How Shape Memory Alloy Tubing Enables Steerable Catheters

Shape memory alloy tubing for steerable catheters plays a crucial role in advancing minimally invasive surgeries. Doctors rely on Nitinol, a unique shape memory alloy tubing for steerable catheters, because of its exceptional flexibility and ability to remember its original shape. This super elastic material allows physicians to navigate catheters through complex pathways within the body. In cardiovascular care, steerable catheters made with shape memory alloy tubing for steerable catheters are widely used. Nitinol guidewires are favored for their ability to bend and return to their shape, enhancing maneuverability. The use of shape memory alloy tubing for steerable catheters revolutionizes how doctors treat patients by providing greater control and safer navigation. This results in improved patient outcomes. Every steerable device incorporates this durable material, making surgeries more efficient and effective. Steerable catheters continue to improve patient care thanks to shape memory alloy tubing for steerable catheters.

Key Takeaways

Shape memory alloy tubing, like Nitinol, helps catheters bend easily. The tubing lets them go back to their first shape. This helps doctors move through small and twisty blood vessels.

Nitinol is safe for the body and very strong. It does not rust, so it is good for medical devices that last a long time, like steerable catheters.

Laser cutting and smart designs help control how the catheter bends. This makes surgeries more accurate and safer for patients.

Steerable catheters with this tubing lower patient risk and help people heal faster. They also work well with MRI scans, so doctors get better pictures during procedures.

Engineers keep making these catheters better by adding sensors and new materials. This will make surgeries safer, quicker, and more exact in the future.

What Are Shape Memory Alloys?

Shape memory alloys are special metals. They can go back to their original shape after being bent or stretched. Scientists and engineers use these metals in many areas. They are used in medicine and robotics. The Journal of Alloys and Compounds says shape memory alloys have superelasticity and the shape memory effect. This happens because of special changes inside the metal. ScienceDirect says these metals change their structure when they get hot or feel stress. That is why they have their special powers.

Nitinol and Its Properties

Nitinol is a shape memory alloy. It is made from almost equal parts nickel and titanium. Doctors and engineers pick nitinol for medical devices. It is strong, flexible, and safe for people. Research shows nitinol is biocompatible. This means it does not hurt living tissue. It also fights corrosion, so it does not rust or break down in the body. These things make nitinol great for implants, stents, and surgical tools. In lab tests, nitinol stayed strong and flexible for months in fluids like those in the body. Its toughness and shape memory help doctors do safer and better procedures.

Note: Nitinol’s special mix of nickel and titanium gives it both strength and flexibility. This makes it perfect for steerable catheters.

Property | Description |

|---|---|

Biocompatibility | Safe for use in the human body |

Corrosion Resistance | Withstands body fluids without rusting |

Durability | Maintains strength over long periods |

Superelasticity | Bends and returns to original shape easily |

Shape Memory and Superelasticity

Shape memory alloys like nitinol have two main powers. They have shape memory and superelasticity. Shape memory means the metal can "remember" its first shape. When it gets hot, it goes back to that shape even if it was bent. Superelasticity lets the metal bend or stretch more than normal metals. It still snaps back to its first shape.

Tests on nitinol show its superelasticity helps absorb energy and lowers wear.

The metal’s structure changes between martensite and austenite phases. This depends on temperature and stress.

Studies show nitinol’s shape memory helps it avoid damage and keep working well, even after many uses.

Researchers found nitinol’s phase changes give it both flexibility and strength. These are important for medical devices.

These things make nitinol a top pick for steerable catheters. They need to move exactly and work every time.

Shape Memory Alloy Tubing for Steerable Catheters

Actuation and Steering Mechanisms

Engineers use shape memory alloy tubing to help catheters move inside the body. The tubing works like a tiny motor. It bends when it gets hot. This lets doctors steer the catheter through narrow or twisty blood vessels.

Scientists found that the tubing can bend at certain spots. This helps make small, careful turns. When the tubing cools down, it goes back to its first shape. This means the movement can be done again and again. Special heating and cooling methods help the tubing bend fast and safely.

When engineers tested these catheters, they saw the tubing could push through soft things like real tissue. They also used new control systems, like temperature and cameras, to help put the catheter tip in the right spot.

Some key facts about actuation and steering with shape memory alloy tubing are:

The tubing bends at joints so the catheter can turn corners.

Special heat treatments help the tubing react better to temperature.

Engineers use new tests to see how the tubing works in different ways.

