Why PET Heat Shrink Tubing Matters for Radiopaque Marker Bands

PET heat shrink tubing plays a vital role in the functionality of radiopaque marker bands, especially in medical applications. Its ability to endure high-temperature sterilization, such as autoclaving at 121–135°C, ensures durability during repeated use. Advanced PET formulations, like those doped with carbon nanotubes, enhance cyclic fatigue resistance by 40%, making them ideal for demanding environments. Additionally, these materials meet stringent ISO standards, retaining elongation-at-break rates above 80% after exposure to sterilization doses. This combination of precision, protection, and resilience makes PET heat shrink tubing for radiopaque marker bands indispensable in modern healthcare.

Key Takeaways

PET heat shrink tubing handles high heat, staying strong during cleaning.

This tubing makes radiopaque marker bands easier to see in scans.

PET is safe to use with human tissue, lowering infection chances.

Its flexibility and accuracy make it great for small medical tools.

Meeting strict rules ensures PET tubing works well in healthcare.

The Role of PET Heat Shrink Tubing in Medical Applications

What is PET Heat Shrink Tubing?

PET heat shrink tubing is a specialized material designed to provide protection, insulation, and precision in various applications. Made from polyethylene terephthalate, it shrinks uniformly when exposed to heat, creating a tight and secure fit around objects. This tubing is known for its high tensile strength, excellent dielectric properties, and resistance to environmental factors. Its operating temperature range spans from -55℃ to +135℃, with a minimum shrink temperature of 60℃ and a maximum of 125℃. Shrink ratios typically range from 1.1:1 to 3:1, offering flexibility for diverse applications. These properties make PET heat shrink tubing indispensable in industries like healthcare, where precision and reliability are paramount.

Why PET is Ideal for Radiopaque Marker Bands

PET heat shrink tubing for radiopaque marker bands offers unmatched benefits in medical applications. Its thin walls and high tensile strength ensure durability without adding bulk, which is critical for minimally invasive procedures. The material’s high dielectric strength enhances safety by providing effective insulation. Additionally, PET tubing maintains its integrity under sterilization processes, ensuring long-term reliability. These features contribute to improving medical device accuracy, making PET the preferred choice for radiopaque marker bands used in critical for safe medical procedures.

Applications of Radiopaque Marker Bands in Medical Devices

Radiopaque marker bands, enhanced by PET heat shrink tubing, play a vital role in various medical devices. In cardiovascular interventions, they are used in catheter-based systems like balloon catheters and stent delivery devices, ensuring precision during procedures. Diagnostic imaging devices, such as MRI coils, rely on these bands to prevent imaging artifacts and improve accuracy. Neuromodulation devices, including spinal cord stimulators, use PET tubing to insulate micro-coils, ensuring long-term reliability. These applications highlight the tubing’s importance in improving medical device accuracy and supporting minimally invasive procedures.

How PET Heat Shrink Tubing Enhances Radiopaque Marker Bands

Improving Visibility in Medical Imaging

Radiopaque marker bands are essential for guiding medical professionals during imaging procedures. PET heat shrink tubing enhances these bands by providing a clear and consistent outline under imaging technologies like X-rays and fluoroscopy. The tubing’s uniform shrinkage ensures that the marker bands remain securely in place, maintaining their position and visibility. This precision is critical for safe medical procedures, as it allows healthcare providers to navigate complex anatomical structures with confidence. By improving medical device accuracy, PET tubing supports minimally invasive procedures, reducing risks and improving patient outcomes.

Ensuring Safety and Precision in Procedures

Safety and precision are paramount in medical applications. PET heat shrink tubing for radiopaque marker bands ensures that these bands perform reliably under demanding conditions. The tubing’s high tensile strength and resistance to environmental factors prevent deformation or displacement during use. This stability is vital for maintaining the accuracy of medical devices, especially in procedures requiring fine control. Additionally, the tubing’s dielectric properties provide insulation, reducing the risk of electrical interference. These features make PET tubing a critical component in ensuring the safety and effectiveness of medical interventions.

Enhancing Biocompatibility and Patient Safety

Biocompatibility is a key consideration in medical device design. PET heat shrink tubing meets stringent biocompatibility standards, ensuring it is safe for use in contact with human tissue. Its smooth surface minimizes the risk of irritation or injury, enhancing patient comfort during procedures. Furthermore, the tubing’s ability to withstand sterilization processes ensures that it remains free from contaminants, reducing the risk of infection. By combining durability, safety, and biocompatibility, PET tubing plays a vital role in supporting the safe and effective use of radiopaque marker bands in medical devices.

Key Benefits of PET Heat Shrink Tubing for Radiopaque Marker Bands

Durability and Resistance to Environmental Factors

PET heat shrink tubing demonstrates exceptional durability, making it ideal for radiopaque marker bands in medical applications. Its ability to withstand high-temperature sterilization methods, such as autoclaving and ethylene oxide treatments, ensures long-term reliability. According to ISO 17665-1:2023, PET tubing endures cyclical steam sterilization without degradation. Additionally, it retains over 80% of its elongation-at-break properties after exposure to 25 kGy irradiation doses, as per ISO 11137-2:2022.

