Essential Tips for Achieving Precision with Thin Wall Niti Tubing

You need to be very careful with thin wall niti tubing. This tubing has very thin walls and is easy to damage. Even a tiny mistake can bend the tubing or make it not work in medicine. Medical devices use niti tubing because it is strong and can bend. Many medical tools use nitinol tubing because it works well in tough jobs. You must watch every step to keep the tubing safe for medical use. Niti tubing needs to be made very exact to work in special medical tools. Each tube must pass strict tests for quality and how well it works.

Tip: Be gentle with niti tubing so it does not get damaged at any time.

Key Takeaways

Be gentle with thin wall niti tubing so it does not bend or break. If it gets damaged, it cannot be used for medical things.

Make sure the wall thickness stays the same. Use cameras, heat, and AI to check this. This helps keep the tubing strong and safe.

Watch the heat closely when you cut or shape the tubing. This keeps its special memory and lets it stay flexible.

Pick the right machines and tools, like grinders and lasers. Make sure they are set up right for the correct size and smooth finish.

Always do careful quality checks and follow medical rules. This makes the tubing safe, strong, and good for medical devices.

Thin Wall Niti Tubing Challenges

Working with thin wall niti tubing is hard. There are many steps that need care. You must keep the wall thickness and size very exact. Even small mistakes can cause big problems in medical devices. Niti alloy tubing has special features like superelasticity and shape memory. These make making the tubing harder. You need special tools and skilled partners to meet medical rules.

Deformation Risks

Thin-walled tubing bends very easily. If you do not handle niti alloy tubing gently, it can bend or whip. This happens more with fast machines or too much force. Bent tubing loses its shape and is not safe for medicine. You must use gentle tools and watch the tubing closely. Many makers use cameras to check for bending or twisting while working.

Tip: Check for bending or twisting at every step when making niti tubing.

Wall Thickness Uniformity

It is very important to keep the wall thickness the same. You must control how you make the tubing very carefully. Most factories use cameras to spot tiny changes in wall thickness. If they see a problem, they can fix it right away. Heat and special tools help make the walls even and strong. AI systems also help keep the tubing the right size. Polishing and finishing remove sharp edges and cracks, making the tubing safer.

Key methods for wall thickness uniformity:

Cameras and real-time checks

Better ways to shape the tubing

Heat and special tools

Polishing and finishing

Cycle Life and Durability

Niti alloy tubing must bend and flex many times. It needs to stay strong and not break. Special ways of making the tubing help it last longer. Cheap tubing may not last and can break quickly. Always pick good quality thin wall niti tubing for medical use. Following rules like ISO 13485 and FDA keeps patients safe and avoids problems.

Note: Good cycle life and strength come from careful checks and following the right steps.

Nitinol Properties in Manufacturing

Superelasticity and Shape Memory

Nitinol has special features that help in making medical tools. The most important are superelasticity and shape memory. When you bend niti tubing, it goes back to its old shape. This helps medical devices move through small spaces without breaking. Nitinol tubing can bend and twist many times. It does not snap or lose its shape. The shape memory effect lets you set a shape by heating the tubing. When you cool it, the tubing keeps that new shape. If you heat it again, it goes back to the first shape. This makes niti tubing great for tools that change shape inside the body.

Tip: The shape memory effect helps make devices that fit the body and then go back to their first shape when needed.

You must control how you make nitinol tubing. Heat treatment changes the inside structure. This step makes superelasticity and shape memory better. You use careful extrusion at high heat to make thin wall tubing. Multi-stage drawing keeps the tubing strong and bendy. You also need to keep the wall thickness the same. Good process control keeps the wall thickness even. Surface finishing makes the tubing smooth and safe for medical use. You check the alloy mix to keep the right nickel and titanium balance. This helps the shape memory and superelasticity work well.

Heat Transfer and Flexibility

You need to watch heat during manufacturing. Heat transfer changes how flexible nitinol tubing is. When you use lasers to cut or weld niti tubing, you must keep the heat low. Too much heat can hurt the shape memory effect. You want to stop heat-affected zones. Ultrafast lasers help you cut tubing without making it stiff. Shape setting uses careful heat to give the tubing its final shape. You heat the tubing in steps to lower strain and keep it flexible.

Key points for heat transfer and flexibility:

Laser welding needs careful heat control.

Ultrafast lasers stop damage to the tubing.

Shape setting with heat keeps the tubing strong and bendy.

You use advanced tools to measure and check the tubing. Laser micrometers and ultrasonic gauges help you keep the tubing the right size. You follow ASTM and ISO rules to make sure the tubing is safe for medical use. When you control heat and use the right steps, you get nitinol tubing with the best shape memory and flexibility.

