Reducing Delamination in Catheters with PTFE Tie Layer Liners

Catheter manufacturing faces critical challenges that demand innovative solutions. PTFE liners with tie layers offer a transformative approach by addressing key issues such as bonding difficulties caused by PTFE's low surface energy, risks of delamination, and the need for enhanced durability. These liners significantly improve adhesion, ensuring reliable mechanical properties and long-lasting performance. By integrating this advanced technology, medical devices achieve superior safety and functionality. AccuPath's PTFE liner with tie layer exemplifies this innovation, delivering unmatched quality and reliability for modern healthcare applications.

Key Takeaways

PTFE liners with tie layers stick better, stopping peeling in catheters.

These liners make catheters stronger and more dependable for surgeries.

The tie layer holds the PTFE liner and outer layer tightly together.

Catheters with PTFE liners work well under pressure, keeping patients safer.

Using PTFE liners can save money by cutting down on mistakes.

The thin tie layer keeps catheters small, making them less invasive.

PTFE liners with tie layers fit many catheter types, even for tough surgeries.

PTFE and Its Role in Catheters

Polytetrafluoroethylene (PTFE) plays a pivotal role in the design and functionality of modern catheters. Its unique properties make it an indispensable material in medical device manufacturing, particularly for applications requiring precision, durability, and patient safety.

Key Properties of PTFE

Low friction and biocompatibility

PTFE is renowned for its exceptionally low coefficient of friction, which allows catheters to glide effortlessly through blood vessels and other bodily passages. This smooth movement minimizes discomfort and trauma during insertion and removal, enhancing patient comfort. Additionally, PTFE's biocompatibility ensures it is well-tolerated by the human body, reducing the risk of adverse reactions such as inflammation or infection. These qualities make PTFE liners an ideal choice for medical devices that demand both performance and safety.

PTFE etched liners further elevate catheter functionality by providing a surface that resists bacterial adhesion. This feature significantly lowers the risk of infections, ensuring safer outcomes for patients. By incorporating these liners, manufacturers can push the boundaries of catheter design, delivering devices that are both effective and patient-friendly.

Chemical resistance and durability

PTFE's chemical resistance is another critical attribute that enhances its suitability for catheters. It withstands exposure to a wide range of chemicals and bodily fluids without degrading, ensuring long-term reliability. This durability is essential for life-saving devices, as it minimizes the need for frequent replacements in demanding medical environments. PTFE-coated catheters also prevent the buildup of biological materials, maintaining their functionality over extended periods.

Since the 1970s, PTFE has been a preferred material for vascular catheter components due to its ability to be extruded into thin-walled tubing. Its smooth inner surface facilitates the deployment of stents, balloons, and other devices, making it a cornerstone of modern medical technology.

Challenges of Using PTFE in Catheters

Non-stick surface and bonding difficulties

Despite its advantages, PTFE's non-stick nature presents significant challenges in catheter manufacturing. Its low surface energy prevents effective adhesion with adhesives and coatings, complicating the bonding process. This issue often results in weak connections between layers, which can compromise the structural integrity of the catheter. Untreated PTFE's smooth surface further hinders integration with biological tissues, limiting its application in certain medical scenarios.

To overcome these obstacles, manufacturers rely on advanced techniques like etching to modify the surface chemistry of PTFE. This process enhances adhesion, enabling the creation of robust and reliable medical devices. AccuPath's PTFE liners exemplify this innovation, offering unmatched quality and performance.

Risks of delamination and performance issues

The risk of delamination is a critical concern in catheter manufacturing. Delamination occurs when material layers separate, often going undetected until final testing. This issue not only increases scrap costs for manufacturers but also poses serious risks to patient safety. Device failures in the field can lead to severe complications, lengthy product recalls, and significant financial losses.

By addressing these challenges, PTFE etched liners provide a solution that enhances adhesion and reduces the risk of delamination. Their durability ensures consistent performance, making them a reliable choice for medical devices. AccuPath's PTFE liners with tie layers set a new standard in the industry, delivering superior adhesion and durability without compromising the catheter's outer diameter.

