Which Radiopaque Nitinol Tubing Is Best for Your Procedure

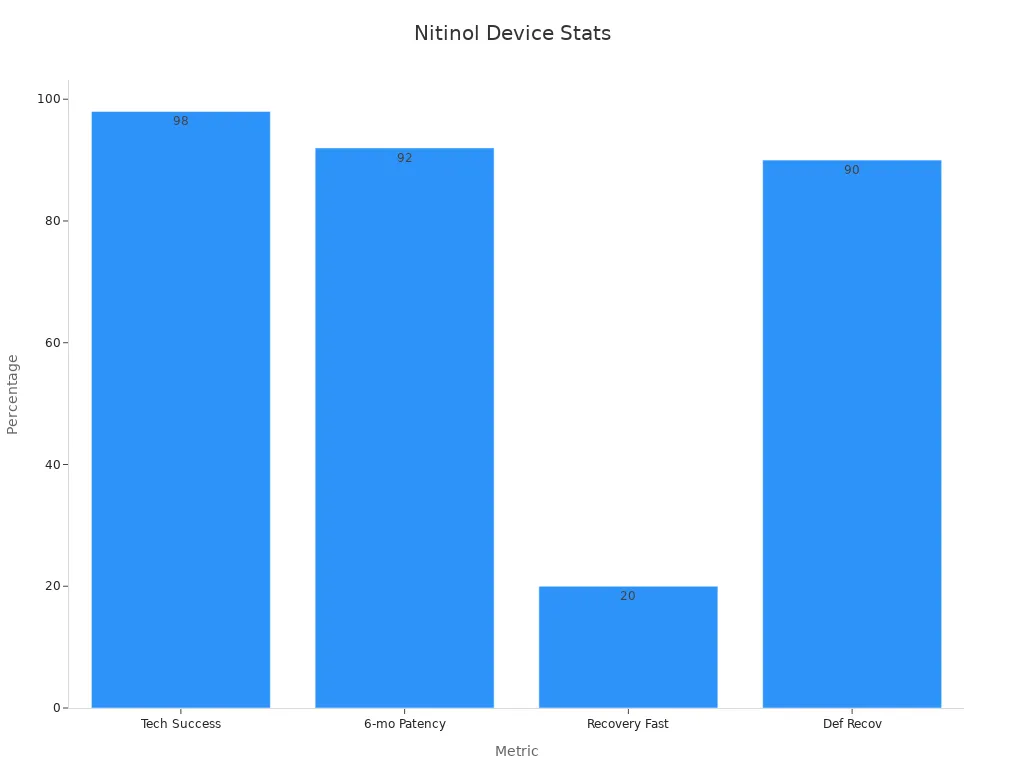

Selecting the right radiopaque nitinol tubing is very important. It can change how well a medical procedure works. Surgeons need clear images to move devices exactly where needed. Radiopaque properties help doctors see nitinol devices in real time. This lowers problems and helps keep patients safer. For example, nitinol devices work well up to 98% of the time. Patients also get better 20% faster.

Metric | Outcome for Nitinol Devices |

|---|---|

Technical Success | Up to 98% |

Patency Rate (6 mo) | 92% |

Recovery Improvement | 20% faster patient recovery |

Complication Rate | Lower, indicating safer outcomes |

Nitinol tubing bends easily and works well with the body. This makes it good for many types of procedures. Radiopaque markers, like tantalum, help doctors see the device better under X-ray. This makes the procedure safer and more accurate.

Key Takeaways

Radiopaque nitinol tubing lets doctors see devices better. This helps make treatments safer and more exact.

There are different tubing types. Each type has good and bad points. Some are easier to see. Some bend more. Some last longer. The best choice depends on what the procedure needs.

Fully radiopaque tubing is easiest to see. But it may not bend as well. Marker-banded and coated tubing bend better. They also show up well in images.

Custom nitinol tubing fits each patient better. This helps the device work well. It can help patients do better, especially in hard surgeries.

Doctors should think about what the procedure needs. They should look at imaging needs and if the device fits. This helps them pick tubing that is safe and works well.

Radiopaque Nitinol Tubing Overview

Key Properties

Radiopaque nitinol tubing is special because it is strong, bendy, and easy to see. Nitinol tube has an elastic modulus of 28 GPa and a Poisson’s ratio of 0.3. Its tensile strength is between 500 MPa and 900 MPa. This makes it good for tough medical jobs. How flexible the nitinol tube is depends on its design. Solitaire FR has a flexibility of 0.38 ± 0.11 N. Trevo XP ProVue has 0.91 ± 0.11 N. Stent D has 0.59 ± 0.05 N.

