The Advantages of PET Heat Shrink Tubing Over Other Materials

PET heat shrink tubing for low-temperature applications delivers exceptional performance and reliability. Its advanced properties set it apart from alternatives, making it an ideal choice for industries requiring precision and durability.

Dielectric strength surpasses 4,000 V/mil, offering robust protection against voltage fluctuations in medical devices.

It operates efficiently across temperatures from -196°C to 135°C and withstands short-term exposure up to 200°C.

With a melting point of 235°C and shrinkage capability exceeding 50%, it adapts to diverse industrial needs.

PET heat shrink tubing meets ISO 10993 biocompatibility standards, ensuring safety in medical applications. It retains its mechanical integrity even after multiple sterilization cycles, maintaining device reliability.

These factors highlight PET's unmatched role in low-temperature applications, where performance and adaptability are critical.

Key Takeaways

PET heat shrink tubing is great at stopping electricity leaks.

It works well in very hot or cold places, from -196°C to 135°C.

PET tubing can shrink up to 75%, fitting odd shapes easily.

This material is better for the planet since it can be recycled.

PET tubing costs more at first but lasts longer, saving money later.

Material Properties and Performance

PET vs. PVC Heat Shrink Tubing

PET heat shrink tubing offers superior performance compared to PVC heat shrink tubing in several key areas. PET tubing achieves a shrink ratio of up to 75%, allowing it to conform tightly to irregular shapes and sizes. In contrast, PVC tubing typically provides a lower shrink ratio of 2:1, limiting its adaptability in complex applications. PET also demonstrates higher temperature resistance, with a maximum operating temperature of 125ºC (257ºF), while PVC tubing operates effectively only up to 85ºC (185ºF).

Property | PET Heat Shrink Tubing | PVC Heat Shrink Tubing |

|---|---|---|

Shrink Ratio | Up to 75% | 2:1 |

Maximum Operating Temp | 125ºC (257ºF) | 85ºC (185ºF) |

These differences highlight PET's reliability in demanding environments, where higher temperature resistance and adaptability are essential. Its advanced properties make it the preferred choice for industries requiring precision and durability.

PET vs. Cold Shrink Tubing

Cold shrink tubing relies on pre-stretched elastomers to provide insulation and protection, but PET heat shrink tubing surpasses it in versatility and ease of use. PET tubing requires heat to shrink and conform to the desired shape, ensuring a tighter and more secure fit. Cold shrink tubing, while convenient, often lacks the precision and reliability needed for critical applications. PET tubing also excels in temperature resistance, maintaining its integrity across a wide range of temperatures, from -196°C to 135°C. Cold shrink tubing, on the other hand, may degrade under extreme conditions, reducing its effectiveness in long-term applications.

PET heat shrink tubing's adaptability and performance make it ideal for industries such as medical devices, electronics, and aerospace, where reliability and temperature resistance are non-negotiable.

Durability and Strength of PET Tubing

PET tubing stands out for its exceptional durability and tensile strength, outperforming alternative materials in rigorous testing. Its semi-crystalline structure provides unmatched resistance to wear and tear, ensuring long-term reliability in demanding environments. Laboratory tests reveal that PET tubing retains its tensile strength even after multiple sterilization cycles, while alternative materials often weaken under similar conditions.

Property | PET Tubing | Alternative Materials |

|---|---|---|

Durability | Varies, often less durable | |

Tensile Strength | Maintains strength after sterilization | Often weakens after sterilization |

Resistance to Sterilization | Retains integrity through multiple cycles | May degrade under sterilization |

Longevity | Long-term reliability in medical applications | Shorter lifespan in demanding environments |

PET tubing's durability ensures consistent performance in applications requiring repeated sterilization, such as medical devices. Its ability to withstand harsh conditions without compromising reliability makes it a top choice for industries prioritizing strength and longevity.

Thermal Stability and Shrink Temperature

Thermal stability and shrink temperature are critical factors that determine the performance of PET heat shrink tubing in industrial applications. PET tubing exhibits exceptional thermal stability, allowing it to maintain its structural integrity under temperature extremes. This characteristic ensures reliable performance in environments where other materials may fail.