The Function of Tie Layers in PTFE Liners

What Is a Tie Layer?

Definition and purpose in catheter construction

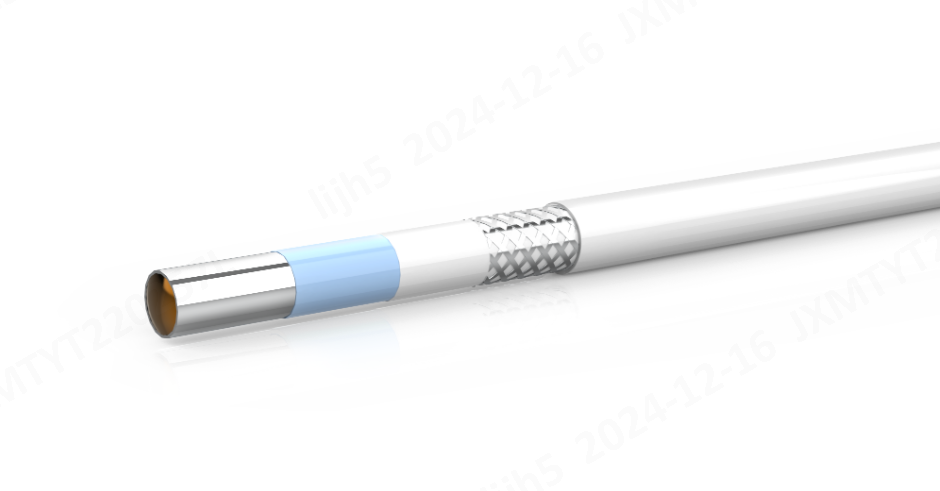

A tie layer is an ultra-thin thermoplastic coating applied over the PTFE liner during catheter construction. This innovative layer creates a melt-bondable interface, addressing the bonding challenges posed by PTFE's low surface energy. By fusing the PTFE liner with the catheter's outer jacket, the tie layer forms strong adhesive bonds that significantly reduce the risk of delamination. Its primary purpose is to enhance adhesion between the inner liner and the outer layers, ensuring the catheter's structural integrity and durability.

How it interacts with PTFE and catheter materials

The tie layer plays a crucial role in bridging the gap between PTFE and other catheter materials.

It creates a melt-bondable interface with PTFE, overcoming its non-stick properties.

Functional groups introduced by the tie layer enhance its interaction with the outer jacket material.

This interaction improves the catheter's structural integrity, even under high stress.

AccuPath's PTFE liners with tie layers exemplify this advanced technology, delivering unmatched performance in catheter construction.

Mechanisms of Tie Layers

Creating a melt-bondable surface

The tie layer achieves its functionality by adhering to the freshly etched surface of the PTFE liner. This ultra-thin thermoplastic coating introduces functional groups that enhance the liner's ability to bond with other materials. During manufacturing, the tie layer melts and fuses with the outer jacket material, forming a robust bond. This process ensures a seamless connection between the PTFE liner and the catheter's outer layers, addressing adhesion challenges effectively.

Enhancing adhesion during the reflow process

The reflow process further amplifies the adhesion properties of the tie layer. As the tie layer melts, it acts as a bridge between the PTFE liner and the outer jacket. This melting process ensures a strong bond with the jacket material, significantly reducing the risk of delamination. The enhanced adhesion achieved during reflow improves the catheter's mechanical properties, ensuring reliable performance in medical applications.

How Tie Layers Prevent Delamination

Strengthening bonds between layers

Tie layers play a pivotal role in preventing delamination by creating strong adhesive bonds between the PTFE liner and the outer jacket. This ultra-thin thermoplastic coating adheres to the etched PTFE surface, melting during manufacturing to fuse with the outer layers. The resulting bond is up to 2.5 times stronger than catheters without a tie layer, ensuring long-lasting durability and reliability.

