Why PET Heat Shrink Tubing Outperforms Electrical Tape

PET heat shrink tubing sets a new standard in electrical insulation and protection. Its tensile strength of 2100 psi and dielectric strength of 500 V/MI make it far more robust than traditional electrical tape. With an elongation rate of 600% and water absorption as low as 0.1%, PET tubing ensures exceptional durability and reliability. Industries such as automotive and electronics rely on it for its superior performance and ease of application, even in high-temperature or chemically harsh environments. This combination of versatility and longevity solidifies PET heatshrink as the ultimate choice for demanding insulation needs.

Key Takeaways

PET heat shrink tubing gives better insulation than electrical tape. It protects delicate parts from electrical problems.

PET tubing is strong and handles high heat and tough chemicals. It works well for a long time in hard conditions.

Using PET heat shrink tubing is simple and quick. It shrinks tightly around parts, making a clean and safe seal without sticky mess.

PET tubing saves money over time because it lasts longer. You won’t need to replace it often, cutting down on repair costs.

Use PET heat shrink tubing for cars, medical tools, and outdoor gear. It’s great where strength and dependability matter most.

Understanding PET Heat Shrink Tubing

Material Composition and Unique Properties

PET heat shrink tubing is crafted from polyethylene terephthalate, a high-performance polymer renowned for its strength and adaptability. This material exhibits exceptional tensile strength, enabling it to endure mechanical stress without deforming. Its lightweight nature enhances usability, particularly in intricate applications like medical devices. PET also maintains excellent dimensional stability, ensuring it retains its shape and size under fluctuating temperatures.

The tubing’s chemical resistance is another standout feature. It remains unaffected by common sterilizing agents such as ethylene oxide and hydrogen peroxide, making it ideal for environments requiring frequent sterilization. Additionally, PET meets stringent biocompatibility standards, confirming its safety for direct contact with human tissues and fluids. These properties make PET heat shrink tubing a versatile solution for demanding insulation needs.

Property | Description |

|---|---|

Dielectric Strength | Over 4,000 V/mil, essential for preventing electrical interference in sensitive devices. |

Volume Resistivity | 10^18 Ohm-cm, indicating excellent insulation properties. |

Biocompatibility | Ensures safety in medical applications, crucial for devices in contact with the human body. |

Heat Resistance | Operates effectively across a wide temperature range, maintaining insulation under thermal stress. |

Sterilization Capability | Can withstand methods like autoclaving and gamma radiation, enhancing reliability in medical use. |

