Comprehensive Guide to Selecting Ultra-Fine Nitinol Tubing for Surgery

Selecting ultra-fine nitinol tubing for precision surgery is a critical decision that directly influences both patient outcomes and the reliability of surgical devices. Its unique properties make it indispensable in advanced medical procedures. For instance, nitinol's superelasticity enables stents to regain their original shape after deformation, which is vital for navigating intricate vascular pathways. Additionally, its biocompatibility ensures smooth integration with human tissue, significantly reducing the risk of complications.

The flexibility of ultra-fine nitinol tubing for precision surgery allows guidewires to adapt seamlessly to blood vessel contours, minimizing procedural risks. Clinical studies highlight its role in improving success rates, particularly in cardiovascular treatments. Devices made from nitinol, such as self-expanding stents, provide long-term solutions by maintaining vessel patency and delivering medications effectively. Furthermore, its fatigue resistance ensures durability, even under repeated stress cycles, making it a reliable choice for intricate surgical applications.

By carefully selecting ultra-fine nitinol tubing for precision surgery, medical professionals can enhance procedural efficiency while offering patients faster recovery times and reduced hospital stays. This underscores the importance of aligning tubing characteristics with specific surgical needs to achieve optimal results.

Key Takeaways

Choosing very thin nitinol tubing improves surgery accuracy and results. Its special features, like flexibility, help tools fit the body better.

Knowing what the surgery needs is very important. Check the environment and physical demands to make sure the tubing works well.

Following medical rules is a must. Pick nitinol tubing that has certifications like ISO 13485 for safety and trustworthiness.

Talking to skilled suppliers gives helpful advice. Their knowledge helps pick the right material and follow the rules.

Focus on quality instead of cost when buying tubing. Good nitinol works better and lowers the chance of tool problems.

Understanding Application Needs for Ultra-Fine Nitinol Tubing

Environmental Conditions and Operating Environments

Ultra-fine nitinol tubing must perform reliably under diverse environmental conditions encountered during surgical procedures. These conditions include exposure to varying temperatures, pressures, and bodily fluids. Nitinol's unique properties, such as superelasticity and shape memory, allow it to adapt to these challenges. For instance, in cardiovascular surgeries, nitinol tubing must withstand the dynamic forces within blood vessels while maintaining its structural integrity.

Manufacturing processes play a critical role in ensuring the tubing's durability in such environments. A study comparing two manufacturing techniques, TM-1 and TM-2, revealed that TM-1 significantly enhances the fatigue life of nitinol tubing. TM-1 demonstrated a fatigue life two to three times greater than TM-2 at 10^7 cycles. This highlights the importance of selecting tubing manufactured using advanced techniques to ensure optimal performance in high-stress surgical applications.

Additionally, environmental sustainability and traceability are increasingly emphasized in the medical industry. The EU Medical Device Regulation (MDR) mandates strict compliance with these factors, ensuring that nitinol tubing meets both performance and ethical standards.

Physical Requirements, Including Dimensions and Tolerances

Precision is paramount when selecting nitinol tubing for medical applications. The tubing's dimensions and tolerances must align with the specific requirements of the surgical device. For example, guidewires and stents require ultra-fine tubing with exacting tolerances to ensure seamless integration and functionality.

