How to Select the Best Polyimide Tubing for Aerospace Projects

Polyimide tubing for aerospace applications is crucial in aerospace engineering. It ensures that systems remain safe and reliable. This specialized tubing boasts features such as high heat resistance, chemical durability, and exceptional strength. These characteristics make it ideal for challenging environments. In 2023, the global market for polyimide tubing for aerospace applications was valued at $1.2 billion, and it is projected to grow to $2.3 billion by 2032, with an annual growth rate of 7.2%. When selecting the best polyimide tubing for aerospace applications, consider its performance in harsh conditions, compatibility with the environment, and overall cost. The right tubing enhances system efficiency and longevity.

Key Takeaways

Polyimide tubing is important for aerospace because it handles heat, resists chemicals, and is strong, keeping systems safe and reliable.

Pick tubing that resists heat and chemicals to work well in tough conditions and last longer.

Get tubing that keeps its shape under pressure to avoid repairs and make systems work better.

Think about weight and space; light tubing saves fuel and fits in small areas.

Check that your supplier follows aerospace rules and uses approved materials for safe and proper projects.

Understanding Polyimide Tubing

What is Polyimide Tubing?

Polyimide tubing is a strong material used in many industries. It is made by combining two chemicals, a diamine and a dianhydride. The process has two steps: first, making a soluble material, and then turning it into polyimide. The final tubing is very stable because of its special structure. By changing the starting chemicals, like pyromellitic dianhydride and 4,4'-diaminodiphenyl ether, makers can adjust the tubing's features for different uses.

Key Properties of Polyimide Tubing

Polyimide tubing has many useful features, such as:

Great heat resistance, so it works well in hot places.

Strong chemical resistance, protecting it from harmful substances.

High strength, keeping it sturdy under pressure.

Excellent electrical insulation, perfect for electronics.

Moisture resistance, stopping damage from wet conditions.

These qualities make it popular in aerospace, cars, and electronics.

Why Polyimide Tubing is Essential for Aerospace Applications

Polyimide tubing is very important for safety in aerospace projects. For instance, DMBZ-15 polyimide can handle heat up to 414 °C (777 °F). It is used in airplane engines and missiles because it resists wear and heat damage. Its light weight also helps save fuel by lowering the aircraft's weight. Polyimide tubing works well in tough conditions, making it a key part of aerospace engineering.

Key Factors in Choosing Polyimide Tubing for Aerospace Projects

Heat Resistance

When picking polyimide tubing, check its heat resistance. Aerospace conditions can be very hot or freezing cold. Polyimide tubing works well in these extreme temperatures. It stays strong even at 400°C (752°F). This makes it great for jet engines and insulation systems. Polyimide film also stays stable over time, keeping performance steady. Choosing tubing with good heat resistance improves safety and reliability.

Chemical Resistance

Aerospace materials often face harsh chemicals like fuels and cleaners. Polyimide tubing is tough against these substances. It doesn’t crack or weaken when exposed to corrosive chemicals. This strength helps it last longer and stay effective. Polyimide film also resists radiation and chemicals, making it useful in tough environments. Picking tubing with strong chemical resistance keeps systems working well.

Strength and Durability

Strength is very important for aerospace tubing. Polyimide tubing is strong, even in small sizes. Its seamless design makes it durable and long-lasting. It resists wear and damage, which is crucial for aerospace use. Below is a table showing its key strengths:

Property | Description |

|---|---|

Tensile Strength | Very strong, even in small sizes, perfect for precision work. |

Thermal Stability | Handles high and low temperatures, important for aerospace. |

Chemical Resistance | Resists cracking and lasts long under stress. |

Flammability | Doesn’t burn easily, safe for aerospace needs. |

Radiation Resistance | Protects against radiation, useful in space conditions. |

Choosing tubing with these features ensures strong and reliable systems. AccuPath provides high-quality polyimide tubing that meets these tough requirements, making it a top choice for aerospace engineers.

Dimensional Stability

Dimensional stability is very important for aerospace polyimide tubing. In tough environments, materials face extreme heat, stress, and chemicals. These conditions can make materials change shape or size. This might harm aerospace systems. But polyimide tubing stays stable and works well in such situations.

Choose tubing that keeps its shape in all temperatures. Polyimide tubing is great because it doesn’t expand or shrink much. It handles heat up to 400°C (752°F) without bending or warping. This makes it perfect for tight spaces like wiring or fluid systems in planes.

Another benefit is its resistance to long-term stress. Some materials bend or weaken under constant pressure. Polyimide tubing stays strong and reliable over time. This means fewer repairs or replacements, saving effort and money.

Tip: Ask your supplier for detailed tubing information. Check data on heat expansion, strength, and long-term performance. This helps you pick tubing with the best stability for your needs.

Using polyimide tubing with great dimensional stability improves safety and efficiency. It ensures your systems work well, even in harsh conditions.