Property/Metric | Quantified Value |

|---|---|

Elastic Modulus | 28 GPa |

Poisson’s Ratio | 0.3 |

Tensile Strength | 500–900 MPa |

Flexibility (Solitaire FR) | 0.38 ± 0.11 N |

Flexibility (Trevo XP ProVue) | 0.91 ± 0.11 N |

Flexibility (Stent D) | 0.59 ± 0.05 N |

Nitinol tubing lasts a long time, even after many bends. Some custom tubes last over 10⁷ cycles. The tube can stretch up to 6% in one spot. Nitinol tube is safe for the body because of its titanium oxide surface. This layer stops rust and keeps nickel from leaking out. It lowers the chance of bad reactions. That is why it works well for sensitive uses, like neurovascular implants.

Why Radiopacity Matters

Radiopaque nitinol tubing is important in today’s medical procedures. The radiopaque feature lets doctors see the tube during placement and changes. This helps make the procedure safer and more exact.

Nitinol tube is hard to see on a regular X-ray, especially near bone.

Adding radiopaque markers, like platinum, helps doctors see the tube, but not always the whole thing.

Flat-panel CT gives clear 3D pictures of radiopaque nitinol tubing. It shows how the tube is placed and if there are problems.

Flat-panel CT lets doctors turn the images and look at the tube from many sides. This helps with tricky blood vessel paths.

Seeing the tube better helps doctors put it in the right spot and avoid problems.

Flat-panel CT is better than old imaging for small metal tubes. It helps find issues like kinks.

Better images of radiopaque nitinol tubing make treatments safer and work better.

Tip: Picking the right radiopaque nitinol tubing gives good strength and clear images. Both are needed for a successful procedure.

Comparison of Tubing Types

Fully Radiopaque Tubing

Fully radiopaque nitinol tubing is easy to see on X-rays. It uses special materials or designs. Platinum or tungsten are mixed into the tube. Doctors can see the whole device during surgery. This helps them place it in the right spot. It also keeps patients safer. Studies show these tubes work very well. The DAWN and PARTNER 3 trials had good results. Patients did better and fewer died when using these tubes. These tubes last a long time. They can bend millions of times and stretch up to 10%. But, adding radiopaque materials can make the tube less bendy. It can also make it harder to use. The table below shows how the tubes compare:

Property | Pure Nitinol Tube (NiTi FD) | Nitinol + Pt/W Wire (NiTi-Pt/W FD) | Platinum Core Nitinol Tube (NiTi(Pt) FD) |

|---|---|---|---|

Radiopacity | Low | Highest | Intermediate |

Flexibility | Best | Lower | Good |

Durability | High | Moderate | Moderate |

Ideal Use Case | Where flexibility is key | Where visibility is critical | Where balance is needed |

Note: Fully radiopaque nitinol tubing is easiest to see. But it may be harder to use and less flexible.

Marker-Banded Tubing

Marker-banded nitinol tube has small bands you can see on X-rays. These bands are made from tantalum or platinum. They are put at important spots on the tube. The rest of the tube stays bendy and strong. In hospitals, these tubes help blood vessels heal. They also stop too much tissue from growing inside. Doctors like marker-banded tubes when only some parts need to be seen. But, the rest of the tube can be hard to see. This can make tricky cases harder.

Marker-banded nitinol tube helps blood vessels heal.

The tube stays bendy and strong.

It can be hard to see the whole tube if needed.

Alloy-Blended Tubing

Alloy-blended nitinol tubing mixes other metals into the tube. Platinum or tungsten are often used. This makes the whole tube easier to see. Alloy-blended tubes are a good mix of visibility and strength. For example, Er-alloyed nitinol tube is about 80% easier to see than regular nitinol. Doctors can see the tube better and place it more easily. The tube stays superelastic and does not change shape much after use. But, mixing metals can make the tube less bendy or change how it works.

Coated Tubing

Coated nitinol tubing has a thin layer of radiopaque metal on top. Gold or platinum are used for the coating. This makes the tube easier to see on X-rays. The inside of the tube does not change. Tests show coated tubes can be 5–10% easier to see than some alloy-blended tubes. The tube stays strong and bendy. Doctors use coated tubes when they need both bendiness and visibility. The main problem is making sure the coating stays on after many bends.

Coated nitinol tube is up to 10% easier to see.

The tube keeps its shape and strength after many uses.

The coating must not come off over time.

Composite Tubing

Composite nitinol tubing mixes nitinol with other things. These can be polymers or metal wires. This makes a tube that is both easy to see and bendy. Doctors use composite tubes for hard surgeries. These tubes can be made special for each job. Extra wires or layers can be added where needed. But, making composite tubes is hard. It is tough to match how each part works together.