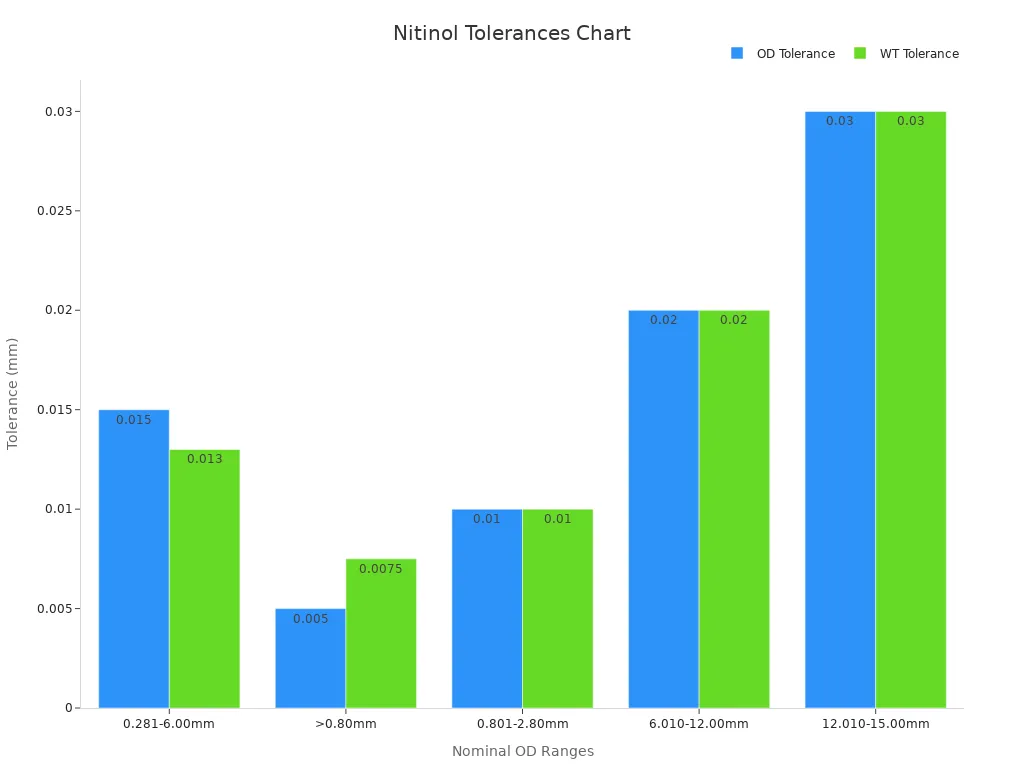

The following table outlines the numerical tolerance measurements for nitinol tubing, which validate its suitability for medical devices:

Nominal OD | OD Tolerances | Wall Thickness | WT Tolerances |

|---|---|---|---|

> 0.80mm | ±0.005mm | 0.05–0.12mm | ±0.0075mm |

0.801-2.80mm | ±0.010mm | 0.13–0.26mm | ±0.010mm |

0.281-6.00mm | ±0.015mm | 0.27–0.40mm | ±0.013mm |

6.010-12.00mm | ±0.020mm | 0.41–0.60mm | ±0.020mm |

12.010-15.00mm | ±0.030mm | 0.61–1.00mm | ±0.030mm |

These precise measurements ensure that nitinol tubing meets the stringent demands of surgical applications. For instance, tubing with a nominal outer diameter (OD) greater than 0.80mm must maintain an OD tolerance of ±0.005mm to ensure compatibility with medical devices. Such precision minimizes the risk of device failure and enhances overall performance.

Compliance with Medical and Industry Standards

Compliance with medical-grade certifications and industry standards is essential when selecting nitinol tubing for surgical applications. Regulatory bodies, such as ISO and the EU, establish stringent guidelines to ensure the safety and efficacy of medical devices. Nitinol tubing must adhere to these standards to guarantee its biocompatibility and reliability.

The following table highlights key compliance metrics for nitinol tubing:

Compliance Metrics | Details |

|---|---|

Temperature | Monitored during manufacturing processes to ensure safety and efficacy. |

Pressure | Assessed to validate material integrity under operational conditions. |

Time | Duration of exposure during testing phases to meet standards. |

Material Composition | Specific alloy ratios to ensure biocompatibility. |

Equipment Settings | Parameters used during manufacturing to maintain quality. |

Environmental Conditions | Conditions under which testing is conducted to simulate real-world use. |

In addition to these metrics, nitinol tubing must comply with certifications such as ISO 9001:2015, ISO 13485:2016, and EU CE marking. These certifications validate the tubing's quality and adherence to industry standards. For example, ISO 10993 testing ensures that nitinol tubing minimizes adverse biological reactions, such as cytotoxicity or irritation, making it suitable for medical applications.

Manufacturers must also consider enforcement statistics when sourcing nitinol tubing. German manufacturers, for instance, produce precision-drawn tubes with burst pressure thresholds exceeding 400 bar, demonstrating high compliance with industry standards. In contrast, 30% of needles from Eastern European markets fail to meet ISO 9626:2016 compliance, underscoring the importance of selecting reputable suppliers.

By ensuring compliance with these standards, medical professionals can trust that nitinol tubing will deliver consistent performance and safety in surgical applications.

Key Properties of Nitinol Tubing for Precision Surgery

Shape Memory and Superelasticity

Nitinol tubing exhibits two remarkable properties: the shape memory effect and superelasticity. These characteristics make it indispensable in precision surgery. The shape memory effect allows nitinol to return to its original form after deformation when exposed to a specific temperature. This property is particularly useful in devices like self-expanding stents, which adapt to the body's internal environment. Superelasticity, on the other hand, enables nitinol to endure significant strain without permanent deformation, ensuring safety during complex procedures.

