Understanding PTFE Etched Liners for Catheters

The PTFE etched liner for medical devices is essential in advancing modern catheter design. These liners, made from polytetrafluoroethylene (PTFE), offer a smooth, low-friction surface that significantly enhances catheter performance. Through a specialized etching process, they achieve exceptional adhesion to other catheter components, ensuring structural integrity during use. Their biocompatibility reduces the risk of infection and adverse reactions, making them a preferred choice for medical applications. Furthermore, the durability and wear resistance of the PTFE etched liner for medical devices enable catheters to function reliably in demanding conditions, ultimately improving patient outcomes and elevating the standards of medical care.

Key Takeaways

PTFE etched liners enhance catheter performance by providing a smooth, low-friction surface, improving patient comfort during procedures.

The biocompatibility of PTFE ensures safety, reducing the risk of adverse reactions and infections associated with catheter use.

Durability and wear resistance of etched PTFE liners allow catheters to function reliably in demanding medical environments, minimizing the need for replacements.

The etching process improves adhesion between catheter components, ensuring structural integrity and preventing delamination during use.

Integrating PTFE etched liners supports innovative catheter designs, enabling the creation of smaller, more effective devices that enhance patient care.

Compliance with industry standards is facilitated by the chemically inert nature of PTFE, ensuring safety and reliability in medical applications.

By utilizing PTFE etched liners, manufacturers can advance medical technology, meeting modern healthcare demands and improving patient outcomes.

What Is a PTFE Etched Liner for Medical Devices?

Overview of PTFE as a Material

Polytetrafluoroethylene (PTFE) is a high-performance polymer widely recognized for its unique properties. Its low coefficient of friction makes it an ideal material for applications requiring smooth surfaces, such as medical devices. PTFE is also chemically inert, meaning it resists reactions with most substances, including harsh chemicals and bodily fluids. This characteristic ensures its durability and reliability in demanding environments. Additionally, PTFE exhibits excellent thermal stability, allowing it to perform effectively under extreme temperatures.

In the medical field, PTFE has become a cornerstone material due to its biocompatibility. It does not provoke adverse reactions when in contact with human tissue, making it safe for use in devices like catheters. Its flexibility further enhances its suitability for intricate medical applications, enabling the creation of thin-walled tubing that maintains strength and performance. These attributes have solidified PTFE's role as a critical component in modern medical technology.

