Top Tips for Selecting Precision Drawn Nitinol Tube with Tight Tolerances

Selecting the right Precision Drawn Nitinol Tube with tight tolerances is very important for success in medical uses. In medical device making, there is a lot at risk. Even small changes in nitinol tube size can hurt the safety and trust of medical devices like stents. You need nitinol tubing with strict tolerances to lower problems when putting in stents and to make sure they work the same every time. Top makers use special checks like laser micrometry and ultrasonic testing to keep quality high and follow ASTM F2063 rules. For the best results, look at both the technical details and how much the supplier knows about medical nitinol stents.

Key Takeaways

Pick nitinol tubing with very exact sizes. This helps medical devices like stents work safely and well.

Always check if your supplier uses important medical rules like ISO 13485 and ASTM F2063. This makes sure the tubing is safe and good quality.

Know how superelastic nitinol is different from shape memory nitinol. This helps you choose the best type for your device.

Use new ways to make and check tubing as it is made. This keeps the tubing the same and meets tough medical rules.

Work with suppliers who have lots of experience. They should offer custom options, good help, and show they make quality products. This will help your project do well.

Define Requirements

Application Needs

First, you need to know what your device needs. Nitinol tubing is used in many medical tools. Some examples are guidewires, stents, and catheters. Each tool needs different things from the tubing. Superelasticity lets nitinol tubing bend and go back to its shape. This is helpful in heart or brain surgeries. Fatigue resistance means the tubing can be used many times without breaking. You should also think about the surface finish and coatings. These help stop rust and make the tubing safe for the body. Getting tubing made just for you and being able to track it helps meet medical rules. The table below lists what is often needed for nitinol tubing in medical devices:

Requirement Category | Details and Examples |

|---|---|

Physical Dimensions & Tolerances | Ultra-fine tubing with tight tolerances (e.g., OD tolerance ±0.005mm for >0.80mm diameter) to ensure device compatibility and functionality in guidewires and stents. |

Mechanical Properties | Superelasticity and shape memory to adapt to physiological environments; fatigue resistance enhanced by manufacturing processes. |

Compliance & Standards | Adherence to ISO 9001:2015, ISO 13485:2016, EU CE marking, ISO 10993 for biocompatibility and safety. |

Material Quality & Integrity | Use of high-purity materials and seamless tubing preferred for structural integrity and durability. |

Surface Treatments | Advanced coatings to improve corrosion resistance and biocompatibility. |

Supplier Requirements | Customization, traceability, and technical support to meet specific application and regulatory needs. |