Clinical tests confirm the reliability of these properties. For instance, cyclic life testing evaluates how nitinol tubing withstands repeated mechanical stress, while fatigue crack initiation studies identify areas prone to fractures. The results emphasize the importance of wall thickness, surface finish, and material composition in enhancing performance under cyclic loads. These findings underscore nitinol's ability to maintain its structural integrity, even under challenging conditions.

Biocompatibility and Corrosion Resistance

Biocompatibility is a critical factor in selecting nitinol tubing for surgical applications. Testing for biocompatibility ensures that the material integrates seamlessly with human tissue, minimizing adverse reactions. Nitinol's thin surface film provides excellent corrosion resistance, protecting it from active dissolution in bodily fluids. In vitro studies using simulated body fluids demonstrated corrosion potential values of -20.313 V/SCE in artificial saliva, -20.334 V/SCE in artificial urine, and -20.239 V/SCE in Ringer's solution. These results highlight nitinol's suitability for implantable devices.

Advanced surface treatments, such as magnetoelectropolishing, further enhance corrosion resistance compared to standard methods. This improvement not only boosts biocompatibility but also ensures long-term safety and durability in medical applications. By resisting corrosion under mechanical loads and fatigue, nitinol tubing provides reliable performance in demanding surgical environments.

Durability and Fatigue Resistance

Durability is essential for surgical devices subjected to repetitive stress. Nitinol tubing excels in this regard due to its exceptional fatigue resistance. High-purity nitinol grades, produced using optimized melting practices, exhibit superior fatigue life by reducing non-metallic inclusions. For example, process-optimized nitinol demonstrates enhanced performance under high-cycle fatigue conditions, making it ideal for long-term use.

The following table highlights the impact of nitinol grades on fatigue resistance:

Nitinol Grade | Description | Impact on Fatigue Life |

|---|---|---|

Standard Grade | Traditional melting practices with nominal purity | Lower fatigue resistance |

High Purity (HP) | Ultra-high-purity raw materials | Improved fatigue resistance |

Process Optimized (PO) | Melting practices to reduce non-metallic inclusions | Enhanced fatigue life |

High-Cycle Fatigue (HCF) | Exceptionally clean Nitinol (not tested) | Expected to have superior fatigue resistance |

By selecting the appropriate grade, medical professionals can ensure the safety and durability of nitinol tubing in surgical applications. This reliability translates to better patient outcomes and reduced device failure rates.

Types of Nitinol Tubing for Medical Applications

Seamless vs. Welded Tubing

Seamless and welded nitinol tubing serve distinct purposes in medical device equipment. Seamless tubing is manufactured without joints, ensuring uniformity and superior structural integrity. This makes it ideal for critical applications such as stents and catheters, where reliability is paramount. Welded tubing, on the other hand, is created by joining edges of nitinol sheets, offering a cost-effective solution for less demanding uses.

The following table highlights the differences between these two types of tubing:

Type of Tube | Applications | Performance Characteristics |

|---|---|---|

Seamless Tubes | Medical devices, aerospace components | High performance, reliability, critical applications |

Welded Tubes | Automotive, heat exchangers | Cost-effective, suitable for less demanding uses |

Medical professionals often prefer seamless tubing for its ability to withstand high-stress environments. However, welded tubing remains a viable option for applications where cost efficiency outweighs the need for extreme durability.

Thin-Walled vs. Thick-Walled Tubing

The choice between thin-walled and thick-walled nitinol tubing depends on the specific requirements of the medical device. Thin-walled tubing offers greater flexibility, making it suitable for minimally invasive devices like neurovascular stents. Its reduced thickness allows for easier navigation through complex anatomical pathways. Conversely, thick-walled tubing provides enhanced durability and mechanical strength, making it ideal for load-bearing implants.

Key structural performance characteristics include:

Thin-walled tubing facilitates flexibility and precision, essential for intricate procedures.

Thick-walled tubing ensures long-term reliability in applications requiring higher mechanical support.

Selecting the appropriate wall thickness ensures that the tubing meets the functional demands of the device while maintaining patient safety.

