How PET Shrink Tubing Is Applied in Minimally Invasive Surgical Graspers

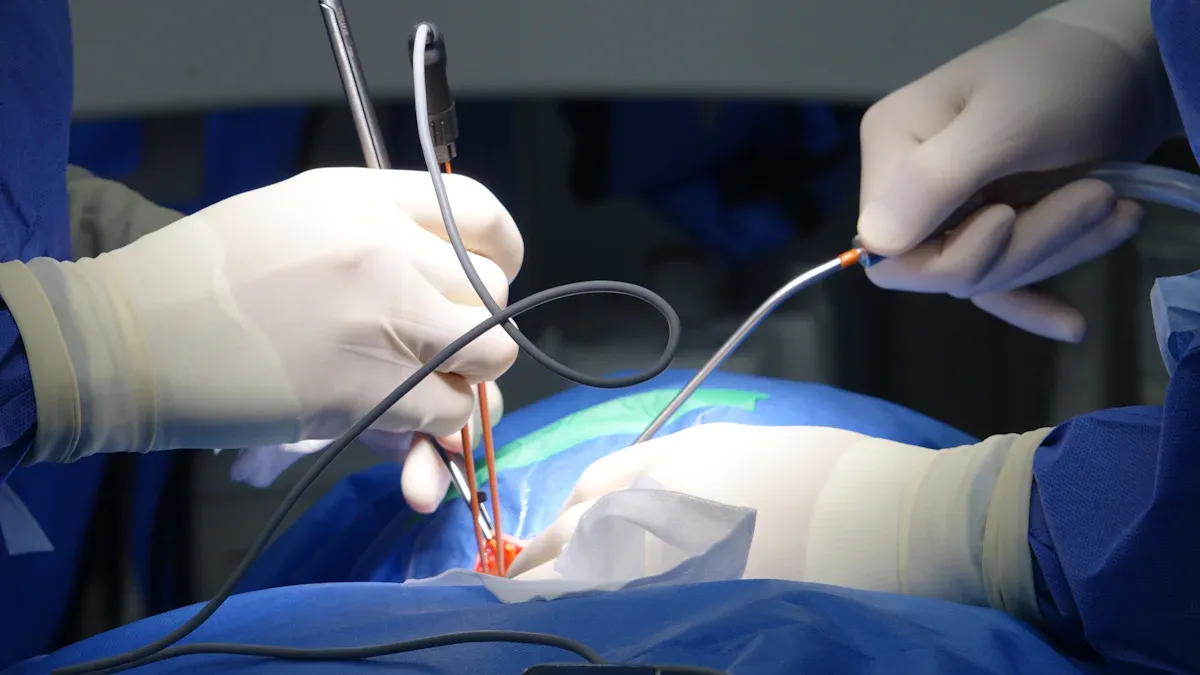

PET shrink tubing in minimally invasive surgical graspers covers, protects, and seals critical components in these small medical devices. Engineers choose PET shrink tubing in minimally invasive surgical graspers because it provides excellent electrical insulation, prevents scratches, and offers a precise fit. This PET shrink tubing remains durable even after repeated sterilization, enhancing patient safety and extending the lifespan of the surgical tools. Its resistance to water, heat, and chemicals ensures reliable protection during surgery. Being biocompatible, flexible, and able to conform to complex shapes, PET shrink tubing in minimally invasive surgical graspers plays a vital role in maintaining safety and performance in advanced surgical instruments.

Key Takeaways

PET shrink tubing keeps surgical graspers safe. It gives strong electrical insulation. It also blocks fluids, chemicals, and dirt.

The tubing shrinks to fit many shapes. This helps parts stay in place. It makes sure devices work safely in surgery.

PET tubing can handle many sterilizations. It also stands up to strong cleaners. This keeps surgical tools safe and strong for a long time.

To use PET tubing, you must clean the tool well. You need the right size tubing. You must heat it evenly. You should check it closely to make sure it fits well.

