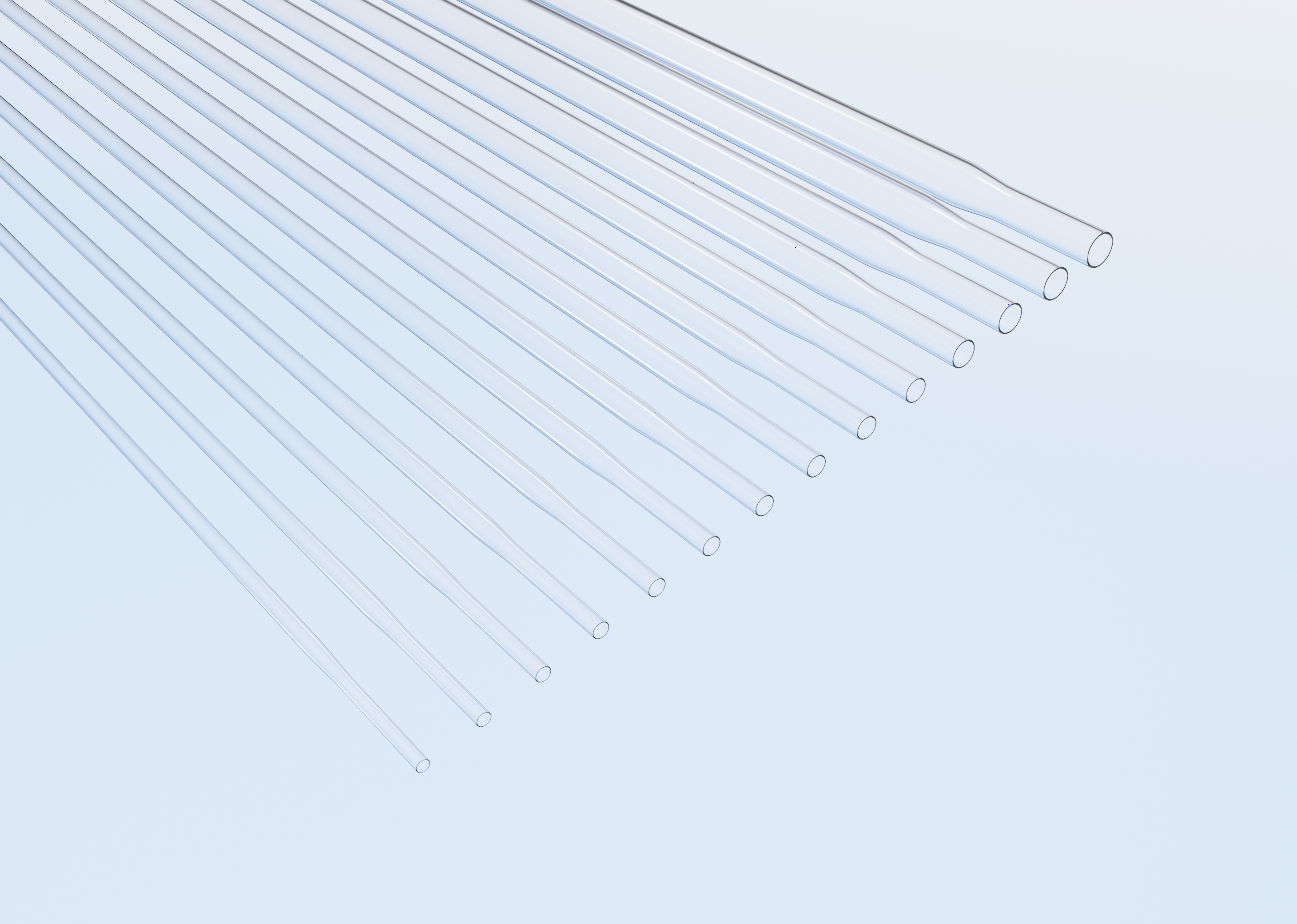

How PET Heat Shrink Tubing Enhances Medical Device Performance

PET heat shrink tubing for medical devices offers unparalleled precision, durability, and adaptability. Its high dielectric strength guarantees reliable electrical insulation, and its biocompatibility ensures safety for patient-facing applications. These attributes make PET heat shrink tubing for medical devices an essential element in the design of medical equipment. By improving functionality and ensuring safety, PET heat shrink tubing supports the performance requirements of contemporary medical devices, even in demanding environments.

Key Takeaways

PET heat shrink tubing is very strong and lasts long. It works well for medical tools that face wear and cleaning often.

It shrinks tightly and fits parts perfectly, helping tools like bendable catheters work better.