Custom vs. Standard Tubing Options

Custom nitinol tubing offers tailored solutions for unique medical applications. Manufacturers can adjust dimensions, tolerances, and material properties to meet specific requirements. For example, custom tubing is often used in cardiovascular devices where precision and fatigue resistance are critical. Standard tubing, while less flexible in design, provides a cost-effective option for general applications.

Studies comparing manufacturing techniques, such as TM-1 and TM-2, reveal that custom tubing often outperforms standard options in fatigue life. High-purity grades of nitinol wire used in custom designs further enhance performance, particularly in demanding surgical environments. Customization also allows for the integration of advanced features, such as optimized surface finishes, which improve biocompatibility and corrosion resistance.

By choosing custom nitinol tubing, medical professionals can ensure that their devices meet the highest standards of performance and safety.

Step-by-Step Selection Guide for Nitinol Tubing

Assessing Application-Specific Needs

Selecting the right nitinol tubing begins with a thorough understanding of the application’s unique requirements. Each surgical device demands specific performance characteristics, which depend on the operating environment, physical constraints, and compliance with medical standards. For instance, cardiovascular implants require tubing that can endure dynamic forces while maintaining biocompatibility.

To determine application-specific needs, professionals often rely on precise assessment metrics. The table below highlights examples of these metrics and their relevance to medical applications:

Evidence Description | Assessment Metric | Application Context |

|---|---|---|

Novel method for shape setting nitinol wires using sacrificial fixtures | Elastic strain stored in copper to predict dimensional variation | Rapid prototyping of patient-specific medical implants |

Fabrication of NiTi wire frames for septal defect occluders | Change of less than 5% in diameter | Designed based on patient’s cardiac image data |

These metrics emphasize the importance of tailoring nitinol tubing to the specific demands of each device. For example, septal defect occluders require tubing with minimal dimensional variation to ensure precise deployment. AccuPath, a leader in nitinol tubing manufacturing, offers customized solutions that align with these stringent requirements, ensuring optimal performance in critical applications.

Evaluating Material Properties for Your Use Case

The next step involves evaluating the material properties of nitinol to ensure it meets the demands of the intended application. Nitinol’s unique characteristics, such as shape memory, superelasticity, and biocompatibility, make it ideal for precision surgery. However, these properties must be rigorously tested to confirm their suitability.

Experimental evaluations provide valuable insights into nitinol’s performance. The table below summarizes key findings from recent studies:

Evidence Type | Description |

|---|---|

Tissue Reactions | Minimal tissue reactions post-implantation, with scores ranging from 0 to 1 for all histological evaluation indices. |

Intraocular Pressure Reduction | Achieved a sustained 30% reduction in intraocular pressure (IOP) from baseline levels over six months. |

Histological Findings | No significant inflammatory responses observed; no polymorphonuclear leukocytes, plasma cells, or necrosis in any of the examined eyes. |

These results highlight nitinol’s exceptional biocompatibility and durability, making it a reliable choice for implantable devices. For example, its ability to reduce intraocular pressure demonstrates its effectiveness in ophthalmic applications. AccuPath ensures that all nitinol tubing undergoes rigorous testing to meet these high standards, providing medical professionals with confidence in their device performance.

Choosing the Right Tubing Type for Your Application

Picking the right tubing type is crucial for achieving the desired performance in surgical devices. The choice between seamless and welded tubing, as well as thin-walled and thick-walled options, depends on the specific application requirements. Seamless tubing offers superior structural integrity, making it ideal for critical applications like stents and catheters. Welded tubing, while more cost-effective, suits less demanding uses.

Wall thickness also plays a significant role in tubing selection. Thin-walled tubing provides flexibility and precision, essential for minimally invasive procedures. Thick-walled tubing, on the other hand, offers enhanced durability and mechanical strength, making it suitable for load-bearing implants.

A step-by-step selection guide can simplify the decision-making process:

Understand Your Application Needs: Consider environmental and physical conditions, compliance rules, and the specific requirements of your application.

Check Material Features: Test for shape memory, flexibility, and ensure safety and durability through various tests.

Pick the Best Tubing Type: Decide between seamless and welded tubing based on strength and application needs, and match wall thickness to the job requirements.

Consult with Experts: Engage with manufacturers for tailored advice and custom solutions.

Try Samples for Testing: Request samples to evaluate performance in real situations, ensuring they meet your project’s specifications.

