How PET Shrink Tubing Protects MRI Device Components

PET shrink tubing keeps important MRI device parts safe. It protects them from damage, electricity, and the environment. Medical devices need materials that are not magnetic. They also need to be safe for the body and last a long time. This is very important in strong magnetic fields. PET Shrink Tube for MRI-Compatible Devices does all these things well. The table below shows how PET shrink tubing makes medical devices safer and more reliable:

Performance Metric | Numerical Evidence |

|---|---|

Sterilization Cycles Endurance | Keeps its shape after 25 or more cleanings |

Tensile Strength Retention | Stays over 88% strong after 50 cleanings |

Dielectric Strength | Handles more than 4,000 V/mil |

Operational Temperature Range | Works from -196°C to 135°C for a long time, up to 200°C for a short time |

Shrinkage Capability | Can shrink by 50% or even more |

These features help keep medical devices safe. They also help these devices work well in tough medical jobs.

Key Takeaways

PET shrink tubing keeps MRI parts safe. It stops magnets, heat, chemicals, and wear from hurting the device. This helps the device work well and last longer.

The tubing is strong but also thin. It wraps tightly around wires and parts. This stops damage and blocks electrical problems.

Medical-grade PET tubing follows strict safety rules. It is safe for devices that touch or go inside the body.

PET shrink tubing can be cleaned many times. It does not get weak after cleaning. This lets hospitals use devices again safely.

PET tubing is better than other materials. It lasts longer, fits better, and costs less for protecting medical devices.

What Is PET Shrink Tubing?

Material and Properties

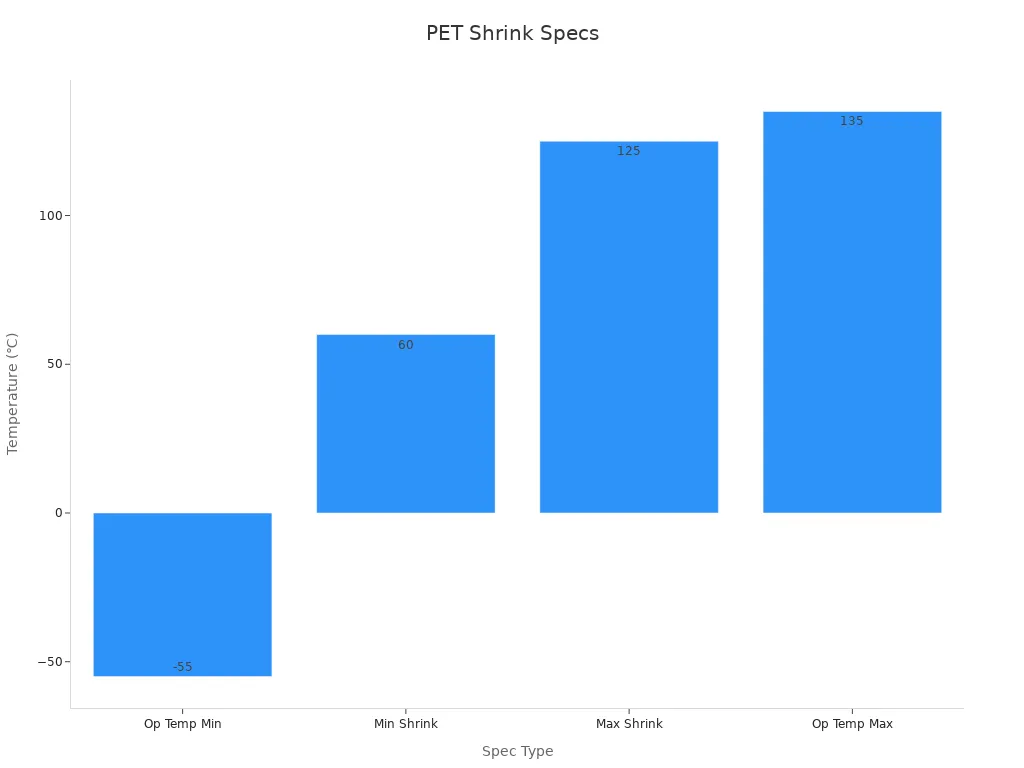

PET heat shrink tubing is made from polyethylene terephthalate. This material makes the tubing strong against heat, chemicals, and stress. It works in temperatures from -55℃ to +135℃. The tubing can shrink at 60℃ and up to 125℃. It meets strict biocompatibility rules like ISO 10993-5 and ISO 10993-10. This means it is safe for medical devices. PET heat shrink tubing also passes checks like ISO 17665-1:2023 and ISO 11137-2:2022. These rules make sure the tubing can handle steam and irradiation cleaning.