Evaluating Aerospace Application Requirements

Weight and Space Constraints

In aerospace, reducing weight is very important. Lighter designs improve fuel use and performance. Polyimide tubing is lightweight but still strong. Its thin walls and high strength make it great for tight spaces. It works well in wiring or fluid systems where space is limited. Using polyimide tubing helps save weight and space, meeting strict efficiency needs.

Tip: Pick tubing with a good strength-to-weight ratio. This keeps it strong while staying light.

Durability in Extreme Conditions

Aerospace conditions are tough on materials. They face heat, pressure, and chemicals. Polyimide tubing handles these challenges well. For example:

Vespel® tubing stays strong in high heat.

It doesn’t release gases, so it’s good for vacuums.

It keeps its shape and doesn’t weaken under stress.

These features make polyimide tubing a top choice for important systems. It performs better than many other materials.

Compliance with Aerospace Standards

Aerospace projects must follow strict rules. Polyimide tubing needs to meet safety and performance standards. Below is a table of key rules:

Compliance Standard | Description |

|---|---|

FAR 25.853 | U.S. rule for fire and smoke safety tests. |

JAR 25.853 | European version of FAR, with similar rules. |

BSS | Boeing’s safety rules for aircraft materials. |

AITM | Airbus’s tests for materials in plane interiors. |

Always check if polyimide tubing meets these rules. Following them ensures safety and reliability for aerospace use.

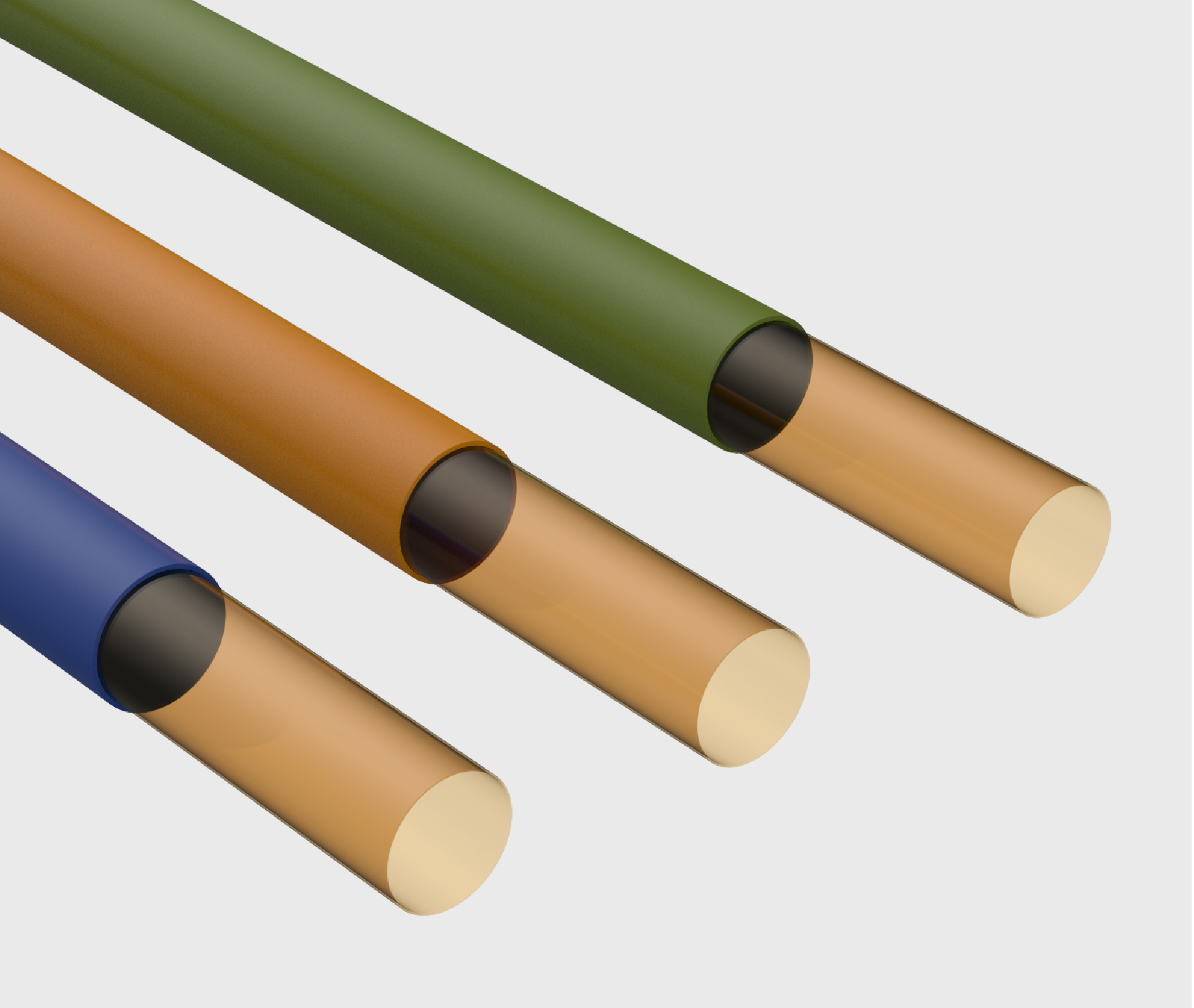

Comparing Types of Polyimide Tubing

General-Purpose Polyimide Tubing

If you need a flexible option, general-purpose polyimide tubing works well. It has balanced features for many aerospace uses. This tubing performs reliably in normal conditions. It is great for covering, protecting, and grouping wires. Its light weight helps lower system weight, saving fuel. General-purpose polyimide film and polyimide tape are good for jobs needing durability and flexibility but not extreme resistance.