Reducing field failure during medical procedures

By enhancing adhesion, tie layers significantly reduce the likelihood of delamination during medical procedures. This improvement minimizes the risk of field failure, safeguarding patient health and ensuring consistent device performance. The incorporation of a tie layer not only enhances the catheter's durability but also reinforces its reliability in critical medical applications. AccuPath's PTFE liners with tie layers set a new standard in catheter design, delivering superior adhesion and safety without compromising the device's profile.

Benefits of PTFE Liners with Tie Layers in Catheters

Enhanced Adhesion and Durability

Increased bond strength by up to 2.5 times

PTFE liners with tie layers revolutionize catheter construction by significantly enhancing adhesion. Testing demonstrates that catheters incorporating this advanced technology achieve bond strength up to 2.5 times greater than those without a tie layer.

This improvement ensures the liner remains securely bonded to the catheter's outer jacket, even under high stress.

The enhanced adhesion minimizes the risk of delamination, a critical factor in maintaining catheter reliability during medical procedures.

AccuPath's PTFE liner with tie layer exemplifies this innovation, setting a new benchmark in catheter design.

Resistance to wear and tear

The durability of catheters equipped with PTFE liners and tie layers is unmatched. The tie layer forms a robust bond between the PTFE liner and the outer jacket, ensuring structural integrity even under repeated use. This durability makes these catheters ideal for prolonged medical applications, where resistance to wear and tear is essential. By reducing the risk of delamination, these liners extend the lifespan of medical devices, offering both reliability and cost-effectiveness.

Improved Performance and Safety

Consistent functionality in medical applications

PTFE liners with tie layers ensure consistent performance in demanding medical applications. The strong bond created by the tie layer maintains the catheter's structural integrity, even in high-stress environments. This reliability is crucial for advanced catheter designs used in life-saving procedures. The smooth surface of the PTFE liner also enhances the catheter's functionality, allowing for precise and efficient operation in medical devices.

Lower risk of complications from delamination

Delamination poses significant risks in medical procedures, including the generation of harmful debris that can compromise patient safety. PTFE liners with tie layers address this issue by improving adhesion and reducing the likelihood of delamination.

Evidence Type | Details |

|---|---|

Bond Strength Comparison | The bond strength of catheters with a tie layer is 2.5 times more durable than those without. |

Risk Reduction | Improved adhesion reduces the likelihood of delamination, which can generate harmful debris. |

Patient Safety | Enhanced bond strength safeguards patient health during medical interventions. |

AccuPath's PTFE liners with tie layers deliver peace of mind to healthcare providers by minimizing risks and ensuring patient safety.

Cost and Manufacturing Advantages

Reduced manufacturing costs and improved yields

PTFE liners with tie layers offer significant cost advantages in catheter manufacturing. By minimizing delamination and manufacturing defects, these liners reduce production costs and improve yields. Manufacturers benefit from fewer rejected products and higher efficiency, making this technology a valuable investment for producing advanced catheter designs.

No increase in catheter outer diameter

Despite their advanced functionality, PTFE liners with tie layers maintain catheter dimensions without increasing the outer diameter. The ultra-thin thermoplastic coating of the tie layer adheres seamlessly to the PTFE liner, adding minimal bulk. With dimensions as thin as 0.0025 mm (0.0001″), this innovation ensures that catheters retain their slim profile while delivering enhanced adhesion and durability. This feature is particularly important for medical devices requiring precision and minimal invasiveness.

AccuPath's PTFE liners with tie layers combine performance, safety, and cost-efficiency, making them the ideal choice for modern catheter construction.

Applications of PTFE Liners with Tie Layers in Medical Devices

PTFE liners with tie layers have revolutionized applications in medical devices, offering unmatched performance and reliability. Their versatility makes them indispensable in various medical tools, particularly catheters and other devices requiring low friction and high durability.

Catheters

Types of catheters benefiting from this technology

PTFE liners with tie layers enhance the functionality of several catheter types, especially those used in minimally invasive procedures. These include:

Catheters designed for angioplasty or stent placement, where flexibility and durability are critical.

High-performance catheters that endure high stress and repeated use during complex medical procedures.

Devices requiring advanced materials to maintain structural integrity under demanding conditions.

