How Precision Manufacturing Shapes Nitinol Tubing for Neurovascular Devices

Precision manufacturing plays a pivotal role in producing high-strength nitinol tubing for neurovascular applications. Advanced techniques, such as cold working and heat treatment, enable manufacturers to achieve the superelastic properties required for medical devices like neurovascular stents. These processes ensure nitinol tubing meets stringent performance demands, including flexibility and durability.

Statistical studies reveal that advanced manufacturing methods improve the fatigue life of nitinol tubing. Data-driven simulations of deformation and uncertainty quantification enhance the reliability of medical devices. This meticulous approach makes high-quality nitinol tubing indispensable for addressing the complexities of neurovascular procedures and improving patient outcomes.

Key Takeaways

Precision manufacturing makes nitinol tubing strong and bendable for tricky brain surgeries.

Nitinol can stretch and return to shape, fitting tight blood vessels.

Special surface treatments, like polishing, make it safer for the body.

Custom nitinol tubing works well for specific brain-related medical tools.

Better nitinol devices help patients heal faster with fewer problems.

Unique Properties of Nitinol for Neurovascular Applications

Nitinol stands out as a material of choice for neurovascular applications due to its unique combination of properties. These characteristics make it indispensable for creating high-quality nitinol tubing used in neurovascular stents and other medical devices.

Superelasticity and Shape Memory in Neurovascular Devices

Superelasticity is one of the defining features of nitinol. This property allows the material to undergo significant deformation and return to its original shape once the stress is removed. In neurovascular applications, this behavior is critical. Devices like stents must navigate intricate and delicate blood vessels without losing their structural integrity. Superelastic nitinol tubing ensures that these devices can adapt to the complex anatomy of the neurovascular system while maintaining their functionality.

Shape memory is another remarkable attribute of nitinol. When exposed to specific temperatures, nitinol can "remember" and revert to its pre-set shape. This characteristic is particularly useful in neurovascular procedures where devices need to be deployed in a compact form and then expand to their functional shape. Engineering tests, such as the Bend Free Recovery (BFR) test, measure how effectively nitinol recovers its shape after deformation. These tests confirm the reliability of superelastic nitinol tubing in demanding medical applications.

Biocompatibility and Corrosion Resistance for Medical Use

Biocompatibility is a non-negotiable requirement for materials used in medical devices. Nitinol excels in this area, making it ideal for neurovascular applications. Its ability to coexist with human tissues without causing adverse reactions ensures patient safety. Biocompatibility for neurovascular applications is further enhanced by nitinol's resistance to corrosion. This resistance is vital in the bloodstream, where exposure to bodily fluids could otherwise degrade the material over time.

Surface finishing techniques, such as electropolishing, play a crucial role in enhancing nitinol's biocompatibility. These processes remove surface imperfections, reducing the risk of thrombosis and improving the overall quality of the material. The combination of biocompatibility and corrosion resistance ensures that nitinol tubing for neurovascular stents meets the stringent standards required for medical use.

High Strength and Flexibility for Complex Neurovascular Procedures

The neurovascular system presents unique challenges due to its intricate network of blood vessels. High-strength nitinol tubing for neurovascular applications addresses these challenges by offering a balance of strength and flexibility. This balance allows devices to withstand the mechanical stresses of deployment while navigating tight and tortuous pathways.

Engineering tests, such as Differential Scanning Calorimetry (DSC), assess the transformation temperatures of nitinol. These tests ensure that the material performs optimally under the thermal conditions encountered during neurovascular procedures. Additionally, design factors like wire diameter and braiding angle significantly impact the performance of nitinol devices. For instance, larger wire diameters increase radial strength but reduce flexibility, while larger braiding angles enhance both radial strength and flexibility. The table below summarizes these design factors and their effects:

Design Factor | Impact on Performance |

|---|---|

Nitinol Wire Diameter | Larger diameter increases radial strength but decreases flexibility |

Braiding Angle | Larger angle increases radial strength and flexibility, but impact decreases with large deformation |

Number of PET Strips | Influences surface coverage significantly |

These properties and design considerations make nitinol tubing an essential component in neurovascular stents and other devices. By combining high strength, flexibility, and biocompatibility, nitinol enables the development of advanced medical devices that improve patient outcomes.

