What You Need to Know About PTFE Liners with Tie Layers in Healthcare

PTFE Liner with Tie Layer technology plays a pivotal role in modern healthcare. A PTFE Liner with Tie Layer, crafted from polytetrafluoroethylene, offers a smooth, low-friction surface that minimizes tissue damage and infection risks. Its biocompatibility ensures safe integration into medical devices. The incorporation of a tie layer enhances adhesion between materials, significantly reducing the likelihood of device failure. This innovative combination provides unmatched durability and precision, making a PTFE Liner with Tie Layer indispensable for advanced medical applications. Whether in catheters or other minimally invasive tools, a PTFE Liner with Tie Layer redefines reliability and performance in healthcare technology.

Key Takeaways

PTFE liners with tie layers provide a smooth, low-friction surface that minimizes tissue damage and infection risks during medical procedures.

The incorporation of a tie layer enhances adhesion between materials, significantly reducing the likelihood of device failure and ensuring structural integrity.

These liners are biocompatible, making them safe for use in various medical applications, including catheters, stents, and guidewires.

PTFE's chemical resistance and durability allow medical devices to perform reliably in harsh environments, maintaining their functionality over time.

The ultra-thin walls of PTFE liners enable precision in medical devices, enhancing maneuverability and accuracy during minimally invasive procedures.

By preventing delamination, tie layers ensure the longevity and reliability of medical devices, contributing to improved patient safety.

Innovations in PTFE liner production continue to enhance their performance, making them essential for advancing medical technology and improving treatment outcomes.

What Are PTFE Liners with Tie Layers?

Definition of PTFE Liners

A PTFE Liner, made from polytetrafluoroethylene, is a critical component in many medical devices. This material is renowned for its smooth, low-friction surface, which minimizes tissue damage during medical procedures. Its biocompatibility ensures that it integrates safely into the human body, reducing the risk of allergic reactions or adverse responses. PTFE liners also feature ultra-thin walls, allowing for precise applications in devices like catheters. These liners provide durability and chemical resistance, making them suitable for use in harsh environments often encountered in healthcare.

What Is a Tie Layer?

A tie layer is an ultra-thin thermoplastic coating applied to the outer surface of a PTFE liner. This layer enhances adhesion between the liner and other materials used in medical device construction. Without a tie layer, the risk of delamination increases, which can compromise the structural integrity of the device. The tie layer acts as a bonding agent, ensuring that the PTFE liner remains securely attached to the surrounding components. Manufacturers often use this layer to improve the overall performance and reliability of medical devices, particularly in high-stress applications.

How PTFE Liners and Tie Layers Work Together in Medical Devices

When combined, PTFE liners and tie layers create a robust and efficient solution for medical devices. The PTFE liner provides a smooth, lubricious surface that facilitates the easy movement of devices like catheters through the body. Meanwhile, the tie layer ensures that the liner adheres firmly to the device's outer structure, preventing separation during use. This combination enhances the device's durability, flexibility, and performance. For example, in catheter manufacturing, the tie layer reduces the likelihood of failure, ensuring that the device performs reliably even under challenging conditions. Together, these components redefine the standards of safety and efficiency in healthcare technology.

Key Features of PTFE Liners with Tie Layers

Ultra-Thin Walls for Precision in Medical Devices

PTFE liners with tie layers feature ultra-thin walls, which are essential for precision in medical devices. These thin walls allow for the creation of compact and lightweight tools, such as catheters and guidewires, that can navigate the intricate pathways of the human body. You benefit from the enhanced maneuverability and accuracy these devices provide during minimally invasive procedures. The ultra-thin design also ensures that the devices maintain their structural integrity while delivering exceptional performance. This combination of precision and durability makes PTFE liners with tie layers a cornerstone of advanced healthcare technology.

Chemical Resistance and Durability in Harsh Environments

The chemical resistance of PTFE liners ensures their reliability in challenging medical environments. PTFE is chemically inert, meaning it does not react with most substances, including bodily fluids and harsh sterilization agents. This property protects the device from degradation, ensuring consistent performance over time. Additionally, the material's durability allows it to withstand extreme temperatures and mechanical stress without breaking or tearing. You can trust that medical devices incorporating PTFE liners with tie layers will perform reliably, even under the most demanding conditions. This resilience is critical for maintaining patient safety and device functionality.

Biocompatibility for Safe Use in Healthcare Applications

Biocompatibility is a defining feature of PTFE liners with tie layers. These materials integrate seamlessly into medical devices, minimizing the risk of adverse reactions when used in the human body. Their non-toxic and hypoallergenic properties ensure that they are safe for patients, even during prolonged use. You can rely on these liners to meet stringent healthcare standards, providing peace of mind for both medical professionals and patients. The biocompatibility of PTFE liners also supports their use in a wide range of applications, from catheters to stents, enhancing their versatility in modern medicine.