AccuPath's PTFE liners with tie layers ensure these catheters deliver exceptional performance, meeting the rigorous demands of modern healthcare.

Use cases in fluid delivery and drainage

PTFE liners with tie layers play a vital role in fluid delivery and drainage applications. Their smooth, low-friction surface facilitates seamless catheter insertion and maneuverability, reducing patient discomfort. These liners also minimize the risk of delamination, ensuring consistent performance in critical procedures like angioplasty. By improving adhesion between the PTFE liner and the outer jacket, they enhance the catheter's structural integrity, even under high stress.

High-quality catheters equipped with this technology excel in delivering fluids or draining bodily fluids efficiently. AccuPath's innovative PTFE liners contribute to the production of reliable, high-performance catheters, setting a new standard in medical device manufacturing.

Other Medical Devices

Guidewires and stent delivery systems

PTFE liners with tie layers are equally valuable in guidewires and stent delivery systems. These devices demand low friction and high durability to navigate complex anatomical pathways. The tie layer ensures a robust bond between the PTFE liner and the device's outer structure, enhancing reliability during use. This technology allows guidewires and stent systems to perform with precision, reducing the risk of complications during life-saving procedures.

Devices requiring low friction and high durability

Beyond catheters and guidewires, PTFE liners with tie layers benefit a wide range of medical devices. Tools used in minimally invasive surgeries, diagnostic procedures, and therapeutic interventions rely on the low-friction properties of PTFE. The tie layer enhances adhesion, ensuring these devices maintain their structural integrity over time. AccuPath's PTFE liners deliver the durability and performance needed for these critical applications, supporting healthcare professionals in delivering optimal patient care.

PTFE liners with tie layers have become a cornerstone of modern medical devices. Their applications extend across various tools, ensuring reliability, safety, and efficiency in healthcare settings. AccuPath continues to lead the industry with its innovative solutions, empowering manufacturers to create cutting-edge medical devices.

Future Innovations in PTFE Liner and Tie Layer Technology

Advancements in Tie Layer Materials

Stronger and more versatile adhesives

Innovations in tie layer materials are transforming catheter technology by enhancing adhesion and versatility. New thermoplastic formulations now offer improved bonding capabilities while maintaining flexibility and durability. These advancements allow catheters to withstand high stress and repeated use, making them indispensable for high-performance medical devices. Adhesion promoters, such as maleic anhydride, further strengthen the bond between the PTFE liner and the outer jacket. This ensures superior adhesion even under extreme conditions. Additionally, sustainable materials like biodegradable polymers are being explored, aligning with global goals for environmentally friendly manufacturing. AccuPath continues to lead in this area, delivering cutting-edge tie layer solutions that redefine catheter performance.

Integration with new catheter materials

Tie layers are becoming increasingly compatible with emerging catheter materials, enabling versatile designs tailored to specific medical needs.

They enhance adhesion between PTFE liners and various outer jacket materials.

Advanced tie layer formulations maintain flexibility, ensuring durability in high-stress applications.

These innovations support the development of smaller, more efficient catheters for minimally invasive procedures.

The durability of PTFE liners with tie layers has set a new standard for reliability in catheter technology, earning praise from manufacturers worldwide.

Enhancements in PTFE Liners

Modifications for better bonding

PTFE liners are undergoing significant modifications to improve bonding properties. Techniques like chemical etching, sodium etching, and plasma etching are creating surfaces that enhance adhesion.

Chemical etching introduces polar functional groups and increases surface roughness.

Plasma etching defluorinates PTFE molecules, creating a bondable surface.

Laser etching offers a chemical-free solution for intricate surface modifications.

These advancements ensure that PTFE liners deliver exceptional adhesion, reducing the risk of delamination and improving the overall performance of medical devices. AccuPath's PTFE liners incorporate these cutting-edge techniques, setting a benchmark for quality and reliability.

Sustainable manufacturing processes

Sustainability is becoming a priority in PTFE liner production. Manufacturers are exploring methods to reduce environmental impact while maintaining high performance.