Control systems help guide the catheter tip very accurately.

The tubing moves through soft, tissue-like stuff in lab tests.

Path planning software helps guide the catheter without moving every part by hand.

Doctors have used these catheters to guide imaging tools, showing they work in real life.

Laser Machining and Design

Laser machining is important for making shape memory alloy tubing for catheters. A laser cuts tiny shapes and lines into the tubing. These shapes help control how the tubing bends and moves.

Designers use computer models to guess how the tubing will act after cutting. They check these guesses with real tests. For example, they look at how hard it is to bend the tubing and how its electrical resistance changes. Even if the models and real tubing are a little different, the main results are close. This means engineers can trust their designs.

Test Type | Simulation Result | Experimental Result | Difference (%) |

|---|---|---|---|

Resistance Change (ΔR/R) | Matches trend | Matches trend | 19-29 |

Stiffness | Matches trend | Matches trend | Up to 14 |

Microscope pictures show the laser can cut very thin lines, almost as planned. Sometimes, the cuts are a bit smaller than expected, but the tubing still works well. Careful design and testing help make sure the tubing bends the right way during surgery.

Multi-Joint and Bidirectional Control

Steerable catheters often need to bend in more than one way. Engineers fix this by putting several bending parts in the catheter tip. Each part has pairs of shape memory alloy wires that pull against each other. This lets the catheter bend left, right, up, or down.

Scientists tested these catheters by bending them many times. The bending angles stayed about the same after a few tries. For example, the tip could bend about 33° one way and 35.5° the other way. They also checked how much the tip twisted when it bent. The average twist was about 11.4° in one direction and 6.7° in the other.

The catheter bends in two ways using pairs of wires.

More bending parts let the tip move in tricky ways.

Fatigue tests show the catheter still works after lots of bends.

Engineers use cameras and markers to see how the tip moves and twists.

The tubing keeps working well, even after many uses.

In the future, new designs may add sensors to give feedback on bending and help stop twisting. These changes will make steerable catheters even better for doctors.

Shape memory alloy tubing helps doctors reach hard places in the body. The tubing can bend, go back to its shape, and last through many uses. This makes it very important for today’s medical tools.

Manufacturing and Engineering

Tubing Fabrication

Manufacturers make shape memory alloy tubing very carefully. They use nickel and titanium metals. These metals are melted together to make an alloy. Workers pull the alloy into thin tubes with special machines. The tubes need smooth surfaces and exact sizes. Engineers look for problems using microscopes and other tools. They also test the tubes for strength and flexibility. Only the best tubes are used in catheters.

Quality checks happen at every step to meet medical rules. This careful work helps doctors trust the tubing in their patients.

Programming Shape and Response

Engineers set the shape memory alloy tubing to bend and return to shape. They use heat to give the metal its "memory." Heating and cooling the tubing locks in the shape. Inside the body, the tubing reacts to heat or electric signals.

Recent studies show new programming can control how tubes move. Researchers use computer models and machine learning to plan bending. They split the tubing into small parts and test each one with software. This helps engineers design tubing that bends just right for surgery. Some designs use smart materials that snap between two shapes with heat or cold. These methods give doctors more control during surgery.

Finite Element Analysis and Quality

Engineers use finite element analysis (FEA) to test tubing. FEA breaks the tubing into tiny parts and checks each one. This helps predict if the tubing will stay strong in the body.

FEA studies on nickel-titanium stents follow strict rules.

Engineers check computer models by comparing them to real tests.

They use mesh sensitivity tests to make sure results are good.

Studies show tubing shape and size matter more than small metal changes.

Special computer parts help avoid mistakes in bending tests.

These careful checks help engineers make tubing that works well and lasts long in medical devices.

Advantages and Applications

Flexibility and Precision

Steerable catheters with shape memory alloy tubing can bend and move very well. Doctors use them to get through twisty blood vessels and reach tough spots. The nickel-titanium alloy gives the catheter its special powers. It lets the device bend and snap back to its first shape. Laser cutting and CNC machining help make catheters with exact shapes and smooth sides. These smooth sides help keep patients safe and lower infection risk.