The tubing’s chemical resistance keeps devices safe from fluids and cleaners. PET heat shrink tubing can be recycled, which helps with FDA 2025 goals. Studies show PET heat shrink tubing keeps over 80% of its strength after many cleanings. This makes it a good choice for medical devices that need to be cleaned often.

PET heat shrink tubing covers micro-coils and stops imaging problems in MRI machines. It also gives electrical insulation, which lowers interference.

Specification / Finding | Details / Values |

|---|---|

Material | Polyethylene terephthalate (PET) |

Operating Temperature Range | -55℃ to +135℃ |

Shrink Ratio | 1.1:1 to 3:1 |

Minimum Shrink Temperature | 60℃ |

Maximum Shrink Temperature | 125℃ |

Mechanical Properties | High tensile strength; retains over 80% elongation-at-break after sterilization doses |

Sterilization Resistance | Withstands multiple cycles including autoclaving, ethylene oxide, irradiation (25 kGy) |

Biocompatibility Standards | Meets ISO 10993-5 and ISO 10993-10 |

Regulatory Compliance | ISO 17665-1:2023 (steam sterilization), ISO 11137-2:2022 (irradiation), MDR 2023 (EU Medical Device Regulation) |

Role in MRI Device Safety | Insulates micro-coils, prevents imaging artifacts, provides electrical insulation reducing interference |

Dimensional Precision | Ensures secure, uniform shrinkage for accurate positioning of radiopaque marker bands |

Chemical Resistance | Resistant to bodily fluids and sterilization chemicals |

Advanced Formulations | Carbon nanotube doping enhances cyclic fatigue resistance by 40% |

Environmental Sustainability | Supports recyclability and mono-material solutions aligned with FDA 2025 initiatives |

Research Findings | Study shows only 12% tensile strength reduction after 50 hydrogen peroxide sterilization cycles |

Application Examples | Cardiovascular catheters, stent delivery devices, MRI coils, neuromodulation devices |

Thin Wall and High Strength

PET heat shrink tubing is known for being thin and strong. The wall can be as thin as 0.0002 inches. Even when thin, it keeps a tensile strength of at least 30,000 PSI. This makes it great for medical devices that need to bend and last long. The tubing can shrink up to 70% in diameter and still stay strong. This helps it fit tightly around small or tricky parts in medical devices.

Property | Specification | Unit |

|---|---|---|

Wall Thickness | 0.0002 | inches |

Tensile Strength | ≥ 30,000 | PSI |

Shrink Ratio | Up to 2:1 | Ratio |

PET heat shrink tubing can stretch a lot before breaking, at least 62%. This means it can bend without ripping, which is good for devices that move. The thin wall keeps medical devices light and small. Doctors and engineers pick PET heat shrink tubing because it protects delicate parts without making devices bulky.

PET Shrink Tube for MRI-Compatible Devices

Non-Magnetic Protection

PET shrink tube for MRI-compatible devices helps keep medical devices safe in MRI machines. MRI machines use very strong magnets. If a part is magnetic, it can cause problems or even break the machine. PET heat shrink tubing is not magnetic. It does not react to magnets at all. Engineers use PET shrink tube for MRI-compatible devices to cover wires, sensors, and connectors. The tubing stops these parts from messing up the MRI’s magnetic field. Hospitals use PET heat shrink tubing because it keeps MRI images clear. Doctors need clear images to help patients.

PET shrink tube for MRI-compatible devices helps stop dangerous problems. It also keeps patients and workers safe from harm.

