Tips for Selecting High-strength PET Heat Shrink Tubing

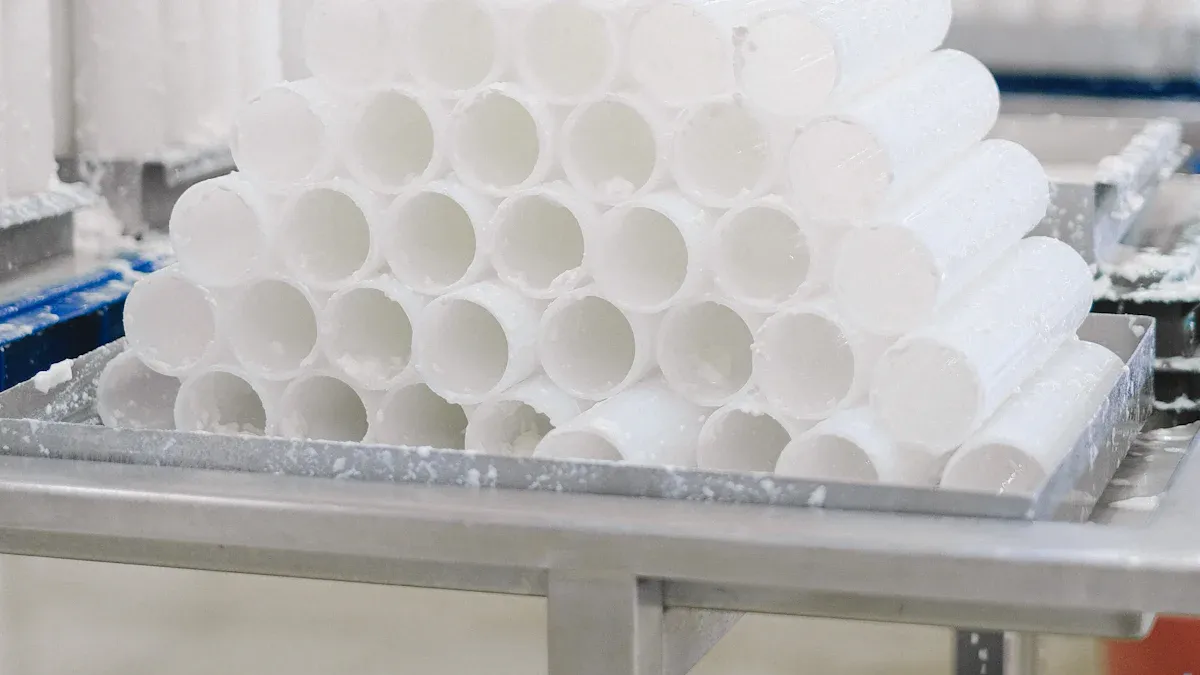

Medical devices demand materials that combine durability, precision, and biocompatibility. High-strength PET heat shrink tubing meets these needs by offering exceptional performance in critical applications. Its ability to achieve shrink ratios as high as 15:1 and wall thicknesses as thin as 0.0003 inches ensures precise fit and functionality. PET heat shrink tubing also withstands recovery temperatures between 275–350°F, making it ideal for diverse medical applications. These qualities not only enhance device performance but also prioritize patient safety. As the market grows, driven by a projected 5.6% annual growth rate, the demand for ultra thin wall PET heat shrink tubing reflects its role in achieving long-term reliability and quality in medical device manufacturing.

Key Takeaways

Strong PET heat shrink tubing is important for medical tools. It lasts long and is safe for the body.

Exact sizing matters; small size errors can harm device use or safety.

Following rules like FDA and ISO keeps devices safe and avoids fines.

Using the right heat stops wrinkles and makes a tight fit.

Testing often ensures good quality and trust in medical tools.

Evaluating Medical Application Needs

Specific use cases in medical device manufacturing

Medical device manufacturing relies on precision and reliability to meet the demands of critical applications. PET heat shrink tubing plays a vital role in producing devices such as catheters, stents, and surgical instruments. Its ability to provide a secure fit and maintain structural integrity under stress makes it indispensable in these applications. For catheter manufacturing, the tubing ensures smooth transitions between components, reducing risks during insertion. PET heat shrink tubing also supports the assembly of diagnostic tools, where dimensional accuracy directly impacts performance. Manufacturers prioritize materials that enhance device safety and functionality, ensuring compliance with medical standards.

Importance of size and dimensional accuracy

Dimensional accuracy is a cornerstone of medical device manufacturing. PET heat shrink tubing must conform to exact specifications to ensure a proper fit and optimal performance. Even minor deviations in size can compromise device functionality or patient safety. High-strength PET heat shrink tubing offers consistent shrink ratios, enabling manufacturers to achieve precise dimensions. This accuracy is particularly critical in applications like catheter manufacturing, where tubing must align perfectly with other components. By maintaining tight tolerances, manufacturers can produce devices that meet stringent quality requirements and perform reliably in medical applications.

