Breakthroughs in Nitinol Tubing for Robotic Surgery

Robotic surgery has been revolutionized by Nitinol tubing, offering enhanced precision and flexibility. The superelasticity of Nitinol tubing allows surgical tools to navigate complex body paths without bending, ensuring smooth operation. Instruments crafted from Nitinol tubing reliably return to their original shape after being bent, making them indispensable for challenging procedures. Research indicates that robotic surgery utilizing Nitinol tubing can reduce operation time by 40%, significantly increasing efficiency. These advancements highlight the critical role of Nitinol tubing in modern robotic surgery.

Key Takeaways

Nitinol tubing helps robotic surgery by being flexible and precise.

It lets tools move easily in small spaces during operations.

Nitinol can bend and return to shape, making tools work better.

Using Nitinol tubing can cut surgery time by almost 40%.

Faster surgeries mean patients recover quicker and feel better sooner.

3D printing makes Nitinol tools fit specific surgery needs perfectly.

This improves how surgeries go and helps patients heal faster.

Nitinol is safe for the body and doesn’t rust, avoiding problems.

Unique Properties of Nitinol Tubing

Superelasticity and Shape Memory

Nitinol tubing has amazing shape memory and superelasticity. These features make it perfect for medical tools. The tubing can bend a lot and still return to its original shape. This is very helpful in robotic surgery, where tools move through tight spaces.

Nitinol's superelasticity lets it bend and stretch without breaking.

Its shape memory helps it return to its shape when heated. This makes it useful in changing surgical conditions.

Medical tools like stents and guidewires use these features for flexibility and strength.

Tests showed Nitinol springs act differently at various temperatures. When hot, they were elastic. When cold, they stretched due to changes in their structure. This shows how Nitinol adapts and works well in tough situations.

Biocompatibility and Corrosion Resistance

Nitinol tubing is safe for the body and resists rust. It works better than materials like stainless steel. Nitinol blends well with human tissue, causing fewer problems.

Its rust resistance helps it last longer inside the body.

With a strength of 500 MPa, it is strong and safe for medical use.

Nitinol is better than titanium alloys for surgical tools and implants.

These qualities make devices safer and last longer, reducing the need for repairs or replacements.

Flexibility for Robotic Surgery Applications

Nitinol tubing's flexibility is key for robotic surgery. It bends and twists easily without breaking, making tools more precise.

Studies show Nitinol tips improve robotic tool movement.

A flexible tip with two movement directions helps surgeons work better.

This flexibility helps robotic systems handle tricky surgeries, improving results for patients and doctors.

Applications of Nitinol Tubing in Robotic Surgery

Minimally Invasive Surgical Instruments

Nitinol tubing is crucial for less invasive surgeries. It offers great flexibility and accuracy. Its superelasticity helps tools move through tight body spaces. This is very useful for devices like vascular dilators that need precise movements. Using nitinol tools has greatly helped patients recover better.

For example, studies showed big improvements in patients after surgery. Prostate symptom scores dropped from 19 to 9, a 53% improvement. Urinary flow rates increased by 67% in one year. Over three years, flow rates rose by 41%, with a symptom score of 12 and a life-quality score of 2. These results show nitinol tubing improves surgeries and recovery times.

Nitinol is also used in stents and guidewires. These tools depend on its shape memory and body-safe properties. They help keep blood vessels open and support healing tissues. Nitinol tubing makes these tools strong and dependable during surgeries.

