How to Protect Ultrasound Probe Cables with PET Shrink Tubing

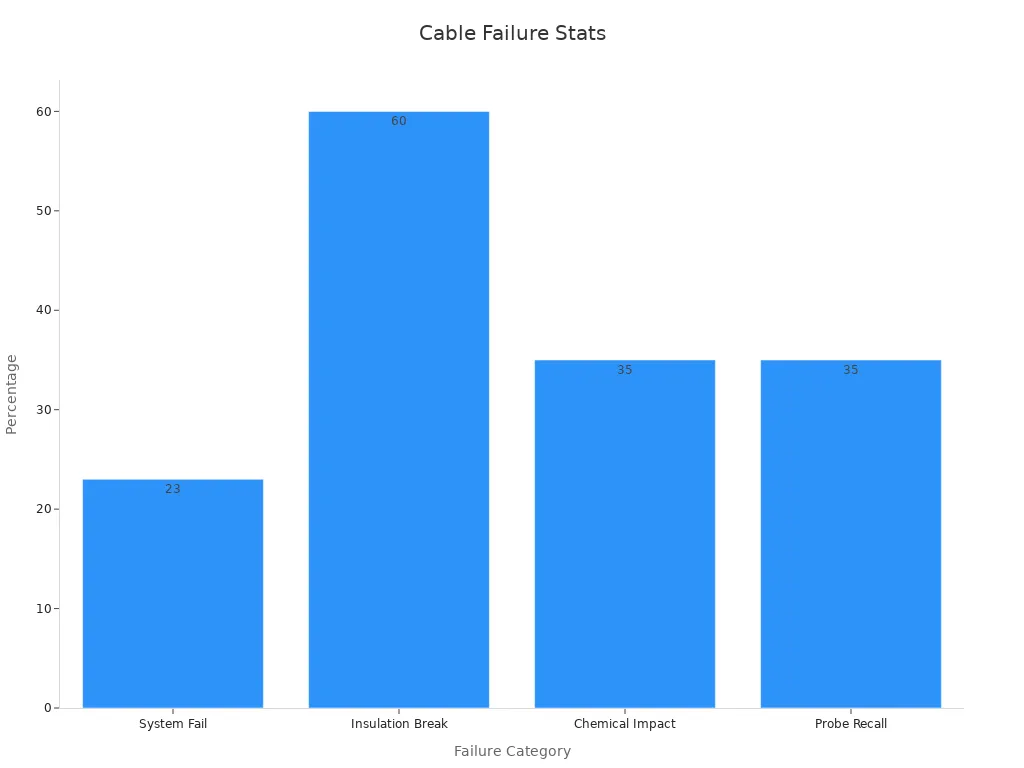

PET heat shrink tubing is a strong way to protect ultrasound probe cables. When you use PET shrink tube for these cables, you help keep medical equipment safe and working well. Cable problems in medical devices can cause serious trouble. For example, about 23% of ultrasound system failures happen because of cable problems. Replacing probe cables can cost up to $15,000. Sometimes, it takes weeks to get new cables because of supply shortages.

PET heat shrink tubing is special because it resists chemicals, can be cleaned many times, and keeps its shape. These things help stop insulation from breaking down and keep patients safe during important medical work. You can see why strong tubing is important in medical devices by looking at these numbers:

Statistic Description | Percentage / Value | Explanation / Impact |

|---|---|---|

Ultrasound system failures due to cable degradation | 23% | Almost one out of four failures are from cable problems, so protection is needed. |

Cable replacements caused by insulation breakdown | 60% | Most failures happen because of wear, so strong tubing is important. |

Premature cable replacements linked to chemical exposure | 35% | Cleaning chemicals hurt cables, so chemical resistance matters. |

When you pick PET heat shrink tubing for medical equipment, you make devices safer and more reliable. PET shrink tube for ultrasound probe cables helps protect your equipment and keeps every patient safe.

Key Takeaways

PET heat shrink tubing keeps ultrasound probe cables safe from harm. This makes medical devices safer and more dependable.

The tubing gives strong protection and electrical insulation. It also stands up to cleaning chemicals.

PET tubing is thin and bends easily, so it wraps cables tightly. It does not make the cables heavy or bulky.

Picking the right size and good quality PET tubing is important. This helps the tubing fit well and meet safety rules for medicine.

Putting on PET tubing with the right tools and heat is important. This helps cables last longer and keeps patients safe.

Protection Benefits

Mechanical Strength

Ultrasound probe cables need strong protection. PET heat shrink tubing helps protect cables from damage. It stops cables from getting scratched or bent. The tubing wraps tightly around the cable. This makes a tough shield. The shield keeps cables safe from sharp things and pulling. PET tubing helps your equipment last longer. You will not need to fix or replace cables as often. Hospitals and clinics trust this strength. It helps keep devices ready for patients.

Tip: Check cables often for signs of damage. Finding problems early lets you fix them before they get worse.