Tolerance and Dimensions

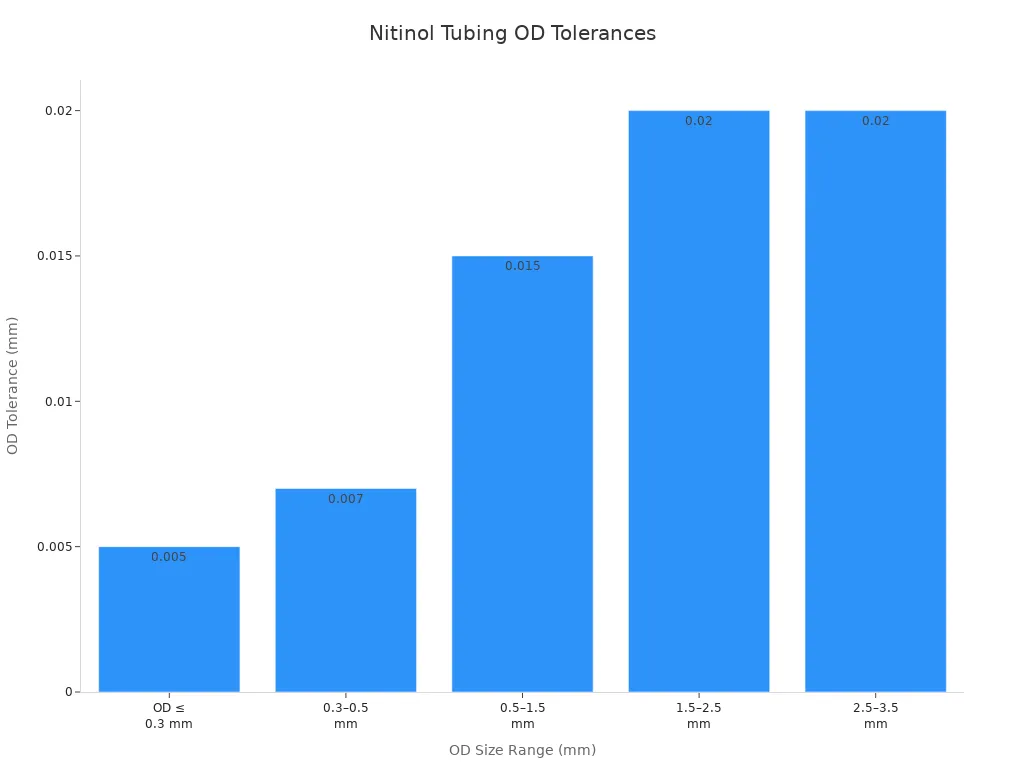

You must check the size details for nitinol tubing. Tight tolerances are very important for safety. Small changes in size can cause problems. For small tubes, the outer diameter can have a tolerance as close as ±0.005 mm. Wall thickness and how even the tube is also matter. If the tube is not even, the device might not work right. The chart below shows how outer diameter tolerances change with tube size:

Pick nitinol tubing that fits your device’s needs. Tubes up to 1.5 mm wide usually have a tolerance of ±0.025 mm. Bigger tubes have looser tolerances. Wall thickness can be as thin as 0.025 mm. But it should be at least 10% of the outer diameter so it does not bend too much. Special ways of making the tubing, like laser cutting and electropolishing, help keep these tight tolerances.

Regulatory Standards

You must make sure your nitinol tubing meets all medical rules. In the US and Europe, ISO 13485 is needed. This rule is about quality for medical devices. Your tubing should also meet ASTM F2063. This is the rule for nitinol alloys. ISO 10993-1 checks if the tubing is safe for the body. Meeting these rules helps you get approval from the FDA and the European Union. Having these certificates shows you care about safety and quality.

Tip: Always ask your supplier for papers that prove they follow ISO 13485, ASTM F2063, and ISO 10993-1. This helps keep your project safe and makes approval faster.

Material and Properties

Nitinol Alloy Selection

You have to pick the right nitinol alloy for your device. Nitinol is special because it can bend and return to shape. This is called superelasticity and shape memory. Superelastic nitinol tubing is good for things that bend a lot. It snaps back fast, like in stents or guidewires. Shape memory nitinol tubing is used when heat makes it change shape. This works for actuators or some surgical tools. The table below shows how these two types are different:

Feature | Superelastic Nitinol Tubing | Shape Memory Nitinol Tubing |

|---|---|---|

Main Mechanism | Stress-induced phase change | Temperature-induced phase change |

Behavior | Returns to original shape immediately after bending (no heat needed) | Holds new shape until heated above transformation temperature |

Activation | Activated by mechanical force above transformation temperature | Activated by heating above set temperature |

Recovery Speed | Immediate shape recovery | Delayed recovery, requires heating |

Typical Strain Limit | Up to approximately 4% strain | Up to approximately 8% strain (after heating) |

Malleability | Not malleable at room temperature | Malleable below transformation temperature |

Fatigue Resistance | Very high, suitable for repeated bending cycles | High, but depends on cycling and heating frequency |

Common Applications | Medical stents, guidewires, eyeglass frames | Actuators, couplings, surgical tools |

Pick the nitinol type that matches your device’s job. Superelastic tubing is strong and bounces back quickly. Shape memory tubing lets you control its shape with heat.

Certifications

Check if your nitinol supplier has the right certificates. Good nitinol for medical use needs strict checks. Look for these certificates:

FDA registration means the supplier follows US safety rules.

