How PET Heat Shrink Tubing Strengthens Medical Device Insulation and Design

PET heat shrink tubing plays a vital role in modern medical devices. You can rely on its exceptional ability to provide insulation, even for sensitive electrical components. Its durability ensures devices withstand mechanical stress during use. PET also resists heat, maintaining its form and function in demanding environments.

This tubing's biocompatibility makes it safe for patient-facing applications. It protects without compromising health standards. As a result, PET heat shrink tubing for medical device insulation not only strengthens the device but also enhances patient safety and performance reliability.

Key Takeaways

PET heat shrink tubing keeps medical devices safe from electrical problems.

It is strong and shields parts from damage, scratches, and tough cleaners.

The tubing is safe for use with patients, like in catheters.

It handles high heat and sterilization, working well in tough conditions.

Picking the right size and shrink level helps it fit tightly and protect parts.

Key Properties of PET Heat Shrink Tubing

Durability and Longevity

PET heat shrink tubing offers exceptional durability, making it a reliable choice for medical devices. Its mechanical strength protects delicate components from abrasion, punctures, and impacts. This ensures that devices maintain their structural integrity even under demanding conditions. Additionally, PET tubing resists chemical exposure, enduring cleaning agents and disinfectants without degrading. This chemical resistance contributes to its long-term usability in medical environments.

The material also withstands repeated sterilization cycles, a critical requirement for medical applications. Whether exposed to high temperatures or harsh sterilization methods, PET tubing retains its performance and shape. Its ability to prevent electrical interference and reduce the risk of short circuits further enhances device reliability.

Attribute | Description |

|---|---|

Prevents electrical interference and reduces the risk of short circuits. | |

Thermal Insulation | Shields components from temperature fluctuations. |

Mechanical Strength | Resists abrasion, punctures, and impacts. |

Structural Integrity | Provides a secure fit to prevent components from shifting. |

Sterilization Resistance | Withstands repeated sterilization without degrading. |

Chemical Resistance | Endures exposure to cleaning agents and disinfectants. |

This combination of properties ensures that PET heat shrink tubing supports the durability and longevity of medical devices, even in challenging environments.

Biocompatibility and Patient Safety

When it comes to medical devices, patient safety is paramount. PET heat shrink tubing meets stringent biocompatibility standards, making it suitable for use in patient-facing applications. It complies with ISO 10993-5, which limits cytotoxicity to less than 30% cell viability inhibition. It also adheres to ISO 10993-10, ensuring it does not cause irritation. For intravascular devices, PET tubing undergoes rigorous leachable testing as per MDR 2023 guidelines.

These certifications demonstrate that PET tubing minimizes risks to patients while maintaining high performance. Its non-toxic nature ensures that it can be safely used in applications such as catheters and other medical devices that come into direct contact with the body. By choosing PET tubing, you can prioritize both device functionality and patient well-being.

Key biocompatibility standards:

ISO 10993-5: Cytotoxicity limits (<30% cell viability inhibition)

ISO 10993-10: Irritation thresholds

MDR 2023: Rigorous leachable testing for intravascular devices

Heat Resistance and Shrink Ratio

PET heat shrink tubing excels in heat resistance, making it ideal for medical devices exposed to extreme temperatures. It can endure long-term use in temperatures ranging from -196°C to 135°C and short-term exposure up to 200°C. This wide temperature range ensures that the tubing remains functional in both cryogenic and high-heat environments.

The tubing's shrinkage capability is another standout feature. It can shrink up to 50% or more, providing a snug fit around components. This ensures secure insulation and protection. PET tubing shrinks effectively within a temperature range of 70°C to 190°C, with an optimal shrinking temperature of 150°C.

Property | Measurement |

|---|---|

Dielectric Strength | > 4,000 V/mil |

Long-term Temperature Range | -196°C to 135°C |

Short-term Temperature Range | Up to 200°C |

Melting Point | 235°C |

Shrinkage Capability | Up to 50% or more |

This heat resistance and precise shrink ratio make PET heat shrink tubing a versatile solution for insulating and protecting medical devices. It ensures that components remain secure and functional, even in extreme conditions.

