What Is PET Heat Shrink Tubing and How Is It Used

PETG heat shrink tubing is a clear and strong plastic tube. It gets smaller and fits tightly when you heat it. People use it to protect, cover, or group things in many jobs. More people like it now because it can be recycled and is safe to use. Look at the industry trends below:

Aspect | Details |

|---|---|

Market Size 2024 | USD 1.27 billion |

Major Application Sectors | Pharmaceuticals, food packaging, electronics, automotive, e-commerce |

Material Advantages | Recyclability, eco-friendliness, new technology innovations |

You get good results with petg heat shrink tubing when you need safe and strong covering for important parts. Many companies use petg heat shrink tubing because it is clear and protects things well.

Key Takeaways

PETG heat shrink tubing is a clear and strong plastic. It shrinks tightly when you heat it. This helps protect and cover things safely.

PETG has great clarity, flexibility, and strength. This makes it good for food packaging, electronics, and medical uses.

This tubing starts to shrink at low heat, about 82°C. It can shrink up to 70%. This helps it fit tightly on products.

PETG is recyclable and good for the environment. It helps cut down on plastic waste. It also meets strict safety rules for food and medical packaging.

Using PETG tubing gives strong protection and clear visibility. It works well for many industries and uses.

PETG Heat Shrink Tubing

What Is PETG

You might wonder why PETG is different. PETG means polyethylene terephthalate glycol. This plastic is a copolyester. Glycol is added to regular PET to make PETG. This makes PETG bend easier and stay clear. It also helps PETG not break as easily. PETG is used in many places because it is strong and safe for food and water. You can find PETG in medical models, packaging, and 3D printing. PETG is easy to recycle, so it is good for the planet. When you use PETG, you get a tough and clear material. It is also easy to shape and print.

PETG has a special chemical structure. It is made from terephthalic acid and ethylene glycol. Extra glycol units are added. This makes PETG amorphous, so it does not have a regular crystal pattern. Because of this, PETG stays clear when you heat or shape it. PETG keeps its strength and clarity even after many uses.

How PETG Heat Shrink Tubing Works

PETG heat shrink tubing uses PETG’s special features to protect things. When you heat the tubing, it shrinks tightly around your item. This happens because PETG is a thermoplastic. The polymer chains inside move and relax with heat. This lets the tubing squeeze down and fit well.

First, you put the PETG heat shrink tubing over your item. Then you use a heat source, like steam or a heat gun. As it gets hotter, the tubing starts to shrink. Most PETG tubing shrinks fast at about 82°C. It can go back to its shape in seconds. The tubing can shrink up to 60% in some cases. This depends on how it was made and what is mixed in. For example, adding polycarbonate changes how much and how fast it shrinks. If you heat it below 130°C, the shrinkage may stop in one direction. Polycarbonate can limit chain movement.

