How to Achieve Ra Less Than 0.2 Micrometers in Electropolished Nitinol Tubing

Ultra-smooth surfaces with ra below 0.2μm in electropolished nitinol tubing play a vital role in medical nitinol tubing and other advanced uses. Market research shows the demand for ra<0.2μm electropolished nitinol tubing is rising, reaching a projected USD 2.1 billion by 2033. The electropolishing process removes surface impurities, which improves surface quality and helps medical devices resist corrosion. Electropolished nitinol tubing achieves tensile strength up to 900 MPa and withstands 10 million cycles, making it ideal for medical nitinol tubing. These features help prevent early failure and boost biocompatibility in medical devices.

Key Takeaways

Start with high-quality, pure nitinol tubing that meets medical standards to ensure safety and durability.

Prepare the tubing surface carefully by grinding, polishing, and cleaning to remove flaws before electropolishing.

Control electropolishing settings like temperature, current, and timing to achieve a smooth surface with Ra below 0.2 micrometers.

Use thorough rinsing, drying, and careful handling after electropolishing to protect the ultra-smooth surface from damage.

Regularly measure surface roughness and maintain equipment and operator training to keep quality consistent and meet strict medical requirements.

Preparation

Nitinol Tubing Selection

Selecting the right nitinol tubing forms the foundation for achieving ultra-smooth surfaces in medical nitinol tubing. High-purity nitinol reduces fracture risk and ensures reliable performance. Manufacturers should follow ASTM F2063 and other regulatory standards to guarantee safety and biocompatibility. Tubing with tensile strength between 500 MPa and 900 MPa provides the mechanical robustness needed for medical nitinol tubing. Customization of dimensions and finishes helps meet specific device requirements. Reputable suppliers offer thorough quality control, including sample testing and facility audits.

Aspect | Best Practices and Benchmarks |

|---|---|

Material Purity | Use high-purity nitinol tubing for long-term reliability. |

Regulatory Standards | Follow ASTM F2063, FDA, and CE guidelines. |

Fatigue Life | Choose tubing with superior fatigue resistance. |

Surface Treatment | Electropolishing enhances corrosion resistance and biocompatibility. |

Supplier Selection | Work with trusted manufacturers who provide quality control and customization. |

Grinding and Polishing

Precision grinding and polishing prepare the surface of nitinol tubing for electropolishing. These steps remove surface irregularities and create a uniform finish. Electropolished nitinol tubing benefits from this preparation, as smoother surfaces improve fatigue life and reduce the risk of mechanical failure. Grinding and polishing also help maintain the shape memory and flexibility of nitinol, which are essential for medical nitinol tubing. A well-prepared surface allows the electropolished process to achieve roughness values below 0.2 micrometers.

Tip: Smoother surfaces reduce friction during device insertion, improving both performance and patient safety.

Cleaning and Inspection

Thorough cleaning and inspection ensure that nitinol tubing is free from contaminants before electropolishing. Chemical cleaning, etching, and micro-blasting remove dirt, oils, and surface flaws. Automated visual inspection systems check for defects and confirm surface readiness. Advanced techniques such as scanning electron microscopy (SEM), atomic force microscopy (AFM), and X-ray photoelectron spectroscopy (XPS) provide detailed analysis of surface morphology and cleanliness. These steps are critical for producing high-quality electropolished nitinol tubing used in medical applications.

Electropolished nitinol tubing with proper preparation supports over 95% healthy cell growth.

Lower protein adsorption reduces blood clot risks in medical nitinol tubing.

Surface defects are eliminated, preserving structural integrity under dynamic forces.

Electropolishing Process

Electrolyte Selection

The electropolishing process starts with the right electrolyte. Many experts choose a 0.2 M NaNO3 ozonated electrolyte for nitinol. This solution helps remove tiny peaks and valleys from the tubing surface. Ozone in the electrolyte increases the reaction rate. It also helps create a more even finish. The 0.2 M NaNO3 solution works well for medical and high-performance applications. It supports the production of ra<0.2μm electropolished nitinol tubing. The electrolyte must stay clean and fresh. Dirty or old solutions can cause defects in electropolished nitinol tubing.

Note: Ozonated electrolytes help achieve ra <0.1μm surface roughness by breaking down stubborn surface layers.

Process Parameters

The electropolishing process depends on several key settings. Each setting affects the final surface roughness. Operators must control temperature, current density, timing, and agitation.

