What is RoHS Compliant Nitinol Tubing and Its Role in Modern Technology

RoHS rules are designed to minimize harmful materials in products, making them safer for both people and the environment. These regulations have transformed industries by emphasizing safety and eco-friendly practices. Nitinol, a unique material used in tubing, has the ability to remember its shape and bend without breaking, making it ideal for medical devices and industrial applications. A RoHS compliant Nitinol tubing supplier adheres to these standards to produce safer and more sustainable products. Businesses that comply with RoHS often benefit from improved supply chains and increased customer trust, despite the higher costs involved.

Key Takeaways

RoHS compliance means Nitinol tubing has no harmful materials. This makes medical devices safer for people to use.

Nitinol can remember its shape and bend without breaking. This makes it perfect for flexible medical tools.

Using RoHS-compliant Nitinol helps the environment by cutting pollution. It also supports making products in a greener way.

Nitinol tubing is strong and precise, so it’s great for healthcare, airplanes, and robots.

Picking a RoHS-compliant supplier builds trust with buyers. It also follows important rules.

Unique Properties of Nitinol Tubing

Shape Memory and Superelasticity

Nitinol tubing is special because it can "remember" its shape. You can bend or twist this nickel-titanium material, and it will go back to its original form when heated or when stress is removed. This makes it perfect for uses that need both flexibility and accuracy.

Scientists found that Nitinol stretched below a certain temperature can fully return to its shape when heated. The material changes phases under stress, letting it bend and then snap back when the stress is gone. Tests also show that applying stress makes the transformation more efficient by narrowing the energy loss loop.

A study on how Nitinol behaves under stretching, squeezing, and bending gave interesting results. Using special cameras, scientists measured how it stretched and noticed differences between pulling and pushing forces. When stretched, it showed steady force levels and specific areas of strain, but when squeezed, it stayed strong without forming weak spots. These results prove Nitinol tubing works well in tough conditions.

Corrosion Resistance and Biocompatibility

Nitinol tubing is great for medical use because it resists rust and works well with the human body. Its ability to avoid breaking down means it lasts a long time, even in harsh places like inside the body. A protective layer forms on its surface over time, making it safe and resistant to corrosion.

Research shows that heating Nitinol at 450 °C makes it much better at resisting corrosion than untreated versions or those heated at 650 °C. This improvement is important for medical tools like heart stents and bone implants. The protective layer also lowers the chance of bad reactions, keeping patients safe.

Durability and Precision in Manufacturing

Nitinol tubing is tough and dependable, making it a top choice for industries needing strong materials. It can handle repeated stress without losing its shape or function, ensuring it works well over time. Its precision also allows for detailed designs and exact measurements during production.

This material is often combined with heat-shrink tubing to protect delicate parts. This pairing improves the strength and safety of medical devices, helping them work well in critical situations. Whether used in robots, airplanes, or gadgets, Nitinol tubing offers unmatched strength and accuracy.

Medical Uses of RoHS-Compliant Nitinol Tubing

Nitinol is important in medical tools because of its special traits. It can remember shapes and stretch without breaking. These features help it work well inside the human body and in tough conditions. Below are ways nitinol is changing heart, bone, and dental care.

Heart Devices

Nitinol has improved life-saving heart tools like stents and catheters. Its bendable and strong nature makes it perfect for these devices. They need to move through narrow body pathways, and nitinol’s flexibility helps them work smoothly.

For example, nitinol stents open blocked arteries to restore blood flow. They can return to their original shape after being squeezed during placement. This ensures they fit correctly and last a long time.

Catheters made with nitinol tubing are strong and flexible. They can twist through blood vessels without breaking, lowering risks for patients. A RoHS-compliant supplier makes sure these tools are safe for people and the planet.

Bone Implants

Nitinol works well for bone implants because it is safe for the body. These implants must handle constant movement and pressure, and nitinol stays strong over time.

