Performance and application differences of PET and PVC heat shrink tubing

When you look at the PET vs PVC heat shrink tubing differences, you can see some notable distinctions. PET is better for tough jobs; it is strong and can handle high heat. Additionally, PET shrinks more and is clearer, making it ideal for applications that require precision. Although PET costs more initially, it lasts longer and can be recycled, which benefits the environment by reducing waste and energy consumption. On the other hand, PVC is suitable for standard jobs and is more affordable. Both types are easy to apply, so you should choose one based on whether you need something very strong or just simple protection.

Key Takeaways

Pick PET heat shrink tubing for strong protection in medical use. It lasts a long time and can handle high heat. PET also stands up to chemicals.

Use PVC heat shrink tubing when you need to save money. It works well if you do not need it to last long. PVC is good for short-term jobs.

Think about how your choice affects the environment. PET is easier to recycle than PVC. PET is better for nature.

Always look at the shrink ratio and temperature resistance. This helps you make sure the tubing fits your medical devices.

Follow hospital safety rules when you pick tubing. Make sure the material meets the standards for medical use.

Pet vs PVC heat shrink tubing differences

Quick comparison overview

When you compare PET and PVC heat shrink tubing, you notice they work differently. In hospitals, tubing needs to protect delicate tools and handle tough use. PET tubing is stronger and can take more heat. PVC tubing bends easily and costs less, but it does not last long in rough places.

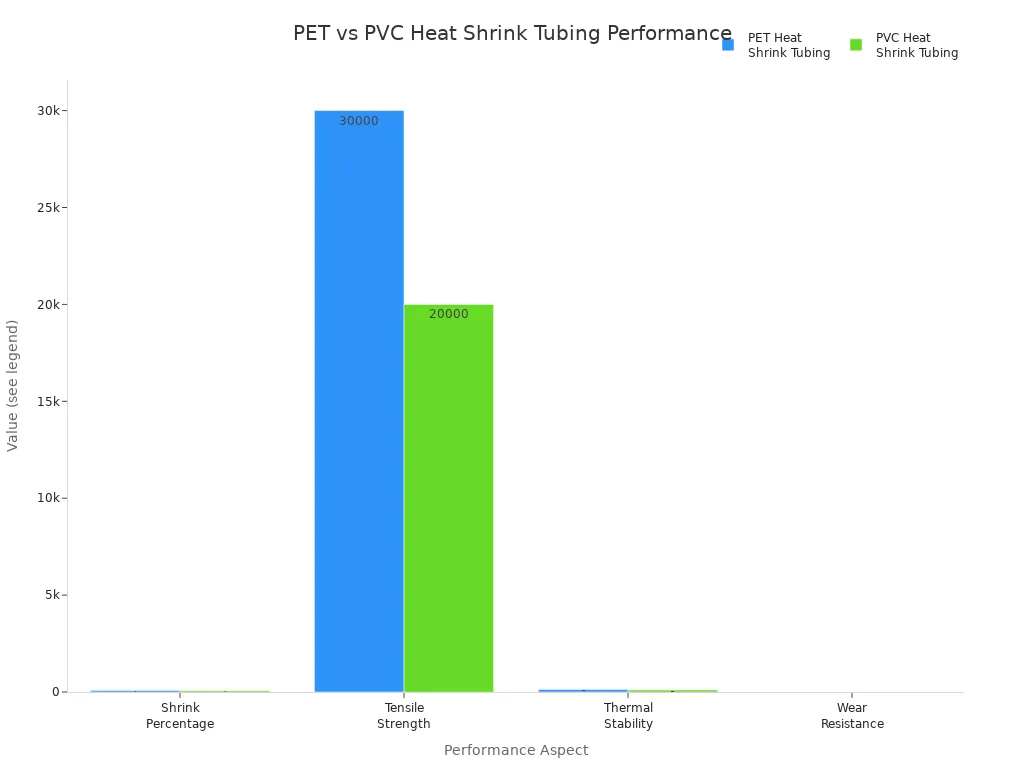

Here is a table that shows how they compare:

Property/Aspect | PET Heat Shrink Tubing Details | Significance/Comparison to PVC |

|---|---|---|

Shrink Percentage | Up to 75% | A little more than PVC (about 70%) |

Tensile Strength | Over 30,000 PSI | PVC is not as strong |

Thermal Stability | -55°C to +125°C, some up to 190°C | PVC cannot handle as much heat |

Wear Resistance | Very good | PVC is not as tough |

The chart shows PET is better for hard jobs. PET is strong and handles heat well. PVC is fine for easier tasks.