The thermal properties of PET tubing are often evaluated using Differential Scanning Calorimetry (DSC). This method identifies thermal transitions, such as melting points and glass transition temperatures, which are essential for understanding material behavior. PET tubing demonstrates a sharp melting point at 235°C, ensuring consistent shrinkage and performance across a wide range of applications. The table below summarizes key thermal stability measurements for PET tubing:

Evidence Type | Description |

|---|---|

DSC Results | Highlights the importance of understanding thermal transitions in PET tubing. |

Baseline Shift | Explains how changes in sample weight and specific heat affect thermal stability. |

Sharp Endothermic Peaks | Warns against misinterpretations of thermal events that could misjudge material performance. |

PET tubing's ability to shrink at low temperatures, starting at approximately 90°C, makes it suitable for applications requiring precision and adaptability. This low shrink temperature minimizes the risk of damaging sensitive components during installation. Furthermore, PET tubing retains its mechanical properties even after exposure to high temperatures, ensuring long-term reliability.

Industries such as aerospace, medical devices, and electronics benefit from PET tubing's thermal stability. For example, in aerospace applications, the tubing withstands rapid temperature fluctuations without compromising its protective capabilities. Similarly, in medical devices, it endures repeated sterilization cycles while maintaining its structural integrity.

The combination of thermal stability and precise shrink temperature makes PET heat shrink tubing a superior choice for demanding environments. Its ability to perform under temperature extremes ensures consistent results, even in the most challenging conditions.

Environmental Impact

Sustainability of PET Material

PET heat shrink tubing demonstrates remarkable sustainability due to its ability to be sourced from recycled materials and renewable resources. Research highlights that PET can be derived from biomass, CO₂, or even orange peel, offering a lower environmental impact compared to first-generation raw materials. Life cycle assessments (LCA) reveal that PET's production process minimizes ecological harm while maintaining high performance.

"The polyester clothing value chain analysis emphasizes the necessity of life cycle assessments to evaluate the sustainability of biobased and CO₂-based solutions. Second-generation materials like orange peel provide a more sustainable option with lower environmental impact."

PET tubing's sustainability metrics make it a preferred choice for industries seeking eco-friendly solutions without compromising quality.