Equipment for Thin Wall Niti Tubing

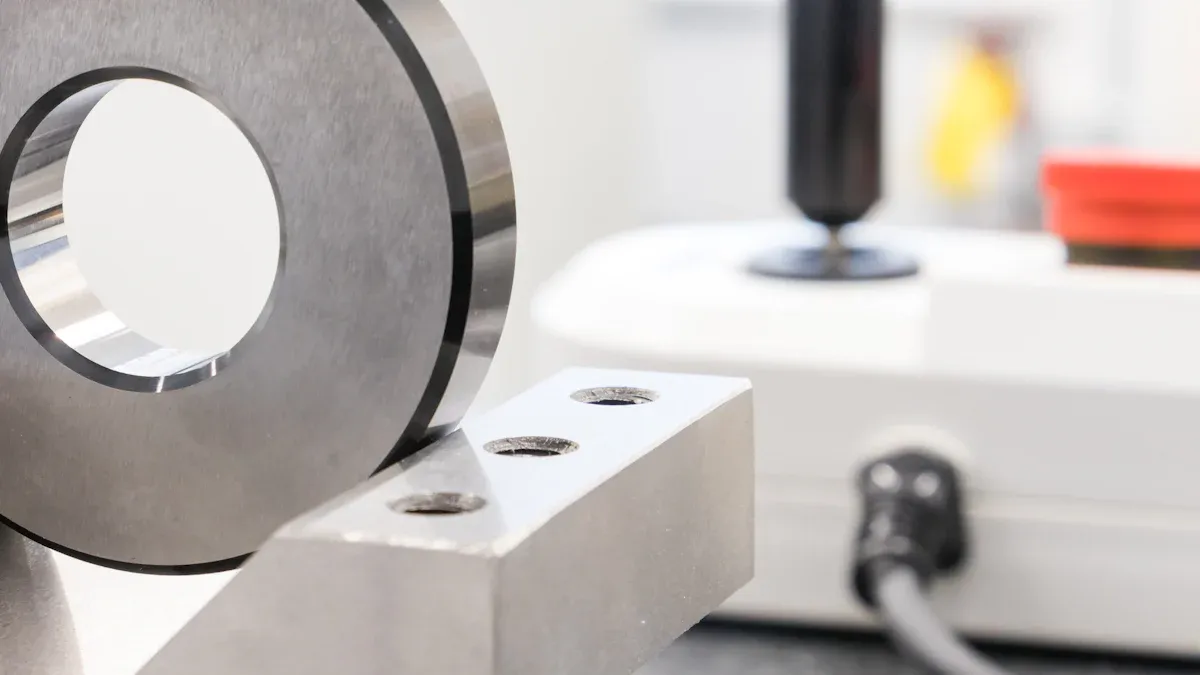

Grinding and Cutting Machines

You need special machines to work with thin wall niti tubing. Grinding is important for making the tubing the right size. Many shops use centerless grinding to finish small round parts. This method is good for making lots of tubing fast. It also makes the tubing smooth and round. A thrufeed centerless grinder, like the Glebar TF-9DHD, can grind long tubes in one go. This saves time and makes the tubes better. Double disk grinding helps keep the tubing flat and the same thickness. OD grinding shapes the outside and makes it round again. ID grinding and honing make the inside smooth. Electrochemical grinding uses both grinding and chemicals for special jobs. Electrochemical cutting makes shiny, smooth tubing with no rough edges. Laser cutting is used a lot for thin wall niti tubing. It works well for wall thicknesses from 0.002” to 0.005”. Laser machines can cut tubing from 0.008” to 0.75” OD. They make very thin cuts, which helps with accuracy. These machines help make catheter parts and other medical tools from niti tubing.

Common grinding and cutting machines for niti tubing:

Centerless grinding (including thrufeed centerless grinder)

Double disk grinding

OD and ID grinding

Honing

Electrochemical grinding and cutting

Tip: Pick the right grinding or cutting machine for each job.

Tooling and Fixturing

You need special tools to hold thin wall niti tubing while you grind or cut it. Good fixtures stop the tubing from bending or moving. This keeps the tubing steady for even grinding. Custom jaws, soft pads, and v-blocks help grip the tubing without hurting it. Air chucks or collets help keep the tubing round. Some setups use spinning supports to keep long tubes straight. The right tools make your work safer and more exact.

Machine Calibration

You must check and set your machines often. Calibration keeps your grinding and cutting machines working well. You use gauges and laser micrometers to measure the tubing. Regular checks help you find problems early. If you skip calibration, your tubing might not be good enough for medicine. Good calibration helps every step, from grinding to the last check. This keeps your niti tubing safe and the right size.