Tubing Type | Radiopacity | Flexibility | Durability | Ideal Use Case |

|---|---|---|---|---|

Fully Radiopaque | Highest | Moderate | High | Neurovascular, cardiovascular |

Marker-Banded | Targeted | High | High | Peripheral vascular, stent markers |

Alloy-Blended | High | Moderate | High | General vascular, GI, orthopedic |

Coated | High | High | High | Cardiac, neurovascular, GI |

Composite | Custom | Custom | Custom | Complex, multi-functional devices |

Tip: Picking the right nitinol tube means finding the best mix of visibility, bendiness, and strength. Doctors must think about what each surgery needs.

Challenges in Balancing Properties

Adding radiopaque features can change how nitinol tube bends and works. Doctors and engineers must pick the right mix of materials and designs. Too much radiopaque material can make the tube stiff. Too little can make it hard to see. The best tube depends on how easy it is to see, how bendy it is, and how long it lasts.

Radiopaque Nitinol Tubing: Applications and Benefits

Peripheral Vascular Nitinol Tubing

Peripheral vascular nitinol tubing is very important in treating blood vessels. Doctors use it in stents and catheters to open blocked arteries. This helps blood flow better. The tubing has superelasticity, shape memory, and high fatigue resistance. These features help it handle many blood pressure cycles. Clinical trials show it works well for these treatments. For example, studies show a 100% technical success rate. The procedural success rate is 98.2% for stent use. Patients get better blood flow and can walk farther. The restenosis rate at six months is low. The SENS-FP trial shows nitinol stents are safe and last a long time.

Metric | Outcome |

|---|---|

Technical success rate | 100% |

Procedural success rate | 98.2% |

Restenosis rate (6 months) | 8.5% |

Walking capacity | +147 meters |

Rutherford index | 72% improvement |

Nitinol tubing helps patients recover faster and have fewer problems. It is reliable for vascular procedures.

Neurovascular and Cardiovascular Uses

Radiopaque nitinol tubing is used in many brain and heart treatments. Devices like flow diverters and aneurysm implants use this tubing. It is flexible and easy to see on images. In one study, the Contour device had high technical success. It also had strong occlusion rates at 6 and 12 months. The Silk Vista Mama flow diverter is made from nitinol and platinum. It worked very well for treating brain aneurysms. These devices fit into tricky blood vessels and can be placed exactly where needed. Doctors can see the tubing clearly during surgery. This makes the procedure safer and lowers risks. Nitinol’s superelasticity and biocompatibility make it a good choice for tough vascular jobs.

Orthopedic and Other Applications

Nitinol tubing is also used in bone and other medical treatments. Surgeons use it in bone anchors, spinal implants, and small tools. The tubing can return to its shape and does not break easily. This makes it dependable for these uses. Nitinol is more flexible and resists rust better than stainless steel. This means less tissue damage and fewer bad reactions. In other devices, radiopaque nitinol tubing helps doctors see and place things correctly. These uses help doctors do safer and better procedures in many areas.

Nitinol tubing is used in many types of medical devices.

Its special features make treatments safer, quicker, and more dependable.

Radiopaque markers help doctors see and place devices in all kinds of procedures.

Choosing the Right Tubing

Assessing Procedure Needs

Picking the best radiopaque nitinol tubing starts with knowing what the procedure needs. Every procedure is different and needs its own level of visibility, flexibility, and safety. Doctors should think about these things:

Visibility: Some procedures, like neurovascular ones, need to see the device very clearly. In these cases, fully radiopaque or alloy-blended tubing might be needed.

Flexibility: Some blood vessels twist and turn a lot. These need tubing that bends without breaking. Marker-banded or coated tubing can give the right mix of bendiness and strength.

Durability: Some devices are used over and over or for a long time. These need tubing that can handle lots of use. Fatigue resistance helps the tubing last through the whole procedure and even longer.

Biocompatibility for medical applications: The tubing must be safe inside the body. The surface of nitinol stops rust and keeps bad reactions low. This makes it good for sensitive jobs.

Tip: Doctors should pick tubing that matches what the procedure needs. For example, a guidewire for a tough blood vessel job needs to bend well and be easy to see on X-rays.

Matching Tubing to Applications

Choosing the right tubing for the job helps patients do better and stay safer. Here is a simple way to pick the best tubing:

Define the clinical goal: Figure out if the job is stenting, blocking blood flow, or moving through small vessels.

Evaluate imaging requirements: Brain and heart procedures often need tubing that shows up well on scans. Newer scans, like 3D X-ray or C-arm cone beam CT, help doctors see better without more radiation.

Balance mechanical properties: Do not just make the tubing thicker to see it better. That can change how it works. Pick tubing that is easy to see and still bends well.

Consider procedural complexity: For less invasive jobs, tubing should fit the shape of the vessel and not hurt tissue. Composite or coated tubing can help with this.

Review device compatibility: Make sure the tubing works with other tools and scans used during the procedure.