Insulation and Organization

Medical devices have lots of wires and small parts. PET heat shrink tubing helps keep these parts neat. It holds wires together so they do not touch each other. This makes devices easier to use and fix. PET shrink tube for MRI-compatible devices also gives strong electrical insulation. It stops electricity from jumping between wires. This keeps medical devices safe to use. PET heat shrink tubing fits tightly around cables and connectors. The tight fit keeps parts from moving and wearing out. Hospitals use PET shrink tube for MRI-compatible devices to keep devices tidy and working well.

PET heat shrink tubing covers metal parts that stick out.

It stops wires from getting tangled.

It helps workers find problems fast.

A neat device lasts longer and works better. PET heat shrink tubing helps every medical device stay this way.

Environmental Resistance

PET heat shrink tubing can handle tough hospital conditions. Medical devices face things like cleaning chemicals, body fluids, and high heat. PET shrink tube for MRI-compatible devices is very strong against chemicals. It does not get ruined by strong cleaners or disinfectants. This helps devices last through many cleanings. PET heat shrink tubing also works well in hot or cold temperatures. Its temperature strength lets it protect devices during use and cleaning. Hospitals use steam or gas to clean equipment. PET shrink tube for MRI-compatible devices keeps its shape and strength after many cleanings.

Environmental Challenge | PET Heat Shrink Tubing Response |

|---|---|

Cleaning Chemicals | High chemical resistance |

Body Fluids | No swelling or breakdown |

Heat from Sterilization | Maintains shape and strength |

Repeated Use | Withstands wear and tear |

PET heat shrink tubing keeps water and dust away from medical devices. This helps devices last longer and need fewer repairs. PET shrink tube for MRI-compatible devices helps hospitals trust their equipment to stay safe and work well.

Tip: PET heat shrink tubing’s chemical strength and heat resistance make it a great pick for medical devices in hard places.

Medical-Grade PET Heat Shrink Tubing

Biocompatibility

Medical-grade PET heat shrink tubing follows strict safety rules. It does not hurt living cells or cause allergies. The tubing passes tests for cell harm, skin irritation, and allergies. These tests prove PET heat shrink tubing is safe to touch people. Some medical devices must touch or go inside the body. Medical-grade PET heat shrink tubing is good for these uses. It meets ISO 10993 and USP Class VI rules. These rules show the tubing is safe and does not leak bad chemicals. The smooth surface also helps stop bacteria from growing.

Test Type | Purpose |

|---|---|

Cytotoxicity Testing | Checks if tubing harms living cells |

Irritation Testing | Looks for skin or tissue irritation |

Sensitization Testing | Finds allergic reaction risks |

In Vitro Testing | Early lab-based safety checks |

In Vivo Testing | Confirms safety in living organisms |

Risk Assessment | Reviews all safety risks |

Sterilization Compatibility

Medical-grade PET heat shrink tubing can handle many ways of cleaning. Hospitals use steam, gas, or radiation to clean devices. PET heat shrink tubing stays strong and keeps its shape after many cleanings. Studies show it keeps over 88% strength after 50 chemical cleanings. It does not break or lose its protective power. This makes it a great choice for hospitals. Medical-grade PET heat shrink tubing still meets safety rules after cleaning. It works well in tough hospital places and helps keep patients safe.

Tip: Medical-grade PET heat shrink tubing stands up to heat, chemicals, and wear, so it is good for cleaning many times.

Patient Safety

Patient safety is the most important thing for medical devices. Medical-grade PET heat shrink tubing helps keep patients safe in many ways. It does not cause skin problems or allergies. The tubing is non-toxic and keeps patients safe during use. Medical-grade PET heat shrink tubing covers sharp or metal parts to lower injury risk. Its strong, smooth surface also stops bacteria from sticking. Hospitals trust PET heat shrink tubing to keep devices safe and clean for every patient. Medical-grade PET heat shrink tubing meets all safety rules, so it is a trusted choice for patient care.

Medical-grade PET heat shrink tubing is safe for catheters, MRI coils, and other devices.

It protects both patients and healthcare workers during use.