It is safe for patients and resists cleaning damage, lowering the chance of germs.

Makers can change the tubing to fit special needs, making it easier to use and identify in hospitals.

Using PET heat shrink tubing saves money by making tools last longer and reducing mistakes during production.

Properties of PET Heat Shrink Tubing

Material Composition and Strength

PET heat shrink tubing is crafted from polyethylene terephthalate, a material known for its exceptional strength and durability. This composition allows the tubing to withstand mechanical stress, making it ideal for demanding medical applications. Ultrathin-wall PET heat shrink tubing enhances flexibility while maintaining structural integrity. This unique combination ensures that medical devices can navigate complex anatomical pathways without compromising performance. Additionally, the tubing acts as a protective barrier for delicate components, extending the lifespan of medical devices and improving their reliability.

Shrink Ratio and Dimensional Accuracy

The shrink ratio of PET heat-shrink tubing plays a critical role in its functionality. This property determines how much the tubing can contract when exposed to heat, allowing it to conform precisely to the underlying components. Medical-grade heat-shrink tubing offers high dimensional accuracy, ensuring a snug fit around intricate device parts. This precision is particularly important for applications like variable-stiffness catheters, where different wall thicknesses are required to achieve the desired flexibility. The ability to customize the tubing's dimensions enhances its versatility across various medical devices.

Biocompatibility and Sterilization Resistance

Biocompatibility is a key property of PET heat shrink tubing, ensuring its safe use in patient-facing applications. The material meets stringent medical standards, including USP Class VI certification, confirming its compatibility with human tissue. Furthermore, PET heat-shrink tubing demonstrates resistance to multiple sterilization methods, such as gamma radiation, ethylene oxide (EtO), and autoclave processes. This resistance ensures that the tubing maintains its properties even after repeated sterilization cycles, making it suitable for reusable medical devices. Its BPA-free composition and compliance with FDA Title 21 regulations further underscore its safety and reliability in healthcare settings.

Uses of PET Heat Shrink Tubing in Medical Devices

Variable-Stiffness Catheters

PET heat shrink tubing plays a pivotal role in the development of variable-stiffness catheters. These catheters require precise control over flexibility to navigate complex vascular pathways during medical procedures. Ultrathin-wall PET heat shrink tubing provides the necessary structural reinforcement while maintaining a lightweight profile. Its ability to conform tightly to catheter components ensures dimensional accuracy, which is critical for achieving the desired stiffness gradient. This application highlights the tubing's adaptability in vascular and electrophysiology devices, where performance and reliability are paramount. Manufacturers like AccuPath leverage the properties of PET heat shrink tubing to create innovative catheter designs that enhance procedural outcomes.

Protective Coverings for Components

Heat shrink tubing serves as an effective protective barrier for sensitive components in medical devices. Ultrathin-wall PET heat shrink tubing shields delicate parts from mechanical stress, environmental factors, and contamination. Its durability ensures long-term protection, even in demanding clinical environments. Protective coverings for medical devices are essential for maintaining functionality and extending the lifespan of equipment. PET heat shrink tubing's resistance to sterilization processes further enhances its suitability for reusable devices. AccuPath's expertise in crafting high-quality tubing ensures that medical device manufacturers can rely on robust protective solutions tailored to their specific applications.

Electrical Insulation in Medical Electronics

Electrical insulation is another critical application of PET heat shrink tubing in medical devices. The tubing's high dielectric strength provides reliable insulation for wires and electronic components, ensuring safe operation in patient-facing equipment. Ultrathin-wall PET heat shrink tubing offers a compact solution that minimizes bulk while maintaining excellent insulating properties. This feature is particularly valuable in applications requiring precise electronic performance, such as diagnostic tools and monitoring devices. AccuPath's advanced manufacturing techniques ensure that their heat-shrink tubing meets stringent medical standards, delivering consistent quality and reliability for electrical insulation needs.

Tube Marking and Identification

PET heat shrink tubing offers a reliable solution for tube marking and identification in medical devices. This application is crucial for distinguishing between different components, ensuring proper usage during medical procedures. Manufacturers can apply permanent markings, such as serial numbers, logos, or measurement indicators, directly onto the tubing. These markings remain intact even after exposure to sterilization processes, ensuring long-term visibility and reliability.

Customization and labeling with PET heat shrink tubing allow manufacturers to tailor devices to specific requirements. For instance, color-coded tubing can help healthcare professionals quickly identify device types or sizes during critical procedures. This feature enhances workflow efficiency and reduces the risk of errors.

Tip: Using PET heat shrink tubing for labeling eliminates the need for adhesive labels, which may peel off or degrade over time.