Note: In brain procedures, seeing the nitinol tubing clearly is very important. Doctors use high-quality scans and special dyes to watch the device and make sure it fits the vessel wall.

Common Clinical Scenarios

Peripheral vascular stenting: Doctors often use marker-banded tubing. It is easy to see in certain spots and bends well.

Neurovascular aneurysm repair: Fully radiopaque or alloy-blended tubing helps doctors see and place the device in tiny vessels.

Cardiac interventions: Coated tubing gives a good mix of being easy to see and bending well for moving through the heart.

Orthopedic device placement: Composite tubing can be made to fit special bone shapes.

Customization and Sourcing

Making tubing special for each patient is very important for some procedures. Companies use new methods, like additive manufacturing, to make nitinol tubing in special shapes for each person. Custom tubing fits better and works better, which helps patients get better results.

Performance Metric | Benefit in Clinical Outcomes |

|---|---|

Superelasticity | Lets stents spring back to shape after bending. This helps them fit and work well in tricky blood vessels. |

Biocompatibility | Makes sure the tubing is safe in the body. This lowers bad reactions and keeps patients safer. |

Fatigue Resistance | Helps the device last a long time, even with lots of use. |

Flexibility | Lets wires and stents bend to fit vessels. This means less damage to tissue during surgery. |

Clinical Outcomes | Custom nitinol devices help doctors succeed more in heart procedures. |

Additive manufacturing lets companies make nitinol tubing just for one patient.

Custom tubing fits better and works better in blood vessels.

Special surface changes make tubing safer and stop rust.

Nitinol can remember its shape and stretch, so doctors can do less invasive surgeries with less damage and faster healing.

Studies show custom nitinol stents and wires help doctors succeed more in heart procedures.

Aspect | Evidence |

|---|---|

Regional Demand | South Korea has more hybrid operating rooms than other places. This means more need for radiopaque nitinol wires in image-guided surgeries. |

Market Variation | In Mexico, many doctors use refurbished nitinol devices. This lowers the use of new, high-quality alloys even though more surgeries are happening. |

Quality Standards | Most U.S. buyers want nitinol wire from ISO 13485-certified factories. Fewer buyers in Latin America ask for this, so the U.S. has stricter rules. |

Alloy Customization | Suppliers change nickel levels to get the right temperature for heart and brain devices. |

Proprietary Processes | Fort Wayne Metals’ Alloy Blue process makes nitinol wire easier to see but still strong. Doctors like this wire for special catheters and protection devices. |

Industry Adoption | Many companies want custom tubing and suppliers are investing more. This shows custom tubing is working well, even if there are not exact numbers. |

Custom nitinol parts made to fit a patient’s blood vessels mean fewer repeat surgeries. Custom stents open to the right size, so they fit and work better. Nitinol catheters can move through tricky blood vessels, giving doctors more control. These new ideas help doctors care for patients better and give more ways to treat them.

Doctors should work with suppliers who can make custom tubing and follow strict quality rules. This helps make sure the tubing works well for tough procedures and gives the best results for patients.

Picking the right radiopaque nitinol tubing helps keep patients safe and makes devices work better. Every medical job needs tubing that is easy to see, bends well, and is safe for the body. Some important things to think about are:

Making sure the tube has the right mix of metals keeps it strong.

Heating and shaping the tube changes how strong and bendy it is.

Radiopaque markers like platinum help doctors see the device during surgery.

Working with suppliers helps find tubing that fits each job.

Doctors should talk to experts to choose the best tubing. If you want more help or advice, ask trusted suppliers or medical partners.

FAQ

What makes nitinol tubing radiopaque?

Radiopaque nitinol tubing has metals like platinum or tantalum. These metals help the tubing show up on X-rays and CT scans. Doctors can see the device during surgery and put it in the right place.

Can radiopaque nitinol tubing be customized for specific patients?

Yes, companies can make nitinol tubing special for each patient. They change the size, shape, and radiopaque parts to fit what is needed. Custom tubing helps the device work better and helps patients get better results.

How does radiopacity affect device flexibility?

Adding radiopaque metals can make tubing less bendy. Engineers try to use just enough metal so the tube is easy to see and still bends well. The right mix helps the device work in hard surgeries.

Is radiopaque nitinol tubing safe for long-term use in the body?

Nitinol tubing has a titanium oxide layer on its surface. This layer stops rust and keeps nickel from coming out. The tubing stays safe and works well in the body for a long time.

See Also

The Importance Of Nitinol Tubing In Minimally Invasive Surgery

The Process Behind Manufacturing Nitinol Tubing For Medicine

Choosing The Right Nitinol Tubing Supplier For Your Requirements

The Critical Role Of Nitinol Tubing In Modern Medical Uses

How Nitinol Tubing Drives Progress In Medical Technology Today