High-Performance Polyimide Tubing

For tougher conditions, high-performance polyimide tubing is a must. It handles very high heat and strong chemicals. This makes it ideal for important aerospace systems. High-performance polyimide film and polyimide tape can take heat up to 400°C (752°F). They stay strong under pressure, making them great for engines and high-heat tape uses. AccuPath offers high-performance tubing to keep systems safe and working well, even in hard conditions.

Custom Polyimide Tubing Options

Sometimes, regular tubing doesn’t fit your needs. Custom polyimide tubing lets you design it for your project. You can change its size, thickness, or features for specific tasks. Custom polyimide film and polyimide tape allow creative designs for better results. Whether for a special aerospace job or unique high-heat tape, AccuPath provides solutions made just for you.

Note: Think about your project’s needs when choosing polyimide tubing. AccuPath’s knowledge ensures you get top-quality products made for your goals.

Cost and Supplier Considerations

Balancing Quality and Budget

Picking polyimide tubing needs a balance of cost and quality. Good tubing is safer and lasts longer but costs more. Think about your project’s needs to decide where to spend more. For example, general-purpose polyimide tape works for simple tasks. High-performance tape is better for tough conditions like heat or chemicals.

To save money, buy in bulk or use JIT delivery. This lowers storage costs and gives you fresh materials when needed. Focus on long-term value, not just short-term savings. Spending more on strong, durable tubing can cut repair costs later and make systems last longer.

Assessing Supplier Reliability

Finding a good supplier is as important as choosing the tubing. A reliable supplier delivers on time, meets standards, and keeps quality high.

Look for suppliers with certifications like ISO 9001:2015 or military compliance. These show they care about quality. Also, check if they have experience in aerospace and offer custom options.

Importance of Certifications and Testing

Certifications and testing are key for safe and strong polyimide tubing. Aerospace projects must follow strict rules like FAR 25.853 for fire safety. Make sure your supplier tests their products to meet these rules.

For example, tubing for hot areas should pass heat tests. Tubing for chemicals must pass corrosion tests. Always ask for test reports and certifications to confirm quality.

Using certified and tested materials makes systems safer and more reliable. It also helps meet important rules and reduces risks in your project.

Choosing the right polyimide tubing for aerospace projects is very important. It helps keep systems safe, reliable, and efficient. You need to look at key factors like heat resistance, electrical insulation, and chemical strength. These features help polyimide tubing work well in tough conditions, making aerospace systems last longer. Also, picking a good supplier ensures you get quality materials when you need them, which is crucial for success. While high-performance tubing might cost more, its strength and great performance make it worth it. Talk to trusted suppliers for expert help and quality materials that fit your needs.

FAQ

Why is polyimide tubing good for aerospace use?

Polyimide tubing handles heat, chemicals, and is very strong yet light. These features make it perfect for aerospace systems in tough conditions. It stays steady under pressure, ensuring systems work well.

Can polyimide tubing be made for special aerospace needs?

Yes, polyimide tubing can be changed to fit your project. You can adjust its size, thickness, or materials for specific tasks. Custom tubing works best for unique aerospace challenges.

Tip: Talk to your supplier about custom options for your project.

How can you check if polyimide tubing meets aerospace rules?

Make sure the tubing follows rules like FAR 25.853 or JAR 25.853. Ask your supplier for test results and certifications. These prove the tubing is safe and meets aerospace standards.

Is polyimide tubing worth the cost for aerospace projects?

Polyimide tubing saves money over time by lasting longer. Its strength and durability reduce the need for repairs or replacements. Spending more upfront prevents costly system failures later.

What should you consider when picking a polyimide tubing supplier?

Pick a supplier with aerospace experience and certifications like ISO 9001:2015. A reliable supplier delivers quality materials on time and offers custom options for your needs.

Note: A trusted supplier helps your aerospace systems succeed with consistent quality.

See Also

Selecting Ideal Ultra-Thin PET Heat Shrink Tubing for Projects

Finding the Perfect FEP Heat Shrink Tubing for Your Needs

A Comprehensive Guide to FEP Autoclavable Heat Shrink Tubing

Key Considerations for Selecting FEP Shrink Tubing Effectively

Choosing the Right Nitinol Tubing Supplier for Your Requirements