The Role of Tie Layers in Medical Applications

Enhancing Adhesion Between Materials

Tie layers serve as a critical component in medical devices by improving adhesion between different materials. When constructing devices like catheters or stents, manufacturers often combine materials with varying properties to achieve optimal performance. Without a tie layer, these materials may fail to bond effectively, leading to weak points in the device. The tie layer acts as a bridge, creating a strong and stable connection between the PTFE liner and the outer layers. This enhanced adhesion ensures that the device maintains its structural integrity during use, even under high stress or in challenging environments.

According to a study published in MarketsandMarkets, tie layer resins significantly enhance the mechanical integrity of medical components by providing robust adhesion between materials. This improvement not only strengthens the device but also enhances its barrier properties against contaminants and moisture.

By incorporating tie layers, you can trust that medical devices will perform reliably, reducing the risk of failure during critical procedures. This feature is especially valuable in minimally invasive tools, where precision and durability are paramount.

Preventing Delamination and Ensuring Structural Integrity

Delamination, or the separation of layers within a device, poses a significant risk in medical applications. It can compromise the functionality of the device and endanger patient safety. Tie layers play a vital role in preventing this issue. By securely bonding the PTFE liner to other materials, the tie layer minimizes the likelihood of delamination, even under extreme conditions.

A report from News-Medical highlights how tie layer technology reduces delamination risks, ensuring the structural integrity of medical devices. This advancement directly contributes to improved patient safety and device reliability.

You benefit from this technology because it ensures that devices maintain their form and function throughout their lifespan. Whether used in catheters, guidewires, or stents, the tie layer provides the stability needed for consistent performance.

Improving Device Performance and Longevity

The inclusion of tie layers in medical devices not only enhances their immediate functionality but also extends their operational lifespan. By creating a durable bond between the PTFE liner and other components, the tie layer reduces wear and tear over time. This durability translates to fewer device failures and longer periods of reliable use.

For you, this means access to medical tools that deliver consistent results, even after prolonged use. The tie layer's ability to withstand mechanical stress and environmental challenges makes it an indispensable feature in modern healthcare technology. Devices equipped with this technology not only perform better but also contribute to advancing medical practices by setting new standards for reliability and safety.

Applications of PTFE Liners with Tie Layers in Healthcare

Use in Catheters for Minimally Invasive Procedures

PTFE liners with tie layers have transformed catheter technology, making them indispensable in minimally invasive procedures. These liners provide a smooth, low-friction surface, which reduces resistance during insertion and withdrawal. This feature enhances patient comfort and minimizes tissue damage. You benefit from the biocompatibility of PTFE, ensuring safe interaction with the human body while reducing the risk of adverse reactions.

The durability and chemical resistance of PTFE liners allow catheters to perform reliably in challenging environments. They withstand exposure to bodily fluids and sterilization processes without degrading. The tie layer further strengthens the catheter by improving adhesion between the PTFE liner and the outer materials. This combination ensures structural integrity and prevents delamination, even under high stress. Whether used in diagnostic or therapeutic applications, catheters with PTFE liners and tie layers deliver precision and reliability.