Key application differences

In hospitals, PET and PVC tubing help protect and cover equipment. PET tubing keeps out chemicals and water, so it works for tools that must stay clean or dry. PET can also take high heat, which helps when cleaning with hot steam. You use PET for catheters, surgery tools, and sensors that need strong and clear covers.

PVC tubing bends easily and is simple to use. You pick PVC for things you throw away or when saving money matters more than lasting a long time. PVC does not hold up well in sunlight or with chemicals, so it is best for short-term or indoor use.

PET tubing keeps medical tools safe from sunlight, chemicals, and water.

PVC tubing bends easily and costs less but wears out faster.

PET follows strict safety rules and lasts longer.

PVC works for simple jobs that are not risky.

When you look at PET and PVC tubing, think about what your medical tools need. PET gives more safety and works better for important uses. PVC is a good choice if you want to save money for basic jobs.

What is PET heat shrink tubing?

PET properties

If you pick PET heat shrink tubing for medical devices, you get a strong and flexible material. PET bends and wraps around small spaces without breaking. This helps cover wires and delicate hospital equipment. PET heat shrink tubing does not get damaged by oils or solvents. You can use it where chemicals might spill. It also protects against hot and cold temperatures. PET works from -40°C to 125°C. You can use it in operating rooms, labs, and storage areas with extreme temperatures.

You can check how PET heat shrink tubing works in the table below:

Property | Test Method | Standard |

|---|---|---|

Tensile strength (Mpa) | ASTM-D 638 | ≥8.5Mpa |

Breaking elongation | ASTM-D 638 | ≥250% |

Operation temperature range | IEC 60216 | -55ºC~200ºC |

Heat aging/Breaking elongation | 168hrs x 250ºC | ≥200% |

Heat shock | 4hrs x 300ºC | No cracking |

Disruptive strength | IEC 60243 | ≥15kV/mm |

Volume resistivity | IEC 60093 | 1x 10^9Ω.cm |

Flame resistance | UL 224 VW-1 | Pass |

PET heat shrink tubing passes flame resistance tests. You can trust it where fire safety is important. Hospitals need materials that last and keep patients safe. PET gives you this reliability.

Tip: Use PET heat shrink tubing when you want a clear, strong, and safe cover for medical wires and tools.

Common PET applications

You find PET heat shrink tubing in many medical places. Hospitals use PET heat shrink tubing to insulate wires in monitors and imaging machines. You can use PET heat shrink tubing to protect sensors and connectors in surgical equipment. PET heat shrink tubing covers catheters and other devices that must stay clean and dry. In labs, PET heat shrink tubing helps organize cables and shields them from spills.

You use PET heat shrink tubing for:

Insulating wires in medical devices

Protecting connectors in surgical tools

Covering sensors in patient monitors

Organizing cables in labs

Shielding catheters from moisture

PET heat shrink tubing lets you see labels and markings clearly. This helps you find equipment fast. You get durability and safety, so PET heat shrink tubing is a top choice for healthcare workers.

What is PVC heat shrink tubing?

PVC properties

PVC heat shrink tubing is used a lot in hospitals and labs. It is flexible and simple to use. When you heat it, the tubing shrinks and fits tightly around wires or tools. PVC heat shrink tubing needs less heat to shrink, so you do not need special tools. It comes in many colors. This helps you organize cables and mark medical devices.

Here is a table that lists the main properties of PVC heat shrink tubing:

Property | Details |

|---|---|

Shrink Ratio | 2:1 |

Operating Temperature Range | -20°C to 105°C |

Wall Thickness Options | Standard (.020”), heavy (.031”) |

Size Range | 3/64” to 4” |

Colors Available | Black, white, red, yellow, blue, clear |

Compliance | UL, CSA, ASTM D 3150 |

Flame Retardant | UL-VW-1 |

Chemical Resistance | Resists chemicals, oils, moisture, sunlight |

Fungus Resistance | Yes |

Weather Resistance | Yes |

RoHS Compliance | Yes |

PVC heat shrink tubing gives you many good things:

It shrinks with low heat.

