What Is PET Heat Shrink Tubing and How Does It Protect Electrical Wires

PET heat shrink tubing is a specialized material crafted from polyethylene terephthalate (PET). This tubing is designed to protect electrical wires by providing a secure layer of insulation. When exposed to heat, the tubing contracts and fits snugly around wires, forming a protective seal. This process prevents damage from external factors such as abrasion or moisture. PET heat shrink tubing for electrical wire protection is widely recognized for its reliability and ease of use, making it a preferred choice in various industries.

Key Takeaways

PET heat shrink tubing keeps wires safe by stopping short circuits. It helps protect important systems and makes them safer.

The tubing shrinks tightly around wires to guard them better. This reduces damage in places where wires face a lot of stress.

Pick the right size and shrink ratio for the best fit. Common ratios like 2:1 or 4:1 make sure the tubing fits snugly.

PET tubing resists chemicals and water, so it works well outside or in tough industrial areas.

Using PET heat shrink tubing makes wires look neat and tidy. It improves how wires work and gives them a clean, professional look.

Understanding PET Heat Shrink Tubing

Material Composition and Properties

PET heat shrink tubing is crafted from polyethylene terephthalate, a thermoplastic polymer known for its exceptional mechanical and thermal properties. This material exhibits high tensile strength, ensuring that the tubing resists mechanical stress without deforming. Its thermal stability allows it to maintain structural integrity even under elevated temperatures, making it ideal for heat-based applications. Furthermore, PET tubing demonstrates excellent chemical resistance, remaining unaffected by oils, solvents, and other harsh substances commonly encountered in industrial environments.

The physical properties of PET make it a standout choice for electrical insulation. A closer look at its attributes reveals why it excels in demanding applications:

Property | Description |

|---|---|

Mechanical Strength | High tensile strength ensures resistance to mechanical stress without deformation. |

Thermal Properties | Maintains structural integrity under high temperatures, suitable for heat-based sterilization. |

Chemical Resistance | Unaffected by common sterilizing agents, ensuring reliability during sterilization processes. |

Biocompatibility | Meets ISO 10993 and USP Class VI standards, confirming safety for direct contact with human tissues. |

These characteristics highlight the versatility of PET tubing, making it a preferred choice across industries such as healthcare, automotive, and aerospace.

Shrinkage Mechanism and Functionality

The functionality of PET heat shrink tubing lies in its ability to contract when exposed to heat. During manufacturing, the tubing undergoes a process called "orientation," where it is stretched and then cooled to lock in its expanded shape. When reheated during installation, the tubing shrinks back to its original dimensions, tightly wrapping around wires or cables. This shrinkage creates a secure seal, providing insulation and protection against environmental factors.

The shrinkage mechanism not only ensures a snug fit but also enhances the durability of the electrical assembly. By conforming to the shape of the wires, the tubing minimizes gaps that could allow moisture or contaminants to penetrate. This feature is particularly valuable in outdoor or industrial settings where exposure to harsh conditions is common.

Why PET Is Ideal for Electrical Applications

PET heat shrink tubing stands out in electrical applications due to its unique combination of properties. Compared to other materials like PVC or Polyolefin, PET offers superior performance in several key areas:

PET tubing is stronger and more durable than PVC, making it suitable for demanding applications.

It maintains its shape at higher temperatures, unlike PVC, which degrades under heat.

PET is environmentally friendly as it is recyclable, while PVC poses challenges for recycling due to harmful chemicals.

Compared to Polyolefin, PET offers superior damage resistance and is ideal for harsh conditions.

In addition to these advantages, PET tubing provides excellent electrical insulation, preventing short circuits and safeguarding sensitive components. Its high dielectric strength ensures reliable performance in high-voltage applications. Moreover, PET resists chemicals, oils, and UV rays better than Polyolefin, making it a reliable choice for outdoor and industrial use.

Published industry reports further emphasize the benefits of PET heat shrink tubing. These reports highlight its high temperature and UV light resistance, which are critical for electrical insulation. The material's high dielectric strength enhances its effectiveness in sealing and insulating cables, contributing to its widespread adoption in the electrical and IT & telecom sectors.