Recyclable or biodegradable versions of PTFE are under development.

Production processes are being optimized to minimize waste and energy consumption.

Sustainable materials are being integrated into tie layers, ensuring eco-friendly catheter designs.

AccuPath is at the forefront of these efforts, offering PTFE liners that meet both performance and environmental standards.

Expanding Applications Beyond Medical Devices

Use in aerospace and automotive industries

The versatility of PTFE liners with tie layers extends beyond medical devices. In aerospace, these liners provide low-friction surfaces for critical components, ensuring reliability under extreme conditions. In the automotive industry, they enhance the durability and performance of systems requiring high precision and wear resistance. These applications demonstrate the adaptability of PTFE liners in addressing diverse industrial challenges.

Broader industrial applications

PTFE liners with tie layers are finding applications in various industries, including electronics and consumer goods.

In electronics, they improve insulation and reduce friction in high-performance devices.

In consumer goods, they enhance the durability and functionality of products requiring low-friction surfaces.

AccuPath's innovative PTFE liners continue to expand their reach, delivering unmatched performance across industries. Their commitment to quality ensures that these liners meet the demands of both medical and industrial applications.

PTFE liners with tie layers represent a groundbreaking advancement in catheter technology. By addressing adhesion challenges and reducing delamination, they enhance the durability and performance of medical devices. These liners improve patient safety and streamline manufacturing processes, making them an essential component in modern healthcare.

Ongoing innovations, such as advancements in etching methods, continue to expand the capabilities of PTFE. Enhanced adhesion properties and customization options allow PTFE liners to meet the demands of diverse medical applications. Their role in microcatheters and steerable catheters demonstrates their importance in minimally invasive procedures, where precision and reliability are critical.

AccuPath's PTFE liner with tie layer exemplifies this transformative technology, setting a new standard for quality and performance in medical devices. As these innovations evolve, they promise to revolutionize industries beyond healthcare, offering tailored solutions to bonding challenges across various sectors.

FAQ

What makes PTFE liners with tie layers unique?

PTFE liners with tie layers offer unmatched adhesion and durability. The tie layer creates a strong bond between the PTFE liner and the catheter's outer jacket, reducing delamination risks. AccuPath's liners set a new standard in reliability and performance for medical devices.

How do tie layers improve catheter performance?

Tie layers enhance adhesion, ensuring the PTFE liner remains securely bonded to the catheter. This improvement minimizes delamination risks, increases durability, and ensures consistent performance during medical procedures. AccuPath's innovative tie layer technology delivers superior results.

Are PTFE liners with tie layers suitable for all catheter types?

Yes, PTFE liners with tie layers benefit various catheter types, including those used in angioplasty, stent placement, and fluid drainage. AccuPath's liners adapt to diverse medical applications, ensuring optimal performance and safety.

Do PTFE liners with tie layers increase catheter size?

No, the ultra-thin tie layer adds minimal bulk. AccuPath's PTFE liners maintain the catheter's slim profile, ensuring precision and minimal invasiveness without compromising adhesion or durability.

Can PTFE liners with tie layers reduce manufacturing costs?

Yes, these liners minimize defects and delamination, improving production yields and reducing waste. AccuPath's advanced technology offers cost-effective solutions for manufacturers without compromising quality.

What industries benefit from PTFE liners with tie layers?

While primarily used in medical devices, these liners also serve aerospace, automotive, and electronics industries. AccuPath's PTFE liners deliver low friction, high durability, and reliable performance across various applications.

Why choose AccuPath's PTFE liners with tie layers?

AccuPath combines cutting-edge technology with unmatched quality. Their PTFE liners deliver superior adhesion, durability, and performance, making them the ideal choice for manufacturers seeking reliable solutions for advanced medical devices.

See Also

The Role of Tie Layers in Enhancing PTFE Liners

A Comprehensive Guide to PTFE Etched Liners in Catheters

Improving Adhesion Through PTFE Etched Liners Technology

Essential Insights on PTFE Liners Featuring Tie Layers

Why PTFE Etched Liners Are Crucial for Catheter Reinforcement