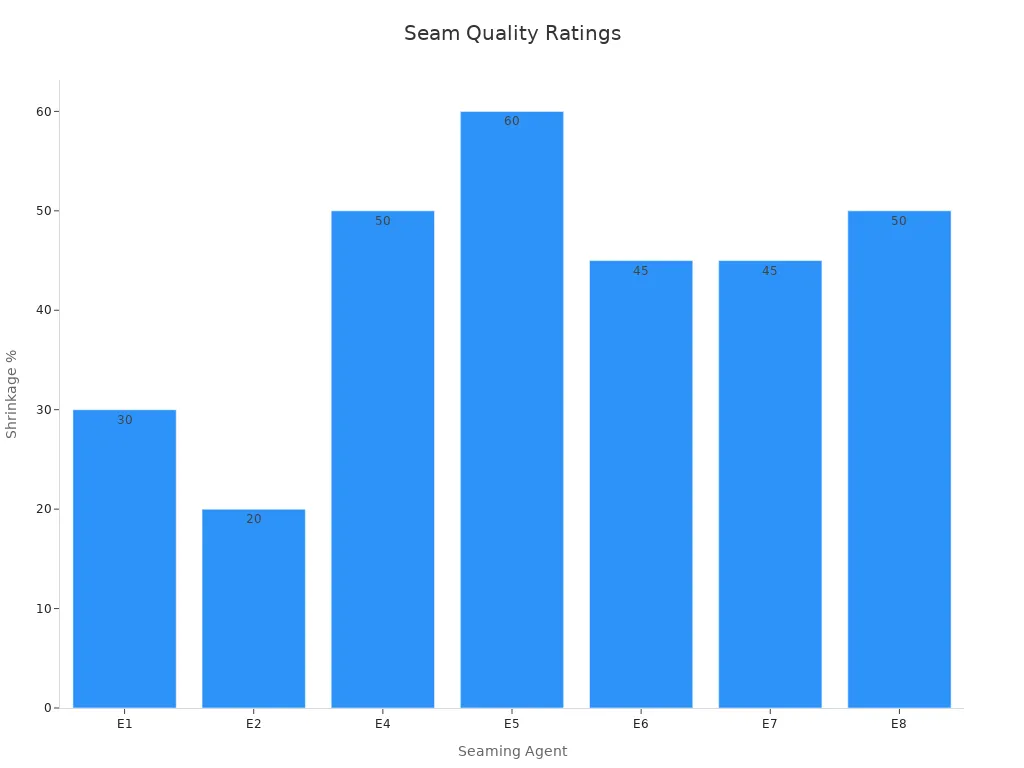

The seam quality in PETG heat shrink tubing is very important. Different seaming agents change how much the tubing can shrink before the seam breaks. You can see in the table below how each agent works:

Seaming Agent | Seam Quality on PETG (Shrinkage %) | Notes on Seam Performance and Failure Modes |

|---|---|---|

E1 | Quality 2 up to 30% | Seam quality drops above 30%; limited by swelling ability; seam brittle due to cross-linking density |

E2 | Quality 2 up to 20% | Lower shrink force resistance than E1; seam opens above 20% |

E3 | Seam failed before radiation curing | Not compatible with PETG; seam brittle and fails due to interfacial and cohesive failure |

E4 | Quality 2 up to 50% | Improved welding strength due to THF solvent; minor clarity impact; withstands shrink forces up to 50% |

E5 | Quality 2 up to 60% | Further improved welding strength; minor clarity loss; withstands shrink forces up to 60% |

E6 | Quality 2 up to 45% | Poor swelling; seam opens above 45%; minor clarity loss |

E7 | Quality 2 up to 45% | Similar to E6; good film clarity |

E8 | Quality 2 up to 50% | Better adhesion with limonene; minor clarity loss; not suitable for PETG |

Some seaming agents let the tubing shrink more before the seam fails. E5 lets the tubing shrink up to 60%. This means you get great shrink performance with the right materials and process.

The heat shrinking process for PETG heat shrink tubing is quick and works well. You put on the seaming agent, weld the seam, and use heat to shrink the tubing. The process uses steam at about 95-100°C for around 7 seconds. The tubing shrinks most in the middle, and the seam must stay strong.

PETG melts at about 260°C. This high melting point means the tubing can take heat without losing its shape. You get a product that is tough, clear, and bends easily. PETG can shrink more than 75% across its width. This makes it great for sleeve labels and covers. Mixing PETG and PET can change how stiff or strong the tubing is. You can pick the tubing that fits your needs.

When you pick PETG heat shrink tubing, you get something clear, strong, and flexible. You can use it for packaging or electrical insulation. PETG shrink film gives you a safe and reliable way to protect your things.

Tip: Always check the shrinkage rate and seam quality before using PETG heat shrink tubing for important jobs. This helps you get the best results and avoid problems.

Properties of PETG

Clarity and Strength

When you use petg shrink film, you notice its clear appearance right away. This clarity helps you see the product inside, which is important for packaging food and medical items. Petg stands out because it lets more than 90% of light pass through, while PVC tubing only allows about 75%. You get a glossy finish and low haze, so your products look clean and bright.