PET shrink tubing follows strict medical safety rules. This helps keep patients safe. It also makes surgical devices work well.

PET Shrink Tubing in Minimally Invasive Surgical Graspers

Electrical Insulation

PET heat shrink tubing gives strong electrical insulation for these graspers. Engineers use it to cover wires and electronic parts inside. PET has high dielectric strength, so it stops electrical problems during surgery. This insulation keeps everyone safe. PET heat shrink tubing also shields circuits from static electricity and short circuits. Many surgical tools need this insulation to work well. The tubing can handle high voltages, so it is a good choice for medical devices. PET heat shrink tubing helps keep electrical signals steady and correct.

Protective Barrier

PET heat shrink tubing acts like a tough shield against fluids, chemicals, and dirt. Medical tools must resist strong cleaners and many sterilizations. PET heat shrink tubing can go through over 25 sterilizations, like steam autoclaving and hydrogen peroxide, and still stay strong. The tubing meets strict biocompatibility rules, such as ISO 10993 and USP Class VI, so it is safe for the body.

PET heat shrink tubing stands up to solvents, oils, and hospital cleaners.

Its strength and heat resistance protect devices during use and cleaning.

PET heat shrink tubing keeps out dirt and fluids, so the device stays safe.

The smooth surface of PET lowers friction, which helps protect tissue during surgery.

These features make PET heat shrink tubing a trusted pick for surgical tools. Its toughness and chemical resistance help keep both the device and patient safe.

Precision Fit

PET heat shrink tubing in these graspers fits tightly around tricky shapes. When heated, the tubing shrinks and hugs small or odd parts. This makes a tight seal that holds everything in place. Many uses need this exact fit to stop parts from moving or leaving gaps. The tubing can fit many sizes and shapes, so it works for lots of medical devices. PET heat shrink tubing also helps keep the device together and protected. This tight fit helps surgical graspers work safely and well in delicate surgeries.

PET Heat Shrink Tubing Properties

High Shrink Ratio

PET heat shrink tubing is special because it can shrink a lot. This means it can wrap tightly around many different parts. The tubing can get up to 48% smaller in diameter. This makes it great for covering small or oddly shaped things. You can see the usual shrinkage amounts in the table below:

Size (mm) | Horizontal (Radial) Shrinkage (%) | Vertical (Axial) Shrinkage (%) |

|---|---|---|

3.0 - 10.0 | About 48 ± 4 | About 8 ± 3 |

12.0 - 30.0 | About 45 ± 4 | About 8 ± 3 |

This high shrink ratio lets PET heat shrink tubing make a tight seal. Sometimes, the tubing only needs to shrink a little, about 10-20%. This helps each tool fit just right.

Chemical Resistance

PET heat shrink tubing is very good at standing up to chemicals. This keeps important parts safe when making medical devices and when they are used. The tubing does not get ruined by solvents, oils, or strong hospital cleaners. PET stays strong even after being cleaned many times. Hospitals like this because it helps keep tools safe and clean. PET heat shrink tubing does not have bad halogens, so it is safer for people and the planet. It can last over 20 years, which means less trash and helps the environment.

Note: PET heat shrink tubing has green certifications and does not let out harmful gases when heated, so it is a safer pick for making medical devices.

Adaptability

PET heat shrink tubing can fit many shapes and sizes. It works for simple and tricky shapes, like catheters, guidewires, and endoscopic tools. This helps medical device makers because PET heat shrink tubing can cover marker bands and electrical parts without making things bulky. The tubing is very thin, less than 0.05 mm, so it fits in small spaces. PET heat shrink tubing keeps its shape and strength even after cleaning and heating. This makes it useful for many things, like ablation devices and implantable sensors.

PET heat shrink tubing fits tightly, so it does not slip.

The tubing helps put parts in the right place, which is important when making medical devices.

PET heat shrink tubing holds marker bands in place for clear pictures during procedures.

PET heat shrink tubing is very important in making medical devices. Its ability to shrink a lot, resist chemicals, and fit many shapes helps keep healthcare tools safe and reliable.

