Precision-Cut Nitinol Tubing Comparison for Medical Applications

Precision-cut nitinol tubing is very important for medical use. It is strong and flexible, making it perfect for many devices. Comparing these tubes helps ensure they work well, especially in life-saving tools. Many things affect the choice of tubing:

Quality is key because good tubing is safe and reliable.

Custom designs meet special needs, like tiny surgeries.

Certifications prove they follow strict industry rules.

Cost depends on how they are made and market needs.

Reliable suppliers make sure tubes arrive on time.

The medical tubing market might grow to $895.10 million by 2027. Checking these factors is crucial to meet healthcare needs.

Key Takeaways

Nitinol tubing is tough and bends easily, perfect for medical tools like stents and heart valves.

Picking good nitinol tubing keeps medical tools safe and dependable.

Custom nitinol tubing can fit special medical needs, making tools work better.

Certifications like ISO 13485 prove nitinol tubing is safe and high-quality.

Trustworthy suppliers help deliver nitinol tubing on time for smooth device making.

Overview of Nitinol Tubing

Properties of Nitinol for Medical Applications

Nitinol is made from nickel and titanium. It is special because of its strength and flexibility. Its tensile strength is between 500 and 900 MPa. This makes it strong enough for tough medical uses. Nitinol can return to its shape after being bent. It also stretches easily to fit body shapes. These features come from careful mixing, heating, and shaping.

Material | Tensile Strength (MPa) | Special Features |

|---|---|---|

Nitinol | 500 - 900 | Stretches, remembers shape, safe for the body |

Stainless Steel | 600 - 1100+ | Strong, resists rust, works in many situations |

Titanium Alloys | 900 - 1200 | Lightweight, strong, resists rust very well |

Nitinol is safe for the body and rarely causes problems. It also resists rust, making it great for implants like stents and heart valves.

Role of Precision in Nitinol Tubing Manufacturing

Making nitinol tubing needs great accuracy. Its performance depends on exact sizes and shapes. This ensures it works well in medical devices. Tools like lasers and special machines are used to cut and shape it. These methods create thin walls and detailed designs. The tubing stays strong even with these changes.

Accurate nitinol tubing makes medical devices safer and more reliable.

Common Uses of Nitinol Tubing in Medical Devices

Nitinol tubing is very useful in medical tools. It is often used in stents because it is flexible and strong. Heart valves also use nitinol to fit different body shapes. Thin and porous nitinol is used in implants and scaffolds.