The ability to customize markings on PET heat shrink tubing demonstrates its versatility across various medical applications. From catheter identification to labeling electronic components, this tubing ensures that devices remain organized and easy to use in high-pressure environments.

Structural Reinforcement and Braid Termination

Structural reinforcement is another significant use of PET heat shrink tubing in medical devices. The tubing provides additional strength to delicate components, ensuring they can withstand mechanical stress during operation. For example, braided catheters often require reinforcement at their termination points to prevent fraying or damage. PET heat shrink tubing offers a secure and durable solution for this purpose.

The tubing's high shrink ratio and dimensional accuracy allow it to conform tightly to braided structures, creating a seamless and robust termination. This process not only enhances the structural integrity of the device but also improves its overall performance. Medical devices that rely on braided components, such as guidewires and catheters, benefit greatly from this application.

Additionally, PET heat shrink tubing's resistance to sterilization processes ensures that reinforced components maintain their properties over time. This durability makes it an ideal choice for reusable medical devices, where long-term reliability is essential.

Note: Structural reinforcement with PET heat shrink tubing minimizes the risk of device failure, contributing to improved patient safety and outcomes.

The uses of PET heat shrink tubing in structural reinforcement and braid termination highlight its critical role in medical device manufacturing. Its ability to provide both protection and durability ensures that devices meet the rigorous demands of healthcare environments.

Benefits of PET Heat Shrink Tubing for Medical Devices

Durability and Longevity

PET heat shrink tubing offers exceptional durability, making it a reliable choice for medical devices. Its robust material composition allows it to withstand mechanical stress, environmental exposure, and repeated sterilization cycles. This durability ensures that medical devices maintain their functionality over extended periods, even in demanding clinical environments.

Ultrathin-wall PET heat shrink tubing enhances this longevity by providing a lightweight yet strong protective layer. It shields delicate components from wear and tear, reducing the risk of device failure. For reusable medical devices, this feature is particularly valuable, as it minimizes the need for frequent replacements.

Tip: Using heat shrink tubing for structural reinforcement can significantly extend the lifespan of medical devices, reducing long-term maintenance costs.

The long-lasting nature of PET heat shrink tubing ensures that medical devices remain reliable, contributing to better patient care and operational efficiency in healthcare settings.

Precision in Manufacturing

Precision is a critical factor in the production of medical devices, and PET heat shrink tubing excels in this area. Its high shrink ratio and dimensional accuracy allow it to conform tightly to intricate components, ensuring a perfect fit. This precision is essential for applications like variable-stiffness catheters, where even minor deviations can impact performance.

Ultrathin-wall PET heat shrink tubing provides manufacturers with the flexibility to create customized solutions. Its ability to achieve consistent wall thickness and uniform shrinkage enhances the quality of medical devices. This level of precision reduces manufacturing errors and ensures that devices meet stringent industry standards.

Note: The use of heat-shrink tubing in manufacturing not only improves accuracy but also streamlines production processes, saving time and resources.

By enabling precise component assembly, PET heat shrink tubing supports the development of innovative medical devices that deliver optimal performance in clinical applications.

Enhanced Safety and Patient Outcomes

Safety is paramount in healthcare, and PET heat shrink tubing plays a vital role in ensuring it. Its biocompatibility and resistance to sterilization processes make it suitable for patient-facing applications. This tubing minimizes the risk of contamination, ensuring that medical devices remain safe for use.

In addition to safety, ultrathin-wall PET heat shrink tubing contributes to improved patient outcomes. For example, its application in variable-stiffness catheters enhances procedural accuracy, reducing complications during surgeries. Similarly, its use in electrical insulation ensures the reliable operation of diagnostic tools, leading to more accurate results.

Callout: Heat shrink tubing not only protects components but also safeguards patients by ensuring the reliability of medical devices.

By combining safety with performance, PET heat shrink tubing supports healthcare professionals in delivering high-quality care. Its role in enhancing patient outcomes underscores its importance in modern medical device manufacturing.

Cost-Effectiveness in Production

PET heat shrink tubing offers significant cost advantages in medical device manufacturing. Its durability and resistance to wear reduce the need for frequent replacements, lowering long-term maintenance expenses. Manufacturers benefit from its ability to withstand repeated sterilization cycles, ensuring reusable devices maintain their functionality over time. This longevity minimizes production costs by extending the lifespan of medical equipment.

The material's high shrink ratio and dimensional accuracy also streamline manufacturing processes. PET heat shrink tubing conforms precisely to components, reducing the likelihood of errors during assembly. This precision eliminates the need for additional adjustments or corrections, saving both time and resources. By simplifying production workflows, manufacturers can achieve higher efficiency and output.