Precision Manufacturing Processes for Nitinol Tubing

Vacuum Melting and Alloy Composition Control

Vacuum melting is a critical step in producing high-quality nitinol tubing for neurovascular applications. This process ensures the purity of the alloy by eliminating contaminants that could compromise its performance. Manufacturers use advanced techniques to control the composition of the nitinol alloy, achieving the precise balance of nickel and titanium required for superelasticity and shape memory.

The effectiveness of vacuum melting and alloy composition control is supported by documented case studies. For example, the table below highlights the consistent transformation temperatures and surface quality achieved through this manufacturing process:

Ingot | Tube Lot | Processing Method | Transformation Temperature (°C) | Surface Quality |

|---|---|---|---|---|

1 | 1-1 | TM-1 | 20 ± 3 | High |

1 | 1-2 | TM-1 | 20 ± 3 | High |

2 | 2-1 | TM-1 | 20 ± 3 | High |

These results demonstrate the precision and reliability of vacuum melting in producing medical-grade nitinol tubing. AccuPath leverages this expertise to deliver tubing that meets the stringent requirements of neurovascular devices.

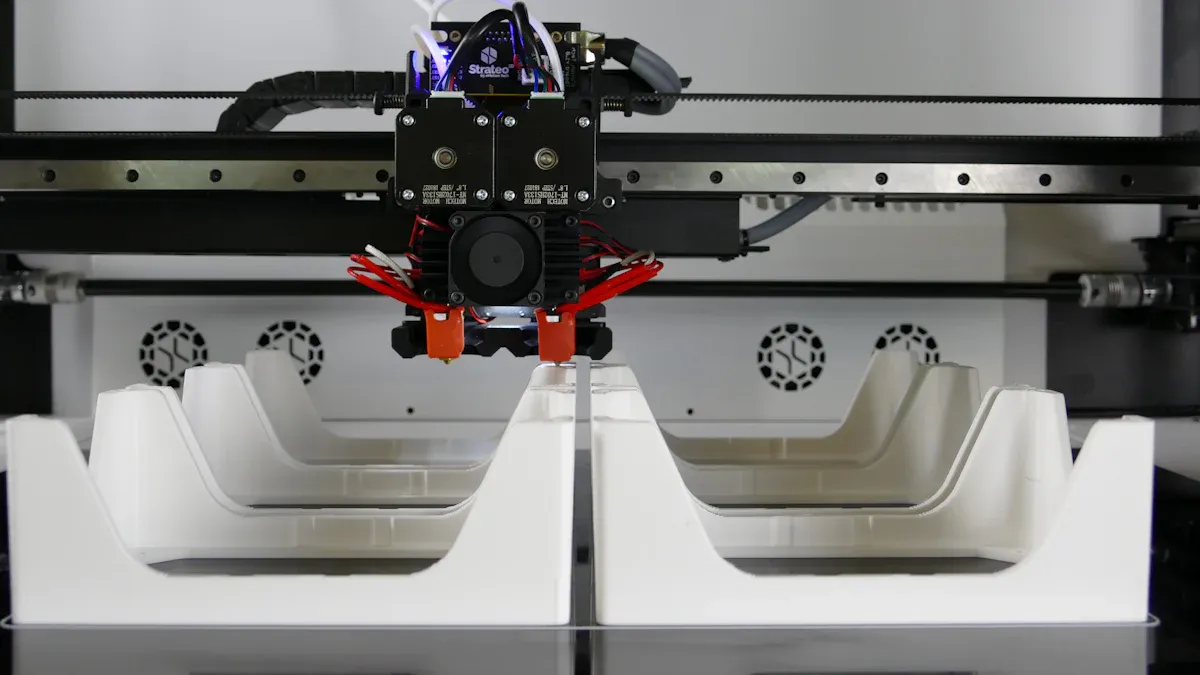

Cold Working and Heat Treatment for Superelastic Nitinol Tubing

Cold working and heat treatment are essential processes for enhancing the superelastic properties of nitinol tubing. Cold working involves deforming the material at low temperatures to refine its microstructure, while heat treatment stabilizes the alloy's phase transformation behavior. Together, these processes optimize the tubing's ability to recover its shape after deformation, a critical feature for neurovascular stents navigating complex blood vessels.

