Shape memory alloy tubing for actuators makes movement easy

Shape memory alloy tubing for actuators lets you move things exactly and easily. This smart material bends and goes back to its first shape, even after being pushed hard. Nitinol is a well-known shape memory alloy. It changes fast when the temperature changes. Many actuator systems use this tubing because it fits in tight spots, uses less energy, and works quickly. These things help your systems move well and work better.

Key Takeaways

Shape memory alloy tubing, like nitinol, helps actuators move smoothly and exactly. Nitinol tubing is small and uses little energy. This makes it great for robots and medical tools. The shape memory effect lets nitinol go back to its first shape after bending. This makes it last longer and work well. Nitinol actuators need less care than old systems. This saves time and money as they are used. These actuators can fit many designs and uses. This makes them useful for new technology in the future.

What is shape memory alloy tubing for actuators

Unique properties of shape memory alloys

Shape memory alloy tubing for actuators is used in many modern machines. These tubes are made from shape memory alloys with special features. If you bend or twist them, they go back to their first shape when heated. This happens because the metal changes inside. Nitinol is the most common material for these tubes. Nitinol gives you both shape memory and superelasticity. Superelasticity means the tube can bend or stretch a lot and still return to its shape. This makes nitinol great for jobs that need careful movement.

Let’s check out some key properties of nitinol:

Property | Ni-Ti (Nitinol) |

|---|---|

Shape Memory Effect | Yes |

Super-elasticity | Yes |

Modulus of Elasticity | 40 to 80 GPa |

Transformation Temperature | Varies based on alloy composition |

Strain Return | Up to 8% |

Yield Stress | Relatively high |

Strain at Yield | Over 1% |

Stress Hysteresis | Adjustable through alloying |

Nitinol gives you both strength and flexibility. This helps you move things with accuracy.

Shape memory nitinol tubing in actuator design

Shape memory nitinol tubing is important in actuator design. You use it when you want smooth and controlled movement. Nitinol changes between two crystal phases called austenite and martensite. This change happens fast, so your actuator works quickly. You get strong mechanical strength and good strain resistance. Shape memory nitinol tubing can bend and stretch many times without losing its shape. This means you can count on it to last a long time.

Here is a table that shows how shape memory nitinol tubing compares to other alloys:

Property | Nitinol Tubing | Other Shape Memory Alloys |

|---|---|---|

Crystal Phases | Austenite and Martensite | Varies by alloy |

Phase Transition Speed | Fast, minimal atomic movement | Slower, more significant atomic movement |

Mechanical Strength | High stress and strain resistance | Varies, often lower than nitinol |

Application Suitability | Ideal for robotics and medical devices | General applications, less specialized |

Shape memory nitinol tubing gives you great precision and superelasticity. This is why it is chosen for many actuator systems. You can also make small devices that move very accurately. Shape memory nitinol tubing helps you build smart and dependable machines that do what you want.

How SMA tubing works in actuator systems

Shape memory effect and phase transformation

Shape memory nitinol tubing changes how actuators move. The shape memory effect lets nitinol go back to its first shape after bending. This happens because nitinol has two phases: martensite and austenite. When you heat the tubing, it turns into austenite. When you cool it, it goes back to martensite. This phase change helps you control how the tubing moves and what shape it takes.

Tip: You can train shape memory nitinol tubing by heating and cooling it. This helps the tubing remember a certain shape, which is important for actuator systems.

Shape memory alloys like nitinol need a special training process. You heat and cool the tubing to make a two-way shape memory effect. This means the tubing can remember and return to a set shape every time the temperature changes. The heat treatment changes detwinned martensite into twinned martensite. This step lets the tubing remember a hot shape, which is important for actuators.

Shape memory alloys switch between martensite and austenite phases.

You use heating and cooling to train the tubing for a two-way shape memory effect.

The heat treatment changes the inside structure, helping the tubing remember its shape.

The shape memory effect lets the tubing return to its first shape when heated.

You can use different alloys, like nitinol or copper-based, for special places.

Shape memory nitinol tubing gives you accuracy and superelasticity. You can use it in actuator systems that need exact and repeatable movement. The shape memory effect makes nitinol tubing great for jobs where you want smooth and steady motion.

Rotary and torque actuator mechanisms

Shape memory nitinol tubing helps you make rotary and torque actuators with high accuracy. The shape memory effect lets the tubing twist or turn when you heat it. You can design actuator systems that use this twisting for many jobs. NASA uses shape memory nitinol tubing to make rotary motion in space devices. You get strong movement in a small size.