Benefits of PET Heat Shrink Tubing for Medical Devices

Enhanced Insulation for Electrical Components

PET heat shrink tubing provides reliable electrical insulation, a critical feature for medical devices. It prevents electrical interference and safeguards sensitive components from short circuits. This ensures that devices operate consistently and safely, even in high-stakes environments like hospitals or surgical rooms.

The tubing's dielectric strength, exceeding 4,000 V/mil, makes it an excellent choice for electrical insulation in medical electronics. It creates a protective barrier that shields components from voltage fluctuations and external electrical noise. This is particularly important for devices like pacemakers and defibrillators, where uninterrupted performance can save lives.

Additionally, PET heat shrink tubing offers a snug fit around electrical components. Its precise shrink ratio ensures that no gaps or loose ends compromise insulation. This tight seal enhances the overall reliability of the device, reducing the risk of malfunctions caused by electrical issues.

Tip: When selecting PET heat shrink tubing for electrical insulation, ensure the tubing's shrink ratio matches the dimensions of your components for optimal performance.

Mechanical Protection and Abrasion Resistance

Medical devices often face mechanical stress during use, transport, and sterilization. PET heat shrink tubing acts as a robust shield, protecting delicate components from abrasion, punctures, and impacts. Its high tensile strength ensures that devices maintain their structural integrity, even in demanding conditions.

The tubing's durability extends to its resistance against wear and tear. It withstands repeated handling and exposure to harsh cleaning agents without degrading. This makes it ideal for devices that require frequent sterilization, such as surgical instruments and diagnostic tools.

PET tubing also excels in abrasion resistance, making it suitable for applications where components may rub against each other or external surfaces. For example, it protects wires and cables in compact medical devices, preventing damage that could compromise functionality.

Key Benefits of PET Tubing for Mechanical Protection:

Shields components from physical damage.

Resists wear and tear during repeated use.

Maintains performance after exposure to cleaning agents and sterilization cycles.

By incorporating PET heat shrink tubing, you can enhance the durability of your medical devices, ensuring they remain reliable and effective over time.

Improved Medical Device Performance and Design

The integration of PET heat shrink tubing significantly improves medical device performance and design. Its versatility allows it to address common manufacturing challenges, enhancing product quality and reliability. For instance, innovations in PET material technology have improved the performance of spring coil systems in medical devices, ensuring consistent functionality.

PET tubing also contributes to sleek and compact device designs. Its ability to shrink tightly around components minimizes bulk, making devices more ergonomic and user-friendly. This is particularly beneficial for wearable medical devices, where comfort and portability are essential.

Moreover, PET tubing supports precise process control during manufacturing. Products like AccuPath® demonstrate how advanced quality management can lead to high-performance medical devices. By using PET tubing, you can achieve a balance between functionality and aesthetics, creating devices that meet both clinical and user needs.

Note: PET heat shrink tubing not only enhances medical device performance but also ensures compliance with stringent industry standards, making it a reliable choice for manufacturers.