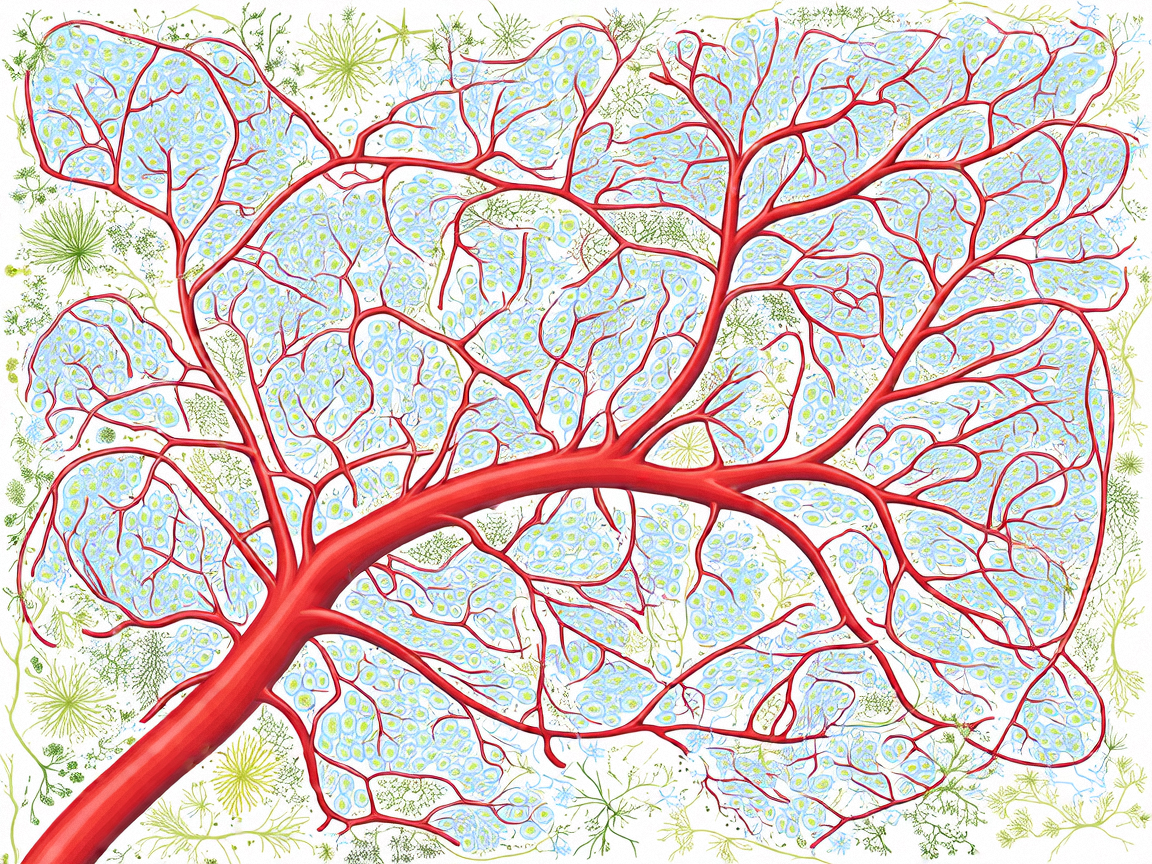

Role in Stents and Vascular Devices

Stents and vascular devices rely on PTFE liners with tie layers to achieve optimal performance. The low-friction properties of PTFE facilitate the smooth delivery of these devices through narrow and delicate blood vessels. This feature is critical in procedures requiring precision, such as angioplasty. You can trust that these liners reduce the risk of complications by ensuring seamless navigation within the vascular system.

The tie layer enhances the durability of stents by bonding the PTFE liner to the device's structure. This bond prevents delamination, ensuring the device maintains its form and function over time. PTFE's chemical stability also protects stents from degradation caused by bodily fluids or medications. These features make PTFE liners with tie layers a cornerstone in the development of advanced vascular devices, offering you safer and more effective treatment options.

Application in Guidewires, Introducers, and Dilators

Guidewires, introducers, and dilators benefit significantly from the integration of PTFE liners with tie layers. The lubricious surface of PTFE allows these devices to glide effortlessly through tight anatomical pathways. This property reduces friction, making procedures less invasive and more comfortable for patients. You gain from the enhanced maneuverability and precision these devices provide.

The tie layer ensures that the PTFE liner remains securely attached to the device, even under mechanical stress. This stability is crucial for maintaining the device's performance during complex procedures. PTFE's durability and flexibility further enhance the reliability of guidewires, introducers, and dilators. These features make them suitable for a wide range of medical applications, from vascular interventions to gastrointestinal procedures. By incorporating PTFE liners with tie layers, manufacturers deliver tools that meet the highest standards of safety and efficiency.

Manufacturing and Quality Control of PTFE Liners with Tie Layers

Overview of the Manufacturing Process

The production of PTFE liners with tie layers involves a meticulous process that ensures precision and quality. Manufacturers begin by extruding PTFE into ultra-thin tubing, which serves as the liner. This step requires advanced extrusion techniques to achieve the desired wall thickness and smooth surface. The tie layer, typically made from thermoplastic materials like Nylon or Pebax®, is then applied to the PTFE liner. This layer enhances adhesion and strengthens the bond between the liner and the outer components of medical devices.

To ensure consistency, manufacturers often use mandrels during the fabrication process. These mandrels help maintain the liner's shape and dimensions while the tie layer is applied. The combination of PTFE's lubricious properties and the tie layer's bonding capabilities creates a product that meets the rigorous demands of healthcare applications. Company like AccuPath has refined this process to deliver high-performance liners tailored to specific medical needs.

Quality Control Measures to Ensure High Performance

Quality control plays a critical role in the production of PTFE liners with tie layers. Manufacturers implement stringent measures to ensure that each liner meets industry standards for safety and performance. These measures include:

Dimensional Accuracy Testing: Ensuring the liner's thickness and diameter align with specifications.

Adhesion Strength Testing: Verifying the bond between the PTFE liner and the tie layer to prevent delamination.

Chemical Resistance Evaluation: Confirming the liner's ability to withstand exposure to bodily fluids and sterilization agents.