By combining durability, thermal stability, and environmental friendliness, PET heat shrink tubing has become an indispensable solution for protecting wires and cables in various applications.

Key Applications of Heat Shrink Tubing

PET heat shrink tubing serves a vital role in safeguarding electrical systems. Its versatility and durability make it indispensable across various industries. Below are some of the key applications of heat shrink tubing.

Insulation and Electrical Safety

PET heat shrink tubing provides exceptional insulation, ensuring electrical safety in critical systems. By tightly wrapping around wires and cables, it prevents electrical leakage and reduces the risk of short circuits. This feature is particularly important in medical devices like defibrillators and pacemakers, where even minor electrical faults can have severe consequences. PET tubing also resists environmental stressors, maintaining its insulating properties even after repeated exposure to sterilization processes.

The biocompatibility of PET tubing meets stringent medical standards, making it safe for use in devices that come into contact with human tissue. Its high dielectric strength further enhances its ability to insulate wires, ensuring reliable performance in high-voltage applications. These qualities make PET heat shrink tubing an essential component in systems where electrical safety is paramount.

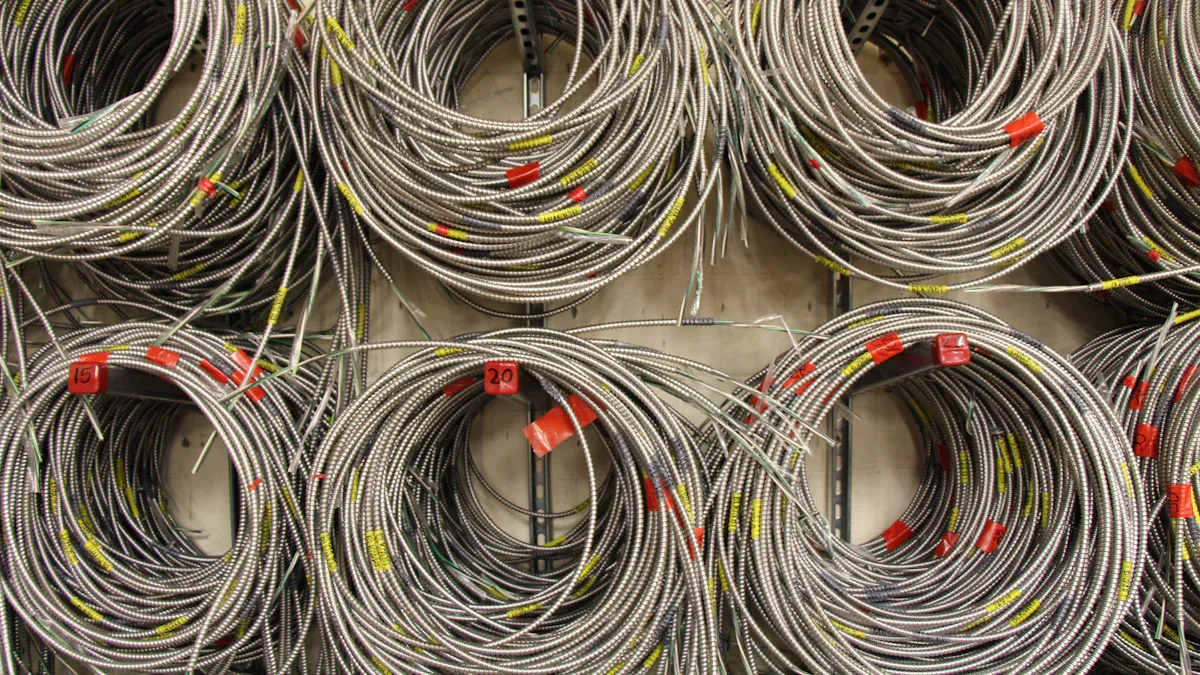

Bundling and Organizing Wires

Managing multiple wires in complex electrical systems can be challenging. PET heat shrink tubing simplifies this task by enabling the bundling of cables into organized groups. This not only improves the visual appeal of wire assemblies but also enhances their functionality. Organized wires are easier to identify and maintain, reducing the likelihood of errors during installation or repairs.