Application Process

Putting pet heat shrink tubing on surgical graspers takes careful work. Each step helps the tubing fit right and protect important parts. This guide shows how engineers use pet heat shrink tubing to make safe medical devices.

Preparation and Sizing

Engineers get all the parts ready first. They clean and dry each piece to take away dust, oil, or dirt. Clean parts help the pet heat shrink tubing stick and seal well. Next, they pick the right size of pet heat shrink tubing. The tubing must go over the part before shrinking but still get tight after shrinking. Engineers measure the part’s width and length. They cut the pet heat shrink tubing to the right size, leaving a little extra at both ends to cover everything.

Tip: Masking tape can keep areas safe that should not be covered by pet heat shrink tubing. This step helps keep the work neat and stops mistakes.

Pet heat shrink tubing comes in many sizes and thicknesses. Engineers pick the best one for each job. In medical device making, the size is important. If the tubing is too loose, it can slip off. If it is too tight, it can hurt the part. Careful work at this stage helps the rest of the process go well.

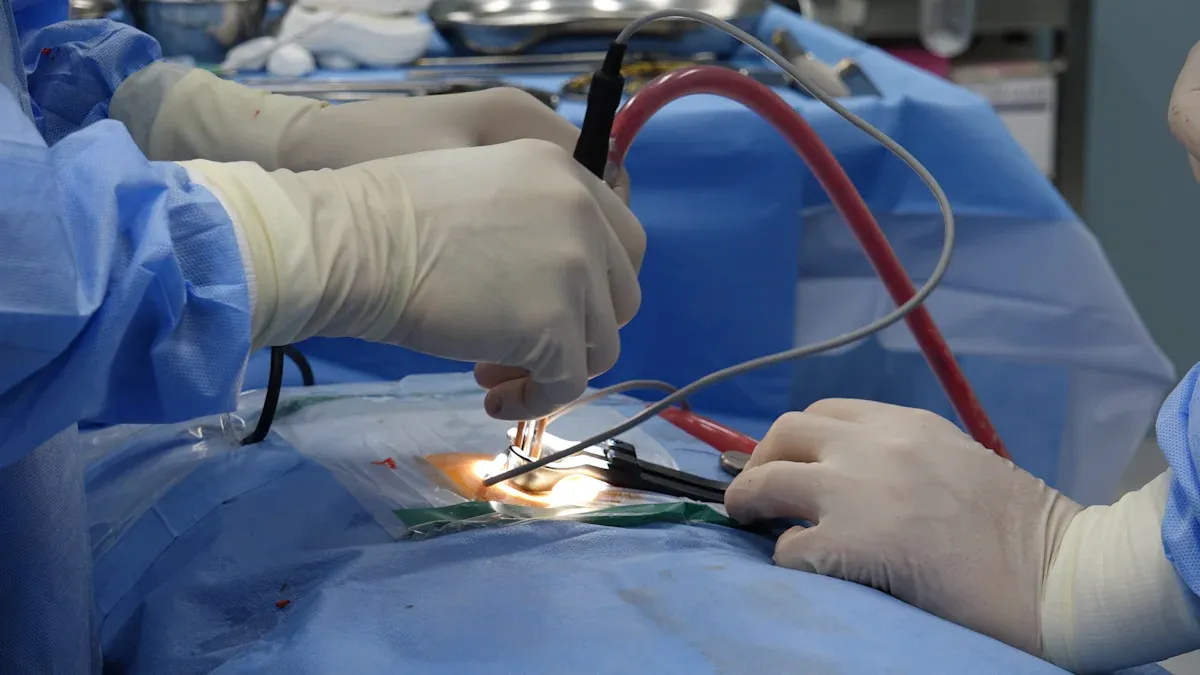

Heat Application

After sizing, engineers start heating. They slide the pet heat shrink tubing over the part. Then, they use heat to shrink the tubing. They use a heat gun or an oven for this. The goal is to heat the tubing evenly. Engineers move the heat and turn the part to get even shrinking.