Bulk production of PET heat shrink tubing further enhances cost-effectiveness. The material's widespread availability and scalability make it an economical choice for large-scale manufacturing. Additionally, its versatility across various applications allows manufacturers to use a single material for multiple purposes, reducing inventory costs.

Tip: Investing in high-quality PET heat shrink tubing can lead to long-term savings by minimizing production errors and extending device lifespans.

The cost-effectiveness of PET heat shrink tubing makes it an indispensable component in the medical device industry. Its ability to balance affordability with performance ensures that manufacturers can produce reliable devices without exceeding budget constraints.

Versatility Across Applications

PET heat shrink tubing demonstrates remarkable versatility, making it suitable for a wide range of medical device applications. Its adaptability stems from its unique properties, including high dielectric strength, biocompatibility, and resistance to sterilization. These characteristics enable it to perform effectively in diverse roles, from structural reinforcement to electrical insulation.

Some common applications of PET heat shrink tubing include:

Variable-stiffness catheters, where it provides precise control over flexibility.

Protective coverings for delicate components, shielding them from mechanical stress and contamination.

Reinforcement of braided structures, ensuring durability and preventing fraying.

Tube marking and printing, offering permanent identification for medical devices.

Electrical insulation in diagnostic tools and monitoring equipment.

This wide range of uses highlights the material's adaptability in addressing the unique challenges of medical device manufacturing. For instance, its role in catheter production enhances procedural accuracy, while its application in electrical insulation ensures the safe operation of electronic devices.

Customization further enhances the versatility of PET heat shrink tubing. Manufacturers can tailor the tubing's dimensions, colors, and markings to meet specific requirements. This flexibility allows for the creation of specialized devices that cater to various medical needs.

Callout: The ability to customize PET heat shrink tubing ensures that it meets the exact specifications of different medical applications, enhancing both functionality and efficiency.

The versatility of PET heat shrink tubing underscores its importance in the medical device industry. Its ability to adapt to multiple applications ensures that manufacturers can rely on a single material to address diverse challenges, streamlining production and improving device performance.

PET heat shrink tubing has become a cornerstone of modern medical device innovation. Its unmatched precision, durability, and versatility make it indispensable in healthcare technology. Applications such as catheter reinforcement, electrical insulation, and structural protection highlight its critical role in enhancing device performance and patient safety.

Key Insight: By leveraging the unique properties of PET heat shrink tubing, manufacturers can design reliable, cost-effective devices that meet the rigorous demands of medical environments. This material continues to drive advancements in healthcare, ensuring better outcomes for patients and professionals alike.

FAQ

What makes PET heat shrink tubing suitable for medical devices?

PET heat shrink tubing offers high dielectric strength, biocompatibility, and resistance to sterilization. These properties ensure safety, durability, and reliability in medical applications. Its ability to conform precisely to components enhances device performance, making it indispensable in healthcare technology.

Can PET heat shrink tubing withstand repeated sterilization?

Yes, PET heat shrink tubing resists multiple sterilization methods, including gamma radiation, ethylene oxide (EtO), and autoclaving. This durability ensures that the tubing maintains its structural integrity and performance, even after repeated sterilization cycles, making it ideal for reusable medical devices.

How does PET heat shrink tubing improve patient safety?

PET heat shrink tubing enhances patient safety by providing reliable insulation, structural reinforcement, and biocompatibility. Its use in medical devices reduces the risk of contamination, device failure, and electrical hazards. These features contribute to safer procedures and better patient outcomes.

Is PET heat shrink tubing customizable for specific applications?

Manufacturers can customize PET heat shrink tubing to meet specific requirements. Options include varying dimensions, colors, and markings. This flexibility allows for tailored solutions, such as color-coded tubing for identification or precise dimensions for intricate components, enhancing functionality and efficiency.

What are the cost benefits of using PET heat shrink tubing?

PET heat shrink tubing reduces costs by extending device lifespans and minimizing maintenance needs. Its precision and durability streamline manufacturing processes, lowering production errors. Bulk production and versatility across applications further enhance its cost-effectiveness for medical device manufacturers.

Tip: Investing in high-quality PET heat shrink tubing ensures long-term savings and reliable device performance.

See Also

Exploring Key Uses of Ultrathin PET Heat Shrink Tubing

The Importance of Ultra-Thin PET Heat Shrink Tubing

FEP Heat Shrink Tubing: Revolutionizing Medical Device Manufacturing

The Significance of Gamma Radiation Resistant Heat Shrink Tubing

Advantages of FEP Heat Shrink Tubing for Healthcare Applications