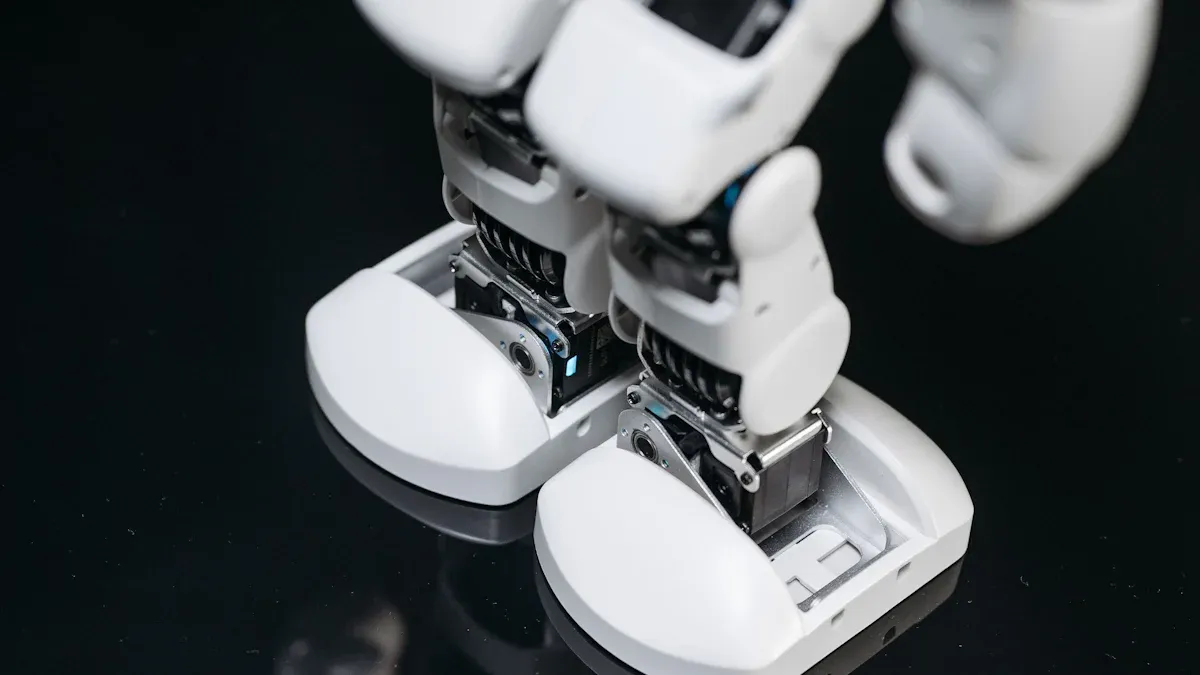

Flexible Robotic Arms

Robotic arms with nitinol tubing have changed robotic surgery. Nitinol's shape memory and flexibility allow complex movements. This helps surgeons reach hard spots and perform better surgeries.

Nitinol-powered robotic arms are better than older systems. They use less energy but give more power and efficiency. The shape memory of nitinol allows smooth and fast movements. Its durability ensures the arms last long without breaking.

Nitinol tubing also resists rust and is safe for the body. This makes it perfect for long-term use in surgeries. These features have made nitinol robotic systems popular in hospitals worldwide.

Precision End-Effectors

End-effectors, the tools at robotic arm tips, benefit from nitinol tubing. These tools need to be very precise for tasks like stitching or moving tissues. Nitinol's strength and flexibility make it perfect for these jobs.

Nitinol-based end-effectors improve robotic surgery accuracy. For example, vascular tools with nitinol tips can safely move through tiny blood vessels. This is important for surgeries involving delicate tissues or organs.

Nitinol tubing also keeps end-effectors working well under different conditions. This reliability reduces surgery risks and ensures better results. Adding nitinol to these tools is a big step forward in robotic surgery.

Latest Advancements in Nitinol Tubing Technology

Bioabsorbable Nitinol Alloys

Bioabsorbable nitinol alloys are a big step in medicine. These materials have nitinol's flexibility and shape memory but can dissolve in the body. This means some implants don’t need to be removed later, making surgeries safer and easier for patients.

Scientists are studying bioabsorbable nitinol for new uses, like temporary implants and tissue repair supports. These materials help the body heal by providing support and then disappearing over time. This could change surgeries like those needing temporary stents in blood vessels.

Bioabsorbable nitinol also solves problems with long-term implants. Since they dissolve, there’s less chance of infections or the body rejecting them. This shows how nitinol tubing keeps improving for robotic surgery and other medical uses.

3D Printing for Customization

3D printing has made nitinol tubing more customizable for surgeries. It helps create tools designed for each patient’s needs. For example, doctors can now use nitinol tools made for tricky surgeries like removing deep brain tumors.

Benefits of 3D printing nitinol tubing include:

Making tools that fit specific surgeries, helping doctors reach tough spots.

Better results for patients with tools made just for them.

Faster production, saving time in creating surgical tools.

Benefit | Explanation |

|---|---|

Fast Production | 3D printing speeds up making custom designs for surgeries. |

Patient-Specific Tools | Tools are made to match each patient’s needs, improving results. |

Strong and Durable | Printed nitinol tubing handles pressure during surgeries without breaking. |

This technology also makes nitinol tubing stronger and better for surgeries. By adjusting to different surgical needs, 3D printing helps robotic systems handle many medical challenges.

AI Integration in Design

Artificial intelligence (AI) is helping design better nitinol tubing for robotic surgery. AI studies data to improve the size, shape, and use of surgical tools. This makes robotic systems more accurate and reduces mistakes during surgeries.

AI also helps create nitinol tubing with advanced features. For example, robots with curved nitinol tubes can move through tight spaces easily. This improves surgeries by making them safer and more precise.

AI’s role in nitinol design goes beyond robots. It could help make smarter implants and medical devices that adjust to patients’ needs. By mixing AI with nitinol’s special abilities, researchers are finding new ways to improve healthcare.

Combining AI, 3D printing, and dissolvable alloys shows how nitinol tubing is advancing. These changes are making robotic surgery safer, faster, and more personalized for patients.

Advantages of Robotic Surgery Nitinol Tubing Innovations

Better Precision and Results

Nitinol tubing has changed robotic surgery by improving precision. Its special features, like stiffness and easy control, help surgeons work more accurately. Tiny robots with nitinol tubes can perform delicate tasks in small areas, like heart surgeries.