Property | PETG Heat Shrink Tubing | PVC Tubing |

|---|---|---|

Tensile Strength | ~5,500 psi (approx. 38 MPa) | ~3,500 psi (approx. 24 MPa) |

Clarity (Light Transmission) | >90% | ~75% |

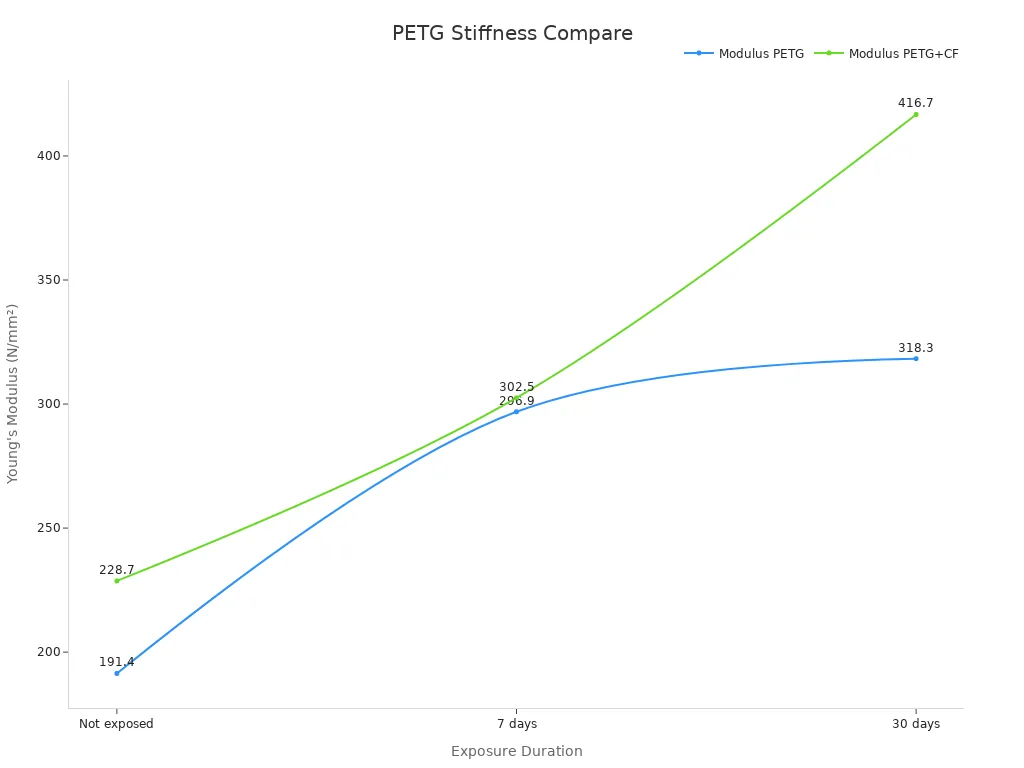

Petg shrink film also gives you high durability and strength. It can handle strong pulls and stretches without breaking. The table below shows how petg keeps its toughness and clarity, even after exposure to different conditions.

Material | Exposure Duration | Young's Modulus (N/mm²) | Tensile Strength (MPa) | Nominal Strain at Break (%) |

|---|---|---|---|---|

PETG | Not exposed | 191.4 | 18.5 | 6.9 |

PETG | 7 days | 296.9 | 15.4 | 8.4 |

PETG | 30 days | 318.3 | 15.5 | 7.9 |

You can trust petg shrink film for packaging that needs both clarity and durability and strength.

Shrinkage and Flexibility

Petg shrink film gives you a high shrinkage rate. When you heat it, the film wraps tightly around objects. This makes it perfect for labeling bottles, jars, and food containers. You get a secure fit every time. Petg shrink film stays flexible, so it does not crack or split when you bend it. Even after shrinking, it keeps its shape and holds up well.

This chart shows that petg shrink film keeps its flexibility and strength, even after being exposed to tough environments. You can use petg shrink film for many jobs, from wrapping electronics to protecting food.

Safety and Compliance

You want safe packaging, especially for food and medical uses. Petg shrink film meets strict safety rules. It is a food-safe material, so you can use it for food packaging without worry. Petg shrink film passes FDA and EU tests for contact with food. It also meets Health Canada standards for medical products. You get a product that is easy to sterilize and resists chemicals and moisture.