Technical data reveals that nitinol alloys exhibit superelasticity due to a reversible stress-induced martensitic transformation. Factors such as alloy composition, prior cold work, and heat treatment parameters significantly influence this behavior. For instance, the cooling rate during quenching affects the material's transformation temperatures, ensuring optimal performance during neurovascular procedures. AccuPath's advanced manufacturing techniques ensure precise control over these variables, delivering tubing with exceptional flexibility and durability.

Surface Finishing Techniques, Including Electropolishing

Surface finishing plays a vital role in enhancing the biocompatibility and corrosion resistance of nitinol tubing. Electropolishing, a widely used technique, removes surface imperfections and reduces roughness, improving the tubing's interaction with human tissues. This process is particularly important for neurovascular devices, where smooth surfaces minimize the risk of thrombosis and ensure long-term reliability.

Electropolishing can reduce surface roughness (Ra) by up to 50%. For example:

A part with an initial roughness of 80 Ra can achieve a final roughness of 40 Ra after electropolishing.

The amount of material removed depends on the run time and amp-minutes applied during the process.

AccuPath's medical-grade expertise and certifications ensure that their nitinol tubing undergoes rigorous quality-control metrics, delivering products with superior surface quality. This commitment to precision manufacturing techniques makes AccuPath a trusted partner in the neurovascular device industry.

Customization and Dimensional Accuracy in Nitinol Tubing

Importance of Tubing Size and Wall Thickness for Neurovascular Stents

Tubing size and wall thickness play a critical role in the performance of neurovascular stents. These factors directly influence the flexibility and maneuverability of stents within the intricate pathways of the neurovascular system. Dimensional specifications, such as effective length, inner and outer diameters, and crossing profiles, require precise measurement at multiple points to meet industry standards.

Wall thickness is particularly significant. Thinner walls enhance adaptability, allowing stents to navigate through microcatheters while maintaining structural integrity under stress. A reduced crossing profile improves the stent's ability to traverse complex neurovascular pathways, ensuring compliance with industry standards for precision and reliability. Manufacturers must carefully control wall thickness during production to achieve consistent performance across devices. This attention to detail underscores the importance of customization for neurovascular applications.

Achieving High Concentricity and Dimensional Precision

High concentricity and dimensional precision are essential for ensuring the reliability of nitinol tubing in neurovascular applications. Advanced manufacturing techniques, such as TM-1 processing, vacuum induction melting, and multiple remelting processes, contribute to achieving these goals.

Technique | Description |

|---|---|

TM-1 | Ensures high concentricity and surface quality, contributing to better fatigue performance. |

Vacuum induction melting | Allows for precise control of the tubing's composition and microstructure. |

Multiple remelting processes | Ensures dimensional precision by controlling the material properties effectively. |

These methods ensure that nitinol tubing meets the stringent standards required for neurovascular stents. High concentricity improves the tubing's fatigue resistance, while precise dimensional control enhances its performance in demanding medical procedures.

Tailoring Tubing for Specific Neurovascular Applications

Customization is vital for tailoring nitinol tubing to specific neurovascular applications. The unique requirements of each procedure demand tubing with precise dimensions, material properties, and surface finishes. For example, segmented (open-cell) stent designs conform better to curved vasculature, making them ideal for navigating tortuous neurovascular pathways.

High-quality medical components, such as nitinol tubing, are essential for the accuracy and efficiency of neurovascular devices. Customization ensures that these components meet the exacting standards of the medical industry, improving device reliability and patient outcomes. By addressing dimensional considerations for neurovascular stents, manufacturers can deliver tubing that aligns with the specific needs of each application, ensuring compliance with industry standards.

Impact of Precision Manufacturing on Neurovascular Device Performance

Enhancing Flexibility and Durability in High-Strength Nitinol Tubing

Precision manufacturing significantly enhances the flexibility and durability of high-strength nitinol tubing for neurovascular applications. Advanced techniques, such as cold working and heat treatment, refine the material's microstructure, enabling it to withstand the mechanical stresses of deployment in intricate neurovascular pathways. These processes also improve fatigue resistance and durability, ensuring the tubing meets the demanding performance requirements for neurovascular stents.