How PET Heatshrink Works

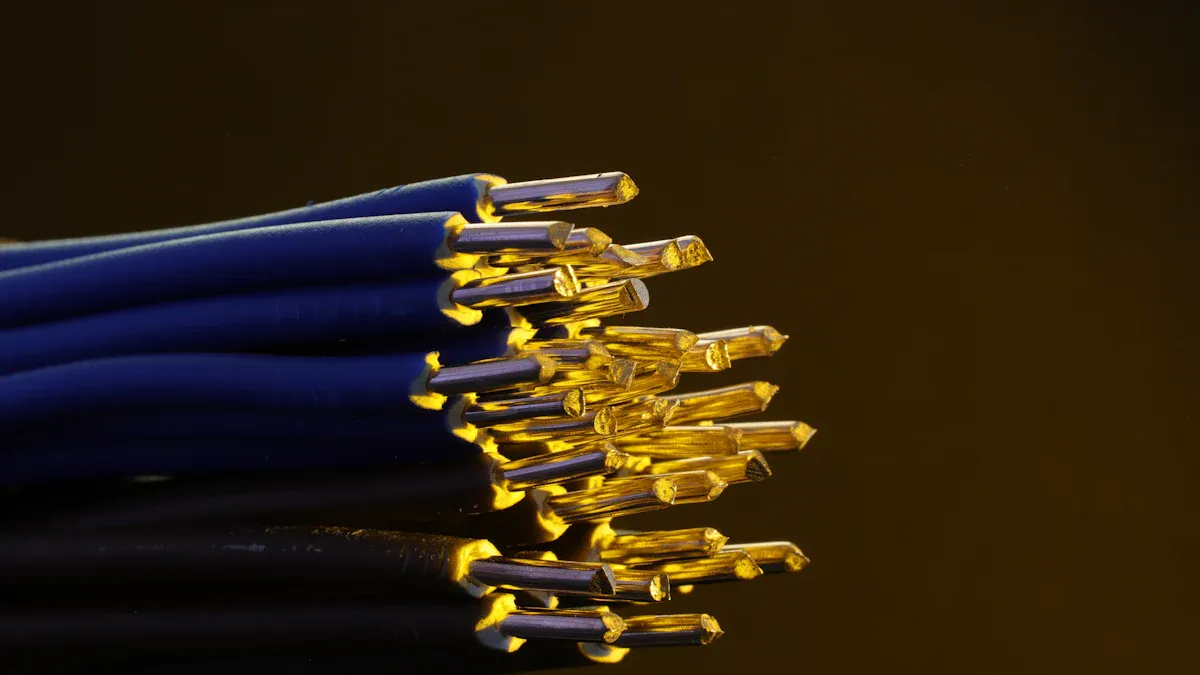

PET heat shrink tubing operates through a simple yet effective mechanism. During manufacturing, the tubing undergoes a process of extrusion and expansion. When exposed to heat, it contracts to its original size, tightly conforming to the object it covers. This shrinkage creates a secure, protective layer that insulates and shields components from environmental factors.

The tubing’s heat resistance ensures it performs reliably across a wide temperature range. It can withstand thermal stress without compromising its insulating properties. This makes it suitable for applications in harsh environments, including those involving high temperatures or exposure to chemicals.