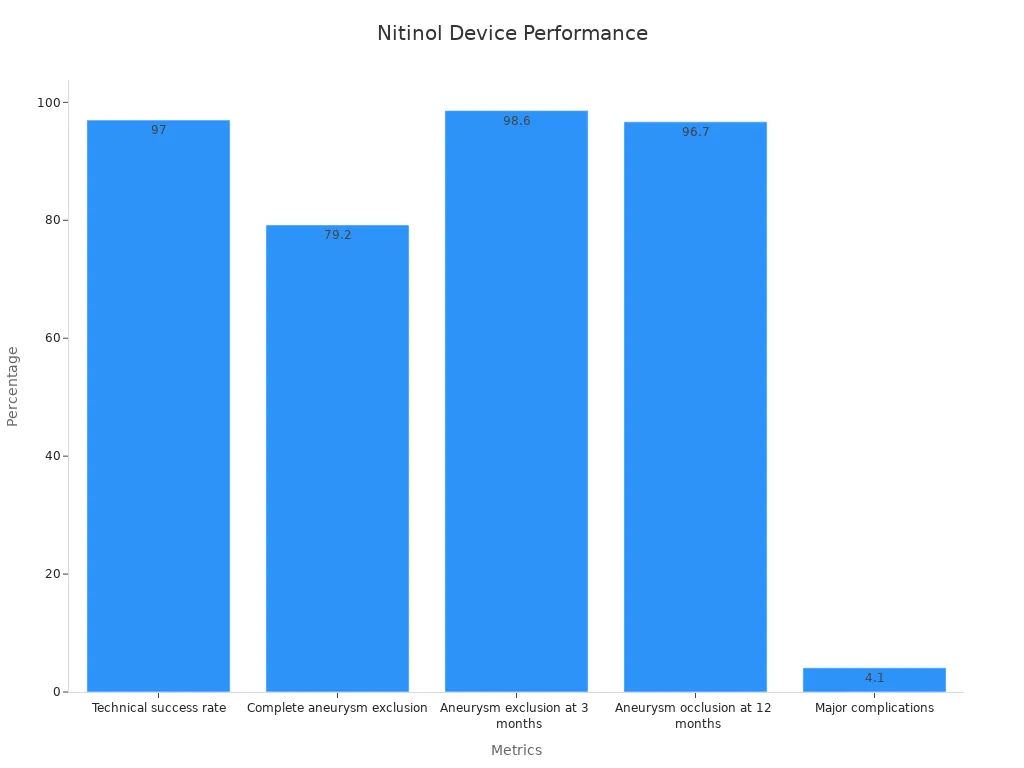

Studies show nitinol devices work very well. For example, nitinol stents succeed 97% of the time. They also help fix aneurysms in 96.7% of cases after a year. This shows how dependable nitinol is for important medical uses.

Leading Precision Tube Makers

GEE SMA: What They Do Best

GEE SMA is great at making shape memory alloy tubes. They create strong nitinol tubing for medical tools. Their tubes are tough and made with exact sizes. GEE SMA uses lasers and heat to make sure tubes work well. They also let customers customize designs for special needs. The company follows strict rules to ensure safety and quality. This makes them a trusted choice in healthcare.

Dynalloy: What They Do Best

Dynalloy is known for making reliable nitinol tubes. Their tubes are flexible and keep their shape well. These are used in stents, catheters, and surgery tools. Dynalloy uses advanced methods to make smooth and precise tubes. They work closely with customers to design and test products. This helps meet the needs of different medical devices. Their focus on new ideas and quality makes them a top company.

Fort Wayne Metals: What They Do Best

Fort Wayne Metals is famous for its material knowledge. They make nitinol tubes that are safe for the body and resist rust. Their tubes are used in implants, heart tools, and bone repairs. They use modern machines to make accurate and high-quality tubes. The company also tests materials to meet medical standards. Their research helps solve tough medical problems with new ideas.

Resonetics: Skills and Products

Resonetics is known for making very precise nitinol tubes. They use advanced laser tools to cut and shape tubing. This makes their tubes perfect for medical devices needing accuracy.

Resonetics invests in new technology to improve their products. They use lasers and grinding machines to make tubes exact in size. These methods make the tubes strong and reliable for stents, catheters, and surgery tools. The company also follows strict medical rules to ensure safety.

To meet more orders, Resonetics built a new factory in Costa Rica. This helps them make more tubes and stay ahead in the industry. Below are some of their key achievements:

Proof Type | Details |

|---|---|

Factory Growth | New Costa Rica factory boosts nitinol tube production to meet demand. |

Laser cutting and grinding improve accuracy for medical device rules. |

Resonetics lets customers design tubes for special medical needs. Their focus on accuracy and safety makes them a trusted choice for healthcare tools.

Resonetics' focus on precision and new ideas keeps their tubes top-quality for medical use.

Comparison of Precision-Cut Nitinol Tubing Products

Material Composition and Quality

The materials in nitinol tubing are key to its use in medicine. Nitinol is made from nickel and titanium. Its special features, like bending back to shape, come from the right mix of these metals. Even tiny impurities can weaken it, especially in small medical tools. High-quality manufacturing ensures the tubing is strong and safe for devices like stents and heart valves.

To check quality, makers use tests like ASTM F2516. This test measures strength and stretch, which are important for durability and safety. The table below shows key tests used to check quality:

Test Type | What It Measures |

|---|---|

ASTM F2516 | Tests strength and stretch during bending and straightening. |

Upper Plateau Strength | Measures strength at 3% stretch on the first bend. |

Lower Plateau Strength | Measures strength at 2.5% stretch when straightening. |

Residual Elongation | Checks how much it stretches after bending and straightening. |

Maximum Load Strain | Measures stretch before breaking. |

Advanced tools like lasers and ultrasonic gauges check the tubing’s size and thickness. These tools help ensure the tubing meets high standards for medical use.