Petg shrink film must follow FDA and EU rules for migration limits and good manufacturing practices.

You need a Declaration of Compliance to show the tubing meets all safety laws.

Petg shrink film offers a strong moisture barrier, keeping food fresh and safe.

The material is recyclable, so you help the environment while keeping high safety standards.

Tip: Always check that your petg shrink film supplier provides the right safety documents. This ensures your packaging is safe for food and meets all legal requirements.

Common Uses of PETG Shrink Film

Packaging and Labeling

You see petg shrink film used a lot in packaging. Companies wrap bottles, jars, and cans with it. When heated, the film shrinks and hugs each product. This tight wrap keeps food safe and fresh. In food packaging, petg shrink film protects snacks, drinks, sauces, and dairy. You can see the food inside, so you know what you are buying.

Pharmaceutical companies use petg shrink film too. They need packaging that shows if someone opened it. The film makes a seal that shows tampering. This helps you know your medicine is safe. Personal care brands use it for shampoo, lotion, and cream bottles. The film looks shiny and helps products stand out in stores.

Market research says food and drink companies use petg shrink film the most. These companies want packaging that keeps food fresh and looks nice. The food industry will keep using more petg shrink film in the future. Reports say this industry will use over one-third of all petg shrink film soon. You will see it more in food, retail, and even industrial packaging.

Note: PETG shrink film gives a tight fit, clear look, and strong protection. It helps keep food safe and fresh every time you use it.

Electrical and Dielectric Protection

You can use petg shrink film to protect electrical items. The film covers wires, cables, and parts. When you heat it, the film shrinks and wraps tightly. This keeps out dust, water, and chemicals. Your electronics stay safe from harm.

In electronics, petg shrink film groups wires and covers connections. You find it in computers, phones, and home gadgets. The film does not crack or split when bent. Your devices get good protection.

Electricians use petg shrink film in control panels and circuit boards. The film stands up to heat and chemicals. It works well in tough places. You can trust it to keep electrical systems safe.

Tip: Always check the fit and coverage when using petg shrink film for electrical work. A good seal keeps electronics safe.

Common Applications of PETG Shrink Film

You find petg shrink film in many jobs. Here are some common uses:

Food packaging: Bottles, jars, and trays use petg shrink film. It keeps food fresh and lets you see inside. The film also shows if someone opened it.

Beverage bottles: Soft drinks, juices, and water bottles use it for labels and seals. The film fits tight and stays on.

Pharmaceuticals: Medicine bottles and boxes use petg shrink film for safety. You know your medicine is safe.

Personal care products: Shampoos, lotions, and creams use it for a shiny, nice look.

Electronics: Wires, cables, and circuit boards use it for covering and protection.

Industrial packaging: Heavy items and machine parts use it for safe wrapping during shipping.

Industry | Application Example | Benefit of PETG Shrink Film |

|---|---|---|

Food and Beverage | Bottles, jars, trays | Freshness, tamper-evidence, clarity |

Pharmaceuticals | Medicine bottles, boxes | Safety, protection, compliance |

Personal Care | Shampoo, lotion bottles | Branding, glossy finish |

Electronics | Wires, cables, components | Insulation, moisture barrier |

Industrial | Machine parts, tools | Secure fit, durability |

You get many good things from using petg shrink film. It gives a tight fit, strong protection, and a clear view of products. It helps keep food safe, electronics covered, and products looking nice. The film works well for shrink and retail packaging. You can trust petg shrink film for many uses.

Callout: PETG shrink film is known for being clear, strong, and safe. You see it in food, electronics, and many other things every day.

The common uses of petg shrink film show why it is important in many jobs. You can count on it for food packaging, electrical safety, and more. The many uses make petg shrink film a top pick for companies that want safe and good-looking packaging.

PETG vs Other Shrink Materials

PETG vs PVC and Polyolefin

You might wonder how petg shrink film stacks up against PVC and polyolefin. Each material has its own good points. But petg is special in many ways. Petg shrink film is very clear. It almost looks like glass. You can see products inside very well. PVC and polyolefin are not as clear as petg. If you want packaging that shows your product, petg is the best choice.