The tubing’s strength helps keep everyone safe for a long time.

PET Heat Shrink Tubing vs. Alternatives

Durability and Fit

PET heat shrink tubing is better than many other materials. Hospitals and engineers like it because it is strong and light. It protects small parts in medical devices. The tubing keeps its shape and strength after many uses. Silicone tubing can get weak and lose its shape over time. PTFE tubing bends well but does not fit as tightly as PET. Polyolefin tubing is not as tough and does not protect as well.

Feature/Metric | PET Heat Shrink Tubing | Silicone Tubing | Polyolefin Tubing | PTFE Tubing |

|---|---|---|---|---|

Tensile Strength | Strong; retains 98% after 2000 uses | Weaker | Not specified | Stronger than silicone but less sturdy than PET |

Durability | Long-lasting, keeps shape under pressure | Average, can lose shape | Less durable than PET | Good chemical and heat resistance but less sturdy |

Structural Integrity | Excellent | Okay | Not specified | Not precisely sized compared to PET |

Dielectric Strength | >600 V/mil (up to 4000 V/mil cited) | Not specified | >600 V/mil | Not specified |

Wall Thickness | <0.1 mm | Not specified | Not specified | Not specified |

PET heat shrink tubing is thin and fits exactly. It wraps wires and connectors tightly. This helps stop damage and fraying. The tubing’s chemical resistance lets it handle strong cleaners and many cleanings. These things make it great for small medical devices that need to be strong and flexible.

PET heat shrink tubing is very thin but still protects well.

It can shrink a lot to fit odd shapes.

The tight fit helps stop mistakes when making devices.

Its chemical resistance and safety help protect patients.

Cost and Performance

PET heat shrink tubing gives good value for the price. It is cheaper to use because it shrinks at lower heat. This saves energy. The tubing meets high standards like ISO 13485 and AS23053. It works well in medical, airplane, and electronics jobs. PET heat shrink tubing costs less and is easier to get than PTFE, PFA, or PEEK.

PET heat shrink tubing lasts longer, so you buy less.

People say it is easy to use and always works well.

Many industries use it because it is strong and reliable.

Companies keep PET heat shrink tubing in stock for quick delivery.

Aspect | Evidence Summary |

|---|---|

Cost-Effectiveness | PET tubing is highlighted as cost-effective across various applications, balancing price and performance. |

Durability | The market report emphasizes PET tubing's durability and compliance with industry standards. |

Installation Efficiency | PET tubing offers advantages in installation energy consumption, reducing operational costs. |

Industry Applications | Widely used in demanding sectors such as medical, aerospace, and electronics, supported by certifications and customer feedback. |

PET heat shrink tubing’s strength, fit, and low cost make it the best choice for medical devices. Its quality and price help hospitals and factories trust it for important jobs.

Medical-grade PET heat shrink tubing helps protect MRI device parts. It does not react to magnets, so it is safe in MRI machines. The tubing is safe for people and stays strong during use. Hospitals use it because it helps devices work well every time. Medical devices need materials that last and keep people safe.

Engineers should think about using medical-grade PET heat shrink tubing when making new MRI devices for hospitals.

FAQ

What makes PET shrink tubing safe for MRI devices?

PET shrink tubing contains no magnetic materials. It does not interfere with MRI images. Hospitals trust it because it keeps devices safe and reliable during scans.

Can PET shrink tubing handle repeated sterilization?

Yes. PET shrink tubing resists heat, chemicals, and radiation. It keeps its shape and strength after many cleaning cycles. This helps hospitals reuse devices safely.

Is PET shrink tubing biocompatible?

PET shrink tubing meets strict medical standards. It does not harm skin or tissue. Doctors use it in devices that touch or enter the body.

How does PET shrink tubing protect wires and connectors?

PET shrink tubing wraps tightly around wires. It keeps them organized and stops them from touching each other. This prevents short circuits and damage.

Why do engineers choose PET shrink tubing over other materials?

Engineers pick PET shrink tubing for its strength, thin walls, and tight fit. It lasts longer than many other materials. It also costs less and works well in tough hospital settings.