Key Manufacturing Steps

Making thin wall nitinol tubing takes many careful steps. Each step changes how good the tubing is at the end. If you want tubing for medical tools, you must watch every part of the process. Here are the main steps you should know:

Laser Cutting and Shape Setting

First, you cut the nitinol tubing to the right size and shape. Laser cutting makes very fine cuts and helps keep the tubing exact. This step lets you make special shapes for medical tools. You must use the laser carefully so the tubing does not get too hot. Too much heat can hurt the shape memory effect and make the tubing stiff. Sometimes, you may see dark or light spots on the tubing after cutting. These spots come from oxides or carbides made earlier. The laser does not make these spots, but you should still look for them.

After cutting, you set the tubing’s shape. You heat the tubing and put it in a mold. This step gives the tubing its shape memory effect. When you cool it, the tubing keeps the new shape. If you heat it again, it goes back to its first shape. This is why nitinol tubing is good for medical tools. You must use the right heat and time to get the best shape memory. If you do not, the tubing may not work right.

Tip: Always look for spots or marks after laser cutting and shape setting. These can change how the tubing works in the body.

Heat Treating and Electropolishing

Heat treating is a key step for nitinol tubing. You heat the tubing to a certain temperature, usually between 450°C and 550°C. This step changes the inside of the tubing and makes the shape memory better. The right heat makes the tubing strong and able to bend back. Too much heat can make the tubing weak. Too little heat can make it stiff or not work for medical use.

You also need to use electropolishing after heat treating. Electropolishing makes the tubing smooth and takes away tiny rough spots. This step helps stop cracks and makes the tubing last longer. A smooth surface also stops rust, which is important for medical tools. Electropolishing keeps the oxide layer on the tubing, which protects it and keeps it strong.

Key benefits of heat treating and electropolishing:

Makes the shape memory better

Makes the tubing strong and bendy

Takes away rough spots and dirt

Stops rust

Polishing and Impurity Removal

The last step is polishing and cleaning the nitinol tubing. You want the tubing to be very smooth and clean. Special polishing, like magnetic abrasive finishing, uses tiny diamond tools and oils to take away small bumps. This way, you get a clean surface without hurting the tubing. Electropolishing also helps clean the tubing and makes it safer for the body.

You must not use harsh cleaning that could hurt the thin walls. Gentle cleaning keeps the oxide layer safe and helps stop rust. You should also use tests like X-rays or ultrasound to look for hidden problems. These tests help you find issues without hurting the tubing.

Note: Using advanced polishing with electropolishing gives you the best nitinol tubing.

If you follow these steps, you can make nitinol tubing that meets strict medical rules. Every step, from cutting to polishing, helps make sure the tubing has the right shape memory, strength, and safety for medical use.

Quality Control for Niti Alloy Tubing

Quality control is very important when making nitinol tubing. You need to check each tube to make sure it is safe. This helps medical devices work well and not fail. Good quality checks help you find problems early. You can fix these problems before the tubing is used.

In-Process Monitoring

You have to watch the tubing at every step. In-process monitoring helps you catch mistakes fast. You can use the UltraGauge+ ultrasonic thickness gauge. This tool measures the wall thickness while you make the tubing. If there is a problem, you can fix it right away. Laser micrometers help you check the outside size of the tubing. These tools show you numbers on a screen. You can change things quickly if you see a problem. Using these tools keeps the tubing strong and safe.

Benefits of in-process monitoring:

Checks wall thickness right away

Finds problems fast

Makes tubing better for devices

Non-Destructive Testing

You need to make sure the tubing has no hidden problems. Non-destructive testing does not hurt the tubing. You can use ultrasound and X-ray to look inside the tubing. These tests find cracks or holes you cannot see. Microscopes help you see tiny problems on the surface. These tests work well for thin wall tubing. They help you meet ASTM rules. You can trust your tubing for medical use if you do these tests.

Tip: Use ultrasound and X-ray to find hidden problems in your nitinol tubing.

Wall Thickness Measurement

Wall thickness is very important for niti alloy tubing. If the wall is too thin or thick, the tubing may not work. You can use ultrasonic gauges and laser micrometers to measure wall thickness. These tools give you exact numbers during and after making the tubing. You can use tables to write down your measurements and see patterns.

Step | Tool Used | What It Checks |

|---|---|---|

In-process | Ultrasonic gauge | Wall thickness |

In-process | Laser micrometer | Outside diameter |

Final inspection | X-ray/Ultrasound | Internal defects |

Measuring wall thickness often keeps your tubing safe for medical devices. It also helps you waste less and save money.

Application Considerations

Medical Device Requirements

When you use thin wall tubing in medical devices, you must follow strict rules. These devices go inside the body, so every part must be safe. Medical-grade nitinol tubing has to pass tests for biocompatibility. This means the tubing will not hurt the body or cause bad reactions. You need to follow standards like ISO 10993 and USP Class VI. These rules check for things like if the tubing is toxic, causes irritation, or is safe for long use. The FDA also has rules for making medical devices. You must keep the tubing clean and free from bad chemicals. A biocompatible surface is needed for all medical uses.