The Role of Etching in Enhancing PTFE Properties

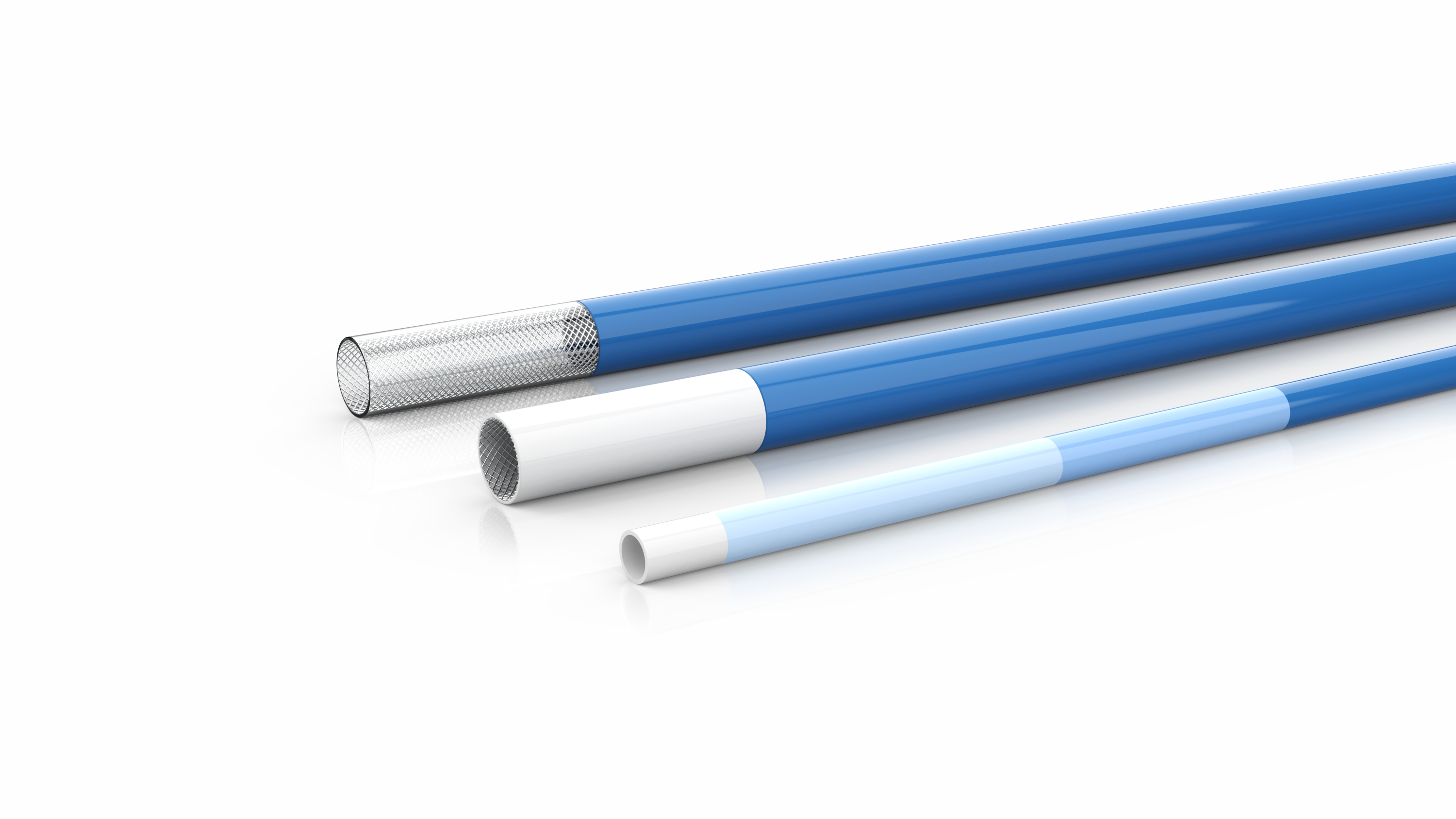

While PTFE offers exceptional benefits, its naturally non-stick surface can pose challenges during manufacturing. This is where etching comes into play. The etching process modifies the surface of PTFE, creating a texture that improves adhesion to other materials. This enhancement is particularly valuable in catheter design, where strong bonds between components are essential for device integrity.

Etching also amplifies PTFE's functionality by maintaining its inherent properties while addressing specific application needs. For instance, etched PTFE liners provide a smooth, low-friction surface that reduces resistance during catheter insertion and withdrawal. This feature minimizes patient discomfort and lowers the risk of tissue damage. Furthermore, the etched surface ensures that the liner adheres securely to the catheter's outer layers, preventing delamination and ensuring consistent performance.

By combining the natural advantages of PTFE with the benefits of etching, manufacturers can produce liners that meet the rigorous demands of medical applications. The result is a PTFE etched liner for medical devices that enhances both the performance and reliability of catheters, ultimately contributing to better patient outcomes.

Benefits of Using Etched PTFE Liners in Catheter Design

Biocompatibility and Patient Safety

When it comes to medical devices, ensuring patient safety is paramount. Etched PTFE liners excel in this area due to their exceptional biocompatibility. These liners do not provoke adverse reactions when in contact with human tissue, making them a reliable choice for catheter applications. Their chemically inert nature ensures they remain stable even when exposed to bodily fluids or medications, reducing the risk of complications.

The smooth surface of etched PTFE liners minimizes the likelihood of bacterial adhesion. This feature plays a critical role in lowering the risk of infections during catheter use. By incorporating these liners into catheter design, you can enhance patient safety while maintaining the device's performance. The biocompatibility of etched PTFE liners ensures that they meet the stringent requirements of modern medical standards, providing peace of mind for both healthcare providers and patients.

Durability and Resistance to Wear

Durability is a key factor in the performance of any medical device, and etched PTFE liners deliver outstanding results in this regard. These liners exhibit high resistance to wear and abrasion, ensuring they maintain their integrity even under demanding conditions. Whether exposed to repeated use or harsh environmental factors, etched PTFE liners retain their structural stability.

Their chemical resistance further enhances their durability. Etched PTFE liners withstand exposure to various substances, including food-grade chemicals and medications, without degrading. This resilience makes them a versatile choice for catheters used in diverse medical procedures. By choosing etched PTFE liners, you ensure that your catheters remain reliable and effective over time, reducing the need for frequent replacements and enhancing overall device longevity.

Reduced Friction and Enhanced Lubricity

One of the standout features of etched PTFE liners is their ability to reduce friction. The low-friction surface of these liners facilitates smooth catheter insertion and withdrawal, minimizing resistance during use. This property not only enhances patient comfort but also reduces the risk of tissue damage, making medical procedures less invasive.

The enhanced lubricity of etched PTFE liners contributes to the overall performance of the catheter. It allows for precise navigation through the vascular system, ensuring accurate placement and reducing procedural complications. The smooth inner layer provided by these liners also supports the efficient flow of fluids, further optimizing the catheter's functionality. By integrating etched PTFE liners into catheter design, you can achieve a balance of performance, comfort, and safety that benefits both patients and healthcare professionals.