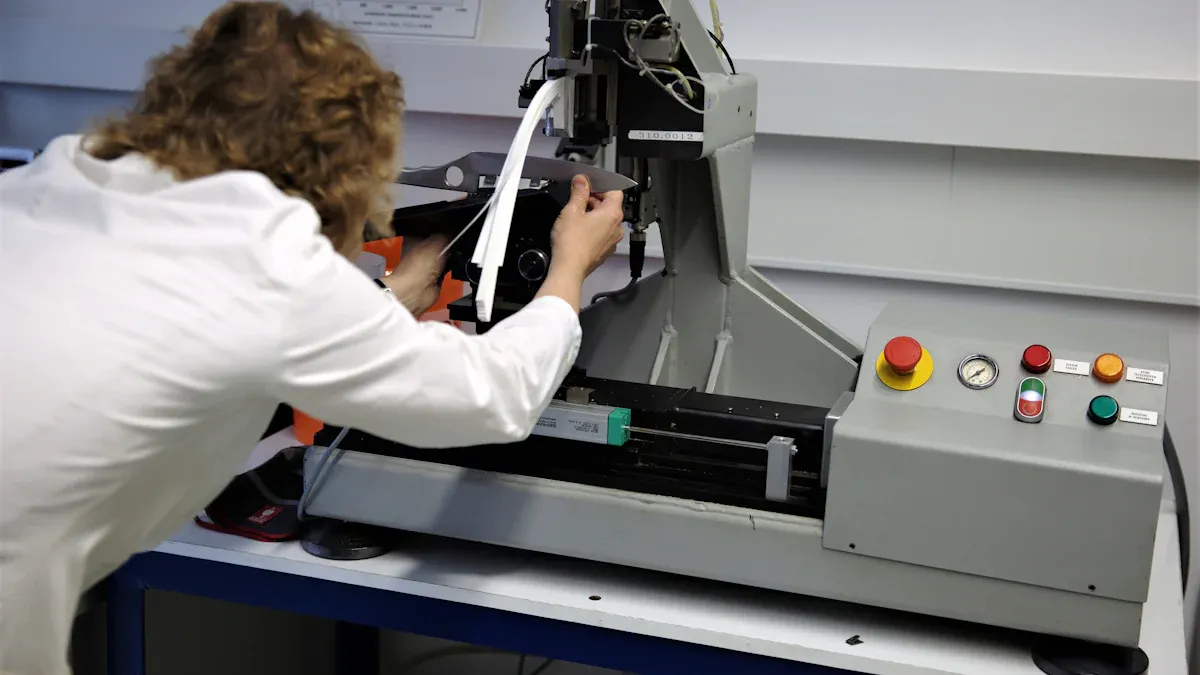

Applications of PET Heat Shrink Tubing in Medical Device Manufacturing

Catheters and Compact Medical Devices

PET heat shrink tubing plays a pivotal role in the development of catheters and other compact medical devices. Its ultra-thin design ensures minimal bulk, which is essential for devices used in minimally invasive procedures. This tubing provides a snug fit around catheter components, enhancing both insulation and mechanical protection. Its biocompatibility ensures patient safety, making it a trusted choice for intravascular applications.

The demand for ultra-thin PET heat shrink tubing has surged due to its critical role in advanced catheter systems. With an estimated market of 200 million units, this tubing supports innovations in medical device manufacturing. Its ability to withstand sterilization cycles and maintain structural integrity ensures reliable performance in high-stakes medical environments. By using PET tubing, you can achieve precision and durability in compact medical devices, meeting the growing need for minimally invasive solutions.

Electrical Insulation for Sensitive Components

PET heat shrink tubing excels in providing electrical insulation for sensitive components in medical equipment. Its high dielectric strength prevents electrical breakdown, ensuring uninterrupted device functionality. The tubing's volume resistivity further enhances its insulating properties, making it ideal for protecting components in devices like pacemakers and defibrillators.

Compliance with certifications such as UL/CSA 224 and ISO 10993 underscores the reliability of PET tubing in medical applications. These standards validate its safety and effectiveness, giving you confidence in its use for critical medical equipment. The tubing's precise shrink ratio ensures a tight seal around electrical components, reducing the risk of short circuits and enhancing overall device reliability.

Key performance metrics for PET heat shrink tubing in electrical insulation:

Dielectric strength for preventing electrical breakdown.

Volume resistivity for superior insulation.

Certifications like UL/CSA 224 and ISO 10993 for safety and reliability.

Protective Coverings for Wires and Tubing

PET heat shrink tubing serves as a protective covering for wires and tubing in medical equipment. Its abrasion resistance shields components from wear and tear, ensuring long-term durability. This is particularly important for devices that undergo frequent handling or sterilization.

The tubing's heat resistance allows it to maintain its protective properties even in extreme conditions. It prevents contamination by creating a barrier against external elements, which is crucial for maintaining the sterility of medical devices. By using PET tubing, you can protect wires and tubing from mechanical damage, contamination, and environmental stress, ensuring the reliability of your medical equipment.

In the healthcare sector, PET heat shrink tubing has become indispensable for insulation, protection, and contamination resistance. The rising use of electronic medical devices and increased investment in healthcare infrastructure have driven its adoption. Major players like Nordson MEDICAL and AccuPath continue to innovate, enhancing the biocompatibility and precision of medical-grade heat shrink tubing.

Practical Tips for Using PET Heat Shrink Tubing Effectively

Selecting the Right Size and Shrink Ratio

Choosing the correct size and shrink ratio for PET heat shrink tubing ensures optimal performance in medical devices. A tight fit is essential for insulation and protection. Aim for a gap of 15% or less between the tubing and the component. Avoid selecting tubing with a diameter more than 15% larger than the maximum diameter of the component.