ISO 13485 shows the supplier uses a good quality system.

These certificates help you follow the rules and gain trust.

Suppliers with these certificates lower your risk and help you sell your product.

A company like HaoLu Tech with ISO 13485 shows they care about quality and rules.

Biocompatibility

Make sure your nitinol tubing is safe for people. Biocompatibility tests check if the material hurts the body or causes allergies. The table below lists common tests for nitinol used in medical implants:

Biocompatibility Test | Purpose / Description | Regulatory Guidance / Notes |

|---|---|---|

Cytotoxicity Testing | Checks if nitinol harms cells | Detects risk from nickel ion release |

Sensitization Testing | Looks for allergic reactions | Evaluates nickel-induced hypersensitivity |

Chemical Characterization | Identifies chemicals in tubing | Supports toxicology review |

Toxicological Risk Assessment | Checks for toxic substances | Ensures safety for implants |

Nickel Ion Release Testing | Measures nickel release | FDA recommends 30-60 day testing |

Surface Treatment Evaluation | Tests coatings and finishes | Improves corrosion resistance |

Always ask for test results that show the nitinol is safe. This keeps patients safe and helps you meet FDA and ISO 10993 rules. Nitinol’s special features and safety make it a good choice for medical devices.

Manufacturing Process

Precision Drawn Nitinol Tube

It is important to know how nitinol tubes are made. Making precision drawn nitinol tube starts with pure nitinol. The tubing is pulled through dies to get the right size. This makes the tube smooth and keeps tight tolerances. Carbide or ceramic cutting tools help make the tubes more exact. These tools last longer and do not wear out fast. Nitinol is very strong, so tough tools are needed. Using these tools gives smoother tubes and better sizes. You should use cooling and slow feed rates. This keeps the tube from getting too hot or stressed. These steps help nitinol keep its special features.

You must take care of your tools often. Keeping tools sharp and clean lowers friction and heat. This stops the nitinol tube from getting too hard. You also need to set the right speed, feed, and depth. These steps lower heat and stress on the tube. This makes the tube smoother and helps tools last longer. Coolant can make cutting much cooler, up to 86.9% less heat. Good equipment care stops problems and keeps tubes the same.

Tip: Always check your polishing and rinsing machines often. This stops dirt and keeps your nitinol tubes at top quality.

Nitinol Tubing Techniques

There are many ways to process nitinol for small tolerances. Here are some good ways to machine nitinol and make it better:

Electropolishing smooths edges and removes damage, helping keep tight tolerances.

Precision centerless grinding removes material very accurately.

CNC machining, like Swiss machining, makes tiny features as small as 25 micrometers.

Photochemical machining gives smooth edges and tight features.

Laser welding and 3D laser micromachining use fast lasers for tiny features with little heat.

Shape setting with custom tools lets you control the tube’s shape and strength.

Hybrid manufacturing mixes CNC and laser for better accuracy and speed.

You should use statistical process control, or SPC, to keep tubes within tight tolerances. SPC helps you watch things like nickel-titanium mix, impurity levels, and tube size. You can use tests and data to set up SPC rules. This helps you control temperatures, strength, and size. You also need to check your chemicals and keep machines set right. Checking during work helps you find problems early and keep tubes the same.

Note: Checking during work and using SPC helps you meet strict medical device rules.

Advanced Micromachining

Advanced micromachining and partial etching let you make small, complex nitinol tubes. These use lasers and electrochemical machines together. You can process nitinol gently, with less heat, so it keeps its special features. Lasers help speed up the chemical reactions, so you can remove material faster and more exactly. You can machine hard materials like nitinol and keep its shape memory and superelasticity.