It does not catch fire easily (UL-VW-1).

It is cheap and can be used in many ways.

It stands up to chemicals, oils, water, and sunlight.

It does not let fungus grow and can handle bad weather.

It meets UL, CSA, and military rules.

It is RoHS compliant and has no lead.

Tip: You can use PVC heat shrink tubing inside or outside. It does not get damaged by weather or fungus.

Common PVC applications

PVC heat shrink tubing is used in many medical places. Hospitals use it to cover and protect wires in monitors, imaging machines, and beds. You can put it on temperature probes and sensors to keep them safe from water and chemicals. Labs use PVC heat shrink tubing as sleeves or covers to stop cables and tools from wearing out.

PVC heat shrink tubing comes in different thicknesses. Thin wall tubing is good for light and bendy insulation. This is great for small electronics in medical devices. Medium wall tubing is stronger and works for equipment that moves a lot. Heavy wall tubing gives the most protection for electrical parts in tough hospital areas.

You can use PVC heat shrink tubing for:

Covering cables in medical devices

Protecting temperature probes and sensors

Sleeves for wires and tubes

Covers for lab tools

Light duty bearing surfaces

Insulating wire bundles

PVC heat shrink tubing helps you follow strict safety rules in healthcare. It is a safe, low-cost, and easy way to protect your medical equipment.

Performance comparison: PET vs PVC

Mechanical strength

You need strong tubing to protect medical devices. PET heat shrink tubing gives you high mechanical strength. It holds up under stress and keeps its shape. In performance comparison tests, PET stands out. It has better tensile strength than PVC. You can use PET in places where wires bend or move a lot. This keeps your equipment safe from breaks or tears. PVC works for lighter jobs, but it does not match PET for strength. When you want long-lasting protection, PET is the better choice.

Chemical resistance

Hospitals use many cleaning agents and chemicals. You want tubing that resists these substances. PET heat shrink tubing does not break down when exposed to most chemicals. It keeps its performance even after contact with oils or solvents. This helps you maintain safety in labs and operating rooms. PVC offers some chemical resistance, but it can degrade faster in harsh environments. PET gives you more reliable protection for sensitive medical tools.

Temperature tolerance

Medical equipment often faces high and low temperatures. PET heat shrink tubing handles a wide range of temperatures. You can use it in freezers or near sterilization equipment. PET keeps its performance from -55°C up to 200°C. PVC, on the other hand, works only up to 105°C. If you need tubing for high-heat areas, PET is the safer option.

Material | Maximum Temperature Tolerance |

|---|---|

PVC | 105°C (221°F) |

PET | 200°C (392°F) |

You see that PET gives you more flexibility for demanding medical uses.

Flame retardancy

Safety is a top concern in hospitals. Both PET and PVC heat shrink tubing use flame-retardant additives. When exposed to fire, these materials release gases that slow down burning. They form a char layer to protect what is underneath. Both types self-extinguish within 10 seconds after you remove the flame. They do not drop burning pieces that could start more fires. This keeps your patients and staff safe.

Both PET and PVC meet UL94 V-0 flame retardancy.

They help prevent the spread of fire in medical settings.

You can trust both for safety in critical areas.

Longevity

You want tubing that lasts. PET heat shrink tubing gives you long service life. It resists wear, heat, and chemicals. This means you replace it less often. PET keeps its performance over time, even in tough hospital environments. PVC works well for short-term or low-stress jobs. It can crack or fade faster, especially with heat or sunlight. For long-term safety and reliability, PET is the better choice.

Shrink ratio and clarity

You need tubing that fits tightly and lets you see labels or wires. PET heat shrink tubing shrinks up to 75%. This gives you a snug fit on many shapes and sizes. PVC usually shrinks at a 2:1 ratio. PET also stays clear after shrinking. You can read markings and check for damage without removing the tubing. This helps you keep track of medical equipment and ensures safety.

Material | Shrink Ratio |

|---|---|

PET | Up to 75% |

PVC | 2:1 |

PET gives you better clarity and a higher shrink ratio. This makes it ideal for applications where you need to see through the tubing or fit it over complex shapes.