Biocompatibility Testing: Ensuring the materials are safe for use in medical devices and do not cause adverse reactions.

Advanced inspection technologies, such as laser micrometers and automated vision systems, are often employed to detect defects. These tools allow manufacturers to identify and address issues early in the production process, ensuring consistent quality. By adhering to these rigorous standards, you can trust that PTFE liners with tie layers will perform reliably in critical medical applications.

Innovations in PTFE Liner with Tie Layer Production

The field of PTFE liner manufacturing continues to evolve, driven by innovations that enhance performance and efficiency. One notable advancement is the development of "strike layers," which are thin thermoplastic coatings applied to the PTFE surface. These layers, available in materials like Tecoflex® and Pebax®, further improve adhesion and reduce the risk of delamination.

Another breakthrough involves the use of custom extrusion techniques to create liners with complex geometries. These techniques allow manufacturers to produce liners tailored to specific medical devices, such as catheters and stents. Additionally, researchers are exploring new ways to enhance the durability and flexibility of PTFE liners, ensuring they can withstand the demands of modern healthcare.

According to a report from AccuPath, these innovations not only improve the reliability of medical devices but also reduce manufacturing costs by streamlining production processes. This progress benefits both manufacturers and end-users by delivering high-quality products at a lower cost.

As these advancements continue, you can expect PTFE liners with tie layers to play an even more significant role in advancing medical technology. Their unmatched combination of precision, durability, and biocompatibility ensures they remain a cornerstone of healthcare innovation.

Benefits of PTFE Liners with Tie Layers in Healthcare

Durability and Flexibility for Advanced Medical Devices

PTFE liners with tie layers deliver unmatched durability and flexibility, making them essential for advanced medical devices. These liners withstand extreme conditions, including exposure to bodily fluids and sterilization processes, without compromising their structural integrity. Their chemical stability ensures consistent performance, even in harsh environments. You can rely on these liners to maintain their form and function over extended periods, reducing the need for frequent replacements.

The flexibility of PTFE liners allows medical devices to adapt to the intricate pathways of the human body. This adaptability is crucial for tools like catheters and guidewires, which require precise maneuverability. The ultra-thin walls of PTFE liners further enhance this flexibility, enabling the creation of compact and lightweight devices. By incorporating these liners, manufacturers ensure that medical tools meet the highest standards of reliability and efficiency.

Enhanced Safety and Reliability for Patients

PTFE liners with tie layers prioritize patient safety by minimizing risks during medical procedures. The smooth, low-friction surface of PTFE reduces tissue damage and discomfort, ensuring a more comfortable experience for patients. This feature also lowers the likelihood of infection, as the liners facilitate seamless device insertion and removal. You benefit from the enhanced safety these liners provide, whether undergoing diagnostic or therapeutic procedures.

The tie layer plays a pivotal role in ensuring device reliability. By preventing delamination, it maintains the structural integrity of medical tools, even under high stress. This stability reduces the risk of device failure, offering peace of mind to both patients and healthcare professionals. Rigorous testing during manufacturing guarantees that each PTFE liner meets stringent quality standards, further enhancing its safety and reliability.

According to AccuPath®, PTFE liners undergo precision testing to ensure optimal performance, making them a trusted choice in critical medical applications.

Contribution to the Advancement of Medical Technology

PTFE liners with tie layers drive innovation in medical technology by enabling the development of advanced devices. Their unique properties, such as chemical resistance and biocompatibility, support the creation of tools that push the boundaries of modern medicine. You gain access to cutting-edge solutions that improve treatment outcomes and elevate the standard of care.

These liners have revolutionized catheter technology, enhancing delivery systems with their low-friction coefficient. They also contribute to the design of stents, guidewires, and other minimally invasive tools, ensuring precision and efficiency. Manufacturers continue to explore new ways to optimize PTFE liners, paving the way for future advancements in healthcare. By integrating this technology, the medical field achieves breakthroughs that benefit both patients and practitioners.

As highlighted by AccuPath, the inclusion of PTFE liners in medical devices sets new benchmarks for performance and longevity, underscoring their role in advancing healthcare innovation.

PTFE liners with tie layers redefine medical technology by combining durability, biocompatibility, and precision. Their low-friction surface and chemical resistance enhance device performance, ensuring safer and more effective patient care. These liners play a pivotal role in applications like catheters, stents, and guidewires, where reliability is critical. By preventing delamination and improving adhesion, tie layers ensure structural integrity and longevity. As advancements continue, you can expect PTFE liners to drive innovation, setting new benchmarks in healthcare. Their unmatched features and benefits make them indispensable for advancing medical devices and improving treatment outcomes.

See Also

Exploring The Role Of PTFE Etched Liners In Catheters

Why PTFE Etched Liners Are Crucial For Catheter Reinforcement