Material durability and biocompatibility

Durability and biocompatibility are essential for materials used in medical applications. PET heat shrink tubing exhibits high strength, allowing it to withstand mechanical stress and environmental factors during use. Its durability ensures long-term reliability, even in demanding conditions. Biocompatibility is equally important, as materials must not cause adverse reactions when in contact with human tissue. PET heat shrink tubing meets biocompatibility standards, making it suitable for applications like surgical instruments and implantable devices. Manufacturers prioritize these qualities to ensure patient safety and device performance, reinforcing the importance of selecting high-quality materials.

Compliance with medical standards

Compliance with medical standards ensures the safety, reliability, and effectiveness of devices used in healthcare. PET heat shrink tubing must meet stringent regulatory requirements to be suitable for medical device manufacturing. These standards safeguard patient health and maintain the integrity of medical devices.

Regulatory bodies like the FDA and ISO establish guidelines that manufacturers must follow. Adhering to these rules minimizes risks and ensures that PET heat shrink tubing performs as intended. For example, compliance with FDA regulations allows manufacturers to avoid penalties and ensures access to the market. Similarly, ISO 13485 certification enhances safety and risk management in medical device manufacturing. These certifications demonstrate a commitment to quality and patient safety.

Non-compliance can lead to severe consequences. Manufacturers may face fines, product recalls, or damage to their reputation. In medical device manufacturing, such outcomes can compromise patient trust and safety. By selecting PET heat shrink tubing that meets regulatory standards, manufacturers can avoid these risks and ensure their devices meet the highest quality benchmarks.

The following table summarizes key compliance considerations:

Key Points | Description |

|---|---|

Importance of Compliance | Following medical device rules is crucial for product safety and quality. |

Consequences of Non-Compliance | Breaking rules can lead to fines, recalls, and loss of trust. |

FDA Regulations | Compliance with FDA rules helps avoid penalties and ensures market access. |

ISO 13485 | Adhering to ISO standards enhances safety and risk management in medical devices. |

Manufacturers must also consider biocompatibility when selecting PET heat shrink tubing. Materials used in medical devices must not cause adverse reactions when in contact with human tissue. Compliance with biocompatibility standards ensures that PET heat shrink tubing is safe for applications like catheter manufacturing and surgical instruments.

Technical Factors to Consider

Shrink temperature settings for uniform results

Temperature control plays a critical role in achieving consistent results when using PET heat shrink tubing. Each type of tubing has a specific shrink temperature range, typically between 275°F and 350°F. Manufacturers must carefully monitor this range to ensure uniform shrinkage across the tubing's surface. Uneven heating can lead to wrinkles, bubbles, or incomplete shrinkage, which may compromise the device's performance.

Using calibrated heat sources, such as hot air guns or ovens, helps maintain precise temperature control. Infrared thermometers or thermal imaging tools can also assist in verifying that the tubing reaches the correct temperature. For medical device manufacturing, achieving uniform results is essential to ensure the tubing fits securely and maintains its structural integrity. Proper temperature control not only enhances the quality of the final product but also ensures safety and reliability in medical applications.

Radial and axial shrinkage control

Radial and axial shrinkage are critical factors to consider when selecting PET heat shrink tubing for medical applications. Radial shrinkage refers to the tubing's ability to reduce its diameter, while axial shrinkage involves changes in its length during the shrinking process. Both dimensions must be carefully controlled to ensure the tubing conforms to the desired specifications.

Excessive axial shrinkage can lead to misalignment or gaps in the device assembly, particularly in catheter manufacturing, where precision is paramount. On the other hand, insufficient radial shrinkage may result in a loose fit, reducing the device's reliability. Manufacturers often rely on high-strength PET heat shrink tubing, which offers predictable shrinkage properties, to address these challenges. By selecting tubing with consistent radial and axial shrinkage characteristics, manufacturers can produce devices that meet stringent medical standards and perform reliably in critical applications.

Compatibility with sterilization processes

Sterilization is a non-negotiable requirement in medical device manufacturing. PET heat shrink tubing must withstand various sterilization processes without compromising its strength, biocompatibility, or dimensional stability. Common sterilization methods include autoclaving, ethylene oxide (EtO) gas, and gamma radiation. Each method subjects the tubing to different conditions, such as high temperatures, chemical exposure, or radiation.