The tubing's ability to shrink tightly around wires ensures a secure hold, preventing them from becoming loose or tangled. This is especially beneficial in automotive and aerospace applications, where space constraints demand efficient wire management. By using PET tubing for bundling, engineers can create streamlined systems that are both reliable and aesthetically pleasing.

Protection Against Environmental Factors

PET heat shrink tubing offers robust protection against environmental factors that can damage wires and cables. Its resistance to moisture, chemicals, and UV radiation ensures that electrical systems remain functional even in harsh conditions. This makes it an ideal choice for outdoor applications, such as telecommunications infrastructure and renewable energy systems.

In industrial settings, PET tubing shields wires from abrasion and mechanical stress, extending their lifespan. Its thermal stability allows it to perform reliably in environments with fluctuating temperatures. By safeguarding wires against these external threats, PET heat shrink tubing enhances the durability and reliability of electrical systems.

Mechanical Protection and Strain Relief

PET heat shrink tubing plays a critical role in providing mechanical protection and strain relief for electrical wires and cables. Its robust design shields wires from physical damage caused by bending, pulling, or external forces. This protection ensures the longevity and reliability of electrical systems, especially in environments where mechanical stress is unavoidable.

One of the key features of PET tubing is its ability to create seamless, waterproof, and airtight seals. When heated, the tubing conforms tightly to the shape of the wires, eliminating gaps that could lead to leaks or movement. This secure fit prevents wires from shifting under strain, maintaining their structural integrity and reducing the risk of disconnection.

Tip: PET heat shrink tubing is particularly effective in applications where wires are exposed to vibrations or frequent movement, such as in automotive or industrial machinery.

How PET Tubing Enhances Mechanical Protection

PET tubing offers several advantages that contribute to its effectiveness in mechanical protection:

Strain Relief: By distributing stress evenly across the wire assembly, PET tubing minimizes the impact of tension and bending. This feature is essential in preventing wire breakage or damage.

Crack Resistance: The use of heat-shrinkable PET fibers enhances the durability of the tubing, making it resistant to cracks and wear over time.

Structural Integrity: PET tubing reinforces the overall structure of wire assemblies, ensuring they remain intact even under challenging conditions.

Heat and Insulation Management: The tubing balances electrical conductivity while managing heat, preventing overheating and ensuring consistent performance.

Applications in High-Stress Environments

Mechanical engineering studies highlight the effectiveness of PET heat shrink tubing in environments that demand high performance. Its ability to provide strain relief and mechanical support makes it indispensable in industries such as aerospace, automotive, and telecommunications. For example, in automotive wiring systems, PET tubing prevents wires from rubbing against sharp edges or vibrating components, reducing wear and tear.

The tubing's thermal stability further enhances its suitability for high-stress environments. It maintains its protective properties even when exposed to fluctuating temperatures, ensuring reliable performance in both indoor and outdoor applications.

By combining mechanical protection with strain relief, PET heat shrink tubing ensures the durability and efficiency of electrical systems. Its ability to prevent leaks, eliminate movement, and withstand mechanical stress makes it a trusted solution for safeguarding wires in demanding applications.

Benefits of PET Heat Shrink Tubing for Electrical Wire Protection

Durability and Longevity

PET heat shrink tubing offers exceptional durability, making it a long-lasting solution for electrical wire protection. Its robust material composition ensures resistance to wear and tear, even in demanding environments. This durability minimizes the need for frequent replacements, reducing maintenance costs over time. The tubing's ability to withstand mechanical stress, such as bending and pulling, further enhances its longevity.

In industrial and outdoor applications, where wires are exposed to harsh conditions, PET tubing provides reliable protection against abrasion and impact. Its crack-resistant properties ensure that the tubing maintains its structural integrity, even after prolonged use. This makes it an ideal choice for applications requiring consistent and reliable insulation over extended periods.

Note: The durability of PET heat shrink tubing contributes significantly to its effectiveness in safeguarding electrical systems, ensuring uninterrupted performance.