The following table highlights key durability factors:

Evidence Type | Description |

|---|---|

Sterilization Resistance | Endures high-temperature sterilization without degradation. |

Mechanical Property Retention | Maintains mechanical properties post-irradiation. |

Durability in Reprocessing | Capable of ≥25 sterilization cycles without dimensional stability loss. |

These properties ensure that PET tubing remains effective even in demanding environments, supporting the reliability of medical devices.

Flexibility and Precision for Medical Applications

PET heat shrink tubing offers the flexibility and precision required for radiopaque marker bands in minimally invasive procedures. Its precise dimensional recovery ensures an accurate fit, which is critical for maintaining the accuracy of medical devices. The tubing’s flexibility allows it to adapt to various medical device designs, enhancing its versatility.

The table below outlines the properties that make PET tubing suitable for precision applications:

Property | Description |

|---|---|

Biocompatibility | Safe for use in medical applications, reducing adverse reactions. |

Chemical Resistance | Protects against bodily fluids and chemicals, ensuring durability. |

Flexibility | Adapts to diverse medical device designs. |

Precise Dimensional Recovery | Ensures accurate fit and performance in precision applications. |

These attributes make PET tubing indispensable for medical devices requiring high precision and adaptability.

Compatibility with Advanced Medical Technologies

PET heat shrink tubing aligns seamlessly with advanced medical technologies. Its biocompatibility ensures safe interaction with human tissue, meeting ISO 10993-5 and ISO 10993-10 standards. Furthermore, its chemical resistance protects against bodily fluids and sterilization chemicals, ensuring long-term performance.

The FDA’s 2025 initiative emphasizes the importance of recyclable materials in medical devices. PET tubing supports this goal by offering mono-material solutions that maintain sterilizability while promoting environmental compliance. This compatibility with modern medical advancements ensures that PET tubing remains a cornerstone of innovation in healthcare.

Manufacturing and Quality Assurance of PET Heat Shrink Tubing

Material Selection and High Standards

The selection of materials for PET heat shrink tubing is critical to ensuring its performance in medical applications. Manufacturers prioritize medical-grade PET that meets stringent standards for durability and biocompatibility. For instance, ISO 17665-1:2023 mandates that tubing materials must endure cyclical steam sterilization without degradation. A study published in the Journal of Medical Materials Research in 2023 revealed that unmodified PET exposed to over 50 hydrogen peroxide sterilization cycles experienced only a 12% reduction in tensile strength. This demonstrates the material's resilience under demanding sterilization conditions.

Regulatory compliance further underscores the importance of material selection. The European Union’s revised Medical Device Regulation (MDR 2023) requires rigorous leachable testing for tubing used in intravascular medical devices. These standards ensure that PET tubing remains safe and effective for use in minimally invasive procedures.

Evidence Type | Description |

|---|---|

Study | PET retains tensile strength after multiple sterilization cycles. |

Compliance Standard | ISO 17665-1:2023 ensures material durability under steam sterilization. |

Regulation | MDR 2023 mandates leachable testing for intravascular device tubing. |

Precision Engineering for Consistency

Precision engineering plays a pivotal role in the production of PET heat shrink tubing. Advanced manufacturing techniques, such as 3D printing and automation, have revolutionized the production process. These technologies enable rapid prototyping and ensure consistent quality across batches. Innovations in material science have also improved the thermal stability and shrinkage characteristics of PET tubing, enhancing its performance in medical devices.

The integration of IoT technology has further elevated manufacturing standards. Real-time monitoring systems detect defects during production, ensuring that each batch meets the required specifications. This level of precision is essential for maintaining the accuracy and reliability of medical devices, particularly in applications requiring fine control.

Testing and Certification for Medical Use

Testing and certification are integral to the quality assurance process for PET heat shrink tubing. Manufacturers conduct rigorous tests to verify the tubing's compliance with international standards. These tests include tensile strength assessments, biocompatibility evaluations, and sterilization resistance trials. Compliance with ISO and FDA standards not only ensures product safety but also enhances market competitiveness.

