PET vs PVC heat shrink tubing performance comparison—what keeps your project safe?

When considering PET vs PVC heat shrink tubing performance comparison, PET heat shrink tubing stands out as the best choice for critical applications. It reliably shrinks back to its original shape over 98% of the time and maintains its strength even at temperatures exceeding 150 °C. Key features include:

Dual wall construction that effectively blocks water and chemicals

Excellent resistance to germs, with minimal microbial growth on PET

Compliance with ISO 10993 and USP Class VI standards for biocompatibility

These advantages have rapidly increased PET’s popularity and have established it as the benchmark in the PET vs PVC heat shrink tubing performance comparison.

Key Takeaways

PET heat shrink tubing is stronger than PVC. It lasts longer and works well for hard jobs. PET tubing can handle heat, water, chemicals, and sunlight better than PVC. This keeps your equipment safe in tough places. PET shrinks evenly and fits tightly. It works well even on weird-shaped connectors. This helps protect important parts. PET tubing meets strict safety rules. It is also good for the environment. PET is a smart choice. Picking PET instead of PVC gives better value over time. This is because it is strong, resists heat, and can be recycled.

Performance Criteria

Mechanical Strength

PET heat shrink tubing is very strong. It does not tear or get holes easily. PET is stronger than PVC. The table below shows important facts:

Property | Direction | Value | Unit | Relevance to Puncture and Tear Resistance |

|---|---|---|---|---|

Tensile Strength | MD | ≥55 | MPa | Withstands pulling forces |

Tensile Strength | TD | ≥200 | MPa | Supports tear resistance |

Elongation at Break | MD | ≥450 | % | High flexibility, less brittle |

Elongation at Break | TD | ≥30 | % | Aids puncture resistance |

These numbers mean PET tubing stays strong under pressure. This makes it good for tough jobs.

Chemical and Moisture Resistance

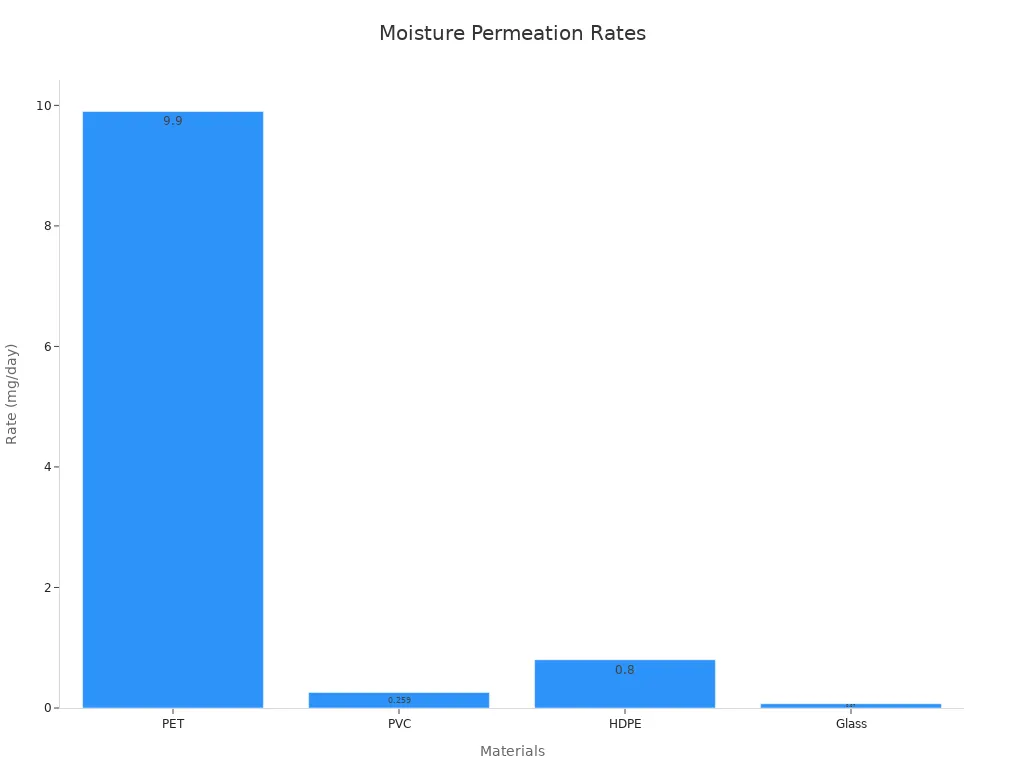

PET keeps out water and chemicals better than PVC. It does not let much gas or water pass through. This protects important parts inside. Tests show PET lets in less water than PVC. This helps in places with lots of moisture.