Electrical Insulation

PET heat shrink tubing gives great insulation for cables. This insulation keeps signals clear and strong. Using PET tubing lowers the chance of short circuits. It also helps stop signal loss. Good insulation keeps patients and staff safe from shocks. PET tubing covers the cable fully. It blocks out water and dust. This helps your devices stay safe and work well. You can trust PET tubing to protect your equipment every time.

PET tubing helps keep signals strong.

It blocks outside noise.

It helps your devices work well.

Chemical Resistance

Ultrasound probe cables get cleaned with strong chemicals. PET heat shrink tubing does not break down from these cleaners. You can clean and sterilize cables many times. The tubing stays strong and keeps its shape. This chemical resistance helps your equipment last longer.

PET heat shrink tubing stands up to chemicals, disinfectants, and cleaning, keeping its shape after many uses.

The tubing does not get weak from harsh cleaners, so cables last longer and stay safe.

PET tubing stays strong and works well in busy hospitals.

It can handle UV light and high heat during cleaning.

The smooth PET tubing surface helps stop germs from growing, which keeps things clean.

You can trust PET heat shrink tubing to protect your equipment during cleaning. This strong chemical resistance means you do not have to worry about replacing cables often.

Biocompatibility

Biocompatibility is very important for medical devices. PET heat shrink tubing meets strict safety rules. You can use this tubing on devices that touch sensitive body parts. It is made from safe, non-toxic materials. PET tubing meets ISO 10993 and USP Class VI standards. This means it is safe for patients and does not cause bad reactions. The tubing passes hard tests for safety, so it is a good choice for medical tools.

PET tubing stays safe after being cleaned with gamma rays or ethylene oxide. This keeps your devices safe and working after each cleaning. Hospitals and clinics pick PET heat shrink tubing because it is safe and reliable.

Note: PET tubing does not have phthalates and uses safe colors, so it lowers the chance of bad reactions in patients.

PET Shrink Tube for Ultrasound Probe Cables

Ultrathin Wall Design

When you use PET shrink tube, your cables stay safe. The tubing is very thin, less than 0.05 mm thick. This thin layer keeps cables light and easy to move. Your medical devices will not get too thick or heavy. The tubing shrinks tightly, so it fits well and does not slip off. You can see how this thin design helps in the table below:

Measurement Aspect | Quantitative Detail | Significance in Minimizing Bulk and Ensuring Protection |

|---|---|---|

Wall Thickness | Less than 0.05 mm | Ultra-thin walls reduce added bulk while maintaining mechanical strength. |

Shrink Ratio | Standard 2:1; 3:1 or higher for irregular shapes | Allows tubing to tightly conform to various shapes, ensuring a snug fit. |

Expanded Diameter | Approximately 25% larger than the largest object | Facilitates easy application without excessive looseness, reducing bulk. |

Mechanical & Thermal Properties | High strength, thermal stability, electrical insulation | Maintains protection without increasing size, critical for device reliability. |

Fit Precision | Tight conformity reduces risk of slippage and failure | Ensures protection and durability in minimally invasive tools. |

PET heat shrink tubing fits cables just right. It can shrink at a 2:1 or 3:1 ratio. This means it wraps tightly around different cable shapes. The snug fit stops slipping and keeps devices safe. You get strong protection without making cables bulky.

Durability and Flexibility

PET heat shrink tubing is tough and bends easily. You can move cables a lot, and the tubing will not break. This matters for medical devices that get used and cleaned often. PET tubing does not wear out from daily use or cleaning. It keeps working after heat, chemicals, or UV light. Hospitals need tubing that can handle hard cleaning. PET heat shrink tubing does this job well. It helps stop cables from failing early. You get tubing that lasts longer and keeps devices safe.

Tip: Pick good PET tubing for your devices. This helps them last longer and stay safe.

Size and Fit

Getting the right size is important for PET shrink tube. The tubing comes in many sizes to match your cable. It starts bigger, about 25% wider than your cable. When you heat it, the tubing shrinks to fit tight. This tight fit keeps out dust, water, and germs. It also helps cables meet medical safety rules. PET tubing is safe for people and works with special cleaning methods. You can use it in medical devices and trust it will pass all tests. PET heat shrink tubing always gives a snug, safe fit.

Application Steps

Selection Guide

Picking the right PET heat shrink tubing is important. The tubing must fit the cable well and protect it. It also needs to follow all medical safety rules. First, measure your cable’s diameter. Choose tubing with a shrink ratio that matches your cable’s shape. Most medical cables use a 2:1 or 4:1 shrink ratio. This helps the tubing fit tight and keeps the cable safe.

Check the tubing’s material quality too. Look for PET tubing that is strong and resists chemicals. It should also handle heat well. Make sure the tubing has medical-grade certifications. These include ISO 10993, USP Class VI, and FDA approval. These show the tubing is safe for patients and works with cleaning.

