How to Use Polyimide Tubing in High-Density Wiring Systems

Polyimide tubing for high-density wiring is an excellent choice for wiring systems that require durability and efficiency. It can withstand extremely high temperatures, making it ideal for use in hot environments. Additionally, it offers robust electrical insulation, ensuring that electronics remain safe and function optimally. Its thin and flexible design conserves space in applications such as circuits or battery covers.

To maximize the benefits of polyimide tubing for high-density wiring, ensure proper installation and conduct regular checks. This practice not only extends the lifespan of the tubing but also enhances the performance of your wiring system.

Tip: Choose the right polyimide tubing for your project to achieve the best results.

Key Takeaways

Polyimide tubing can handle heat and is very strong. It works well in hot places like factories and airplanes.

Its thin and bendable shape saves space. This helps organize wires in small spaces like circuit boards and battery packs.

Polyimide tubing stops electricity from leaking, avoiding short circuits. It keeps systems working well even in tough conditions.

Installing it correctly and taking care of it often makes it last longer and keeps your wiring system working better.

Always make sure it works with your wires. Avoid mistakes when installing to get the best results.

Benefits of Polyimide Tubing for High-Density Wiring

Heat resistance and durability

Polyimide tubing works well in places with high heat. It can handle extreme temperatures, making it great for industrial and aerospace wiring. Even with long heat exposure, it stays strong and reliable. Unlike other materials, it doesn’t break down from heat, keeping your wiring safe and working.

Thermoplastic polyimides, a type of polyimide, are extra tough. They resist damage from movement or shaking, making them perfect for busy wiring systems. Using polyimide tubing lowers the chance of damage and helps your system last longer.

Note: Check the tubing’s heat limit before using it to match your needs.

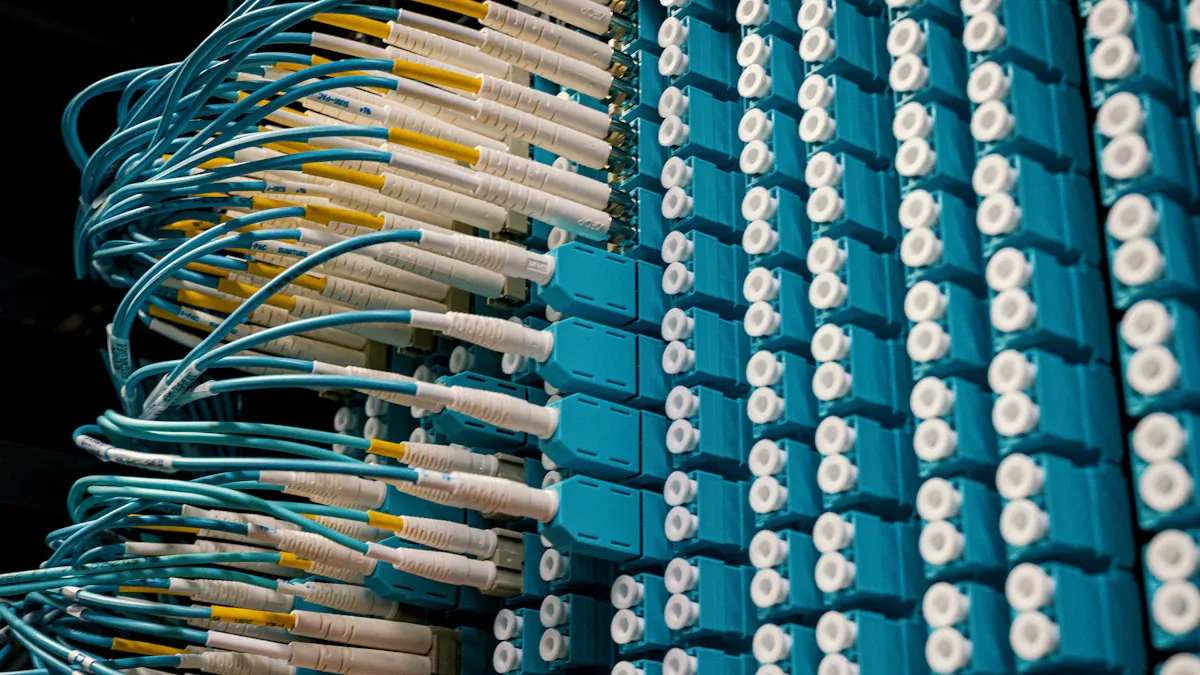

Space-saving properties

High-density wiring often has limited space. Polyimide tubing solves this with its thin and bendable design. Its small size lets you pack wires tightly without losing performance. This is helpful for circuit boards, medical tools, and battery packs where space is tight.

Polyimide tubing helps organize and protect wires while saving space. Its flexibility makes it easy to fit wires into small areas, keeping things neat. By saving space, you make your wiring system work better and look cleaner.