Careful testing and advanced tools make sure nitinol tubing is safe and reliable for medical devices.

Dimensional Accuracy and Tolerances

Exact sizes are very important for nitinol tubing, especially for heart tools. Small size mistakes can affect how well it works. Makers use precise tools to cut tubing to exact sizes for outer and inner diameters and wall thickness.

The table below shows how accurate nitinol tubing is:

Measurement Type | Value |

|---|---|

Positional Accuracy | ±2.5 microns |

Cutting Tolerance | ±10 microns |

Comparison to Traditional | Over 10 times more accurate than older methods |

Strict checks are done to make sure all tubing is the same. Wall thickness and diameter are checked often to keep quality high. Makers also test the nickel-titanium mix to keep the tubing flexible and able to return to shape. These features are needed for advanced medical tools.

Accurate sizes make nitinol tubing work better and last longer in life-saving devices.

Certifications and Compliance Standards

Certifications prove nitinol tubing is safe and works well in medical tools. For example, ISO 13485 shows the tubing meets global safety rules. This certification helps companies sell their products worldwide and avoid legal problems.

The table below lists key certifications and why they matter:

Certification Type | Importance |

|---|---|

ISO 13485 Certification | Proves tubing is safe and meets global medical rules. |

Product Defects and Recalls | Certified makers report fewer defects and recalls, showing better quality. |

Compliance with Regulations | Makes it easier to follow global rules and sell products worldwide. |

Certified companies have fewer problems with their products. Following these rules also ensures the tubing is safe for the body and resists rust. This is very important for implants and other medical tools.

Following certifications improves product safety and builds trust with doctors and patients.

Customization Choices for Medical Uses

Making nitinol tubing fit medical needs is very important. Companies create special designs to match different medical tools. These changes improve how the tubing works and make it perfect for life-saving devices.

Customization Type | What It Does | Examples of Use |

|---|---|---|

Sizes | Changes tubing size for specific medical tasks. | Stents, guidewires, surgery tools. |

Shapes | Adjusts tubing shape for certain purposes. | Stents, guidewires. |

Material Mix | Changes alloy to improve flexibility and memory. | Stents, guidewires. |

Body Safety | Makes sure the material is safe for humans. | All medical tools. |

Rust Resistance | Improves how long the tubing lasts in medical use. | All medical tools. |

Nitinol is great for custom medical tools because it is safe and resists rust. Companies work closely with clients to make tubing with exact sizes, thicknesses, and finishes. This ensures the tubing works well in stents, guidewires, or surgery tools.

Custom nitinol tubing is flexible and meets advanced medical needs.

Costs and Value

Nitinol tubing costs more than steel, but it lasts longer. Its strength means fewer replacements, saving money over time. This makes it a smart choice for important medical tools.

Feature | Nitinol Tubing Benefits | Steel or Other Materials |

|---|---|---|

Starting Price | Costs more at first | Costs less at first |

Strength | Lasts longer, needs fewer replacements | Needs more repairs and checks |

Maintenance Costs | Lower because it lasts longer | Higher due to frequent fixes |

Total Cost Over Time | Cheaper in the long run | More expensive over time |

Custom Options | Can be made for special uses | Limited custom choices |

Custom nitinol tubing improves performance and reduces failures. This lowers repair costs and makes it worth the higher price.

Nitinol tubing costs more upfront but saves money long-term.

Dependable Supply and Delivery

Getting nitinol tubing on time is very important. Good suppliers can handle changes without lowering quality. Reliable delivery keeps medical tool production on track, even when demand is high.

What makes supply chains reliable:

Deliveries arrive on time, showing strong planning.

Good inventory systems handle changing needs.

Backup plans keep supplies steady during problems.

Big suppliers can handle custom orders and give accurate delivery times. Fast delivery is key for custom tubing, as delays can affect medical tools. Trusted companies with advanced factories are best for meeting these needs.