It is important to pick a good supplier. Choose one with a good reputation and follows the rules. This helps you get safe and high-quality tubing for your devices. The table below lists the main things to check when picking PET heat shrink tubing:

Decision-Making Criterion | Supporting Data and Explanation |

|---|---|

Size and Fit | Measuring right helps the tubing shrink evenly and protect well; shrink ratios (2:1, 4:1) work for different shapes. |

Material Quality and Performance | Strong, resists chemicals and heat; has medical certifications like ISO 10993, USP Class VI, FDA approval. |

Supplier Reliability | Check if the supplier follows rules (FDA, CE), has a good name, and is trusted by customers for safe and good tubing. |

Compliance with Medical Standards | Follows ISO 10993, USP Class VI, FDA rules to make sure it is safe and works after cleaning. |

Insulation and Electrical Protection | Gives electrical and heat protection, stops problems, and keeps devices working in hospitals. |

Mechanical Protection and Durability | Stops scratches, holes, and bumps; stays strong after many cleanings and tough use. |

Biocompatibility and Safety | Not toxic, lowers germ risk, and follows medical rules to keep patients safe. |

Chemical and Sterilization Resistance | Handles strong cleaners, disinfectants, UV light, and cleaning without getting weak. |

Support for Miniaturization | Fits tightly to small parts, helping make smaller and better tools like ultrasound probes. |

Tip: Always make sure the tubing fits your cable and meets all safety rules.

Preparation

Before you put on PET heat shrink tubing, get your cables and area ready. Clean the cable to remove dust, oil, or old covering. Use a lint-free cloth and a safe cleaner. Make sure the cable is dry before you start. Cut the tubing to the right length. Leave a little extra on each end to cover the cable fully. Check that the tubing slides over the cable but is not too loose.

Set up your workspace in a clean spot. Keep your tools, like scissors and heat guns, close by. Wear gloves and safety glasses to protect yourself. Good preparation helps you avoid mistakes and keeps your devices safe.

Heat Shrink Tubing Process

Putting on PET heat shrink tubing takes careful steps. First, slide the tubing over the cable. Center it over the spot you want to protect. Use a heat gun with adjustable temperature. For PET tubing, set the heat gun to about 150°C. PET tubing starts shrinking at 70°C and can go up to 190°C. Move the heat gun slowly in circles around the tubing. This helps the tubing shrink evenly and stops overheating.

Hold the tube ends if you want to control how it shrinks. This gives more shrinking around and less along the length. PET tubing can shrink up to half its diameter. Let the tubing cool before you touch it. This keeps the fit tight and safe. PET heat shrink tubing works in temperatures from -55°C to +125°C. You can use it in many medical device factories.

Note: Do not use open flames. Always use a heat gun for even heating and better safety.

Best Practices

You can get the best results by following some easy tips. Always measure your cables and tubing before you start. Double-check the shrink ratio and tubing size. Clean your cables well so the tubing sticks and protects better. Use a heat gun with a steady hand. Move the heat evenly to avoid burning the tubing.

After shrinking, let the tubing cool before you touch the cable. This helps the tubing set and keeps the fit tight. Check the tubing for gaps, bubbles, or uneven spots. If you see problems, take off the tubing and try again. Good PET heat shrink tubing should look smooth and fit snug.

Safety Reminder: Wear gloves and safety glasses during the process. This keeps you safe from heat and sharp tools.

PET heat shrink tubing gives strong protection, insulation, and lasts long for medical devices. When you follow these steps, your cables last longer and stay safe through many cleanings. Good tubing and careful work help keep your medical device process safe for patients.

When you use PET heat shrink tubing, your equipment lasts longer. This tubing helps keep your devices safe and strong. Picking the right PET heat shrink tubing is important for safety. You should put it on carefully to protect your equipment. Always follow good steps so your tubing works well. PET heat shrink tubing helps your equipment work better and keeps patients safe. 🏥

FAQ

How do you choose the right size of PET shrink tubing?

First, measure how wide your cable is. Choose tubing that is a bit wider than your cable. Pick a shrink ratio like 2:1 or 3:1. This helps the tubing fit tightly after shrinking. Always look at the sizing chart from the maker to get the best fit.

Can you reuse PET heat shrink tubing after removal?

You cannot use PET heat shrink tubing again. After you shrink it, the tubing keeps its new shape. If you take it off, it will get damaged. Always use a new piece each time you need it.

Is PET shrink tubing safe for all medical cleaning methods?

You can use PET shrink tubing with most cleaning ways. It works with chemical disinfectants, steam, and UV light. The tubing does not get ruined by these cleaning steps. Always check the tubing’s details to make sure it works with your cleaning method.

What tools do you need to apply PET heat shrink tubing?

Heat gun with adjustable temperature

Scissors or a tubing cutter

Lint-free cloth for cleaning

Gloves and safety glasses

These tools help you put on the tubing safely and the right way.