Doctors use nitinol staples to hold broken bones together. These staples adjust to body heat, fitting securely as they return to their original shape.

Small surgeries also benefit from nitinol. Implants like spinal cages can be placed with tiny cuts, helping fix herniated discs. This leads to faster healing and better results for patients.

Dental Tools

Dentists use nitinol for braces and root canal tools because it is flexible and precise. These tools need to be strong and easy to use.

Braces with nitinol wires gently move teeth into the right spots. The wires adjust to the shape of the mouth, making them comfortable and effective.

Root canal tools made from nitinol can reach tricky areas without breaking. Nitinol screws also provide lasting fixes for missing teeth.

A RoHS-compliant supplier ensures dental tools meet strict safety rules. This gives patients reliable care while protecting the environment.

Industrial Uses of RoHS-Compliant Nitinol Tubing

Robotics and Automation

Nitinol is important in robotics and automation. Its special traits, like shape memory, make it useful. Robotic arms use nitinol for smooth and exact movements. It helps robots do repeated tasks without wearing out.

In automation, nitinol is used in sensors and actuators. These tools react to heat or pressure changes. For instance, nitinol actuators shrink or stretch to move systems. This makes them great for jobs needing accuracy and dependability.

Aerospace Parts

The aerospace field uses nitinol for its strength and light weight. Planes and spacecraft need materials that handle tough conditions. Nitinol resists rust and keeps its shape under stress.

Nitinol is found in jet engines to save fuel by adapting to heat. Satellites also use nitinol to stay strong in space's harsh environment. Using RoHS-compliant nitinol ensures safety and eco-friendliness in aerospace tools.

