | Excellent in body fluids | Titanium oxide (TiO2) | Stable, low ion release |

Stainless Steel (S31603) | Good, but surface-dependent | Chromium oxide | Widely used, but can release ions |

You can use shape memory alloys for tubing in tough places without worrying about rust. This makes them great for medical, industrial, and consumer products that need to last a long time.

Applications of Memory Metal Tubing

Medical Devices

Memory metal tubing is used in many medical tools. Nitinol tubing bends easily and does not kink. It is also superelastic. These features help doctors do surgeries with small cuts. You can find nitinol tubing in catheters and biopsy forceps. It is also in tissue ablators and retrieval baskets for laparoscopy. These tools must bend and move inside the body. They cannot break while doing this. Nitinol tubing makes this safe and possible.

Doctors use nitinol tubing in self-expanding stents. These stents go into blood vessels while small. When they reach body temperature, they get bigger and support the vessel. Superelasticity helps the stent keep blood vessels open. This works even when the body moves. Studies show nitinol stents help blood flow and lower blockages. Nitinol tubing is also in guide wires for radiology. These wires must be flexible and easy to steer. Nitinol tubing is perfect for these medical uses.

Note: Nitinol tubing makes medical tools safer and more dependable for patients.

Industrial Uses

Memory metal tubing is used in many industries. You can find nitinol tubing in planes, robots, and cars. In planes, nitinol tubing is used in couplings and landing gear. The tubing does not rust and is light. This helps planes last longer and use less fuel. Robots use nitinol tubing in actuators and sensors. These parts must bend and move many times. Nitinol tubing gives them the strength and flexibility they need.

Here is a table showing common industrial uses:

Sector | Use of Nitinol Tubing | Benefit |

|---|---|---|

Aerospace | Couplings, landing gear | Corrosion resistance, light |

Robotics | Actuators, sensors | Flexibility, repeated bending |

Automotive | Engine controls, safety parts | Smart actuation, reliability |

You see memory metal tubing in many machines because it lasts longer than regular tubing.

Consumer Products

You use memory metal tubing in daily life, sometimes without knowing it. Nitinol tubing is in eyeglass frames that bend and return to shape. It is also in electronics like phones and wearables. These devices use nitinol tubing for flexible hinges and connectors. This makes them stronger and easier to use.

In cars, nitinol tubing is in engine parts and seatbelt tensioners. It is also in airbag systems. The tubing helps these parts work fast and stay safe. You can also find nitinol tubing in camera lenses and automatic mirrors. These uses show how memory metal tubing makes products safer and better.

Tip: If you want products that last and work well, choose ones with nitinol tubing in their design.

Shape memory alloy tubing helps you fix hard design problems. Nitinol tubing is flexible and can stretch and bend. It always goes back to its first shape. You can twist or bend the tubing, and it returns to normal. This tubing lasts a long time and does not rust. It is safe for medical tools and strong for machines.

Tubing goes back to shape after bending, so products last longer.

Superelastic tubing can handle stress and works in tough places.

Medical tubing keeps patients safer and makes surgeries faster.

Tubing in things like eyeglasses stays bendy and strong.

Application Area | Example Use Case | Description |

|---|---|---|

Medical | Self-expanding stents | Nitinol tubing grows inside blood vessels to help blood flow. |

Medical | Orthodontic archwires | Gives gentle, steady force to move teeth slowly and safely. |

Orthopedics | Fracture fixation devices | Matches bone strength to help bones heal better. |

Orthopedics | SMA Patellar Concentrator | Gives steady force to fix knee bones and helps patients heal. |

This tubing helps in medicine, factories, and things you use every day. You get safe, strong, and new answers with shape memory alloy tubing.

FAQ

What makes shape memory alloy tubing different from regular metal tubing?

Shape memory alloy tubing has special features. It can bend or stretch and then go back to its first shape when heated. Regular metal tubing cannot do this. The shape memory effect and superelasticity help solve hard design problems. For example, a stent uses these features in many jobs.

How does nitinol tubing work in medical devices?

Nitinol tubing uses the shape memory effect and superelasticity. You find it in stents, guide wires, and catheters. These tools bend and move inside the body. Nitinol tubing goes back to its set shape. This makes medical care safer and better.

Why is biocompatibility and corrosion resistance important for biomedical applications?

Biocompatibility and corrosion resistance are needed for medical uses. Shape memory alloys like medical nitinol do not rust. They stay safe inside the body. These features help medical devices last longer and lower risks during treatment.

What are the main advantages of shape memory alloys in tubing?

Shape memory alloys in tubing have many good points. They are flexible, strong, and can return to their shape. These features make them great for medical, industrial, and consumer uses. Superelastic alloys can bend many times without breaking.

How do you train shape memory materials for specific uses?

You train shape memory materials by heating them into a shape. When cooled, the tubing remembers this form. This lets you use the tubing in devices that must change shape and then return, like in medical or industrial jobs.

See Also

Understanding The Mechanisms Of Nitinol's Unique Properties

The Impact Of Nitinol Tubing On Medical Innovations

Processes Involved In Producing Nitinol Tubing For Medicine

The Role Of Cyclic Testing In Enhancing NiTi Tubing Lifespan