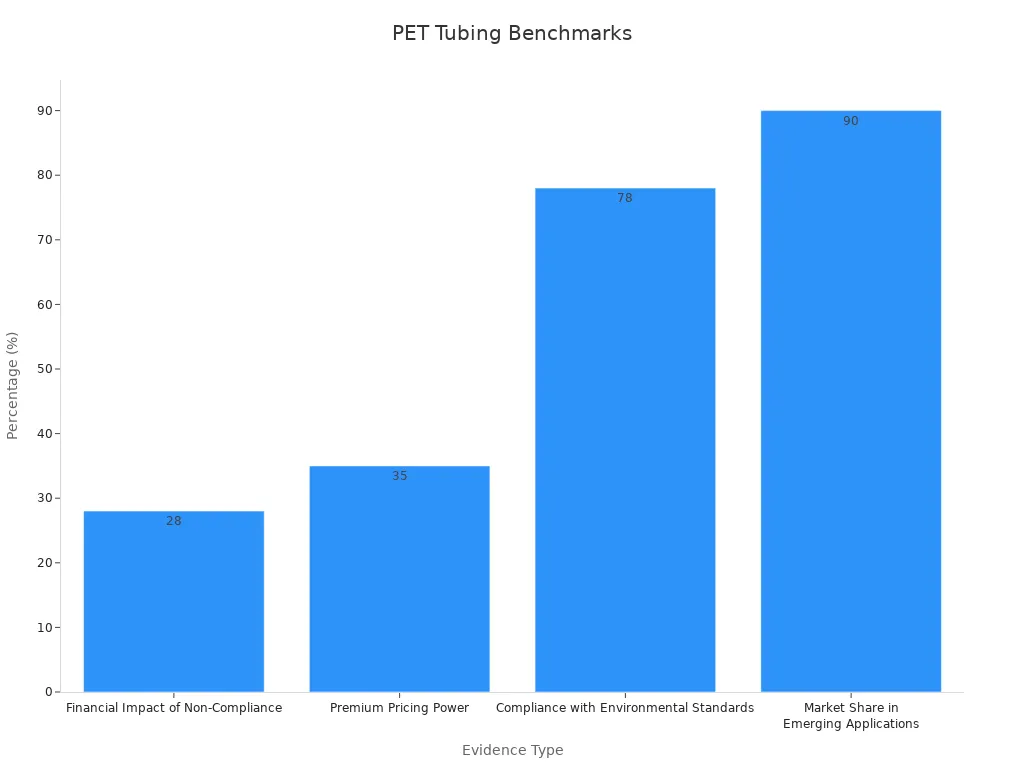

The financial impact of non-compliance highlights the importance of adhering to quality benchmarks. In 2023, recalls related to material delamination in PET tubing led to a 28% decline in stock prices for non-compliant suppliers. Conversely, companies achieving FDA, CE, and MHLW approvals reported a 35% premium pricing power in specialized segments. This demonstrates that maintaining high standards benefits both manufacturers and end-users.

Evidence Type | Details |

|---|---|

Financial Impact of Non-Compliance | Recalls due to material delamination caused significant financial losses in 2023. |

Premium Pricing Power | FDA/CE/MHLW approvals enable companies to charge premium prices in specialized markets. |

Compliance with Environmental Standards | 78% of OEM RFQ requirements now demand REACH SVHC-free material formulations. |

Market Share in Emerging Applications | Suppliers with compliance dominate emerging applications like biodegradable electronic skin patches. |

PET heat shrink tubing plays a pivotal role in enhancing the functionality and safety of radiopaque marker bands. Its durability, flexibility, and biocompatibility make it indispensable in modern medical devices. The growing demand for advanced materials in industries like electronics highlights its versatility. As medical technology advances, PET tubing will continue to support innovation by improving device performance and patient outcomes. This material’s ability to meet stringent clinical and regulatory standards ensures its lasting impact on healthcare and beyond.

FAQ

What makes PET heat shrink tubing biocompatible?

PET heat shrink tubing meets stringent biocompatibility standards, such as ISO 10993. Its smooth surface reduces irritation risks, while its resistance to sterilization ensures it remains free from contaminants. These properties make it safe for use in medical devices that contact human tissue.

How does PET tubing improve radiopaque marker band visibility?

PET tubing enhances visibility by securely holding radiopaque marker bands in place. Its uniform shrinkage ensures consistent positioning, which improves imaging clarity under X-rays or fluoroscopy. This precision helps medical professionals navigate complex procedures with greater confidence.

Can PET heat shrink tubing withstand repeated sterilization?

Yes, PET tubing endures multiple sterilization cycles, including autoclaving and ethylene oxide treatments. It retains mechanical properties, such as tensile strength and elongation, even after exposure to high temperatures or irradiation. This durability ensures long-term reliability in medical applications.

Why is PET tubing preferred for minimally invasive devices?

PET tubing offers thin walls, high tensile strength, and precise dimensional recovery. These features minimize bulk while maintaining durability, making it ideal for minimally invasive devices like catheters and stent delivery systems. Its flexibility also adapts to complex device designs.

Is PET heat shrink tubing environmentally sustainable?

PET tubing supports sustainability through its recyclability and compliance with environmental standards like REACH. Manufacturers increasingly use mono-material solutions to reduce waste. This aligns with global initiatives promoting eco-friendly medical device materials.

See Also

The Importance of Gamma Radiation Resistant Tubing in Healthcare

The Significance of Ultra-Thin PET Tubing in Medical Applications

Essential Information on PET Heat Shrink Tubing for Electronics

Evaluating FEP Tubing Against Alternatives for Radiation Treatment

Selecting Optimal Ultra-Thin PET Heat Shrink Tubing for Projects