For example, autoclaving involves exposure to steam at temperatures exceeding 250°F, which can challenge the tubing's durability. PET heat shrink tubing designed for medical applications must resist deformation or degradation during such processes. Similarly, EtO gas sterilization requires materials that do not absorb or retain harmful residues. Gamma radiation, often used for implantable devices, demands tubing with exceptional strength and resistance to radiation-induced changes.

Manufacturers must evaluate the sterilization requirements of their specific applications to select tubing that aligns with these needs. Ensuring compatibility with sterilization processes not only guarantees patient safety but also enhances the device's long-term reliability. By prioritizing materials that maintain their properties under sterilization, manufacturers can uphold the highest standards of quality in medical device production.

Shrink ratio and its impact on fit

The shrink ratio of PET heat shrink tubing plays a crucial role in determining its effectiveness in medical applications. This ratio refers to the tubing's ability to reduce its diameter when exposed to heat. For example, a 2:1 shrink ratio means the tubing can shrink to half its original size, while a 4:1 ratio allows it to shrink to one-fourth. Selecting the appropriate shrink ratio ensures a secure fit, which is essential for maintaining the reliability and functionality of medical devices.

In medical device manufacturing, achieving a precise fit is critical. PET heat shrink tubing with a higher shrink ratio offers greater flexibility, allowing it to conform to irregular shapes or varying diameters. This adaptability proves invaluable in applications like catheter assembly, where components often have complex geometries. A proper fit minimizes gaps, ensuring the device operates as intended and meets stringent quality standards.

The shrink ratio also impacts the tubing's strength and durability. Tubing with a lower shrink ratio may provide a tighter fit but could compromise flexibility. Conversely, a higher shrink ratio enhances adaptability but may require careful handling to maintain structural integrity. Manufacturers must balance these factors to select tubing that aligns with the specific requirements of their applications.

Sterilization processes further highlight the importance of the shrink ratio. PET heat shrink tubing must retain its properties after exposure to high temperatures, chemicals, or radiation. A well-chosen shrink ratio ensures the tubing maintains its fit and strength, even after repeated sterilization cycles. This reliability is vital for medical devices that prioritize patient safety and long-term performance.

To optimize the fit, manufacturers should consider the tubing's shrink ratio alongside other factors like radial and axial shrinkage. Testing and quality assurance methods can help verify that the selected tubing meets the desired specifications. By prioritizing the shrink ratio, manufacturers can enhance the reliability and quality of their medical devices, ensuring they perform effectively in critical applications.

Tip: Always consult with material experts to determine the ideal shrink ratio for your specific medical application. This step ensures the tubing meets both performance and regulatory requirements.

Practical Application Tips

Ensuring tight fit and alignment

Achieving a tight fit and proper alignment is essential when applying high-strength PET heat shrink tubing in medical applications. A secure fit ensures the tubing performs reliably and maintains its structural integrity. Following best practice guidelines can help manufacturers achieve optimal results.

Guideline | Description |

|---|---|

Choosing the Correct Size | Ensure the tubing’s pre-shrink diameter is no more than 15% larger than the maximum diameter of your component to avoid uneven shrinkage. |

Mastering Shrink Temperature Settings | Recommended temperature setting is 150°C (302°F) for balanced shrinkage. |

Controlling Shrinkage | Limit total shrinkage to 15%-20% for optimal performance; hold ends during heating to prevent axial shrinkage. |

Tube Drawing for Extreme Radial Shrinkage | Apply axial tension while heating to achieve over 50% radial shrinkage. |

Preventing Wrinkles | Maintain tension on both ends during heating to inhibit wrinkles and apply heat in a controlled manner. |

By adhering to these guidelines, manufacturers can ensure the tubing fits securely and aligns perfectly with medical device components.

Techniques to prevent wrinkles or uneven shrinkage

Wrinkles or uneven shrinkage can compromise the functionality and reliability of medical devices. Proper techniques can help prevent these issues during the application of heat shrink tubing.

Issue | Corrective Action |

|---|---|

Webbing | Lower the forming temperature, redesign the mold tool, and check for vacuum functionality and leaks. |

Warpage | Check the parts cooling system and ensure consistent mold tool temperature. |

Blisters or bubble formation | Dry plastic sheets at high temperatures below melting, lower the forming temperature, and ensure uniform heating of plastic sheets. |

Maintaining consistent heating and applying tension on both ends of the tubing during the shrinking process are critical steps. These strategies ensure the tubing conforms smoothly to the underlying component, enhancing its reliability in medical applications.

Best practices for heat application

Applying heat correctly is crucial for achieving uniform shrinkage and maintaining the tubing's properties. PET heat shrink tubing performs optimally when the heat source is calibrated and applied evenly. Design engineers recommend selecting tubing that closely matches the final diameter of the product, as this minimizes the need for excessive shrinkage.