Petg is also flexible and strong. You can bend and stretch petg shrink film. It does not crack easily. Polyolefin bends well but is not as strong as petg. PVC can get brittle after some time. The table below shows how petg, PVC, and polyolefin compare:

Property | PETG | PVC | Polyolefin |

|---|---|---|---|

Clarity | Excellent | Good | Good |

Flexibility | High | Medium | High |

Durability | Very High | Medium | Medium |

Shrinkage Rate | High | Medium | High |

Chemical Resistance | High | Medium | Medium |

Recyclability | Yes | Limited | Yes |

Cost | Moderate | Low | Moderate |

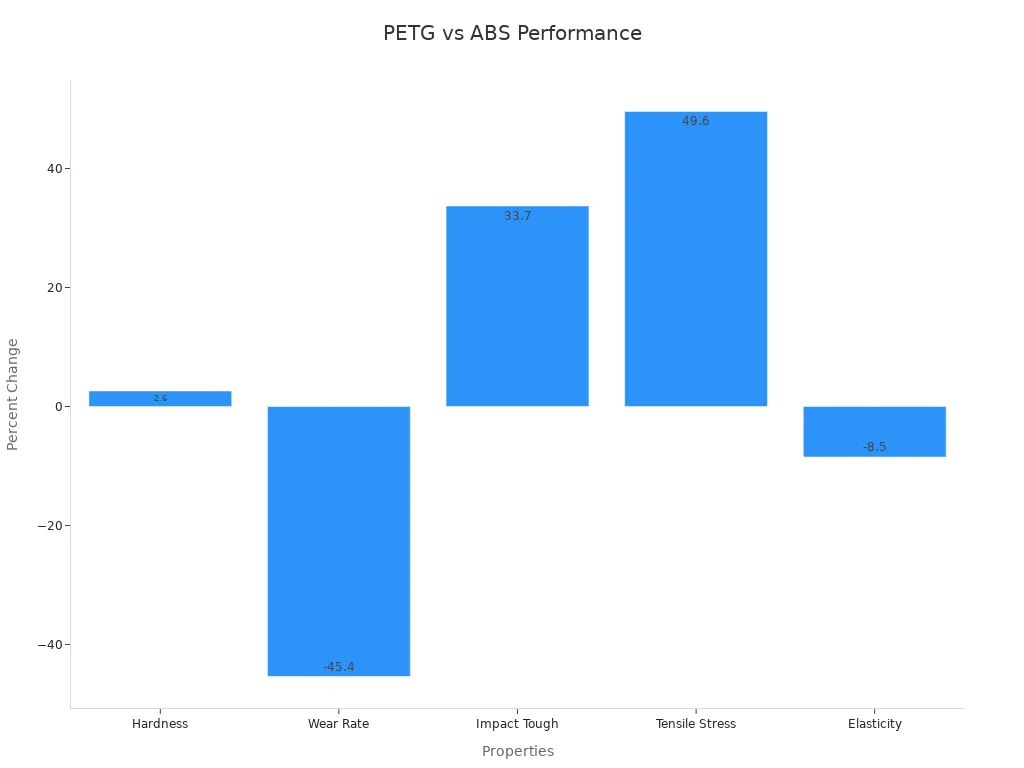

Petg shrink film gives you a great mix of clear looks, flexibility, and strength. The chart below shows petg is better than ABS in hardness, wear, and toughness:

If you compare petg shrink film to TPU and PLA, you see more good things:

Petg shrink film is stronger than TPU and PLA.

Petg shrink film takes hits better than PLA, which breaks easier.

Petg shrink film stays clear and keeps its shape after heat or water.

Petg shrink film works well outside and for many uses.

When to Choose PETG

Pick petg shrink film when you want packaging that is clear, tough, and safe. If you need a shiny wrap that shows the product, petg shrink film is best. It protects food, electronics, and medical items well. Petg shrink film also stands up to chemicals and water better than PVC or polyolefin.