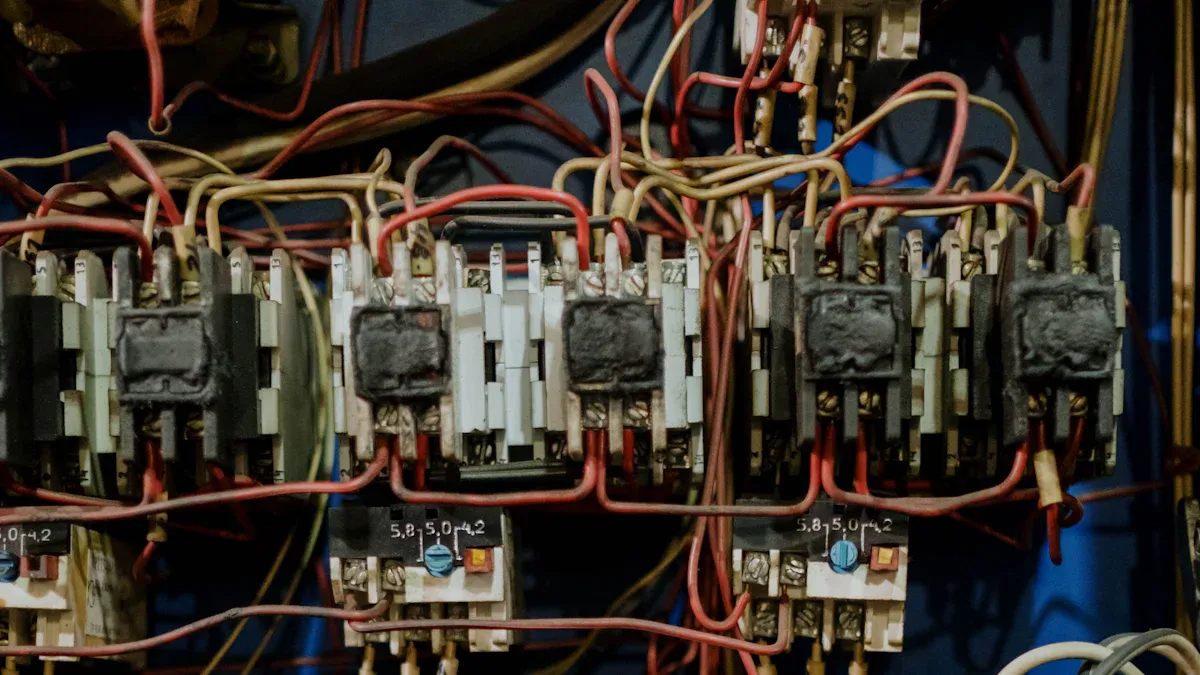

Applications of PET Heat Shrink Tubing in Various Industries

PET heat shrink tubing finds applications across diverse industries due to its unique properties. In the electrical sector, its high dielectric strength makes it ideal for insulating energy-generating or sensing devices. The tubing also serves as a protective covering, bundling components tightly while providing a robust outer layer.

In the medical field, PET tubing plays a critical role in manufacturing catheters and other devices. Its biocompatibility and ability to withstand sterilization methods like autoclaving ensure safety and reliability. Additionally, the tubing is used in renewable energy sectors, such as solar and wind power installations, where it protects cable connections in harsh outdoor environments. These applications for shrink tubing demonstrate its versatility and importance in modern industries.

Application Type | Description |

|---|---|

Electrical Insulation | High dielectric strength makes it ideal for energy-generating or sensing devices. |

Variable-Stiffness Shafts | Adds stiffness with minimal profile increase due to ultrathin walls. |

Braid Termination | Encapsulates braid terminations, preventing end-wire exposure while maintaining a low profile. |

Pad Printing or Marking | Custom configurations allow for printing on the tubing instead of directly on devices. |

Protective Covering/Coating | Provides a strong outer layer or bundles components tightly. |

Bonding | Bonds ends of balloons to catheters or strengthens existing bonds. |

Masking | Applied to sections of catheters to prevent unwanted coatings. |

Manufacturing Aid | Used for bundling or preserving the profile of devices during manufacturing processes. |

Overview of Electrical Tape

Material Composition and Characteristics

Electrical tape is a pressure-sensitive adhesive tape designed for insulating and protecting electrical wires and components. Most electrical tapes are made from polyvinyl chloride (PVC), a material known for its flexibility, durability, and resistance to moisture and abrasion. For example, Scotch Vinyl Electrical Tape 35, a popular choice, uses PVC to provide excellent electrical and mechanical properties. This makes it suitable for tasks like phase identification and safety marking.

Several technical standards define the material composition and performance of electrical tape. These include:

ASTM D2686-19: Specification for Polytetrafluoroethylene-Backed Pressure-Sensitive Electrical Insulating Tape.

ASTM D3005-24: Specification for Low-Temperature Resistant Vinyl Chloride Plastic Pressure-Sensitive Electrical Insulating Tape.

ASTM D2301-24: Specification for Vinyl Chloride Plastic Pressure-Sensitive Electrical Insulating Tape.

These standards ensure that electrical tape meets specific requirements for insulation, adhesion, and environmental resistance.

Common Uses of Electrical Tape

Electrical tape serves a variety of purposes in electrical work and beyond. Its versatility makes it a staple in many toolkits. Common applications include:

Application | Description |

|---|---|

Insulating electrical wires | Electrical tape is primarily used to insulate electrical wires and prevent short circuits. |

Sealing connections | It can seal connections to protect them from moisture and dust. |

Repairing damaged wires | Electrical tape is often used to repair frayed or damaged wires. |

Additionally, electricians use it to cover cable ends, shield exposed conductors, and repair small breaks in insulation. It also provides temporary solutions for electrical work and protects components from dust and water splashes.

Limitations of Electrical Tape in Demanding Applications

While electrical tape is versatile, it has limitations in harsh or demanding environments. Its adhesive can degrade over time, especially when exposed to high temperatures, UV light, or moisture. This reduces its effectiveness in providing long-term insulation. Electrical tape also lacks the mechanical strength to withstand significant stress or abrasion, making it unsuitable for applications requiring high durability.