AccuPath excels in guiding medical professionals through this process. Their expertise in manufacturing high-quality nitinol tubing ensures that clients receive tailored solutions that meet the most demanding surgical requirements. By partnering with trusted suppliers like AccuPath, professionals can confidently select tubing that enhances device performance and patient outcomes.

Consulting with experts and suppliers

Selecting the right nitinol tubing for surgical applications often requires collaboration with industry experts and trusted suppliers. Their specialized knowledge and experience can help medical professionals navigate the complexities of material selection, ensuring the tubing meets both performance and regulatory requirements.

Why Consult Experts?

Experts in nitinol manufacturing possess a deep understanding of the material's unique properties, such as shape memory and superelasticity. They can provide insights into how these characteristics align with specific surgical applications. For instance, an expert might recommend a particular grade of nitinol for devices requiring high fatigue resistance or suggest advanced surface treatments to enhance biocompatibility.

Additionally, experts can assist in interpreting technical specifications, such as tolerances and wall thicknesses, which are critical for device performance. Their guidance ensures that the selected tubing not only meets design requirements but also performs reliably under real-world conditions.

Benefits of Partnering with Reliable Suppliers

Working with reputable suppliers offers several advantages. First, established suppliers often have access to high-quality nitinol materials that comply with medical-grade certifications, such as ISO 13485. This ensures that the tubing meets stringent safety and efficacy standards.

Second, reliable suppliers typically offer customization options. They can produce nitinol tubing tailored to specific dimensions, tolerances, and mechanical properties. This level of customization is particularly valuable for innovative medical devices that require unique designs.

Finally, trusted suppliers provide consistent quality and traceability. They maintain rigorous quality control processes, ensuring that each batch of tubing meets the required specifications. Traceability also allows medical professionals to verify the origin and manufacturing history of the nitinol, which is essential for regulatory compliance.

Steps to Engage with Experts and Suppliers

Identify Reputable Suppliers: Research suppliers with a proven track record in nitinol manufacturing. Look for certifications, client testimonials, and case studies that demonstrate their expertise.

Request Technical Support: Engage with the supplier's technical team to discuss your application needs. Provide detailed information about the operating environment, physical requirements, and compliance standards.

Evaluate Customization Capabilities: Inquire about the supplier's ability to produce custom nitinol tubing. Ask about their manufacturing techniques, such as seamless or welded tubing production, and their capacity to meet specific tolerances.

Review Samples and Prototypes: Request samples or prototypes to evaluate the tubing's performance. Conduct tests to ensure it meets the desired specifications and performs reliably in simulated surgical conditions.

Establish Long-Term Partnerships: Build a collaborative relationship with the supplier. Regular communication and feedback can help refine the tubing design and improve future iterations.

Pro Tip: Leverage Industry Events and Networks

Attending industry conferences and trade shows can provide opportunities to connect with leading nitinol manufacturers and suppliers. These events often feature presentations on the latest advancements in nitinol technology, offering valuable insights for medical professionals.

By consulting with experts and partnering with reliable suppliers, medical professionals can ensure that their nitinol tubing selections align with the highest standards of quality and performance. This collaborative approach not only enhances device reliability but also contributes to better patient outcomes.

Common Mistakes to Avoid When Selecting Nitinol Tubing

Ignoring Specific Application Requirements

One of the most common mistakes to avoid is neglecting the specific requirements of the intended application. Each surgical device has unique demands, such as precise dimensions, tolerances, and material properties. For example, cardiovascular stents require nitinol tubing with exceptional flexibility and fatigue resistance to navigate complex vascular pathways. Ignoring these needs can lead to device failure, compromising patient safety and surgical outcomes.

Medical professionals should conduct a thorough assessment of the operating environment and physical constraints before selecting tubing. Collaborating with experienced manufacturers like AccuPath ensures that the tubing aligns with the device's functional requirements. AccuPath specializes in tailoring nitinol tubing to meet the stringent demands of advanced medical applications, providing reliable solutions for critical procedures.

Overlooking Compliance and Regulatory Standards

Overlooking compliance with medical and industry standards can have severe consequences. Regulatory bodies, such as ISO and the FDA, establish strict guidelines to ensure the safety and efficacy of medical devices. Non-compliance can result in:

Device recalls, disrupting surgical procedures and patient care.

Legal penalties, increasing financial burdens for manufacturers.

Compromised patient safety, leading to adverse health outcomes.

Limited marketability, restricting sales in regions with stringent regulations.

Reduced profitability due to restricted market access.