Resistance to Chemicals and Moisture

PET heat shrink tubing demonstrates remarkable resistance to chemicals and moisture, making it suitable for environments where exposure to harsh substances is common. It effectively withstands solvents, oils, and cleaning agents, ensuring reliable protection for sensitive components. This chemical resistance is particularly valuable in medical and industrial settings, where equipment often undergoes sterilization processes.

Property | Value |

|---|---|

Chemical Resistance | Resistant to pharmaceuticals, ensuring consistent dosing in drug delivery systems. |

Compliance | ISO 17665-1:2023 for high-temperature sterilization. |

Chemical/Solvent Resistance |

The tubing's moisture resistance prevents water ingress, which could compromise electrical insulation. This feature is critical for outdoor applications, such as telecommunications infrastructure, where wires are exposed to varying weather conditions. By protecting against both chemicals and moisture, PET tubing ensures the longevity and reliability of electrical systems.

Thermal Stability and High Dielectric Strength

PET heat shrink tubing excels in thermal stability, maintaining its performance across a wide temperature range. It can operate continuously at temperatures up to 150°C (302°F) and endure short-term exposure to 200°C (392°F). This thermal resilience makes it suitable for high-temperature applications, such as automotive and aerospace systems.

Property | Value |

|---|---|

Continuous Operating Temp | Up to 150°C (302°F) |

Short-Term Exposure | Up to 200°C (392°F) |

Dielectric Strength | > 4,000 V/mil |

Long-term use (cryogenic) | -196°C (-320.8°F)–135°C (275°F) |

Melting point | 235°C (455°F) |

The tubing also offers high dielectric strength, exceeding 4,000 V/mil, which ensures effective electrical insulation in high-voltage applications. This property prevents electrical leakage and enhances safety, making PET tubing a reliable choice for critical systems. Its ability to combine thermal stability with high dielectric strength underscores its effectiveness in providing reliable insulation under extreme conditions.

Professional Finish for Wire Assemblies

PET heat shrink tubing enhances the appearance of wire assemblies by creating a clean and professional finish. Its ability to shrink tightly around wires eliminates loose ends and irregularities, resulting in a streamlined and uniform look. This feature is particularly valuable in industries where aesthetics and functionality are equally important, such as consumer electronics and automotive manufacturing.

The tubing's transparency or color options allow engineers to match it with specific design requirements. Transparent PET tubing provides visibility for wire labels or markings, while colored variants help differentiate wires in complex systems. This customization improves both the visual appeal and the efficiency of wire management.

Tip: Using heat shrink tube with color coding simplifies troubleshooting and maintenance by making wire identification faster and more accurate.

PET heat shrinkable plastic tubing also contributes to a polished finish by concealing splices, connectors, and other imperfections. By covering these elements, it ensures that wire assemblies maintain a professional appearance even in exposed installations. This feature is especially beneficial in applications like medical devices, where both reliability and aesthetics are critical.

Feature | Benefit |

|---|---|

Tight Shrinkage | Eliminates loose ends and irregularities for a clean look. |

Color Options | Enhances wire identification and matches design requirements. |

Concealment of Imperfections | Covers splices and connectors for a polished appearance. |

The professional finish provided by PET tubing not only improves aesthetics but also reflects the quality and precision of the overall assembly. This attention to detail builds trust with end users and reinforces the reputation of manufacturers in competitive markets.

Choosing the Right PET Heat Shrink Tubing

Factors to Consider (Size, Shrink Ratio, Temperature Range)

Selecting the right PET heat shrink tubing requires careful evaluation of key factors to ensure optimal performance. Size is a critical consideration. The tubing must fit snugly over the wire or component before shrinking. Measuring the diameter of the wire and choosing tubing with an appropriate shrink ratio ensures a secure fit. Common shrink ratios, such as 2:1 or 4:1, indicate how much the tubing will contract when heated. For instance, a 2:1 ratio means the tubing will shrink to half its original diameter.

Temperature range is another essential factor. PET tubing must withstand the operating temperatures of the application. For high-temperature environments, such as automotive or aerospace systems, tubing with a range of -40°C to 150°C is ideal. Compatibility with sterilization processes, like steam, is also crucial in medical and industrial settings.