The best temperature for shrinking pet heat shrink tubing is about 150°C (302°F). The tubing can shrink between 70°C (158°F) and 190°C (374°F). Heating should be slow and even. Too much heat can hurt the tubing or the part. Engineers test on a sample to find the right heat and time.

Parameter | Details |

|---|---|

Shrinking Temperature Range | 70°C (158°F) to 190°C (374°F) |

Recommended Shrinking Temp | About 150°C (302°F) |

Heating Method | Slow and even heat |

Tools | Heat gun (best), oven |

Caution | Do not overheat to avoid damage |

Pet heat shrink tubing gets smaller fast when heated. The tubing wraps the part and makes a tight, smooth cover. Engineers look for bubbles or folds as they work. Even heating helps pet heat shrink tubing fit well and last longer.

Inspection

Checking is the last step. Engineers let the pet heat shrink tubing cool before looking at it. They check for a smooth, even cover with no holes or air bubbles. The tubing should cover all needed spots and not touch taped areas. If the tubing has burns, cracks, or shrinks unevenly, engineers take it off and try again.

A good check looks at how it looks and how it works. Engineers test if the pet heat shrink tubing stays in place. They make sure it does not slip or twist. They also check that the tubing does not block moving parts or sensors. In medical device making, checking quality is very important. Each grasper must be safe and work well.

Note: Careful checking helps find problems early. This step makes sure pet heat shrink tubing keeps the device safe for surgery.

Pet heat shrink tubing is important in many uses. Doing each step—getting ready, sizing, heating, and checking—makes sure each tool works right. Engineers use these steps to make safe, strong tools for healthcare.

Biocompatibility and Safety

Patient Safety

PET heat shrink tubing helps keep patients safe during surgery. Medical device makers pick PET because it follows strict safety rules, like ISO 10993 and USP Class VI. These rules show that PET does not hurt people or cause bad reactions when it touches the body. PET heat shrink tubing stays strong and keeps its shape after being cleaned many times. This means it protects important parts inside surgical graspers. PET heat shrink tubing lasts longer than silicone because it does not wear out or break as fast. This helps keep devices safe for patients. PET heat shrink tubing comes in different sizes and thicknesses. This lets it fit each device just right. A good fit stops parts from moving or leaving gaps that could be unsafe.

PET heat shrink tubing helps doctors and patients feel safe because it meets top safety rules in medicine.

Here is a table that lists the main safety approvals for PET heat shrink tubing in medical devices:

Regulatory Approval | Purpose |

|---|---|

ISO 10993 | Makes sure PET tubing is safe with human tissue and does not cause bad reactions. |

USP Class VI | Checks that the material is safe and has no harmful chemicals for long use in medicine. |

FDA Approval | Shows PET tubing follows U.S. medical device rules so it can be sold. |

REACH (EU Regulation 1907/2006) | Makes sure PET tubing is safe for people and the environment in Europe. |

RoHS Directive | Limits dangerous substances to help keep the environment safe. |

Sterilization

Sterilizing medical devices is very important. PET heat shrink tubing can handle many ways of cleaning, like steam, gamma rays, and ethylene oxide. PET keeps its strength and does not break down, even after being cleaned many times. This means PET heat shrink tubing keeps protecting and covering device parts, so every surgery stays safe. New PET heat shrink tubing can now resist damage from heat and chemicals during cleaning. These changes help PET tubing stay safe and strong in tough hospital places.

PET heat shrink tubing can handle very hot and very cold temperatures, from -196°C to 135°C, and still work well.

The tubing does not let out bad chemicals when cleaned, which helps keep people and the planet safe.

PET heat shrink tubing now uses materials without phthalates and special colors to lower the chance of bad reactions in patients.

PET heat shrink tubing helps keep devices safe by following strict rules and working well after every cleaning. Hospitals and device makers trust PET because it is safe, strong, and works well every time.