Tip: For tight spaces, measure the tubing size to fit perfectly.

Electrical insulation advantages

Polyimide tubing gives excellent electrical insulation, making it dependable for dense wiring. Its strong insulation stops electrical problems, keeping electronics stable. It also resists oils, solvents, and radiation, which adds to its usefulness in tough conditions.

Certifications like ISO9001 and CE prove its quality and performance. These show the tubing meets industry rules for safety and durability. With polyimide tubing, you protect your wiring from short circuits and other issues.

Key Features of Polyimide Tubing's Electrical Insulation:

Strong insulation to prevent electrical problems.

Resists oils, solvents, and radiation.

Certified for safety and quality (ISO9001, CE).

Polyimide tubing keeps your wiring system safe and efficient, even in hot and demanding conditions.

Step-by-Step Guide to Using Polyimide Tubing

Picking the right polyimide tubing for your system

Choosing the right polyimide tubing helps your wiring work well. First, figure out what your project needs. Think about heat tolerance, size, and flexibility. For tight wiring spaces, thinner tubing is better. It saves space but stays strong.

Check the tubing details to match your wires. Look for certifications like ISO9001 to ensure safety and quality. If your system faces tough conditions, pick tubing that resists heat or chemicals.

Tip: Measure your wires before buying tubing to avoid mistakes.

Getting the wiring system ready

Getting ready is important for a smooth setup. Start by cleaning the wires to remove dirt or grease. These can affect how well the tubing insulates. Check the wires for any damage. Replace broken wires to stop future problems.

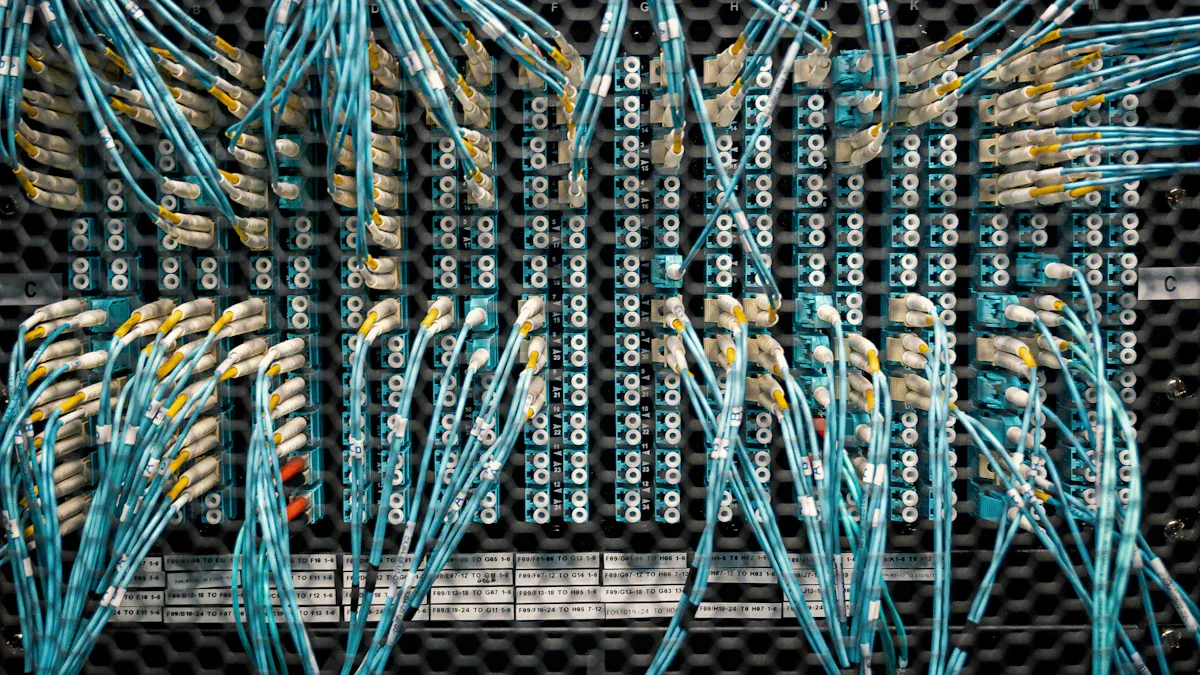

Group the wires by their job or where they go. This makes installation easier and keeps things tidy. Use ties or clips to hold the groups together for now.

Note: Mark each wire or group to find them easily later.

Putting on the tubing correctly

Carefully slide the tubing over the wires. Don’t pull or twist it too much, as this can weaken it. For long wires, attach the tubing to one end and pull it along gently.

Make sure the tubing covers all parts of the wire. If you need to cut it, use sharp scissors for clean edges. Secure the tubing with heat-shrink wraps or adhesive, depending on your needs.