Durability tests and flexibility metrics highlight these improvements. For example:

Metric | Result |

|---|---|

Tensile Strength | 500 MPa to 900 MPa |

Local Strains | Up to 6% |

Cycles to Failure | Up to 10⁷ cycles |

Strain Amplitudes | 0.5% to 2.9% |

Cold Work Percentage | 20–30% |

These results demonstrate how precision manufacturing optimizes nitinol tubing for neurovascular stents, ensuring both flexibility and long-term reliability.

Ensuring Compatibility with Neurovascular Procedures

Compatibility with neurovascular procedures is critical for the success of medical devices like stents. Precision manufacturing ensures that nitinol tubing aligns with the unique anatomical and procedural demands of neurovascular applications. Techniques such as electropolishing enhance surface quality, reducing the risk of thrombosis and improving biocompatibility. This ensures optimal performance and patient safety during procedures.

Cyclic fatigue tests and physiological temperature evaluations further validate the tubing's compatibility. These tests reveal that nitinol tubing endures significant strain while maintaining its structural integrity. Its strength-to-weight ratio matches that of stainless steel and titanium alloys, making it ideal for neurovascular stents.

Improving Patient Outcomes Through Advanced Device Design

Advanced nitinol tubing design directly improves patient outcomes. Devices made from nitinol, such as stents and guidewires, demonstrate exceptional effectiveness in treating vascular conditions. Clinical studies show that nitinol stents significantly reduce restenosis rates, ensuring long-term vessel patency. This improvement minimizes complications and enhances recovery.

A comparison of nitinol devices with traditional materials underscores their advantages:

Metric | Nitinol Devices | Traditional Materials |

|---|---|---|

Recovery Improvement | 20% | N/A |

Pain Level Reduction | Quicker recovery | N/A |

Risk of Complications | Lower | N/A |

These advancements in nitinol tubing for neurovascular stents highlight the role of precision manufacturing in achieving optimal performance and patient safety. By addressing the complexities of neurovascular procedures, precision manufacturing continues to drive innovation in medical devices.

Precision manufacturing plays a vital role in shaping nitinol tubing for neurovascular devices. Its advanced techniques ensure the material's strength, flexibility, and biocompatibility meet the demands of intricate neurovascular procedures. The unique properties of nitinol, such as superelasticity and shape memory, enable the creation of innovative devices that improve patient outcomes. Future advancements in manufacturing will refine these processes further, driving progress in neurovascular technologies and enhancing care quality.

The continuous evolution of precision manufacturing promises groundbreaking improvements in neurovascular device performance and reliability.

FAQ

What makes nitinol tubing ideal for neurovascular devices?

Nitinol tubing offers superelasticity, shape memory, and biocompatibility. These properties allow it to adapt to complex blood vessel pathways while maintaining structural integrity. Its corrosion resistance ensures durability in the bloodstream, making it a reliable material for neurovascular stents and other medical devices.

How does precision manufacturing improve nitinol tubing?

Precision manufacturing enhances nitinol tubing by refining its microstructure and surface quality. Techniques like cold working, heat treatment, and electropolishing ensure high strength, flexibility, and biocompatibility. These processes help meet the stringent requirements of neurovascular applications, improving device performance and patient outcomes.

Why is surface finishing important for nitinol tubing?

Surface finishing, such as electropolishing, removes imperfections and reduces roughness. This improves biocompatibility and minimizes the risk of thrombosis. A smooth surface ensures better interaction with human tissues, enhancing the safety and reliability of neurovascular devices.

Can nitinol tubing be customized for specific procedures?

Yes, manufacturers can customize nitinol tubing by adjusting dimensions, wall thickness, and surface finishes. This ensures compatibility with specific neurovascular applications. Customization allows devices to navigate intricate pathways effectively, improving their performance and patient outcomes.

How does nitinol tubing improve patient outcomes?

Nitinol tubing enables the creation of advanced neurovascular devices like stents and guidewires. These devices reduce complications, improve recovery times, and enhance long-term vessel patency. Clinical studies show that nitinol-based devices outperform traditional materials in treating vascular conditions.

See Also

The Process of Creating Nitinol Tubing for Healthcare Use

A Comprehensive Guide to Nitinol Microtubing Production Steps

Nitinol Tubing: Transforming the Future of Medical Devices

The Importance of Nitinol Tubing in Modern Medical Uses

Investigating Nitinol Tubing Uses in Medical Device Technology