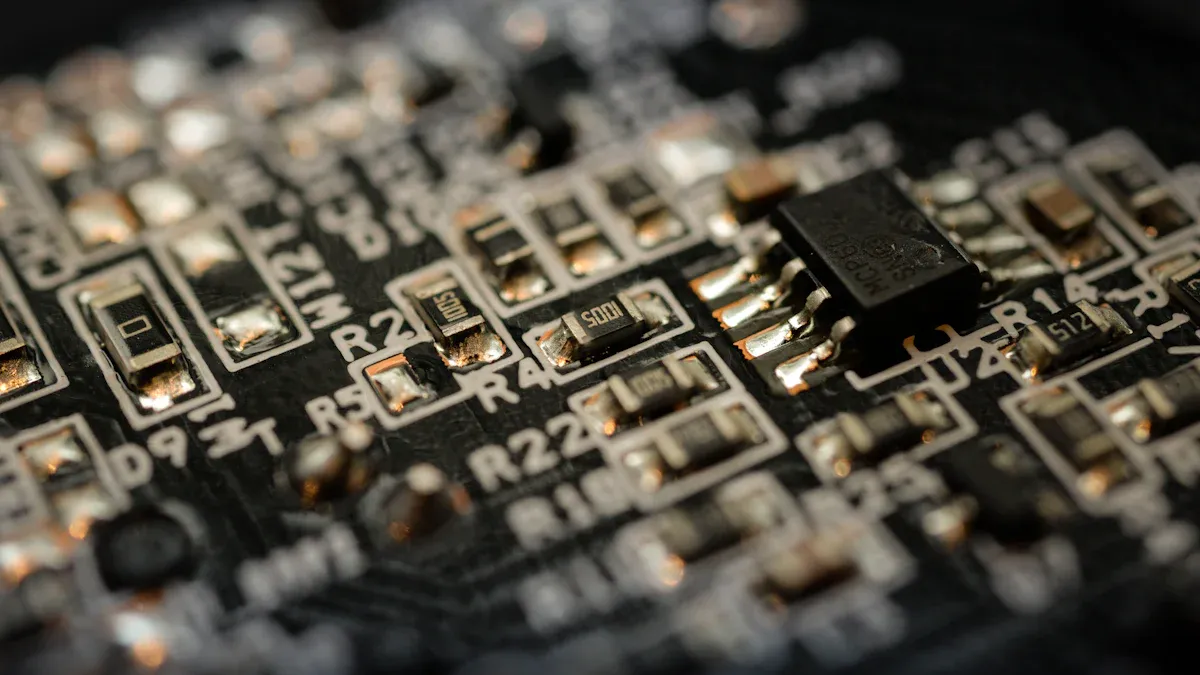

Everyday Electronics

Nitinol has changed how electronics are made and work. Its bendable and strong nature is perfect for wearables like smartwatches. These gadgets use nitinol parts that bend but don’t break.

Headphones with nitinol adjust to fit your head comfortably. Foldable phones and other devices use nitinol for strength and flexibility. RoHS compliance ensures these items are safe and good for the planet.

Why RoHS Compliance Matters for Nitinol Tubing

Keeping Medical Devices Safe

RoHS compliance is very important in making medical devices. It ensures nitinol devices follow strict safety rules. Using RoHS-compliant nitinol tubing lowers the chance of harmful materials entering the body. This is crucial for tools like stents, implants, and surgical instruments.

A RoHS-compliant nitinol tubing supplier makes sure their products are free from dangerous materials like lead or mercury. This helps protect patients and healthcare workers from harm. Choosing compliant tubing means safer and more reliable medical devices.

Tip: Always check if your supplier follows RoHS rules to keep your medical tools safe.

Helping the Environment

RoHS compliance also helps protect the environment. Nitinol made under these rules reduces the release of harmful substances. This cuts pollution and supports eco-friendly practices.

By buying nitinol from a RoHS-compliant supplier, you help keep the planet clean. These suppliers use safe methods to make their products. This helps reduce waste and save resources, supporting global environmental goals.

Following Important Rules

Meeting RoHS standards is necessary to follow legal rules. Many countries require compliance for medical and industrial devices. Using RoHS-compliant nitinol ensures your products meet these laws.

Not following these rules can cause fines, product recalls, or losing market access. Working with a RoHS-compliant supplier helps you avoid these problems. It also gives you an advantage by offering safe and eco-friendly products.

Note: Following RoHS rules builds trust with customers and partners, not just meeting laws.

RoHS-compliant Nitinol tubing has special features like shape memory. It is strong, safe for the body, and lasts long. These qualities make it perfect for medical tools and machines. It helps create safer products that follow strict rules. Nitinol is also important in robotics and space technology.

In the future, Nitinol tubing could improve new medical tools. It may also help in making better machines and devices. By using RoHS-compliant materials, you support safety and protect the planet. This choice keeps you ahead in technology and helps build a greener world.

FAQ

What does RoHS compliance mean for Nitinol tubing?

RoHS compliance means Nitinol tubing has no harmful materials. It avoids substances like lead or mercury, making it safer to use. This helps protect people and reduces damage to the environment.

Why is Nitinol tubing used in medical devices?

Nitinol tubing is special because it remembers shapes and is body-safe. These features make it great for medical tools that need to last. It also allows for precise and reliable performance in important uses.

How does RoHS compliance benefit the environment?

RoHS compliance helps the planet by cutting down pollution. It removes harmful materials during production, keeping nature cleaner. Choosing compliant tubing supports green practices and saves resources.

Can RoHS-compliant Nitinol tubing be used in robotics?

Yes, Nitinol tubing works well in robots. Its bendable and strong nature helps robots do tasks over and over. It ensures robots stay accurate and dependable for a long time.

What industries rely on RoHS-compliant Nitinol tubing?

Many industries use RoHS-compliant Nitinol tubing, like healthcare and aerospace. It is also used in electronics because it is strong, safe, and flexible for different jobs.

See Also

Nitinol Tubing's Impact on the Future of Medicine

Transforming Medical Devices with Innovative Nitinol Tubing

The Importance of Nitinol Tubing in Modern Medicine