Temperature: Keep the electrolyte between 20°C and 30°C. Higher temperatures can cause pitting. Lower temperatures slow the process.

Current Density: Use a current density of 0.1 to 0.3 A/cm². This range removes material evenly. It helps achieve ra<0.2μm electropolished nitinol tubing.

Timing: Most cycles last 2 to 5 minutes. Longer times can over-polish the tubing. Shorter times may not remove enough material.

Agitation: Gentle stirring or bubbling keeps the electrolyte moving. This prevents buildup on the nitinol surface.

Parameter | Recommended Value | Effect on Surface Roughness |

|---|---|---|

Temperature | 20°C - 30°C | Prevents pitting, ensures uniformity |

Current Density | 0.1 - 0.3 A/cm² | Controls material removal |

Timing | 2 - 5 minutes | Balances removal and finish |

Agitation | Gentle, continuous | Avoids uneven polishing |

Operators must monitor these factors during every electropolishing process. Small changes can affect ra and surface roughness. Consistent control leads to better ra<0.2μm electropolished nitinol tubing.

Ra<0.2μm Electropolished Nitinol Tubing

Achieving ra less than 0.2 micron takes skill and attention to detail. The electropolishing process removes surface flaws and creates a mirror-like finish. Many labs now reach ra <0.1μm surface roughness with advanced controls. This level of smoothness improves device safety and performance.

Steps to achieve ra <0.1μm surface roughness:

Start with high-quality nitinol tubing.

Use precision grinding and polishing before electropolishing.

Select a 0.2 M NaNO3 ozonated electrolyte.

Set process parameters carefully.

Monitor ra and surface roughness after each cycle.

Tip: Regularly check the electrolyte and equipment. Clean tools and fresh solutions help maintain ra <0.1μm surface roughness.

The electropolished nitinol tubing must pass strict tests. Operators use profilometers and microscopes to measure ra and surface roughness. Only tubing that meets the ra<0.2μm electropolished nitinol tubing standard moves to the next step. Some facilities now produce ra <0.1μm surface roughness for the most demanding uses.

The electropolishing process gives nitinol its best properties. It improves corrosion resistance and biocompatibility. It also reduces friction and wear. Medical devices made from ra<0.2μm electropolished nitinol tubing last longer and perform better. The process supports the highest surface quality for critical applications.

Post-Processing

Rinsing and Neutralization

After electropolishing, thorough rinsing and neutralization protect the ultra-smooth surface of electropolished nitinol tubing. Operators remove all traces of electrolyte and by-products to prevent staining or white spots. A typical process uses a mild alkaline dip, such as a soda ash solution, followed by several clean water rinses. This step ensures that no chemical residues remain on the tubing. If residues stay, they can cause surface contamination and reduce corrosion resistance.

Proper rinsing and neutralization keep the surface free from stains and help maintain low ra values.

Problem | Cause of Issue | Correction |

|---|---|---|

Staining | Poor, inadequate, slow, or contaminated rinsing | Proper rinsing with alkaline neutralization dip and clean water rinse |

Researchers have found that post-processing steps targeting inclusion size and surface chemistry are critical. These steps help maintain the surface roughness and prevent pitting corrosion in electropolished nitinol tubing.

Drying and Handling

Drying and careful handling come next. Operators use filtered air or heated drying ovens to remove all moisture. Tubing must not touch any unclean surfaces during this stage. Clean gloves and tools prevent new contaminants from reaching the electropolished surface. Even small particles or fingerprints can increase surface roughness and affect ra measurements.

A controlled environment reduces the risk of recontamination. This step supports the long-term stability of the electropolished nitinol tubing and keeps the surface ready for final inspection.

Surface Measurement

Accurate measurement of surface roughness confirms the success of the process. Technicians use profilometers to scan the tubing and record ra values. Atomic force microscopy and scanning electron microscopy provide detailed images of the surface. These tools help detect any remaining inclusions or defects.

Surface roughness measurements must show ra below 0.2 micrometers for medical and high-performance uses. Regular checks ensure that the electropolished nitinol tubing meets strict quality standards. If measurements show higher ra, operators repeat cleaning or adjust earlier steps.

Consistent surface measurement protects product quality and patient safety.