Studies show petg is a smart choice for parts in tough places or under stress. You save money and time because petg costs less and prints faster than some other materials. Experts use special tools to help pick petg for planes, cars, and batteries. These studies say petg shrink film gives you strength, toughness, and fast production.

Tip: Use petg shrink film for products that must look nice and stay safe. You get great results and feel confident in hard jobs.

Safety and Environmental Impact

Recyclability

When you pick petg, you help the earth. This material is a green choice because you can recycle it many times. It stays strong and clear after recycling. In lots of places, not much plastic gets recycled. For example, Brazil recycles only 1.0 million tons out of 7.1 million tons of plastic waste. Recycling petg means we use less new plastic and keep the planet cleaner.

You can turn petg into things like 3D printing filaments.

Recycled petg stays strong and flexible for many uses.

Mixing recycled petg with PET fibers makes it even stronger.

Chain extenders help recycle petg with small bits of dirt, so it costs less and is easier.

Recycling petg from face shields cuts down on waste and helps make a loop where things get reused.

Note: Petg is safe for food and does not react with chemicals, so you can use it for food and medical packaging.

Handling and Use

You must be careful when using petg, especially in factories or with 3D printers. Always work where air moves well so you do not breathe in fumes. When printing with petg, set the hotend to 230°C to 245°C. The bed should be 70°C to 75°C. Glue sticks or PVA on glass beds help prints stick and stay safe.

Performance Indicator | PETG Characteristics and Safety Implications |

|---|---|

Food Safety | Food-grade petg is safe for food and is not toxic. |

Chemical Stability | Petg does not react with chemicals and keeps its shape, so it is safe for food and medicine. |

Impact Resistance | Petg is tough and keeps things safe during use and shipping. |

Heat Deflection Temperature | Petg works up to 80°C, but do not use it in very high heat. |

VOC Emissions | Petg gives off little gas, so it is safer than many plastics. |

Environmental Friendliness | Petg can be recycled and burns clean, leaving no bad stuff behind. |

Petg does not have BPA or other bad chemicals. You can use it for food, medical, and factory products. Always use food-grade petg for things that touch food. If you print things for food, use safe coatings and keep your area clean. Petg can be cleaned with heat, so it is good for food and medical uses.

Tip: Pick petg if you want a safe, strong, and earth-friendly material for your work.

You have learned why PETG heat shrink tubing is special. It gives clear and strong protection for many products. You can use PETG tubing for packaging, electronics, and medical things.

PETG is very clear, tough, and resists chemicals.

You can recycle PETG, so it helps the planet.

PETG tubing is strong and easy to change for different jobs.

Advantage | Description |

|---|---|

Extremely High Shrink | PETG tubing can shrink up to 70%, which is more than PVC. |

Lower Shrink Temperature | PETG starts shrinking at only 60ºC, so it is easy to use. |

Dielectric Protection | PETG keeps electrical parts safe by covering and insulating them. |

Tip: Choose PETG heat shrink tubing if you want something safe, strong, and good for the environment for your next project.

FAQ

What temperatures do you need to shrink PETG tubing?

You need to heat PETG tubing to about 82°C (180°F) for it to shrink. Most people use a heat gun or steam tunnel. Always check the product label for the best temperature.

Is PETG heat shrink tubing safe for food packaging?

Yes, PETG tubing is food-safe. You can use it for food and drink packaging. It meets FDA and EU safety standards. Always ask your supplier for safety certificates.

Can you recycle PETG heat shrink tubing?

You can recycle PETG tubing in most recycling programs. Look for recycling code #1. PETG keeps its strength and clarity after recycling. This helps you reduce waste and protect the environment.

What makes PETG better than PVC for shrink tubing?

PETG is clearer and stronger.

PETG does not get brittle.

PETG is easier to recycle. You get better protection and a cleaner look with PETG.

How do you store PETG heat shrink tubing?

Store PETG tubing in a cool, dry place. Keep it away from sunlight and heat. This helps the tubing stay clear and strong until you use it.

See Also

Essential Information About PET Heat Shrink Tubing Usage

Selecting The Ideal Ultra-Thin PET Heat Shrink Tubing

The Role Of Heat Shrink Tubing In Wire Insulation