Benefit | Explanation |

|---|---|

Gentle material processing | Laser-ECM uses less heat and keeps nitinol’s microstructure safe. |

Localized and accelerated dissolution | Lasers make reactions faster, so you can remove material in small spots. |

Improved precision and surface finish | You can make complex shapes with smooth surfaces, better than old laser cutting. |

Capability for hard materials | Works well with nitinol, which needs careful control. |

Overcoming aspect ratio limits | Hybrid tools let you make deeper features than nozzle systems. |

Preservation of properties | Partial etching keeps nitinol’s shape memory and superelasticity. |

Laser cutting is also very important for making nitinol for smart and medical devices. You can shape nitinol tubes very exactly and keep their special features. This is very important for medical and aerospace uses. When you use these new ways, you get nitinol tubes with the best tolerances and performance.

Quality Control

Inspection Methods

You have to use careful inspection methods to check nitinol tubing. Good inspection tools help you check every size of your nitinol tubes. Laser micrometers and special cameras measure the outside and inside very exactly. These tools can find tiny changes, as small as ±5 micrometers. Real-time systems watch wall thickness and help keep the tube even. Machines that check by themselves make sure every tube is the right size from start to finish. This way, you follow strict rules like ASTM F2063 and ISO 10993.

Dimension Aspect | Inspection Method | Measurement Precision / Tolerance | Additional Notes |

|---|---|---|---|

Outer Diameter (OD) | Laser micrometers, advanced imaging systems | Variations as small as ±5 µm; OD tolerances range from ±0.005 mm to ±0.020 mm depending on size | Enables real-time adjustments during production to maintain tight tolerances |

Inner Diameter (ID) | Laser micrometers, advanced imaging systems | ID tolerances range from ±0.010 mm to ±0.040 mm depending on size | Critical for ensuring tubing meets exacting standards for medical/industrial use |

Wall Thickness | Real-time monitoring systems, advanced imaging | Detects variations as small as ±5 µm | Ensures uniformity and durability, especially important for high-stakes applications |

Automated and validated inspection equipment | 100% dimensional compliance ensured throughout manufacturing | Supports prototype to full production, validated per ASTM F2063 and ISO 10993 |

You should also check the surface and use tests that do not damage the tube. These tests help you find problems that could hurt how the tube works in medical devices. Companies like Norman Noble use machines that check every tube by themselves to make sure they are the best quality.

Tip: Always check your tubes during and after making them. This helps you find problems early and keep your nitinol tubing at top quality.

Batch Consistency

You must keep every batch of nitinol tubing the same for safety. Batch consistency starts with checking every tube’s size. Laser micrometers and ultrasound check each tube for size and wall thickness. You use tight size rules, sometimes as close as ±0.005 mm, for both outside and inside. Statistical Process Control tools, like control charts, help you watch and control your work.

You control heat treatment between 350–600 °C to keep the tubes strong.

Surface finishing, like electropolishing, removes rough spots and keeps sizes right.

Non-destructive tests, like X-rays and ultrasounds, find inside problems and keep batches the same.

You follow rules like ASTM F2063, ISO 13485, and FDA for tracking and quality.

Custom tools and making tubes in your own shop help you fix problems and keep batches the same.

You also make nitinol alloys in a vacuum to get the right mix. Pulling and shaping the tubes in steps, with heating in between, helps keep sizes tight. Watching the pulling force and speed all the time keeps the tubes the right size. After making them, special measuring tools check that your nitinol tubing meets all the rules.

Note: Write down every step and keep records for tracking. This helps you follow strict quality rules and meet what the law needs.

Real-Time Monitoring

You need real-time checks to find problems while making nitinol tubing. Laser micrometers and measuring machines check the outside size very closely. Optical comparators make sure your tubes match the design. Bore gauges check the inside, and ultrasound tools watch wall thickness with tight rules, like ±0.01 mm.

Automated AI systems watch tube sizes and surfaces as you make them. These systems find problems early and lower mistakes. Non-destructive tests, like ultrasound and eddy current, find inside and outside problems before they get worse. Real-time systems can see tiny changes in wall thickness, as small as ±5 micrometers. This lets you fix things right away and keep your nitinol tubing within tight rules.

These tools help you keep the tube strong and superelastic. They also make sure your nitinol tubing meets medical standards during making. By using these checks, you can give nitinol tubing that is safe and high quality.