For medical applications, using heat sources like hot air guns or ovens ensures precise temperature control. Infrared thermometers can verify that the tubing reaches the recommended temperature range of 150°C (302°F). Applying heat gradually and evenly prevents overheating, which could damage the tubing or underlying components. These practices enhance the tubing's performance and ensure its compatibility with sterilization processes, a critical requirement in medical device manufacturing.

Tip: PET heat shrink tubing offers high dielectric strength and thin wall construction, making it ideal for applications requiring electrical insulation and durability.

Testing and quality assurance methods

Testing and quality assurance play a critical role in ensuring that PET heat shrink tubing meets the rigorous demands of medical applications. Manufacturers rely on standardized testing protocols to validate the tubing's performance, durability, and compliance with industry regulations. These methods ensure that the tubing performs reliably under various conditions, safeguarding both device functionality and patient safety.

One of the most widely recognized standards is UL/CSA 224, which defines requirements for electrical insulation tubing. This standard evaluates properties such as flexibility, oil resistance, and dielectric voltage. Another key standard, AMS-DTL-23053, focuses on heat shrinkable tubing, assessing factors like specific gravity and fungus resistance. For applications involving public health, the 3-A Sanitary Standards require materials to pass testing at independent laboratories. These certifications ensure that PET heat shrink tubing meets the stringent requirements of the medical field.

The following table summarizes key testing standards and their requirements:

Specification | Description | Testing Requirements |

|---|---|---|

UL/CSA 224 | Defines requirements for electrical insulation tubing. | Physical Properties, Oil Resistance, Flexibility, Dielectric Voltage, etc. |

AMS-DTL-23053 | Establishes guidelines for electrical heat shrinkable tubing. | Specific Gravity, Dielectric Constant, Fungus Resistance, etc. |

3-A Sanitary Standards | Provides material specifications for public health. | Must pass testing at a qualified independent laboratory. |

In addition to adhering to these standards, manufacturers conduct in-house testing to verify the tubing's performance in specific medical applications. Tests often include tensile strength assessments, dimensional accuracy checks, and compatibility evaluations with sterilization processes. These procedures help identify potential weaknesses and ensure the tubing maintains its integrity during use.

Note: Regular quality assurance audits further enhance reliability by identifying inconsistencies in production. These audits ensure that every batch of PET heat shrink tubing meets the high standards required for medical device manufacturing.

By prioritizing rigorous testing and quality assurance, manufacturers can deliver tubing that aligns with the critical demands of the medical industry. This commitment to quality not only ensures compliance with regulations but also enhances the safety and effectiveness of medical devices.

Selecting the right high-strength pet heat shrink tubing requires a clear understanding of application needs, technical factors, and proper application techniques. Each step, from evaluating material durability to mastering heat application, plays a vital role in ensuring device reliability and patient safety. Precision and quality remain the foundation of successful medical device manufacturing, enabling devices to meet stringent industry standards.

Consulting with material experts can provide tailored solutions that address specific challenges. Their guidance helps manufacturers optimize tubing selection and application, ensuring long-term performance and compliance with medical regulations.

Tip: Partnering with experienced suppliers can streamline the process and enhance product outcomes.

FAQ

What is the ideal shrink temperature for PET heat shrink tubing?

The ideal shrink temperature ranges between 275°F and 350°F. Manufacturers should use calibrated heat sources to maintain consistent heating. Infrared thermometers can help verify the tubing reaches the correct temperature for uniform shrinkage.

How can manufacturers prevent wrinkles during application?

Wrinkles can be avoided by applying tension on both ends of the tubing during heating. Gradual and even heat application ensures smooth shrinkage. Using controlled heat sources like ovens or hot air guns enhances precision.

Is PET heat shrink tubing compatible with all sterilization methods?

PET heat shrink tubing withstands common sterilization methods, including autoclaving, EtO gas, and gamma radiation. Manufacturers should confirm the tubing’s durability and dimensional stability under specific sterilization conditions.

What shrink ratio is best for medical applications?

The shrink ratio depends on the application. A higher ratio, like 4:1, offers flexibility for irregular shapes. Lower ratios, such as 2:1, provide a tighter fit. Consulting material experts ensures the right choice for specific needs.

How can manufacturers ensure quality during production?

Manufacturers should conduct in-house testing for tensile strength, dimensional accuracy, and sterilization compatibility. Adhering to standards like UL/CSA 224 and AMS-DTL-23053 ensures compliance and reliability.

Tip: Regular audits help identify inconsistencies and maintain high-quality production standards.

See Also

Selecting The Ideal Ultra-Thin PET Heat Shrink Tubing

Key Advice For Effectively Utilizing FEP Heat Shrink Tubing

Comprehensive Guide To Determining The Correct Heat Shrink Size