In extreme conditions, such as those involving heavy vibrations or chemical exposure, electrical tape may fail to maintain a secure seal. These limitations highlight the need for more robust solutions, such as PET heat shrink tubing, in demanding applications.

Comparing PET Heat Shrink Tubing and Electrical Tape

Insulation Performance: PET vs. Electrical Tape

PET heat shrink tubing offers superior insulation compared to electrical tape. Its high dielectric strength ensures reliable electrical insulation, even in demanding environments. This makes it ideal for protecting sensitive components from electrical interference. In contrast, electrical tape provides only basic insulation, which may not suffice for high-performance applications. Over time, the adhesive on electrical tape can degrade, reducing its effectiveness as an insulator.

A comparative study highlights the differences in insulation performance between these two materials:

Feature | PET Heat Shrink Tubing | Electrical Tape |

|---|---|---|

Insulation | Superior insulation for electrical components | Basic insulation, less reliable |

Durability | Highly durable, resistant to chemicals and abrasion | Less durable, can wear out quickly |

Application Flexibility | Versatile for various applications including strain relief and environmental protection | Limited to basic electrical applications |

This table underscores the advantages of PET heat shrink tubing in providing long-lasting and reliable electrical insulation. Its ability to maintain performance under harsh conditions makes it a preferred choice for industries requiring robust solutions.

Durability and Longevity of PET Heat Shrink Tubing

Durability is a critical factor when comparing PET heat shrink tubing to electrical tape. PET tubing excels in this area due to its resistance to chemicals, abrasion, and environmental factors. It maintains its structural integrity even in extreme temperatures or when exposed to moisture. This ensures a longer lifespan and consistent performance, reducing the need for frequent replacements.

Electrical tape, while flexible and easy to use, lacks the same level of durability. Its adhesive can weaken over time, especially in high-temperature or high-humidity environments. This can lead to peeling or detachment, compromising its ability to provide effective electrical insulation. PET heat shrink tubing, on the other hand, forms a tight, secure seal when heated, offering unmatched longevity and reliability.

The durability of PET heat shrink tubing makes it a cost-effective solution in the long run. Its ability to withstand harsh conditions ensures that it outlasts electrical tape in most applications, providing better value over time.

Ease of Application: Heat Shrink Tubing vs. Electrical Tape

Applying PET heat shrink tubing is straightforward and efficient. Users simply slide the tubing over the component and apply heat, causing it to shrink and form a secure, protective layer. This process ensures a neat and professional finish, with no risk of adhesive residue. The waterproofing capabilities of heat shrink tubing further enhance its appeal, making it suitable for outdoor and underwater applications.

In contrast, electrical tape can be challenging to apply neatly. Its adhesive nature often results in uneven wrapping, which can compromise its effectiveness. Overlapping layers of tape may create bulk, making it less suitable for applications requiring a streamlined profile. Additionally, electrical tape is prone to loosening over time, especially in environments with heavy vibrations or temperature fluctuations.

Studies on application efficiency highlight the advantages of heat shrink tubing:

Users report that heat shrink tubing is easier to apply than electrical tape.

It provides superior insulation and protection, making it a more reliable choice.

Its waterproofing capabilities make it ideal for demanding applications.

These factors demonstrate why PET heat shrink tubing is the preferred option for professionals seeking a durable and efficient solution for electrical insulation.

Cost-Effectiveness Over Time

PET heat shrink tubing provides significant cost advantages over electrical tape in the long run. Its durability ensures fewer replacements, reducing maintenance expenses. Unlike electrical tape, which often requires frequent reapplication due to adhesive degradation, PET tubing maintains its performance for extended periods. This longevity minimizes downtime and labor costs associated with repairs or replacements.

The material composition of PET contributes to its cost-effectiveness. Its resistance to environmental factors like moisture, UV light, and chemicals prevents premature wear and tear. Industries that rely on PET heat shrink tubing benefit from reduced operational costs, as the tubing withstands harsh conditions without compromising its insulating properties.