Remember: Real-time checks are very important for good quality control. They help you keep tight rules and give safe nitinol tubing for important jobs.

Supplier Evaluation

Experience with Nitinol

When picking a nitinol tubing supplier, look for lots of experience. Not all companies know how to make nitinol right for medical devices. The best suppliers handle every step, from melting nitinol to making the tube. This helps keep quality high and stops mistakes. You want a partner who understands nitinol’s special changes and how it acts. They should follow FDA and ISO rules and work with safety groups. Using wire EDM, waterjet cutting, and making custom alloys shows they have good skills. Suppliers who can make quick samples and grow fast help you get products out sooner. Good records and tracking are needed for medical nitinol tubing. Companies with their own machines can keep quality steady. You should also find suppliers who talk with you and give design help.

Handle every step from melting nitinol to finished tubing.

Know a lot about nitinol’s special features and changes.

Follow FDA and ISO rules with strong quality checks.

Use new ways to cut, coat, and test nitinol.

Make quick samples and grow fast for new ideas.

Keep good records and track every batch.

Use special machines for making nitinol tubes.

Give clear advice and help with designs.

Customization Options

You need nitinol tubing that matches your needs. Top suppliers let you pick size, wall thickness, and length. Some let you set transformation temperatures, which is important for special uses. You can choose different surface looks, like shiny or black, to help stop rust. New ways like laser cutting, shape setting, and electropolishing help make special designs. Many suppliers take small orders and give samples to test. Certifications like ISO 13485 and ASTM F2063 show they care about quality.

Supplier | Customization Options | Certifications | Order Flexibility | Delivery Speed | Customer Service |

|---|---|---|---|---|---|

SIZEN | Custom sizes, transformation temperatures, surface finishes | N/A | Custom orders available | N/A | N/A |

Memry Corporation | Custom sizes, finishes, traceability, strict quality controls | ISO 13485, ASTM F2063 | Flexible order sizes | Fast | Responsive |

AccuPath | Polishing, annealing, transformation temperature control, coatings | ISO 13485, ASTM F2063 | Very flexible, small batches | Fast | Excellent |

Resonetics | Laser cutting, braiding, shape setting, electropolishing | ISO 13485, ASTM F2063 | Flexible | Fast | Strong |

New England Tubing Tech. | Tipping, flaring, grinding, coating, thermal forming | ISO 13485 | Flexible | Fast | Good |

Johnson Matthey Medical | Custom sizes, microlumen tubing | ISO 13485 | Flexible | Moderate | Good |

Confluent Medical Tech. | Spiral Ridge™, custom shapes | ISO 13485, ASTM F2063 | Flexible | Very fast | Strong |

Support and Reputation

You want a supplier who helps you at every step. Good companies answer fast and fix problems quickly. They give tips on making nitinol tubing and suggest the best ways for your project. A good name means other people trust them. Look for reviews and stories that show they do well with nitinol tubing in medical devices. Reliable suppliers keep you updated and deliver on time. They help you pick the right ways and guide you through each step. This help makes your project easier and helps you meet tough medical rules.

Cost and Value

Long-Term Performance

You want nitinol tubing that works well for many years. Nitinol is strong and does not break easily. Tests show nitinol can handle up to 4% strain. It can last through 400 million pressure cycles in arteries. This means your device can work for at least 10 years. It keeps working even when used all the time. Nitinol does not crack or rust, so devices fail less. You do not need to replace them as often. Its superelasticity lets stents and catheters bend with the body. This helps patients feel better and safer. Reports show nitinol stents last longer than other metal stents.

Nitinol tubing can last through 400 million cycles in heart devices.

Devices often work for 10 years or more, and new ones may last 15–30 years.

Superelasticity and rust resistance make them safe for long use.

Fewer replacements mean less risk for patients and doctors.

Total Cost of Ownership

Nitinol tubes cost more at first than steel or other metals. But you save money over time because they last longer. Nitinol’s strength means you do not need to replace devices as much. It can go through many cleaning cycles without breaking. This lowers the cost each time you use it. Using nitinol can make devices easier to build. This can lower the cost to make them. You also get fewer problems and less fixing needed. When you add up all costs, nitinol can be cheaper in the end.