Material | Moisture Permeation Rate (mg/day) | Conditions | Notes |

|---|---|---|---|

PET | 9.9 (per bottle) | 40 °C / 75% RH | Lower permeability than PVC |

PVC | 0.259 (per blister) | 23 °C / 75% RH | Higher moisture rate, less effective barrier |

HDPE | 0.8 (per bottle) | 40 °C / 75% RH | Higher than PET |

Glass | 0.07 (per bottle) | 40 °C / 75% RH | Best barrier |

Temperature Tolerance

PET heat shrink tubing can handle high heat. It works up to 200 °C for a short time. It can also work at 135 °C for a long time. PET stays clear and bendy after being cleaned with heat. This is important for hospitals and factories.

Flame Retardancy

Fire safety matters a lot for PET vs PVC heat shrink tubing. PET tubing can be made safer with special flame retardant chemicals. It passes hard fire tests like IMO FTPC Part 7. PET with these chemicals does not catch fire easily. It also does not drip burning pieces. This lowers fire danger.

Longevity

PET heat shrink tubing lasts a long time. It does not get damaged by sunlight or chemicals. It can be cleaned many times and still work. The tubing keeps electricity inside and stays strong. These things help protect important parts for a long time.

PET vs PVC heat shrink tubing performance comparison

Durability

Durability is very important when comparing PET and PVC heat shrink tubing. PET tubing is tougher than PVC. It does not wear out or get scratched easily. PET can handle lots of bending and twisting. It keeps its shape even after many uses. PET has a tensile strength over 30,000 PSI. PVC is not as strong as PET. PET also does not kink, so it lasts longer in hard places.

PET tubing shrinks fast at about 60ºC. This helps make things quicker in factories.

PET can shrink up to 75%. PVC only shrinks about 70%.

PET stays strong under high pressure and heat, up to 200°C for short times.

PVC is cheaper, but it does not last as long or resist damage like PET.

Property/Aspect | PET Heat Shrink Tubing Details | Significance/Comparison to PVC |

|---|---|---|

Shrink Percentage | Up to 75% | A little more than PVC (about 70%) |

Tensile Strength | Over 30,000 PSI | PVC is not as strong |

Thermal Stability | Works from -55°C to +125°C, some types up to 190°C | PVC cannot handle as much heat |

Wear Resistance | Very good | PVC is not as tough |

Environmental Protection

Environmental protection is also important when choosing between PET and PVC tubing. PET tubing does not get damaged by sunlight, chemicals, or water. It keeps important parts safe outside or in tough places. PET does not let oils or harsh liquids hurt it. PVC can soak up more water and break down faster in the sun or with chemicals.

Note: PET heat shrink tubing follows RoHS and REACH rules. This makes it good for projects that need to be safe for the environment.

PET blocks water and chemicals well. This stops rust and keeps electricity working right. That is why PET is picked for jobs that need to be very safe and reliable.

Electrical Insulation

Electrical insulation is very important for PET and PVC tubing. PET tubing stops electricity from leaking out. This keeps wires and devices safe. PET is used for medical tools and electronics because it meets safety standards. PVC can insulate, but it is not as good as PET for strong or fast electrical needs.

PET can be made very thin, down to 0.0001 inch. This gives good insulation without making things bulky.

PET keeps its insulation even after being cleaned many times or touched by chemicals.

Shrinkage Consistency

Shrinkage consistency is another reason PET is better than PVC. PET tubing shrinks evenly every time. This gives a tight and safe fit. This is important when you need exact coverage and protection.

Nominal Size (mm) | Horizontal Shrinkage Ratio (%) | Vertical Shrinkage Ratio (%) |

|---|---|---|

3 to 10 | 48 ± 4 | 8 ± 3 |

12 | 45 ± 4 | 8 ± 3 |

20 | 32.9 ± 0.3 | 8 ± 3 |

PET keeps its shape even when heated or pulled. PVC can shrink unevenly and may not cover as well. PET’s better shrink and tight fit make it great for important and careful work.

Safety and Reliability

Failure Risks

PVC heat shrink tubing does not work well in tough places. It can break, lose its shape, or let water in when it gets hot or meets chemicals or sunlight. These problems can hurt electrical systems and important equipment. PET tubing helps stop these problems. It does not tear easily and stays strong under pressure. PET also keeps out water and chemicals. It keeps its shape and keeps protecting even after being cleaned many times or used in hard conditions. When comparing PET and PVC, PET is much safer for hard jobs.

Real-World Use

Many companies use PET heat shrink tubing for important work. Medical device makers pick PET because it stays clear and bendy after cleaning. Factories use PET for wires and sensors that get hot or touch chemicals or rain. The table below shows how PET works in real jobs:

Case Study | Sector/Application | PET Used | Description and Outcome |

|---|---|---|---|

Signal | Communication | Trusted Execution Environment (Intel SGX) | Keeps private contact safe and hides user data from servers. |

Provinzial & Statice | Insurance | Synthetic Data | Helps train ML models safely, saves time, and lowers privacy risks. |

Statistics Canada | National Statistics | Synthetic Data | Lets people share data for study without showing private information. |

Statistics Korea | National Statistics | Homomorphic Encryption, MPC, Differential Privacy | Links government data safely and keeps business and personal info safe. |

Tsinghua University & Microsoft | Health and Social Care | Federated Learning | Makes medical data study better without putting all records in one place. |

These examples show PET works well in hospitals and factories.