Benefit | Description |

|---|---|

Precision | Nitinol tools allow very accurate and careful surgeries. |

Less Patient Trauma | Smaller cuts mean less pain and damage for patients. |

Faster Recovery | Patients heal quicker because of smaller and safer surgeries. |

Better Surgeon Control | These tools give surgeons more control during operations. |

Happier Patients | Patients feel better about their surgeries with these tools. |

These tools not only make surgeries better but also make patients happier. Nitinol tubing is now a key part of modern healthcare.

Stronger and Longer-Lasting Tools

Nitinol tubing makes surgical tools last longer, even with heavy use. Tests show it can handle repeated stress without breaking. Special manufacturing methods make it even stronger for surgeries like heart operations.

Property | Description |

|---|---|

Rust Resistance | Nitinol doesn’t rust, so it works well in tough conditions. |

Stress Resistance | It handles repeated use without wearing out. |

Wear Resistance | Nitinol stays strong and lasts longer in surgeries. |

It resists wear and tear, lasting a long time.

Strict tests ensure it meets high standards.

New methods make it eco-friendly and reliable.

These features make nitinol tubing a smart and lasting choice for medical tools. It reduces the need for replacements and keeps working well.

Faster Healing for Patients

Robotic surgery with nitinol tubing helps patients heal faster. A study showed 100% success in opening blocked vessels, with over half of patients recovering well. Another study showed lower success rates of 74%.

Smaller cuts mean less damage and faster healing.

Patients recover quicker and feel better after surgery.

These tools improve life quality after operations.

These breakthroughs show how nitinol tubing makes surgeries safer and recovery times shorter. It’s a big step forward for patient care.

Challenges and Future Trends in Nitinol Tubing

Manufacturing Challenges

Making Nitinol tubing is hard and needs careful work. Producers face problems with strength, purity, and how blood cells stick to it.

After 10,000 uses at high stress, the material changed. This shows better methods are needed to make it last longer.

Very pure Nitinol tools are safer, but making them is tricky and needs exact steps.

Tests showed blood cells stuck much more to ePTFE than Nitinol. This means Nitinol's surface needs improvement for better body safety.

These issues show why new ways of making Nitinol tubing are important. They help ensure it works well and is safe for medical use.

Smart Materials and Coatings

New materials and coatings are improving Nitinol tubing. These changes make it stronger, safer, and better for medical use.

Property | Description |

|---|---|

Body-Safe | Nitinol works well with body tissues. |

Flexible and Stretchy | It bends like body parts, making it useful in surgeries. |

Long-Lasting | It resists rust and damage, lasting a long time. |

MRI Safe | It can be used safely in MRI scans. |

Heat-Activated | It changes shape with heat, helping in stent placement. |

Strong and Stable | It stays strong while holding its shape, helping stents stay in place. |

Studies found that DLC-coated Nitinol stents lower tissue growth compared to regular ones. But adding PEG coatings might increase tissue growth. These results show coatings can improve tools but need careful choices.

Next-Generation Robotic Systems

Nitinol tubing is helping create better robotic surgery tools. The market for Nitinol is growing fast because of its use in small surgeries. Companies are teaming up to make better products and grow the market.

Robots with Nitinol tubing are more flexible and strong. They help doctors do hard surgeries more accurately. As the need for precise tools grows, Nitinol tubing leads the way in medical technology, creating new surgery solutions.

Nitinol tubing has improved robotic surgery by making tools more precise, flexible, and safe. Its ability to bend and return to shape helps tools move through tricky body areas. It is also safe for the human body, making surgeries safer for patients.

A special Nitinol tool can sense tiny forces, as small as 1 mN. This tool is helpful for delicate surgeries, like eye surgeries, where forces are very small.

Robots made with Nitinol tubes can be customized for each patient. For example, a doctor used one to remove a kidney stone from a child. This shows how useful Nitinol is in real surgeries.

In the future, Nitinol tubing will help make cheaper and better tools. It will also let surgeons help design tools for their needs. These changes will make robotic surgeries safer and more accurate for everyone.

FAQ

Why is Nitinol tubing special for robotic surgery?

Nitinol tubing can bend and return to its shape. This makes it great for tight spaces in robotic surgeries. It also resists rust, staying safe and strong in medical use.

How does Nitinol tubing help patients heal faster?

Smaller cuts are possible with Nitinol tools. This means less damage and quicker healing. Patients feel less pain and leave the hospital sooner.

Can Nitinol tubing be made for specific surgeries?

Yes, 3D printing helps create custom Nitinol tools. These tools fit tricky surgeries like brain or heart operations. Custom designs improve results and make patients happier.

Is Nitinol tubing safe to stay in the body?

Nitinol tubing is safe and works well with body tissues. Special coatings can make it even safer, lowering risks of irritation or rejection.

What problems come up when making Nitinol tubing?

Making Nitinol tubing is hard and needs careful work. Challenges include keeping it pure, strong, and safe for the body. Better methods are being developed to fix these issues.