Practical Considerations

Common Challenges

Engineers have some problems when using pet heat shrink tubing in surgical graspers. Making a smooth seal is not always easy. The tubing must shrink the same way everywhere to cover all parts. If it gets too hot, the tubing can get weak or lose its insulation. Cleaning the tubing many times, like with steam or chemicals, can make it weaker. The tubing can break down from heat, chemicals, or being used a lot. Keeping the insulation strong is very important. If the tubing fails, it can be dangerous and not meet IEC 60601-1 rules.

There are other problems too. The tubing must stay in place when joining and bonding medical tubing. It should not slip or twist, even after cleaning. Every device needs to turn out the same. If the heat or tubing size changes, there can be mistakes. Engineers also need to keep up with new rules and make sure there is enough space between parts.

Tip: Picking good pet heat shrink tubing, like AccuPath PET, helps lower these risks. Careful testing and checking during making also make the tubing more reliable.

Troubleshooting Tips

When there are problems with pet heat shrink tubing, engineers use some simple tips. If the tubing does not shrink evenly, they check the heat and change the temperature. Heating slowly and evenly stops bubbles or folds. If the tubing gets weak after cleaning, they look at how it was cleaned and pick tubing that resists chemicals better. For insulation problems, engineers test the dielectric strength before putting the tubing on.

Here is a table with common problems and ways to fix them:

Problem | Solution |

|---|---|

Uneven shrinkage | Use slow, even heat; turn the part while heating |

Tubing slips after sterilization | Check the fit; use the right size and thickness |

Material degradation | Pick tubing that resists chemicals well |

Insulation failure | Test dielectric strength before using |

Trouble joining and bonding medical tubing | Cover areas and line up parts right |

Engineers also work with trusted suppliers and labs to make sure pet heat shrink tubing is safe and clean. Planning for insulation early in design helps stop problems later. Making and checking the tubing the same way every time keeps devices safe and working well.

PET heat shrink tubing helps make surgical graspers safer and work better. It has special features that help doctors during surgery:

Medical grade PET is safe for the body, stands up to chemicals, and is very strong.

The walls are very thin, but the tubing is tough, so graspers bend easily and are simple to use.

It shrinks at a low temperature, so it covers parts tightly without being bulky.

It can handle high voltage, so it keeps electrical parts safe.

Some PET tubing now has sensors that watch things in real time during surgery. These new ideas mean PET shrink tubing will keep making surgery tools and patient care better.

FAQ

What makes PET shrink tubing safe for medical use?

PET shrink tubing follows tough medical rules like ISO 10993 and USP Class VI. It does not cause allergies in people. Hospitals trust it because it stays strong after lots of cleanings. Doctors use it safely in many surgical tools.

How does PET shrink tubing handle repeated sterilization?

PET shrink tubing stands up to heat, chemicals, and water. It keeps its shape and strength after many cleanings. Hospitals can clean devices with PET tubing using steam, gamma rays, or chemicals. The tubing does not break or lose its protection.

Can PET shrink tubing fit complex shapes?

Engineers use PET shrink tubing because it shrinks tightly around small or odd parts. The tubing can fit many sizes and shapes. This helps protect small parts in surgical graspers and other medical tools.

Does PET shrink tubing affect device flexibility?

PET shrink tubing has thin walls and is very strong. It covers parts without making them stiff or thick. Surgical graspers stay bendy and easy to use. Doctors can move and control the tools during surgery.

What should engineers check after applying PET shrink tubing?

Engineers look for smooth coverage, no bubbles, and a tight fit. They test if the tubing stays in place and does not block moving parts. Careful checking makes sure the device works safely and meets medical rules.

See Also

Top Uses Of Ultrathin PET Heat Shrink Tubing In Medicine

The Importance Of Nitinol Tubing In Minimally Invasive Surgery

Enhancing Neurosurgical Catheters With FEP Shrink Tubing Technology

Critical Role Of Ultra-Thin PET Heat Shrink Tubing In Healthcare

Building Multi-Layer Catheters Using Medical Grade FEP Tubing