Let’s compare the torque output and design features of rotary SMA actuators and traditional electric actuators:

Actuator Type | Torque Output Characteristics | Design Features |

|---|---|---|

Rotary SMA Actuator | Achieves similar power output to larger actuators | Compact design, higher power density |

Traditional Electric Actuator | Requires larger footprints and mass for same output | Bulkier design, less power density |

Shape memory nitinol tubing gives you more power in a smaller space. You can use it for actuator systems where size and weight are important.

You can also look at the efficiency and response time of different actuator mechanisms using shape memory nitinol tubing:

Actuator Type | Maximum Actuating Torque | Maximum Actuating Twist Angle |

|---|---|---|

SMA Plate | 4 × 10−3 N·m | 180° |

Novel SMA Tube | 1400 N·m | 25° |

Wire-based Actuators | Smaller Torque | Larger Twist Angle |

Cylindrical Actuators | Larger Torque | Smaller Twist Angle |

Shape memory nitinol tubing gives you high torque and accuracy. You can pick the right design for your needs. If you need more twist, wire-based actuators are good. If you want more torque, novel SMA tubes work better.

Shape memory nitinol tubing also gives you superelasticity. You can bend and stretch the tubing many times and it will not lose its shape. This makes your actuator systems last longer and work better. You get smooth motion, quick response, and steady control. Shape memory nitinol tubing helps you get accuracy in every movement.

Benefits of shape memory alloy tubing

Precision and smooth motion

You want your machines to move in a careful way. Shape memory nitinol tubing helps you control movement. When you use nitinol, you get the same motion every time. The shape memory effect lets the tubing go back to its first shape when heated. This means you can trust it to move the same way again and again. The tubing bends and straightens without any sudden stops or jerks, so your actuator works smoothly.

Nitinol’s superelasticity helps you get smooth motion. You can bend the tubing many times, and it always snaps back to its trained shape. This makes your actuator systems work well and last longer. You do not have to worry about the tubing losing its shape. Shape memory nitinol tubing also gives you high accuracy. You can make small changes and get the exact movement you want. Other materials cannot match this level of precision.

Note: Shape memory nitinol tubing uses the shape memory effect for both careful and smooth movement. You get steady and repeatable results every time.

Compactness and energy efficiency

Shape memory nitinol tubing is special because it is thin and light. You can build actuator systems that are much smaller and lighter than those with regular parts. Here are some ways shape memory nitinol tubing helps you save space and weight:

Nitinol actuators are very thin and light.

You can get the same power as regular actuators that are 2-5 times bigger.

The tubing fits into small spaces, so your systems are more compact.

You do not have to give up power for a smaller size. Shape memory nitinol tubing gives you strong movement in a small size. This makes it great for robots, medical devices, and other places where space is important.

Shape memory nitinol tubing also helps you save energy. The SMART brake, which uses shape memory alloy technology, shows how you can use less energy. This brake changes friction to match what you need. It can go from low friction for easy movement to high friction for strong stopping. The brake holds a lot of force but weighs only 0.3 grams. This means you use less energy to get the same or better results. You can run your actuator longer and use less power.

Fluidic cooling and multifunctionality

Shape memory nitinol tubing does more than just move. You can use the tubing for cooling too. Some designs let you run fluids through the tubing. This helps keep your actuator cool while it works. You do not need extra cooling systems. The tubing can move and cool at the same time.

You also get more uses with shape memory nitinol tubing. The tubing can bend, twist, and go back to its shape because of the shape memory effect. You can use it in many ways. For example, you can make actuators that twist or pull. You can also use the tubing in places where you need both movement and cooling.

Here are some main advantages of shape memory nitinol tubing:

Advantage | How It Helps You |

|---|---|

Simplicity | Fewer moving parts, easy to design |

Reliability | Lasts longer, needs less maintenance |

Cooling Integration | Can carry fluids for cooling |

Precision | Gives you exact, repeatable movement |

Superelasticity | Bends and returns to shape many times |

Compactness | Fits in small spaces, reduces weight |

Energy Efficiency | Uses less power, runs longer |

Shape memory nitinol tubing makes movement easier in actuator systems. You get simple, reliable, and efficient solutions. The tubing’s shape memory effect, superelasticity, and precision help you build better machines. You can trust your systems to work smoothly and last longer.