Performance Metric | Explanation |

|---|---|

Material Composition | The nickel-titanium mix controls shape memory and strength. |

Dimensional Accuracy | Ensures the catheter fits and works as planned. |

Surface Quality | Smooth surfaces make the device safer and more precise. |

Durability | Supports long-term use and flexible performance. |

Mechanical Stress Resistance | Allows repeated bending without losing precision. |

Corrosion Resistance | Keeps the device safe and reliable in the body. |

Studies show steerable catheters work well in hard surgeries. In one animal test, doctors reached the right blood vessel 97% of the time. The design lets doctors turn the tip and put it in the right spot.

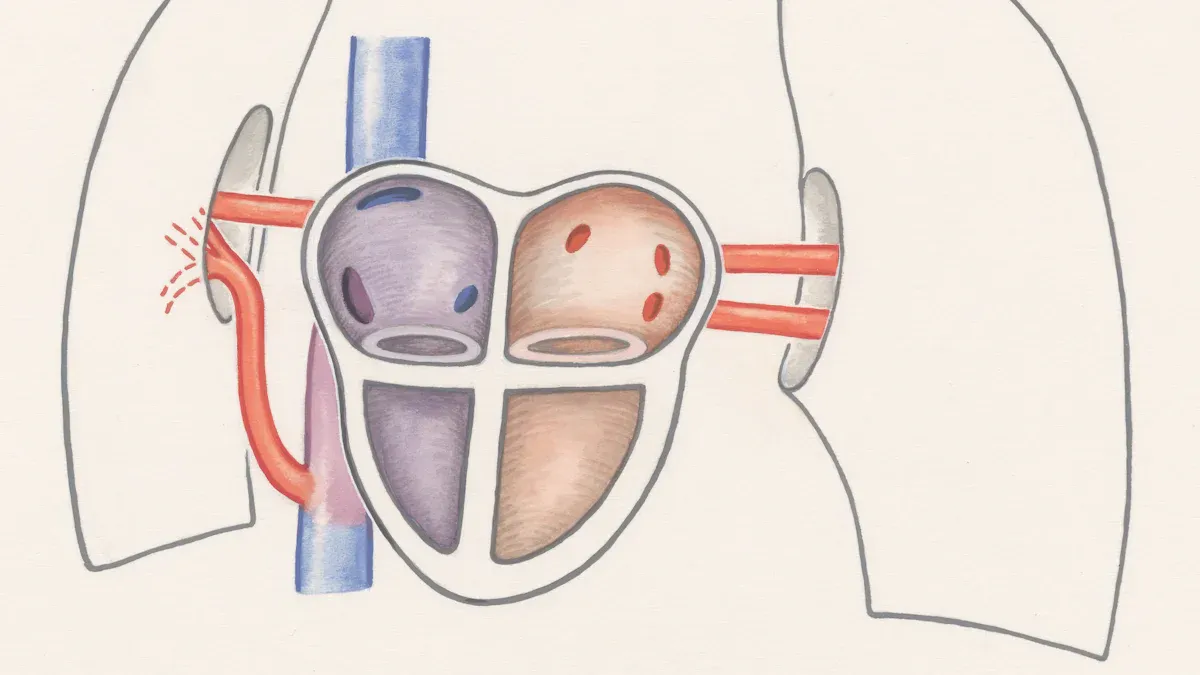

Patient Safety and MRI Compatibility

Patient safety is very important for every medical device. Steerable catheters have fewer moving parts inside the body. Fewer parts mean less chance of breaking or problems. The smooth tubing helps protect blood vessels from harm. Many new catheters use mri-compatible materials. These let doctors use MRI scans during surgery. MRI-compatible catheters do not mess up the pictures. This helps doctors see inside the body while they work. It makes guiding the catheter safer and helps patients get better results.

Tip: MRI-compatible catheter technology lets doctors do surgery without using X-rays.

Reliability and Minimally Invasive Use

Steerable catheters with nitinol tubing are very strong and last a long time. The tubing can bend and twist over and over without breaking. This makes the device great for surgeries with small cuts. Doctors can help patients with less pain and faster healing. The shape memory effect lets the catheter go back to its first shape after each use. Tests and reviews show these catheters work well for many jobs, like fixing blood vessels and heart problems.

Nitinol tubing makes the catheter strong and bendy.

The device does not rust or wear out, even after many uses.

Steerable catheters help doctors reach hard places with less risk.

Patients heal faster and have fewer problems.

Steerable and mri-compatible catheters are used more and more in medicine. They help doctors treat patients safely, quickly, and with more accuracy.