A comparison of cost-effectiveness between PET heat shrink tubing and electrical tape highlights the financial benefits:

Feature | PET Heat Shrink Tubing | Electrical Tape |

|---|---|---|

Initial Cost | Higher upfront investment | Lower upfront cost |

Maintenance Costs | Minimal due to long lifespan | Frequent replacements required |

Labor Costs | Reduced due to ease of application | Increased due to reapplication |

Total Cost Over Time | Lower due to durability and reliability | Higher due to recurring expenses |

Tip: While PET heat shrink tubing may have a higher initial cost, its long-term savings make it a more economical choice for demanding applications.

Specific Scenarios Where PET Heat Shrink Tubing Excels

PET heat shrink tubing outperforms electrical tape in scenarios requiring high durability and reliable insulation. Its ability to withstand extreme temperatures makes it ideal for environments like automotive engines or industrial machinery. In these settings, electrical tape often fails due to adhesive breakdown or material degradation.

Applications involving chemical exposure also benefit from PET tubing. Its resistance to solvents, oils, and cleaning agents ensures consistent performance in laboratories, factories, and medical facilities. Electrical tape, in contrast, deteriorates quickly when exposed to such substances, compromising its insulating properties.

PET heat shrink tubing excels in outdoor applications. Its UV resistance prevents cracking or fading, making it suitable for solar panel installations and wind turbines. Electrical tape lacks this resilience, leading to frequent replacements in outdoor environments.

Specific use cases where PET heat shrink tubing proves indispensable include:

Automotive Wiring Harnesses: Protects wires from heat, vibration, and moisture in engine compartments.

Medical Devices: Ensures biocompatibility and withstands sterilization methods like autoclaving.

Renewable Energy Systems: Shields cable connections in solar panels and wind turbines from UV exposure and weather conditions.

Industrial Equipment: Provides insulation and strain relief for machinery operating in chemically harsh environments.

Underwater Applications: Maintains waterproof seals for cables and connectors used in marine equipment.

Note: PET heat shrink tubing is the preferred choice for professionals working in industries where reliability and durability are critical.

Why PET Heat Shrink Tubing is the Better Choice

Key Advantages of PET Heatshrink

PET heat shrink tubing offers a range of benefits that make it a superior choice for electrical insulation and protection. Its excellent electrical insulation capabilities create a reliable barrier around sensitive components, preventing electrical interference. This ensures stable performance in devices where precision is critical. The tubing also provides exceptional mechanical protection, resisting abrasion and impacts to safeguard delicate parts during handling or operation.

Another key advantage of PET heat shrink tubing is its chemical resistance. It withstands exposure to harsh disinfectants and sterilization processes without degrading, making it ideal for environments like medical facilities and laboratories. Its biocompatibility further enhances its suitability for medical applications, ensuring safety for both patients and healthcare professionals. Additionally, PET tubing supports miniaturization by conforming tightly to components. This allows engineers to design compact and lightweight devices without compromising durability or performance.

The following table summarizes the key advantages of PET heat shrink tubing:

Advantage | Description |

|---|---|

Excellent electrical insulation | Provides a protective barrier around sensitive electronic components, preventing electrical interference. |

Mechanical protection | Resists abrasion and impacts, safeguarding delicate components from damage during handling. |

Chemical resistance | Withstands exposure to harsh disinfectants and sterilization processes without degrading. |

Biocompatibility | Ensures safety for patients and healthcare professionals in medical applications. |

Support for miniaturization | Conforms tightly to components, allowing for the design of compact and lightweight medical devices. |

These advantages highlight why PET heat shrink tubing outperforms traditional solutions like electrical tape in demanding applications. Its combination of reliability, versatility, and long-term durability makes it the preferred choice for professionals across industries.