Description | |

|---|---|

Size | Measure carefully to match wire or component dimensions. |

Shrink Ratio | Common ratios include 2:1 or 4:1, indicating how much the tubing shrinks. |

Temperature Range | Ensure compatibility with operating and sterilization temperatures. |

Matching Tubing to Specific Electrical Needs

Matching PET heat shrink tubing to specific electrical and electronic applications involves understanding the requirements of the system. For instance, in high-voltage systems, tubing with high dielectric strength is essential to prevent electrical leakage. In environments exposed to moisture or chemicals, tubing with strong resistance to these elements ensures the protection of components.

Professionals should follow these steps for proper selection and installation:

Strip wire ends cleanly to avoid damaging the conductor.

Choose tubing with the correct size and material for the wire gauge.

Use a calibrated heat source to shrink the tubing evenly, starting from the center.

Inspect the tubing for proper adhesion and coverage after cooling.

Common Mistakes to Avoid

Errors during installation can compromise the effectiveness of PET heat shrink tubing. One common mistake is forgetting to slide the tubing onto the wire before splicing. This oversight often requires redoing the connection. Another frequent error is using tubing that is too short, leaving parts of the wire exposed. Professionals should always ensure the tubing is longer than the splice area for complete coverage.

Precision is vital in selecting and installing PET tubing. Dimensional accuracy, material compatibility, and proper handling techniques ensure reliable performance in electrical and electronic applications. By avoiding these mistakes, users can maximize the durability and efficiency of their systems.

PET heat shrink tubing offers a reliable solution for protecting electrical wires through its unique ability to shrink tightly around components when heated. This process ensures insulation, mechanical protection, and resistance to environmental factors, making it indispensable in industries like automotive, electronics, and medical devices. Its versatility extends to bundling wires, safeguarding against moisture, and providing strain relief, all while delivering a professional finish.

The growing demand for PET heat shrink tubing underscores its effectiveness. The global market is projected to reach $960 million by 2032, driven by its adoption in sectors such as automotive and electronics. With a compound annual growth rate of 5.8%, this material continues to prove its value in cost-effective and durable wire protection solutions.

For those wondering how does heat shrink tubing work, its mechanism is both simple and efficient. By applying heat, the tubing contracts to form a secure seal, ensuring long-lasting performance. Whether for industrial machinery or medical devices, PET heat shrink tubing remains a trusted choice for enhancing electrical safety and durability.

Explore the possibilities: PET heat shrink tubing combines functionality, durability, and cost-efficiency. It’s time to consider this innovative solution for your electrical systems.

FAQ

What is the typical shrink ratio for PET heat shrink tubing?

PET heat shrink tubing commonly features shrink ratios of 2:1 or 4:1. A 2:1 ratio means the tubing shrinks to half its original diameter when heated. Selecting the correct ratio ensures a snug fit around wires or components.

Can PET heat shrink tubing be used outdoors?

Yes, PET heat shrink tubing is suitable for outdoor use. Its resistance to UV radiation, moisture, and temperature fluctuations makes it ideal for protecting wires in harsh environmental conditions, such as telecommunications or renewable energy systems.

How do you install PET heat shrink tubing?

To install PET heat shrink tubing, slide it over the wire or component, then apply heat evenly using a heat gun. Start from the center and move outward to ensure uniform shrinkage. Allow the tubing to cool before inspecting the seal.

Is PET heat shrink tubing environmentally friendly?

PET heat shrink tubing is more environmentally friendly than PVC alternatives. It is recyclable and does not release harmful chemicals during disposal. This makes it a sustainable choice for industries prioritizing eco-friendly materials.

What industries benefit most from PET heat shrink tubing?

Industries such as automotive, aerospace, medical devices, and telecommunications benefit significantly from PET heat shrink tubing. Its durability, thermal stability, and chemical resistance make it indispensable for protecting wires in demanding applications.

Tip: Always choose tubing that matches the specific requirements of your application for optimal performance.

See Also

Understanding PET Heat Shrink Tubing for Electronic Applications

Applications of Heat Shrink Tubing for Electrical Wire Insulation

Comparing Medical and Industrial Grade Heat Shrink Tubing