Reliable supply chains ensure tubing arrives on time for life-saving tools.

Picking the Right Nitinol Tubing for Medical Use

Matching Features to Medical Needs

To pick the best nitinol tubing, know what the device needs. Each tool needs special features like flexibility, strength, and accuracy. For example, stents need tubing that remembers its shape and resists rust. Surgical implants need nitinol that is safe for the body and lasts a long time without breaking.

Pure nitinol tubing is very important for safety and reliability. Studies show low-purity nitinol can break under stress, causing device problems. Makers must use tubing without flaws like cracks or gaps. These flaws can cause breaks when the tubing is bent or stretched. By matching tubing features to medical needs, devices can work better and help patients more.

Tip: Work with makers to adjust tubing size and materials for better results.

Balancing Price, Quality, and Strength

It’s important to balance cost, quality, and strength when choosing nitinol tubing. Nitinol is strong and precise but costs more because it uses nickel and titanium. Making nitinol tubing also needs special tools and skilled workers, which adds to the price.

Even though it costs more at first, nitinol saves money over time. It lasts longer, so devices need fewer repairs or replacements. But in markets where price matters a lot, the high cost can be a problem. Makers should find ways to make tubing cheaper while keeping it strong and reliable.

Things that raise costs:

Expensive materials like nickel and titanium.

Special machines and trained workers.

Differences in material quality that affect performance.

Note: Spending more on good nitinol tubing lowers the chance of device failure, making it worth the cost for important medical tools.

Why Working with Makers Matters

Working closely with tubing makers helps pick the best product. Makers can customize tubing to fit specific medical tools. They can change sizes, materials, and finishes to meet the needs of stents, implants, or other devices.

Good makers also give support during the product’s life. They make sure tubing meets strict medical rules like ISO 13485 and works well under pressure. Reliable makers also deliver tubing on time, so device production isn’t delayed.

Good nitinol tubing depends on makers who focus on teamwork and new ideas.

Precision-cut nitinol tubing is important for improving medical tools. Its special features, like bending easily, being strong, and safe for the body, make it perfect for devices like stents and implants. Comparing top companies shows how they make high-quality tubing for different medical uses. Companies such as GEE SMA, Dynalloy, Fort Wayne Metals, and Resonetics are great at making precise, custom, and safe tubing.

Doctors and hospitals should focus on what their tools need when picking tubing. Things like good materials, exact sizes, and on-time delivery are key. Working with trusted companies helps get tubing that meets strict medical rules and works well every time.

Picking the best nitinol tubing makes devices safer and helps patients, making it a big part of modern healthcare progress.

FAQ

Why is Nitinol tubing good for medical tools?

Nitinol tubing has special traits like shape memory and flexibility. It can move with the body and return to its shape. It is safe for the body and does not rust, making it great for implants and tools.

How does precise cutting help Nitinol tubing work better?

Precise cutting makes sure sizes are exact and edges are smooth. It also keeps wall thickness even. This helps the tubing work well in medical tools. Careful cutting lowers the chance of problems, making it safer for important uses.

Do Nitinol tubes need special certifications?

Yes, certifications like ISO 13485 and ASTM F2516 are needed. These prove the tubing is safe and meets quality rules. Following these standards ensures the tubing works well in medical tools and lowers risks.

Can Nitinol tubing be made for specific medical uses?

Yes, makers can change the size, shape, and material mix. These changes make the tubing fit tools like stents or catheters. Custom tubing helps tools work better and improves patient care.

Is Nitinol tubing worth the cost?

Nitinol tubing costs more at first but lasts longer. It needs fewer repairs and replacements, saving money over time. This makes it a smart choice for important medical tools.

See Also

The Manufacturing Process of Nitinol Tubing for Medicine

The Importance of Nitinol Tubing in Modern Medicine

Investigating Nitinol Tubing Uses in Healthcare Equipment

Nitinol Tubing's Impact on the Future of Medical Devices

Nitinol Tubing's Contribution to Progress in Medical Technology