The starting price is higher, but nitinol lasts 3–5 times longer than steel.

You spend less on fixing and checking devices.

You do not need to replace them as much, even in hard places.

Big supplies and direct shipping help stop delays in making devices.

Supply Chain Stability

You need a steady supply of good nitinol tubing. There are only a few companies that make pure nitinol. Prices can change a lot, and rules are strict. Not many places have the pure nickel and titanium needed. It can take longer to get approval and find skilled workers. This can slow down making the tubing. You can help by picking suppliers who use more than one source. Some recycle materials and use machines to help make tubing faster. Good partners keep extra stock and use two sources to avoid problems.

Challenge | Impact on Supply Chain |

|---|---|

Limited Suppliers | Fewer places to get pure nickel and titanium |

Price Volatility | Changing prices make it hard to plan |

Regulatory Compliance | Rules can slow things down and cost more |

Skilled Labor Shortages | Not enough workers slows making more tubing |

Geopolitical Risks | Trouble in some areas can stop or slow supply |

Tip: Pick suppliers who plan for risks and use many sources. This helps keep your projects moving.

Medical Applications

Manufacturing Nitinol Stents

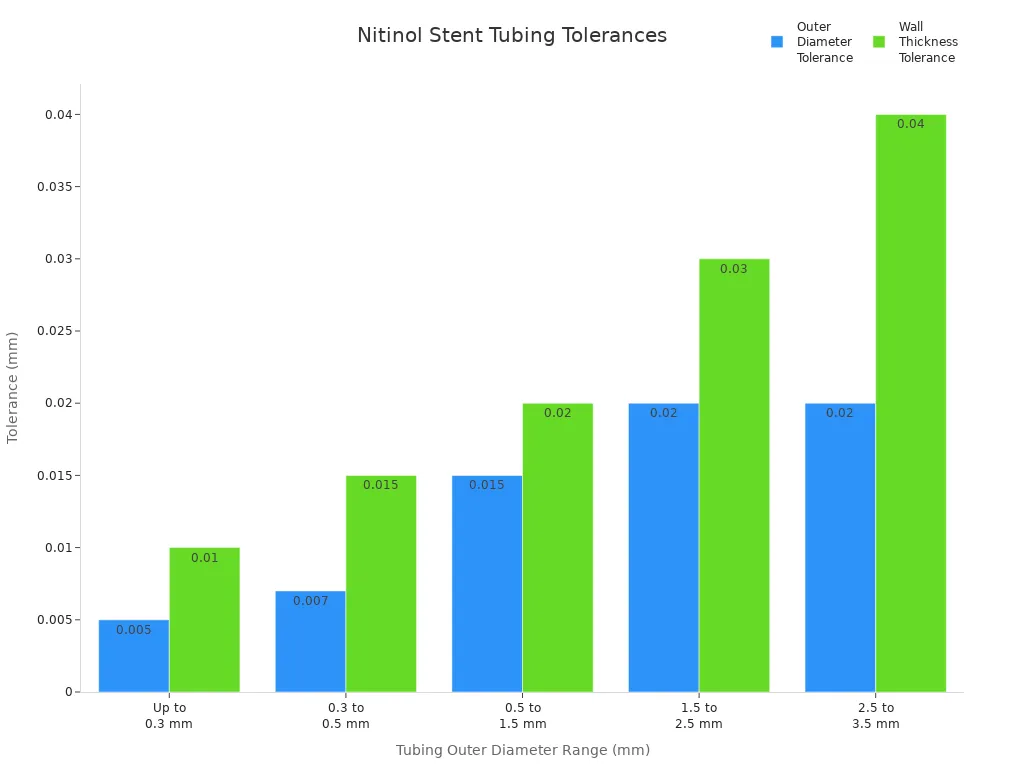

You need very exact sizes when making nitinol stents for the brain and heart. These stents must fit just right in tiny blood vessels. If the size is even a little off, the stent might not work or could hurt someone. The table below shows the size rules for nitinol tubing in these stents:

Tubing Outer Diameter Range (mm) | Outer Diameter Tolerance (mm) | Wall Thickness Tolerance (mm) |

|---|---|---|

Up to 0.3 | ±0.005 | ±0.010 |

0.3 to 0.5 | ±0.007 | ±0.015 |

0.5 to 1.5 | ±0.015 | ±0.020 |

1.5 to 2.5 | ±0.020 | ±0.030 |

2.5 to 3.5 | ±0.020 | ±0.040 |

You also need the tube’s surface to be very smooth, less than 0.1 μm rough. The tube must be round, with a difference of less than 0.01 mm. These strict checks help stents bend and stay strong. Using cold drawing and heat treatment makes the stents last longer. Pure nitinol and careful finishing stop weak spots and lower nickel from coming out.

Catheters and Drug Delivery

Tight size rules help catheters and drug delivery tools work safely. You get a good fit and smooth movement in the body. Even wall thickness keeps the tube strong and stops breaks. This helps you avoid kinks or hard pushing. Laser cutting makes smooth edges and perfect shapes. Your medical tools become safer and easier to use.

Tight size rules help stop kinks and make tubes bend better.

You can move the device smoothly through blood vessels.

You can change how stiff the tube is along its length.

Drug delivery tools need exact nitinol tubes for safe medicine flow.

Same size tubes help stop leaks or clogs in medical tools.

Regulatory Validation

You must follow strict rules for nitinol in medical tools. ISO 13485 is about making sure quality is high. The FDA checks your company and your quality steps. ASTM F2063 gives the rules for nitinol material and tests. ISO 14971 is for managing risks. Making stents and drug tools in cleanrooms, like ISO 8, keeps them safe from germs. You must test the size, strength, and safety for the body. These steps help you follow all medical rules and keep people safe.

Tip: Always write down your making and testing steps. This helps you pass checks and show your nitinol medical tools meet every rule.

When you pick precision drawn nitinol tube with tight tolerances, your stents become safer and more reliable. First, think about what your medical device needs. Always check the size rules for your tubing. Pick suppliers who follow ISO 13485 and ASTM F2063 for good quality. Good partners let you change the tubing for your stents. They keep their work areas clean and use special checks. Keeping quality the same and tracking tubes helps you follow medical rules and lower risks. Ask for samples and talk to suppliers with lots of experience. When you care about quality, your stents work well in all medical uses.

Pick nitinol tubing with tight tolerances to help stop stent failures.

Work with certified makers to get the same good quality every time.

Choose suppliers who let you change your stents and deliver fast.

Learn about nitinol’s features to make sure stents are safe for medical use.

FAQ

What is the tightest tolerance you can expect for nitinol tubing?

Small nitinol tubes can have very tight tolerances. The outer diameter can be as close as ±0.005 mm. This high precision is needed for tough medical and industrial jobs.

How do you verify the quality of nitinol tubing?

You should ask for inspection reports from your supplier. They use laser micrometers and ultrasonic tests to check the tubes. These tools measure size, wall thickness, and surface finish. Always get certificates and test results to be sure.

Why does biocompatibility matter for nitinol tubes?

Biocompatibility means the tubing is safe for the body. This is important for any device that touches blood or tissue. Testing helps stop allergic reactions and helps with getting approval.

Can you customize nitinol tubing for special projects?

Yes, you can ask for custom sizes and wall thicknesses. You can also pick transformation temperatures and surface finishes. Special coatings are available too. Custom options help you fit your device’s needs.

See Also

A Complete Process For Choosing Proper Nitinol Tubing

Tips For Finding The Ideal Nitinol Tubing Supplier

The Manufacturing Process Of Nitinol Tubing For Medicine

Detailed Instructions For Making Nitinol Microtubing Neurovascular

Comprehensive Overview Of Nitinol Parts And Production Methods