Applications of SMA tubing actuators

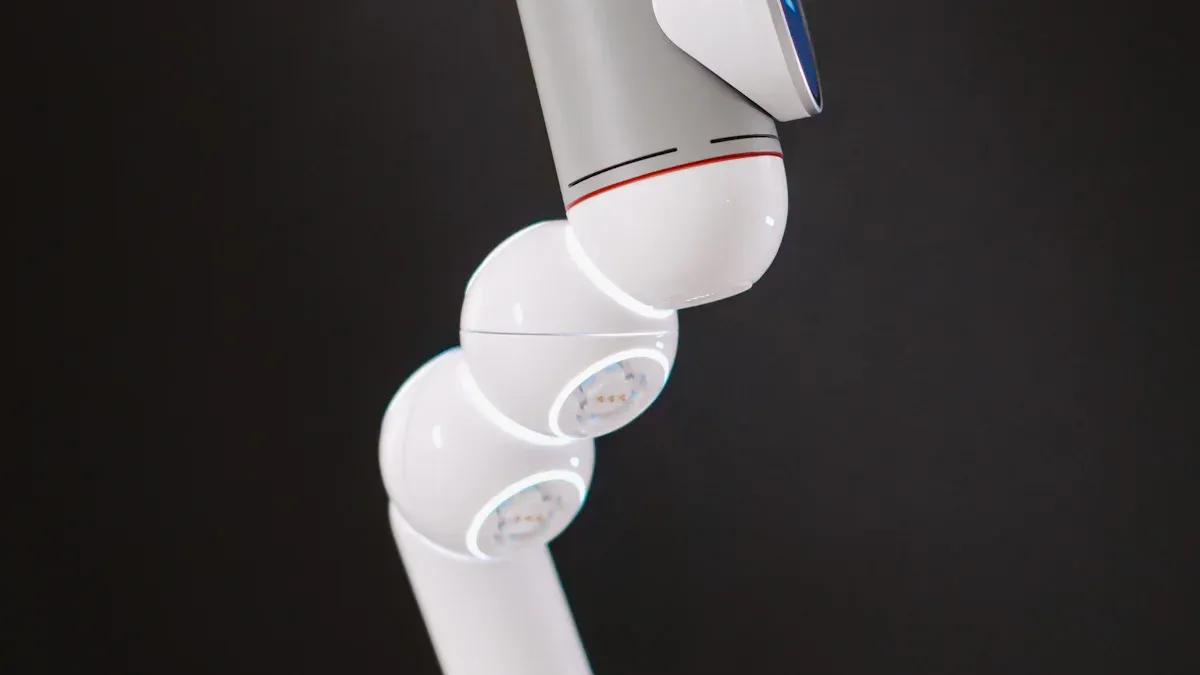

Robotics and intelligent devices

Nitinol is changing how robots and smart devices move. When you use shape memory alloy tubing, robots can grip, twist, and bend easily. Nitinol wires work like muscles in robots. They help soft grippers pick up heavy things. These grippers can be as strong as ones that use air. Nitinol is also used in origami robots. These robots fold and unfold with nitinol wires that twist. This lets you make new shapes and designs.

Here is a table that shows how nitinol helps different robots:

Application Type | Description |

|---|---|

Soft Robotic Actuators | Nitinol wires act as tendons, letting grippers lift heavier items. |

Soft Grippers | Nitinol tubing actuators make grippers work as well as air-powered systems. |

Origami-based Structures | Nitinol wires with twists help robots fold and change shape. |

Medical Tools | Nitinol tubing lets you design tools that move with great precision. |

Nitinol is used in devices that help people move their arms or hands. These devices use nitinol for smooth and natural motion. They also use less energy, so they last longer.

Medical and aerospace uses

Nitinol is important in medicine and aerospace. In medicine, nitinol is used in self-expanding stents. These stents open blocked blood vessels. They help make surgeries better and faster. Nitinol is also used in orthodontic wires and implants that break down in the body. These tools are flexible and precise. They help doctors do surgeries with smaller cuts and help people heal faster.

In aerospace, nitinol helps make lighter and smarter parts. Nitinol is used in wings and control surfaces that change shape during flight. This helps planes fly better and use less fuel. Nitinol is also used in engine parts. It works well in high heat and under stress.