Note: PET heat shrink tubing also keeps ink and labels readable, even in humid or hot environments. This helps you maintain safety and organization in busy hospitals.

Application and cost comparison

Installation and handling

You want to put heat shrink tubing on fast and safely. There are many ways to shrink PET heat shrink tubing and PVC shrink film. Each way works best for different jobs and tubing types.

Use a heat gun for quick shrinking. You can change the heat for thin PET or PVC shrink film. This is good for small fixes.

Pick a blowtorch for outdoor jobs or thick tubing. You finish fast, but you must be careful not to overheat.

Try a lighter, hair dryer, or hot water for small tasks. These tools help you shrink PET or PVC when you do not have special gear.

Use an oven for big jobs. You get even heat, which is important for making medical devices.

Conveyor ovens help you shrink lots of tubing. You get steady shrinking for wire bundles in medical equipment.

Infrared heaters give you exact control. You use these for delicate medical devices that need perfect shrinking.

PET shrink film and PVC shrink film are easy to use. You can cut them, slide them over wires, and shrink them with heat. You do not need special training, but you must follow safety rules in hospitals. You keep your area clean and do not overheat to protect medical tools.

Tip: Always check if the tubing fits your medical device before you install it. This helps you avoid damage and keeps patients safe.

Cost factors

You need to think about cost when you pick PET heat shrink tubing or PVC shrink film for medical use. PET shrink film costs more than PVC shrink film. You pay more for PET because it lasts longer and meets strict safety rules. You use PET for devices that need strong protection.

PVC shrink film costs less. You pick PVC for short-term use or when you want to save money. Hospitals use PVC shrink film for covers you throw away, sleeves for a short time, and color coding. You get good results for less money, but PVC does not last as long as PET.

Material | Initial Cost | Durability | Replacement Frequency | Typical Use in Healthcare |

|---|---|---|---|---|

PET shrink film | Higher | High | Low | Long-term, important devices |

PVC shrink film | Lower | Moderate | High | Disposable, short-term covers |

You balance cost and how well it works for your needs. You spend more on PET heat shrink tubing for devices that must follow safety rules. You save money with PVC shrink film for simple protection.

Environmental impact

You need to think about the environment when you pick tubing for medical devices. PET shrink film is easier to recycle than PVC shrink film. You can recycle PET heat shrink tubing with other PET items. You help the planet by making less trash and using less energy.

PVC shrink film is harder to recycle. You can hurt the environment if you burn or throw away PVC the wrong way. PVC can make bad chemicals, which is a problem in hospitals with strict trash rules.

Material | Recyclability | Environmental Concerns |

|---|---|---|

PET | Easier to recycle; can be processed with other PET items. | Better for the planet, but needs proper disposal. |

PVC | Hard to recycle; not as good for the environment. | Can make bad chemicals if burned or thrown away wrong. |

You help the planet by picking PET shrink film for long-lasting medical devices. You lower your impact and help your hospital stay green.

Note: Always follow hospital rules for throwing away tubing. You keep patients and staff safe from bad chemicals.

Use case suitability

You need to match the tubing to your medical job. PET heat shrink tubing works best for devices that need to bend, last long, and be safe. You use PET shrink film for catheters, devices you can clean with heat, and covers that protect. PET heat shrink tubing gives a smooth surface that is safe for people. You keep patients safe and your devices working after they touch liquids or chemicals.

You use PET shrink film for:

Catheters and guidewires

Devices that need cleaning with heat

Covers for sensors and connectors

Insulating wires in monitors

Devices that touch body fluids

PET shrink film fits odd shapes and shrinks at lower heat. You get good protection and keep devices working well.

PVC shrink film is good for basic medical jobs. You use PVC shrink film for packing, sleeves, and color coding. Hospitals use PVC shrink film to bundle wires, protect things during shipping, and stop damage from chemicals and sunlight.

Use Case | Description |

|---|---|

Part and Product Packaging | Protects items from damage or wear during shipping or use. |

Permanent Sleeving | Bundles wires and cables for neatness, color coding, and similar jobs. |

Strengthening Dielectric Performance | Stops electricity from moving between things, good for batteries and cables. |

Resisting Chemicals | Keeps things safe from chemicals that can cause damage. |

Resisting UV Light Damage | Protects from sunlight that can spoil or change color. |

You pick PET heat shrink tubing for important medical devices that need to last and stay safe. You choose PVC shrink film for easy jobs where saving money and simple use matter most.