AccuPath ensures that all nitinol tubing meets or exceeds regulatory standards, including ISO 13485 certification. Their commitment to quality and compliance guarantees that medical professionals receive tubing that performs reliably while adhering to global safety guidelines.

Choosing Tubing Based Solely on Price

Selecting nitinol tubing based solely on price is a short-sighted approach that can lead to long-term issues. Low-cost options often compromise on quality, resulting in tubing with inferior material properties, inconsistent tolerances, or inadequate durability. These shortcomings increase the risk of device failure, which can harm patients and damage a manufacturer's reputation.

Investing in high-quality tubing from reputable suppliers like AccuPath ensures superior performance and reliability. AccuPath offers a range of customizable solutions, allowing medical professionals to balance cost-effectiveness with the highest standards of quality. By prioritizing value over price, professionals can enhance surgical outcomes and ensure patient safety.

Failing to consult with experienced suppliers

Failing to consult with experienced suppliers often leads to suboptimal outcomes when selecting nitinol tubing for surgical applications. Suppliers with expertise in nitinol manufacturing possess the technical knowledge required to ensure the tubing meets stringent medical standards. Without their guidance, medical professionals risk selecting tubing that fails to perform as intended.

Experienced suppliers understand the complexities of nitinol's unique properties, such as shape memory and superelasticity. They can recommend specific grades and manufacturing techniques tailored to the application. For instance, a supplier might suggest seamless nitinol tubing for cardiovascular stents due to its superior structural integrity. Without this insight, professionals may choose tubing that lacks the necessary durability or flexibility.

Another risk of bypassing expert consultation involves regulatory compliance. Nitinol tubing must adhere to strict certifications, including ISO 13485 and FDA guidelines. Suppliers with a proven track record ensure that their products meet these requirements. In contrast, sourcing from inexperienced manufacturers increases the likelihood of non-compliance, which can result in device recalls or legal penalties.

To avoid these pitfalls, medical professionals should prioritize collaboration with reputable suppliers. They should evaluate the supplier's certifications, request technical support, and review product samples. Engaging in open communication allows professionals to address specific concerns, such as wall thickness tolerances or biocompatibility. Additionally, attending industry events can help establish connections with leading nitinol manufacturers.

Consulting with experienced suppliers not only ensures the quality and reliability of nitinol tubing but also enhances patient safety. By leveraging their expertise, medical professionals can make informed decisions that align with both clinical and regulatory requirements.

Selecting the right ultra-fine nitinol tubing is crucial for achieving precision in surgical applications. Its unique properties, such as shape memory and durability, make it indispensable for medical devices. Balancing application-specific needs with material characteristics ensures optimal performance and patient safety. Consulting with trusted suppliers provides access to tailored solutions that meet stringent medical standards.

Professionals should prioritize quality and expertise when sourcing tubing to enhance surgical outcomes and device reliability.

By making informed decisions, medical teams can improve procedural efficiency and deliver better care to patients.

FAQ

What makes nitinol tubing ideal for surgical applications?

Nitinol tubing offers unique properties like shape memory, superelasticity, and biocompatibility. These features allow it to adapt to the human body, endure stress, and resist corrosion. Its durability ensures reliable performance in demanding surgical environments.

How does wall thickness affect nitinol tubing performance?

Wall thickness determines flexibility and strength. Thin-walled tubing provides precision and adaptability for minimally invasive procedures. Thick-walled tubing offers enhanced durability, making it suitable for load-bearing implants or devices requiring mechanical support.

Can nitinol tubing be customized for specific medical devices?

Yes, manufacturers can customize nitinol tubing to meet precise dimensions, tolerances, and material properties. Customization ensures compatibility with unique device designs, improving performance and patient outcomes.

What certifications should nitinol tubing meet for medical use?

Nitinol tubing must comply with ISO 13485, ISO 10993, and FDA standards. These certifications ensure safety, biocompatibility, and reliability, making the tubing suitable for surgical applications.

Why is consulting with experts important when selecting nitinol tubing?

Experts provide insights into material properties, manufacturing techniques, and regulatory compliance. Their guidance ensures the tubing meets application-specific needs, enhancing device reliability and patient safety.

See Also

A Comprehensive Approach to Choosing Nitinol Tubing Wisely

The Importance of Nitinol Tubing in Minimally Invasive Surgery

The Manufacturing Process of Nitinol Tubing for Healthcare

Choosing the Right Supplier for Your Nitinol Tubing Requirements