Quality Control

Ra Measurement Methods

Quality control teams use several methods to verify that ra<0.2μm electropolished nitinol tubing meets strict standards for medical devices. Profilometry stands as the most common tool. It scans the surface of nitinol and measures the average roughness, or ra, across the tubing. Atomic force microscopy and scanning electron microscopy give even more detail. These methods can detect tiny changes in surface roughness, including ra <0.1μm surface roughness. Technicians often check multiple points along the tubing to ensure consistency. Regular calibration of measurement tools helps maintain accuracy. By using these advanced techniques, manufacturers confirm that electropolished nitinol tubing achieves the required ra and surface roughness for safe use in medical devices.

Common Defects

During the electropolishing process, some defects can appear in medical nitinol tubing. These flaws can affect the performance and safety of medical devices. Researchers have identified several common defects:

Non-metallic inclusions, such as oxides and carbides, can form during tube drawing.

Particle-void assemblies develop when brittle particles break and create voids.

Inclusion-cluster stringers appear as lines of defects in the tubing.

These defects often act as starting points for cracks, which can lower fatigue life.

Microstructural anisotropies show up as stringer-like defects in certain sections.

Matrix healing can sometimes close elongated voids, changing how defects look.

Technicians use scanning electron and optical microscopy to find and measure these defects. Automated image analysis helps detect flaws as small as 108 nanometers. All fractures in tested samples started at inclusion particles, showing their importance in quality control. By understanding and controlling these defects, manufacturers improve the reliability of ra <0.1μm surface roughness in medical nitinol tubing.

Documentation

Proper documentation supports every step of the electropolishing process for medical nitinol tubing. Manufacturers follow strict standards and keep detailed records to meet regulatory requirements for medical devices. The table below shows key types of documentation and their roles:

Evidence Type | Description |

|---|---|

Regulatory Certification | ISO 13485 and ISO 9001 certifications prove quality management for medical devices. |

Validation Data | ASTM standards confirm chemical makeup, mechanical strength, and fatigue resistance. |

Quality Control Processes | Validation plans, process checks, and change controls ensure ongoing product quality. |

Manufacturing Environment | FDA-registered sites and cleanrooms keep conditions controlled for electropolished tubing. |

Documentation | Certificates of analysis and test reports confirm compliance with all specifications. |

Risk Management | Risk analysis and supplier audits help maintain safety and compliance for medical devices. |

These records help manufacturers prove that ra <0.1μm surface roughness and other standards are met. Certified companies report fewer defects and recalls, which improves patient safety and supports global market access for medical nitinol tubing.

Consistency Tips

Equipment Maintenance

Regular equipment maintenance keeps the electropolishing process stable. Clean and calibrated machines help operators achieve ultra-smooth surfaces on nitinol tubing. Well-maintained tools prevent unexpected changes in tubing thickness and surface finish. This control is important for making medical devices like stents, where even small defects can cause problems. When technicians keep post-process equipment in good condition, they support high yields and reduce the risk of surface flaws. Consistent maintenance also helps control the inner diameter and concentricity of nitinol tubes, which leads to better results in downstream manufacturing.

Tip: Schedule routine checks for all polishing and rinsing equipment to avoid contamination and maintain predictable results.

Operator Training

Skilled operators play a key role in producing high-quality nitinol tubing. Training programs teach workers how to set up machines, monitor process parameters, and spot early signs of trouble. Operators learn to follow strict cleaning steps and handle tubing with care. They also practice using measurement tools like profilometers and microscopes. When operators understand each step, they can quickly fix issues and keep the process on track. This training helps maintain low surface roughness and supports safety in medical applications.

Operators should:

Follow standard operating procedures.

Use gloves and clean tools.

Record all process data for traceability.