When to Choose PET Heat Shrink Tubing Over Electrical Tape

PET heat shrink tubing is the ideal choice in scenarios where durability, performance, and reliability are critical. For applications involving extreme temperatures, such as automotive wiring harnesses or industrial machinery, PET tubing excels. Its ability to maintain structural integrity under thermal stress ensures consistent electrical insulation, even in harsh environments. Electrical tape, by contrast, often fails due to adhesive breakdown or material degradation.

In settings where chemical exposure is common, PET heat shrink tubing proves indispensable. Laboratories, factories, and medical facilities benefit from its resistance to solvents, oils, and cleaning agents. This ensures that the tubing continues to perform effectively without compromising the safety of the components it protects. Electrical tape, on the other hand, deteriorates quickly when exposed to such substances, making it unsuitable for these environments.

Outdoor applications also demonstrate the superiority of PET heat shrink tubing. Its UV resistance prevents cracking or fading, making it an excellent choice for solar panel installations, wind turbines, and other renewable energy systems. Electrical tape lacks this resilience, leading to frequent replacements and increased maintenance costs.

Professionals should choose PET heat shrink tubing over electrical tape in the following scenarios:

High-temperature environments: Automotive engines, industrial equipment, or other settings with significant thermal stress.

Chemical exposure: Laboratories, medical devices, or manufacturing processes involving harsh substances.

Outdoor applications: Solar panels, wind turbines, or marine equipment requiring UV and weather resistance.

Compact designs: Devices where space constraints demand a streamlined and lightweight solution.

Long-term reliability: Projects where durability and consistent performance are essential.

By selecting PET heat shrink tubing for these applications, users can ensure superior electrical insulation, enhanced durability, and reduced maintenance over time. Its unmatched performance in challenging conditions makes it the better choice for professionals seeking reliable and cost-effective solutions.

PET heat shrink tubing delivers unmatched insulation, durability, and versatility, making it a superior choice for electrical applications. Its ability to withstand harsh conditions ensures reliable performance over time. Industries such as automotive, telecommunications, and medical benefit from its protective properties, which enhance safety, meet regulatory standards, and reduce maintenance costs. The long-term impact of heat shrink tubing includes extended component lifespans, minimized signal loss, and eco-conscious practices. Choosing PET heat shrink tubing guarantees superior performance and cost-effectiveness, making it the ideal solution for demanding insulation needs.

FAQ

What is the primary advantage of PET heat shrink tubing over electrical tape?

PET heat shrink tubing provides superior durability and insulation. It resists extreme temperatures, chemicals, and UV exposure, ensuring long-term reliability. Electrical tape, in contrast, often degrades under harsh conditions, making it less suitable for demanding applications.

Can PET heat shrink tubing be used in outdoor environments?

Yes, PET heat shrink tubing excels in outdoor applications. Its UV resistance prevents cracking or fading, and it withstands moisture and temperature fluctuations. This makes it ideal for solar panels, wind turbines, and other outdoor installations.

Is PET heat shrink tubing reusable?

No, PET heat shrink tubing is not reusable. Once it shrinks and conforms to the component, it forms a permanent seal. This ensures reliable insulation and protection but prevents reapplication.

How does PET heat shrink tubing handle chemical exposure?

PET heat shrink tubing resists solvents, oils, and cleaning agents. Its chemical resistance ensures consistent performance in laboratories, factories, and medical facilities. Electrical tape, by comparison, deteriorates quickly when exposed to such substances.

Does PET heat shrink tubing require special tools for application?

Applying PET heat shrink tubing requires a heat source, such as a heat gun or lighter. The heat causes the tubing to shrink and form a secure seal. This process is straightforward and does not require advanced tools or expertise.

Tip: Always follow the manufacturer’s guidelines for safe and effective application of PET heat shrink tubing.

See Also

Essential Insights Into PET Heat Shrink Tubing for Electronics

Applications of Heat Shrink Tubing for Electrical Wire Insulation

Comparing FEP Heat Shrink Tubing Brands for Heat Resistance

Selecting Optimal Ultra-Thin PET Heat Shrink Tubing for Projects

Exploring Non-Toxic FEP Heat Shrink Tubing for Industrial Applications