Here is a table that shows how nitinol changes medical and aerospace designs:

Sector | Application | Impact on Design |

|---|---|---|

Medical | Self-expanding stents | Better surgery results and shorter operation times |

Aerospace | Adaptive wing structures | Improved flight performance and fuel savings |

Aerospace | Control surfaces | Lighter parts and better aerodynamics |

Aerospace | Aircraft engine components | Reliable in changing temperatures |

Medical | Orthodontic wires | Flexible and precise for dental care |

Medical | Biodegradable implants | Good for surgeries with small cuts |

Nitinol helps actuator systems work in hard places. It gives strong, flexible, and reliable movement in medical and aerospace devices.

Implementation and comparison with other actuators

Installation and control considerations

When you put nitinol tubing in your system, it is easy. The tubing bends and fits into small spaces. You do not need lots of extra parts. The tubing moves when you heat it or use electric current. This makes it easier to set up than big motors.

You have different ways to control the tubing. You can use simple ON/OFF switches or more advanced systems. Some systems use basic switching or pulse-width modulation. If you want better control, you can use active control methods. These include PID or fuzzy-PID controllers. Real-time monitoring lets you change the current for the movement you want. The table below shows some common control strategies:

Control Strategy | Description |

|---|---|

Simple Control Strategy | Changes nitinol temperature fast, no complex model needed |

Real-time Monitoring | Adjusts input current based on movement |

Active Control | Uses feedback for exact actuation, like PID or fuzzy-PID |

Tip: Pick your control method based on how much accuracy you need.

Maintenance and operational factors

Nitinol tubing actuators need less care than regular systems. They have only one moving part, so there is less to break. You do not need to oil them or change gears. Regular actuators have more parts that can wear out.

Nitinol tubing lasts a long time because it bends and goes back to shape. You can trust it to work with little attention. This saves you time and money over the life of your machine.

SMA tubing vs traditional actuators

When you look at nitinol tubing actuators and regular ones, you see big differences. Nitinol actuators move smoothly and the motion repeats with high accuracy. There is no backlash, so you get better control. The strong connection in nitinol systems makes them respond fast and keeps them safe.

Here is a table to help you compare:

Feature | Traditional Actuators | Nitinol Tubing Actuators |

|---|---|---|

Backlash | Can lower accuracy | Very little, gives better accuracy |

Maintenance | Needs regular care and oil | Needs little maintenance |

Size and Weight | Often big and heavy | Small and light |

Energy Density | Changes | High |

Stroke Capabilities | Often higher | Limited |

Brittleness | More tough | Can break if stressed |

Applications | Used in many places | Best for soft robotics, sensing, actuation |

Nitinol tubing actuators are best when you need small size, light weight, and exact movement. They move with heat, not motors or hydraulics. You get high energy density and smooth motion, but the stroke length can be short. Nitinol actuators can act like muscles and fit into smart machines. You can count on them for strong control and accuracy in many advanced uses.

Shape memory alloy tubing for actuators helps you build machines that move exactly and work well. You can use these actuators in many areas, like robots and healthcare.

They can take a lot of force and bend a lot, but still stay light and strong.

You can make them in different shapes and sizes for many kinds of movement.

More people want small and energy-saving machines, so the market is getting bigger.

Property | How It Helps Actuators |

|---|---|

High Power Density | Makes devices smaller and more efficient |

Versatility in Design | Fits many movement needs |

Adaptability | Works in many types of machines |

You can count on shape memory alloy tubing for actuators to help you make smart and energy-saving machines for the future.

FAQ

What is shape memory alloy tubing used for?

Shape memory alloy tubing helps devices move in a careful way. It is used in robots, medical tools, and airplane parts. The tubing bends and goes back to its shape when it gets hot.

How do you control the movement of SMA tubing?

You change the tubing’s movement by making it hotter or cooler. You can use electricity or warm air to heat it up. When it cools down, it goes back to how it started.

Can SMA tubing replace traditional actuators?

Yes, SMA tubing can work as an actuator in many machines. It gives smooth and steady movement in a small space. It uses less energy and needs less care than normal motors.

How long does shape memory alloy tubing last?

Shape memory alloy tubing can last for thousands of uses. You can bend and stretch it many times and it keeps its shape. Checking it often helps it work well for a long time.

See Also

Innovations in Laser-Cut Hypotube Tech Expected by 2025

Understanding Nitinol's Unique Shape Memory and Superelastic Properties

Comprehensive Guide to Selecting Ideal Nitinol Tubing Options

Why NiTi Tubes Are Revolutionary for Medical and Aerospace Fields

The Influence of Cyclic Life Testing on NiTi Tubing Durability