The shrink ratio plays a critical role in achieving a secure fit. A target shrink ratio of 1.1:1 works well for most medical applications. Proper techniques can achieve a recovery capability of over 20%, ensuring the tubing conforms tightly to the component. For best results, maintain minimal shrinkage between 15% and 20%.

Specification | Details |

|---|---|

Tight fit | 15% gap or less |

Maximum diameter sizing | No larger than 15% above maximum diameter |

Target shrink ratio | 1.1:1 |

Recovery capability | >20% achievable with proper techniques |

Recommended shrinking temperature | 150°C (302°F) for most applications |

Shrinkage performance | Best with minimal shrinkage (15%-20%) |

By following these guidelines, you can protect and insulate components effectively, enhancing safety and durability in medical devices.

Ensuring Material Compatibility

Material compatibility is crucial for maintaining the reliability of medical devices. PET heat shrink tubing must align with the properties of the components it covers. Check for biocompatibility to ensure patient safety, especially for patient-facing applications. PET tubing complies with stringent standards, making it suitable for medical environments.

Consider the tubing's chemical resistance when selecting materials. PET tubing withstands exposure to cleaning agents and sterilization cycles without degrading. This ensures long-term reliability and quality. Always verify that the tubing's thermal and mechanical properties match the requirements of your device to avoid performance issues.

Best Practices for Heat Application

Applying heat correctly ensures PET tubing shrinks uniformly and securely. Use a heat source that provides consistent temperatures. The recommended shrinking temperature for PET tubing is 150°C (302°F). Avoid overheating, as excessive temperatures can compromise the tubing's structural integrity.

Position the heat source evenly around the tubing to achieve uniform shrinkage. Start at one end and work your way along the tubing to prevent air pockets or uneven fits. Monitor the process closely to ensure the tubing conforms tightly to the component. Proper heat application enhances the quality and reliability of medical devices, ensuring they perform as intended.

Tip: Use a heat gun with adjustable settings for precise temperature control during the shrinking process.

PET heat shrink tubing plays a vital role in advancing medical device design and functionality. Its high durability ensures long-term protection against mechanical stress and sterilization cycles. You can rely on its biocompatibility and sterilization resistance to enhance safety and patient outcomes. The tubing’s precision in manufacturing reduces errors, ensuring high-quality PET tubing fits intricate components perfectly. Its ability to withstand repeated sterilization while maintaining structural integrity makes it indispensable for medical applications. By leveraging its unique properties, you can optimize device performance and longevity, ensuring reliable solutions for healthcare needs.

FAQ

What makes PET heat shrink tubing ideal for medical devices?

PET heat shrink tubing offers durability, biocompatibility, and heat resistance. It protects sensitive components from mechanical stress and electrical interference. Its compliance with medical standards ensures patient safety, making it a reliable choice for various applications like catheters and electrical insulation.

How does PET tubing improve medical device performance?

PET tubing enhances performance by providing superior insulation, mechanical protection, and a snug fit. It minimizes bulk, enabling compact designs. Its resistance to sterilization and cleaning agents ensures long-term reliability, even in demanding medical environments.

Can PET heat shrink tubing withstand sterilization?

Yes, PET tubing resists high temperatures and harsh sterilization methods. It maintains its structural integrity and performance after repeated cycles, making it suitable for medical devices that require frequent cleaning and sterilization.

Is PET tubing safe for patient-facing applications?

PET tubing meets stringent biocompatibility standards, including ISO 10993. It is non-toxic and safe for use in patient-facing applications like catheters. Its compliance with medical regulations ensures it does not cause irritation or harm to patients.

What factors should you consider when selecting PET heat shrink tubing?

You should consider size, shrink ratio, and material compatibility. Ensure the tubing fits tightly around components and aligns with the thermal and mechanical requirements of your medical device. Proper selection enhances insulation, protection, and overall device reliability.

See Also

Key Uses of Ultrathin PET Heat Shrink Tubing in Healthcare

The Importance of Ultra-Thin PET Tubing in Medicine

Essential Insights on PET Heat Shrink Tubing for Electronics

The Significance of Gamma Resistant Tubing in Medical Applications