Here is a table that shows some important standards for medical tubing:

Regulatory Standard | Description | Key Requirements |

|---|---|---|

USP Class VI | Biocompatibility for medical devices | Tests for toxicity and reactions in animals |

ISO 10993 | Biocompatibility for medical and dental materials | Tests for irritation, toxicity, and more |

FDA Title 21 CFR | U.S. rules for medical devices | Non-toxic and safe for body contact |

EU REACH | Chemical safety in medical materials | Limits on harmful chemicals like DEHP |

Tip: Always make sure your tubing meets these standards before you use it in medical devices.

Flexibility and Strength Balance

The tubing needs to bend but not break. Medical devices often move through tight spaces in the body. The tubing must be flexible for this job. It also needs to stay strong and not kink or snap. Nitinol tubing has superelasticity and shape memory. These features help you get the right mix of flexibility and strength. You can make the tubing with very thin walls for medical uses. This helps guidewires and catheters move easily. For other jobs, like in airplanes, you may want thicker walls for more strength. You control the tubing’s features by changing how you make it. Drawing, laser cutting, and heat treatment all help you get the right balance.

Key points for flexibility and strength:

Superelasticity lets tubing bend without damage

Shape memory helps tubing return to its shape

Thin walls give more flexibility for medical devices

Joining and Welding

You often need to join tubing to other parts in medical devices. Welding must keep the tubing safe for the body and not add bad materials. Laser welding works well for thin wall tubing. It makes a clean joint and keeps the tubing strong. You must control the heat so you do not hurt the tubing or change how it works. After welding, you should check the joint for cracks or weak spots. Good joining methods help your devices last longer and stay safe for medical uses.

Note: Always test welded parts to make sure they are safe and strong enough for medical use.

Continuous Improvement

Operator Training

You are important in making thin wall nitinol tubing. Learning the right skills helps you avoid mistakes. Training teaches you to handle tubing gently. You also learn to use machines the right way. You can spot problems early, like small bends or wall changes. Training shows you how to use laser micrometers and ultrasonic gauges. These tools help you check tubing size and shape at every step.

Many companies use checklists and guides for training. You can follow these to not miss any steps. Some places use videos or hands-on practice to help you learn. When you know what to look for, you keep tubing safe for medical use.

Tip: Keep learning new skills and ask questions if you are unsure. This helps you make better tubing every day.

Process Feedback

You can make tubing better by using feedback from each step. During manufacturing, you collect data about the tubing. You check if it is smooth, if the walls are even, or if the ends are cut right. You measure things like taper angle, overcut, and surface roughness. Looking at this data helps you see what works and what needs to change.

Some companies use special ways to study feedback. For example, they use Taguchi’s Grey Relational Analysis and Principal Component Analysis. These help you compare different data and find the best machine settings. You can change things like voltage or electrode type to get better tubing. Using feedback this way makes tubing more exact and safe for medical devices.

Ways to use process feedback:

Collect data at each step

Compare results with special analysis

Change machine settings for better tubing

Note: Using feedback helps you make tubing that meets medical rules and lasts longer.

You get the best results with thin wall niti tubing by being careful at every step. Check your work often to make sure your medical products are safe. Use smart tools and follow strict rules to stop mistakes. Try new ways, like the Drawn Over Mandrel process and Magneform, to get better at your job. Look into new ideas like making things smaller, using machines to help, and testing without breaking the tubing. Keep learning new things and always try to make your medical tubing even better.

FAQ

What makes thin wall niti tubing different from regular tubing?

Thin wall niti tubing uses a special nickel-titanium alloy. You get superelasticity and shape memory. The walls are much thinner than regular tubing. This makes the tubing flexible and strong for medical devices.

How do you prevent bending or kinking during manufacturing?

You must handle the tubing gently. Use soft fixtures and supports. Monitor the tubing with cameras or sensors. This helps you spot bending or kinking early. Gentle handling keeps the tubing safe.

Why is wall thickness so important for medical devices?

Wall thickness controls how strong and flexible the tubing is. If the wall is too thin, the tubing may break. If it is too thick, the tubing may not bend well. You need the right thickness for safe devices.

Can you weld thin wall niti tubing to other metals?

Yes, you can weld thin wall niti tubing. Laser welding works best. You must control the heat to avoid damaging the tubing. Always test the welds for strength and safety before using them in medical devices.

See Also

A Complete Guide To Choosing Proper Nitinol Tubing

Tips For Finding The Best Nitinol Tubing Supplier

Detailed Process For Making Nitinol Microtubing In Neurovascular Use

The Importance Of Nitinol Tubing In Minimally Invasive Surgery