Challenges and Innovations

Technical Limitations

Shape memory alloy tubing helps steerable catheters in many ways, but engineers still have problems to solve. The table below lists some main issues that researchers found:

Technical Challenge | Explanation |

|---|---|

Maneuvering in narrow and complex vessels | It is hard to move through tiny, twisty blood vessels. This makes surgeries take longer and tires doctors. Doctors need better control without moving the whole catheter. |

Nonlinear friction and force loss in cable-driven actuators | Cable-driven systems are used in surgical robots. These systems lose force and have a lot of friction. This makes them work less well. |

Low force and speed output in SMA actuators | SMA actuators do not push very hard or move very fast. This limits how well they can move the catheter. |

Small-scale actuation without sacrificing force | It is tough to make small parts that still push with enough force. Engineers want tiny parts that are still strong. |

Stabilizing catheter tip in dynamic cardiothoracic environment | The heart, lungs, and blood flow move the catheter tip. This makes it hard to keep the tip steady. Some tools like baskets or balloons help, but they can block blood or hurt tissue. |

Lack of haptic feedback | Doctors cannot feel how hard they are pushing. This makes it harder to move the catheter safely. |

Dimensional and geometrical constraints in sensor integration | Sensors are hard to add because of size and shape limits. Some sensors do not fit or work well in catheters. |

Controlling deployment speed and stiffness of mechanisms | Tools like baskets need to open at the right speed and stiffness. This is hard to control, especially with SMA parts that do not change stiffness easily. |

These problems show that SMA tubing is flexible and helpful, but it also brings tough engineering problems. Engineers need to find new ways to fix these issues.

Recent Advances

Scientists and companies are working on new ways to solve these problems. One big step is using special fibers called SMPFs. These fibers let catheters change how stiff they are during surgery. For example, a catheter can be soft while moving and then turn stiff when needed. This helps doctors guide the catheter safely and reach deep places in the body. SMPFs also help the catheter go back to its first shape after bending.

New designs use fibers with more than one channel and different materials. This lets engineers change how the catheter bends and how stiff it is for different jobs, like ear or brain implants. The market for medical tubing is growing as companies make new patents and better ways to build tubing. Strong and bendy tubing helps doctors do less invasive surgeries and helps people at home.

Many of these new ideas make surgeries safer and better for patients.

Future Trends

The future of SMA catheter tubing is about making devices smarter and safer. Engineers want to add sensors that tell doctors what is happening in real time. This will help doctors move the catheter tip more exactly. Scientists are also making new materials that move faster and push harder. The goal is to make catheters that move easily, change stiffness when needed, and give doctors more control.

Smarter sensors that give real-time information

Faster and stronger SMA materials

Better designs for tricky paths in the body

These new trends will help shape memory alloy tubing keep making patient care and surgeries better.

Shape memory alloy tubing is very important for new medical tools. Steerable catheters help doctors move and bend inside the body. These catheters let doctors reach places that are hard to get to. They make it easier to be careful and gentle. The steerable tips help keep patients safe from harm. Scientists keep working on better and smarter steerable designs.

Steerable technology keeps making patient care better and changes how doctors use medical devices.

FAQ

What is shape memory alloy tubing used for in catheters?

Shape memory alloy tubing lets catheters bend and move inside the body. Doctors use it to help guide catheters through blood vessels. The tubing goes back to its shape after bending.

Why do doctors prefer Nitinol for steerable catheters?

Doctors like Nitinol because it is strong and flexible. It bends easily and returns to its shape. This helps doctors control the catheter during surgery.

Are steerable catheters with SMA tubing safe for MRI scans?

Yes, most steerable catheters with SMA tubing work with MRI scans. They do not mess up MRI pictures. This helps doctors see inside the body during procedures.

How long does shape memory alloy tubing last in medical devices?

Shape memory alloy tubing lasts a long time in medical tools. It does not rust or break easily. Tests show it can bend many times and still work. This makes it good for using again and again.

Can shape memory alloy catheters help in different surgeries?

Yes! Doctors use these catheters in heart, brain, and blood vessel surgeries. The tubing is flexible and strong, so it can reach hard places.

Steerable catheters help doctors care for patients in many surgeries.

See Also

Improving Catheter And Implant Function With Nickel-Titanium Tubing

Nitinol Tubing's Impact On Progressing Medical Device Innovation

Discovering How Nitinol Tubing Is Used In Medical Devices

Latest Advances In Etched PTFE For Catheter Production

Understanding The Science Of Nitinol’s Shape Memory Properties