Continuous Improvement

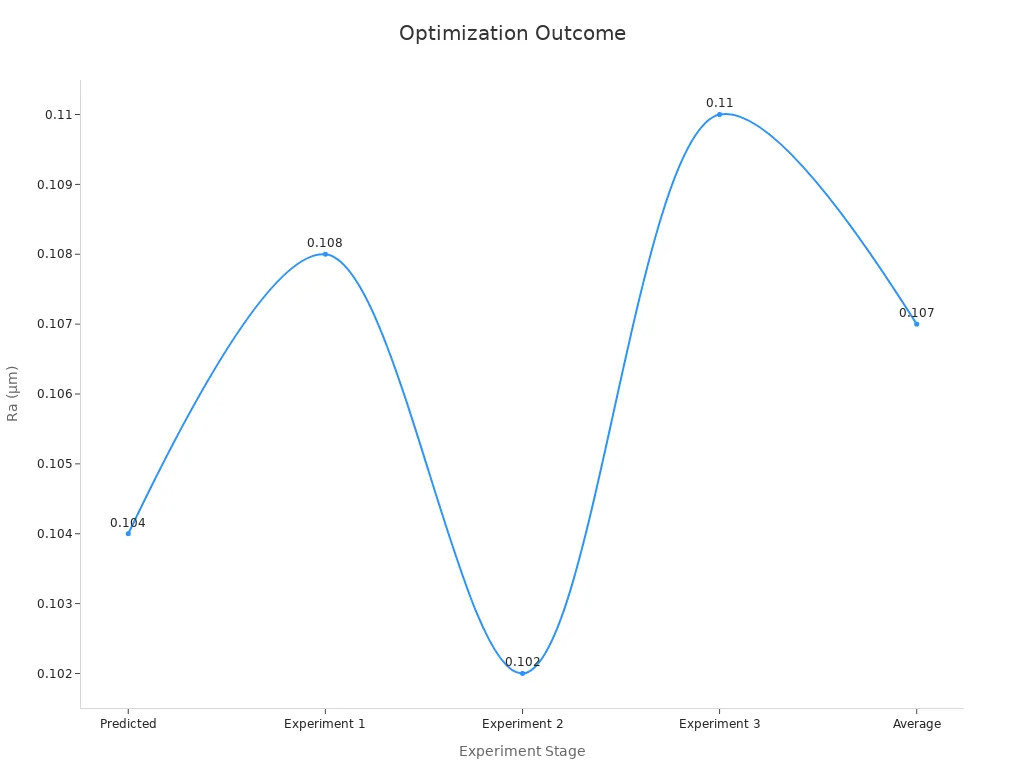

Continuous improvement strategies help manufacturers reach new levels of quality. By using response surface methodology, teams can optimize finishing parameters for nitinol tubing. For example, adjusting tubing rotation speed, magnetic pole feed rate, abrasive filling, and machining gap can lower surface roughness. The table below shows how these optimized values lead to better results:

Parameter | Optimized Value |

|---|---|

Tubing rotation speed | 600 r/min |

Magnetic pole feed rate | 150 mm/min |

Magnetic abrasive filling | 0.150 g |

Machining gap | 0.500 mm |

Surface Roughness (Ra) | Value (µm) |

|---|---|

Predicted | 0.104 |

Experiment 1 | 0.108 |

Experiment 2 | 0.102 |

Experiment 3 | 0.110 |

Average Experimental Value | 0.107 |

Prediction Error | 2.9% |

Manufacturers also track quality metrics like material removal rate, porosity, and dimensional accuracy. These improvements help nitinol tubing meet strict standards for biocompatibility and durability. Over time, better surface finishes and stable mechanical properties support safer and more reliable medical devices.

Manufacturers achieve low ra by following strict steps for medical nitinol tubing. They select high-quality tubing, control each process, and check every surface. These actions help medical nitinol tubing meet safety and performance goals. Regular quality checks and ongoing improvements keep ra values low. Medical nitinol tubing with smooth surfaces passes tough regulatory tests. Teams should use these best practices and watch for new technology in the field.

FAQ

What does Ra mean in surface roughness?

Ra stands for "roughness average." It measures the average height of tiny bumps and dips on a surface. Lower Ra values mean a smoother surface. Medical devices often need Ra less than 0.2 micrometers for safety and performance.

A lower Ra value helps reduce friction and improve biocompatibility.

Why is electropolishing important for nitinol tubing?

Electropolishing removes surface flaws and creates a shiny, smooth finish. This process improves corrosion resistance and makes the tubing safer for medical use. It also helps devices last longer and work better inside the body.

How do technicians measure Ra on nitinol tubing?

Technicians use special tools called profilometers. These tools scan the tubing and show the Ra value. Sometimes, they use microscopes for a closer look. Regular checks help ensure the tubing meets strict quality standards.

Tool | Purpose |

|---|---|

Profilometer | Measures Ra value |

Microscope | Checks for defects |

What problems can occur if Ra is too high?

High Ra values can cause more friction and increase the risk of blood clots. Rough surfaces may also collect bacteria or damage tissue. Medical devices with high Ra may fail safety tests or not last as long.

See Also

The Process Behind Manufacturing Nitinol Tubing For Medicine

Finding The Most Cost-Effective 2mm Nitinol Tubing Supplier

Detailed Steps To Create Nitinol Microtubing For Neurovascular Use

How To Choose The Best Nitinol Tubing: A Complete Guide

The Importance Of Nitinol Tubing In Minimally Invasive Surgery