Tip: Check your hospital’s safety and rules before you pick tubing. You make sure you follow the rules and keep patients healthy.

Selection guide: Choosing PET or PVC

Decision factors

When you pick heat shrink tubing for medical devices, you must think about a few key things. The tubing should fit your equipment and follow safety rules. It also needs to last in busy hospitals. The table below shows how PET and PVC are different in important ways:

Property | PET Heat Shrink Tubing | PVC Heat Shrink Tubing |

|---|---|---|

Shrink Ratio | Up to 75% | Nominal 2:1 |

Temperature Resistance | Up to 125ºC (257ºF) | Maximum 85ºC (185ºF) |

Chemical Resistance | Excellent, suitable for harsh environments | Good, but less durable than PET |

Cost | Generally more expensive | Typically more affordable |

Environmental Impact | More recyclable, lower impact | Environmental concerns during production/disposal |

You should think about how the tubing will handle cleaning chemicals and heat. It also needs to last a long time. Hospitals often use PET for tools that need to be strong and clear. PVC is good for simple covers or things you only use for a short time.

Rules also help you decide which tubing to use. Some rules say you cannot use PVC in some medical products. This is important for things used by kids or with food. The table below lists some important rules:

Regulation | Description | Impact on Material Selection |

|---|---|---|

EU REACH | Restricts harmful substances like DEHP in PVC | Encourages use of PET for safety in food and children's products |

CPSIA | Limits phthalate content in children's products | Similar to EU, promotes alternatives to PVC |

NSF-51/61 | Safety criteria for food and drinking water applications | Influences choice of tubing material based on compliance |

Checklist for selection

Here is a checklist to help you pick the right tubing for your medical device:

Check what temperatures your device will face.

Decide if you need tubing that resists chemicals.

Look at the shrink ratio to get a tight fit.

Think about how much money you can spend.

Make sure the tubing follows hospital safety and green rules.

Check if it meets local and world regulations.

Pick PET for strong, clear, and long-lasting protection.

Choose PVC for covers that are cheap, bendy, and easy to use.

Tip: Always ask your supplier for test results and certificates before you buy tubing for medical devices.

If you follow these steps, you can make a safe and smart choice. This helps keep patients safe and your equipment working well.

You should pick PET heat shrink tubing for most medical devices. It gives strong insulation and keeps out water. PET protects tools for a long time. It works well in tough hospital places. You do not need to fix things as often with PET. PVC is good for simple covers that do not cost much. Use PVC in places that are not very important. Here are some things to remember:

PET lasts longer and can take more heat.

PVC is cheaper but breaks more easily.

Always check the selection guide before you choose tubing. Think about cost, how long it will last, and how it affects the environment.

FAQ

What makes PET heat shrink tubing better for medical devices?

PET tubing gives you strong protection. It resists chemicals and high heat. You can see through it, which helps you check labels and wires. Hospitals use PET when they need long-lasting and safe covers for important equipment.

Can you recycle PET and PVC heat shrink tubing from hospitals?

You can recycle PET heat shrink tubing more easily than PVC. PET fits with other plastic recycling programs. PVC is harder to recycle and may release harmful chemicals if not handled properly.

Is PVC heat shrink tubing safe for all medical uses?

PVC tubing works well for basic protection and short-term use. Some rules limit PVC in devices for children or food contact. Always check if your hospital allows PVC for your specific application.

How do you choose the right shrink ratio for medical tubing?

You should measure the size of your device before shrinking. PET tubing shrinks more and fits tight shapes. PVC has a standard 2:1 ratio. Pick the tubing that matches your equipment for a secure fit.

Does heat shrink tubing affect sterilization of medical tools?

You can use PET tubing with high-temperature sterilization. It keeps its shape and strength. PVC tubing may not handle high heat as well. Always check the tubing’s temperature rating before sterilizing.

See Also

Essential Insights on PET Heat Shrink Tubing for Electronics

Comparative Analysis of FEP Heat Shrink Tubing Brands

Selecting The Ideal Ultra-Thin PET Heat Shrink Tubing

Understanding The Differences Between Medical and Industrial Heat Shrink Tubing