Standards Compliance

PET heat shrink tubing follows strict safety and quality rules. It passes ISO 10993 tests to show it is safe for skin and body. The tubing uses special pigments that are safe for medical use and does not have bad chemicals like phthalates. PET stays strong and keeps its shape after being cleaned with heat, gamma rays, or hydrogen peroxide. The table below lists important certifications:

Certification / Standard | Description |

|---|---|

ISO 10993 | Checks if it is safe to use with living tissue. |

FDA Quality System Regulation | Needs strong tests for medical safety and cleaning. |

USP Class VI | Says pigments are safe for medical use. |

ISO 17665-1:2023 | Makes sure materials can handle hot cleaning. |

These certifications show PET tubing is safe and works well for important jobs.

Practical Selection

Installation

PET heat shrink tubing is easy to use for many jobs. It starts shrinking at about 90°C. This helps protect parts that can get hurt by heat. Workers like PET tubing because it is light and bends easily. It wraps tightly around wires and connectors, even if they are odd shapes. This is because PET can shrink up to 75%. You can buy PET tubing in short pieces or long rolls. This makes it simple to find the right size for your project. Many businesses, like electronics and phone companies, use PET tubing because it saves time. PET tubing does not wear out fast. It keeps its shape after getting hot or cold. These things help lower repairs and stop work delays.

Tip: Always read the maker’s guide before you put on the tubing. This helps you get the best fit and keeps things safe for a long time.

Cost vs Value

Picking PET or PVC heat shrink tubing is not just about price. PET and PVC cost about the same. But PET gives more value because it lasts longer, can be recycled, and is easy to use. PET is very strong and does not get hurt by sunlight. This makes it good for outdoor jobs. PVC bends well and stands up to chemicals. This can save money for building or factory work. Both PET and PVC meet big safety rules, like ISO 9001 and FDA for PET. PET can be recycled, which is good for the earth and saves money later.

Property | PET | PVC |

|---|---|---|

Tensile Strength | 55–75 MPa | 25–40 MPa |

UV Resistance | Excellent | Moderate |

Recyclability | Widely recyclable | Limited |

Cost | Competitive | Competitive |

Application Fit

PET heat shrink tubing is safe for food, medicine, and electronics. It does not have bad chemicals and meets tough safety rules. PET keeps important things safe inside because it blocks out harm. It is strong and good for tough packaging. But PET soaks up more water than PVC. This means PET is not the best in very wet places. PVC works better where it is damp or needs to fight off chemicals. Building and factory jobs often use PVC because it bends and does not burn fast. Both PET and PVC need to be stored and handled right. This keeps them working well and easy to use.

PET is a safer and better choice than PVC. It is strong and does not scratch easily. PET can handle high heat without breaking. This helps protect important systems in tough places. The table below shows why PET is a good pick:

Feature | Benefit |

|---|---|

High strength | Lasts longer, resists damage |

Heat resistance | Stays stable at high temperatures |

Environmental safety | Reduces waste, supports sustainability |

Choosing PET keeps projects safe and working well. PET gives the best protection for hard or important jobs.

FAQ

What makes PET heat shrink tubing safer than PVC?

PET heat shrink tubing stands up to heat, chemicals, and water better than PVC. It does not rip or break easily. PET follows strict safety rules. These things help keep wires and devices safe in hard places.

Can PET heat shrink tubing be used outdoors?

Yes, PET heat shrink tubing works great outside. It blocks sunlight and water. PET does not get weak in the sun. This makes it a good pick for outdoor jobs.

Is PET heat shrink tubing environmentally friendly?

PET heat shrink tubing can be recycled in many places. It does not have bad chemicals like phthalates. Many companies use PET to help the planet and cut down on waste.

How does PET tubing perform after sterilization?

PET tubing stays clear and bendy after being cleaned with heat or chemicals. Hospitals and labs use PET because it stays strong after cleaning. This helps keep tools safe and working well.

Does PET heat shrink tubing fit odd-shaped connectors?

Yes, PET heat shrink tubing shrinks tight and even. It covers odd-shaped connectors with no gaps. This gives a safe fit and strong protection for all kinds of connections.

See Also

Comparing FEP Heat Shrink Tubing Brands By Temperature Tolerance

Differences Between Medical And Industrial Grade Heat Shrink Tubing

Selecting The Ideal Ultra-Thin PET Heat Shrink Tubing For Projects

Essential Facts About PET Heat Shrink Tubing Used In Electronics

Using Heat Shrink Tubing To Insulate Electrical Wiring Effectively