Tip: Bend the wires a little to check the tubing. It should stay in place without tearing or slipping.

Securing and testing the system

Keeping your wiring system secure and tested ensures it works well. After adding the polyimide tubing, you need to secure it tightly and check its performance. This helps avoid problems and keeps the system running smoothly.

First, make sure the tubing stays in place. Use heat-shrink wraps, glue, or clamps to hold it firmly. Check that the tubing doesn’t move or loosen when wires are shifted. In areas with lots of vibrations, double-check the tubing is stable. A tight fit stops damage and keeps the insulation strong over time.

After securing the tubing, testing is very important. Start by looking closely at the tubing. Check for cracks, tears, or worn spots on the surface. Pay extra attention to areas where the top layer might have come off, as this can expose the material underneath. If you see a lot of wear, check those spots more often.

Next, test the tubing’s performance step by step:

Check the wires to ensure they meet safety rules.

Confirm the wires follow the MIL-W-81831 style, known for reliability.

Regularly check the insulation and materials for early signs of trouble.

Also, test the electrical performance of the wires. Use a multimeter to measure resistance and insulation. This ensures the polyimide tubing is doing its job. If the numbers don’t look right, check the setup again and replace damaged tubing.

Keep a record of all your tests and fixes. Write down the results and note any repairs or changes. This helps you track the system’s condition and follow safety rules.

Tip: Inspect your system regularly to find small problems early. Fixing them quickly makes your wiring last longer and saves money.

By securing and testing carefully, you get the most out of polyimide tubing. These steps keep your wiring safe, strong, and efficient, even in tough conditions.

Best Practices for Polyimide Wire Insulation Repair System

Ensuring compatibility with wiring materials

To fix wires with polyimide tubing, check material compatibility first. Most wires work well with this tubing, but some may not. Look at the wire's details and compare them to the tubing's features.

For instance, wires in hot or chemical-filled areas need special tubing. Using the wrong tubing can cause insulation to fail or work poorly. Always pick tubing that fits the wire's needs to stay safe and efficient.

Tip: Read the maker's instructions to confirm compatibility before starting.

Avoiding common installation mistakes

Errors during setup can make your polyimide tubing repair less effective. A big mistake is not cleaning wires before adding the tubing. Dirt or grease can stop the tubing from sticking well, lowering its insulation power.

Another issue is cutting the tubing unevenly. Rough edges can leave gaps, exposing damaged wires. Use sharp tools for smooth cuts. Also, don’t stretch the tubing too much, as it can tear or weaken.

Reminder: Work carefully to avoid mistakes and costly fixes later.

Maintenance and inspection tips

Checking and maintaining your polyimide tubing system keeps it working well. Condition-Based Maintenance (CBM) programs help find problems early. These programs stop small issues from becoming big ones.

Make a schedule to do these tasks:

Look at the tubing yearly for cracks or wear.

Check for loose tubing, especially in shaky areas.

Test wire performance with a multimeter.

Studies on airplanes show regular checks prevent wiring failures. Following these steps saves money and keeps your system reliable.

Pro Tip: Write down all checks and repairs. This helps track the system’s health and follow safety rules.

Polyimide tubing is great for high-density wiring systems. It handles heat well, saves space, and insulates electricity. These features make it useful in many projects. Follow the steps and tips to install it correctly. This keeps your wiring system strong and working well.

Check and maintain the tubing often to improve its performance. Use it properly to make it last longer and work better. With care, polyimide tubing becomes a helpful tool for tight wiring setups.

FAQ

Why is polyimide tubing good for aerospace use?

Polyimide tubing works well in aerospace because it handles high heat. It stays strong in tough conditions, making it safe and reliable for wiring in planes and spacecraft.

How is polyimide tubing better than other materials?

Polyimide tubing resists heat, bends easily, and insulates electricity well. Unlike other materials, it works great even in extreme conditions. NASA tests show it’s dependable for aerospace and industrial wiring.

Can you use polyimide tubing again after taking it off?

You can reuse polyimide tubing if it’s still in good shape. Check for tears or damage first to make sure it still protects wires properly.

How often should polyimide tubing be checked?

Check polyimide tubing once a year or more in busy areas. Regular checks help find cracks or loose spots early, keeping the system safe and working well.

Is polyimide tubing eco-friendly?

Polyimide tubing doesn’t break down naturally but lasts a long time. Its durability means fewer replacements, which helps reduce waste and makes it a greener choice for wiring systems.

See Also

Applications of Heat Shrink Tubing for Electrical Wire Insulation

Key Guidelines for Effectively Utilizing FEP Heat Shrink Tubing

Exploring FEP Non-Toxic Heat Shrink Tubing in Industrial Applications

Important Information Regarding PET Heat Shrink Tubing for Electronics