How PTFE Etched Liners Improve Catheter Performance

Enhanced Adhesion to Catheter Components

The adhesion between catheter components plays a critical role in ensuring the device's reliability. PTFE etched liners excel in this area by offering a surface that bonds effectively with other materials. The etching process modifies the naturally non-stick properties of PTFE, creating a textured surface that enhances adhesion. This improvement ensures that the liner integrates seamlessly with the catheter's outer layers, preventing delamination during use.

By using a PTFE etched liner for medical devices, you can achieve a stronger and more durable bond between components. This enhanced adhesion contributes to the structural integrity of the catheter, even under challenging conditions. Whether exposed to bodily fluids, medications, or mechanical stress, the liner maintains its position and functionality. This reliability reduces the risk of device failure, ensuring consistent performance throughout its use.

Contribution to Advanced Catheter Designs

Modern catheter designs demand innovation, and PTFE etched liners provide the flexibility to meet these requirements. Their ultrathin walls and precise dimensions allow for the creation of smaller catheter profiles. This reduction in size improves patient comfort and minimizes trauma during insertion. The smooth, low-friction surface of the liner also supports advanced designs by facilitating easier navigation through the vascular system.

The durability and chemical resistance of PTFE etched liners further enhance their contribution to innovative catheter designs. These properties enable the development of devices that can withstand harsh environments and repeated use. Additionally, the biocompatibility of the liners ensures they meet the stringent standards of modern medical technology. By incorporating PTFE etched liners, you can push the boundaries of catheter design, delivering devices that are both effective and patient-friendly.

Why PTFE Etched Liners Are Essential in Modern Medical Devices

Supporting Innovation in Medical Technology

PTFE etched liners play a pivotal role in driving innovation within the medical technology sector. Their unique properties, such as low friction and high durability, enable the development of advanced catheter designs that prioritize both functionality and patient comfort. By incorporating these liners, you can create thinner-walled catheters with precise dimensions, which reduce the overall device profile. This smaller size enhances patient comfort during procedures and minimizes trauma during insertion.

The flexibility of PTFE etched liners allows for customization to meet specific medical requirements. For instance, manufacturers can tailor the liners to fit complex catheter designs, ensuring optimal performance in specialized applications. This adaptability supports the creation of cutting-edge medical devices that address diverse healthcare challenges. Additionally, the chemical resistance of PTFE ensures that these liners maintain their integrity even when exposed to harsh substances, making them suitable for a wide range of medical environments.

The advancements in extrusion technology have further enhanced the production of PTFE etched liners. Modern manufacturing processes now deliver ultrathin, high-quality liners that meet the rigorous demands of the medical field. These innovations not only improve the reliability and operability of catheters but also contribute to better patient outcomes. By leveraging the capabilities of PTFE etched liners, you can stay at the forefront of medical technology and deliver devices that set new standards in healthcare.

Meeting Industry Standards and Regulations

Compliance with industry standards and regulations is a critical aspect of medical device manufacturing. PTFE etched liners help you meet these stringent requirements by offering exceptional biocompatibility and safety. Their chemically inert nature ensures that they do not react with bodily fluids or medications, reducing the risk of complications during use. This stability makes them a reliable choice for medical applications, aligning with the high standards expected in the healthcare industry.

The etching process used on PTFE liners enhances their adhesion properties, ensuring that they integrate seamlessly with other catheter components. This strong bond prevents delamination and maintains the structural integrity of the device, even under demanding conditions. By using PTFE etched liners, you can produce medical devices that not only meet but exceed regulatory expectations for performance and safety.

Collaborations with coating technology companies have also contributed to the development of PTFE etched liners that comply with environmental and safety regulations. For example, reformulated coatings now reduce the use of restricted chemicals while maintaining product performance. These advancements ensure that your devices adhere to both current and emerging standards, providing peace of mind for healthcare providers and patients alike.

Incorporating PTFE etched liners into your catheter designs demonstrates a commitment to quality and compliance. Their proven track record in meeting industry benchmarks underscores their importance in modern medical devices. By choosing these liners, you can confidently navigate the complexities of regulatory requirements while delivering innovative solutions that improve patient care.

PTFE etched liners deliver unmatched benefits in catheter design. Their biocompatibility ensures patient safety by minimizing adverse reactions and reducing infection risks. The durability of these liners allows catheters to withstand demanding conditions without compromising performance. Their low-friction surface enhances lubricity, ensuring smooth insertion and reducing tissue damage. These features collectively improve catheter functionality and elevate patient outcomes. By integrating PTFE etched liners, you contribute to advancing medical device technology, meeting modern healthcare demands, and setting new standards in patient care.