Recycling and Disposal Benefits

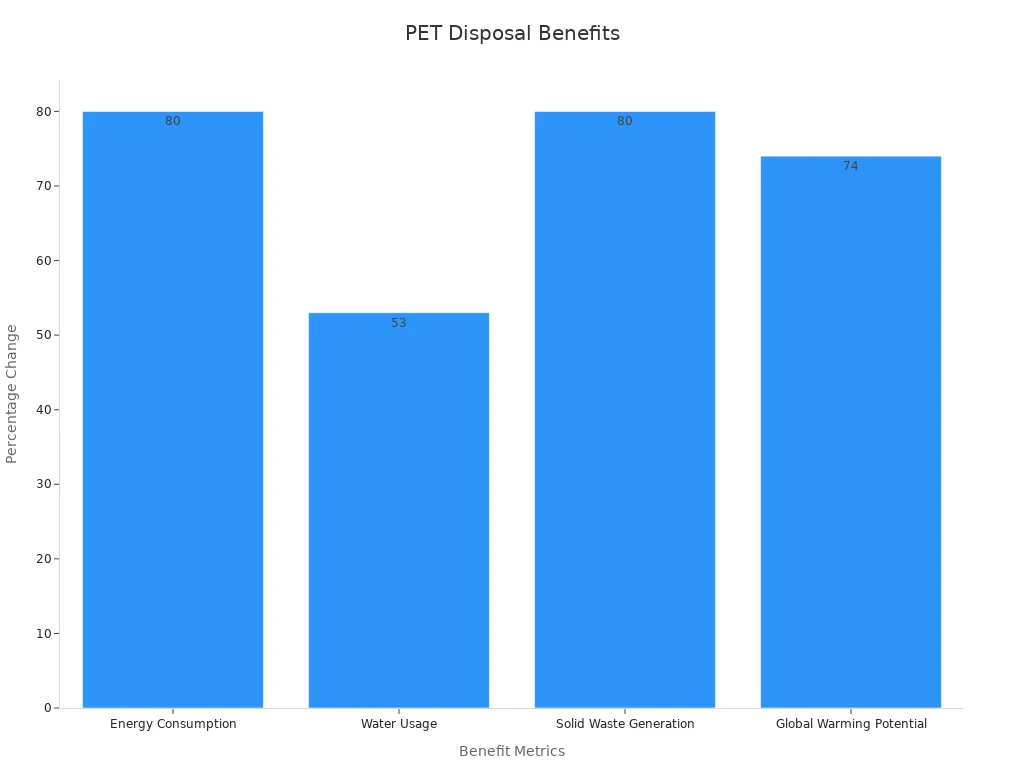

PET heat shrink tubing excels in recycling efficiency, reducing energy consumption and waste generation. Compared to other materials, PET requires 80% less energy and produces 80% less solid waste during recycling. Its water usage is 53% lower, and its global warming potential is 74% lower than alternatives like aluminum and glass.

Material | Energy Consumption | Water Usage | Solid Waste Generation | Global Warming Potential |

|---|---|---|---|---|

PET | 80% less | 53% less | 80% less | 74% lower |

Aluminum | Higher | N/A | N/A | N/A |

Glass | Higher | N/A | N/A | N/A |

PET's recyclability ensures reduced environmental impact, making it an ideal material for industries prioritizing sustainability.

Comparison with Non-Eco-Friendly Alternatives

PET heat shrink tubing outperforms non-eco-friendly alternatives in emissions and waste reduction. Its lightweight structure and low energy requirements during production result in significantly lower greenhouse gas emissions. Aluminum and glass, by comparison, generate two to three times the emissions of PET. This advantage extends to the disposal stage, where PET's recyclability further reduces its environmental footprint.

PET tubing's eco-friendly profile makes it a superior choice for industries aiming to reduce their carbon footprint while maintaining high-quality standards.

Cost Analysis

Initial Cost of PET Tubing vs. Alternatives

PET heat shrink tubing often has a slightly higher initial cost compared to materials like PVC or cold shrink tubing. This difference arises from the advanced properties and manufacturing processes of PET. However, the upfront expense is justified by its superior performance and durability. PET tubing offers higher temperature resistance, better shrink ratios, and enhanced reliability, which make it a worthwhile investment for critical applications.

In contrast, cold shrink tubing may appear more affordable initially. Yet, its limited temperature range and susceptibility to degradation under extreme conditions can lead to frequent replacements. Similarly, PVC tubing, while cost-effective, lacks the adaptability and strength of PET. Industries requiring precision and long-term reliability often find PET tubing to be the more economical choice in the long run.

Long-Term Value and Maintenance Savings

The long-term value of PET heat shrink tubing surpasses that of its alternatives. Its durability and resistance to wear and tear reduce the need for frequent replacements. PET tubing retains its structural integrity even after exposure to harsh environments, making it ideal for demanding applications.

Cold shrink tubing, on the other hand, may degrade over time, especially in extreme temperatures. This degradation increases maintenance costs and downtime. PVC tubing also requires more frequent replacements due to its lower temperature resistance and limited shrink capabilities. PET tubing's ability to withstand repeated sterilization cycles further enhances its value in industries like medical devices and aerospace.

Cost Efficiency in Industrial Applications

PET heat shrink tubing delivers exceptional cost efficiency in industrial applications. Its high shrink ratio and adaptability allow it to conform to complex shapes, reducing material waste. The tubing's thermal stability ensures consistent performance, minimizing the risk of equipment failure and costly repairs.

Cold shrink tubing, while convenient, often lacks the precision and reliability needed for critical applications. This limitation can lead to increased costs over time. PVC tubing, though inexpensive, may not meet the stringent requirements of industries like electronics and aerospace. PET tubing's superior performance and long-term reliability make it the preferred choice for cost-conscious industries.

Application Suitability

Performance in Low-Temperature Environments

PET heat shrink tubing demonstrates exceptional performance in low-temperature environments, making it a reliable choice for industries requiring precision and durability. Its ability to operate efficiently at temperatures as low as -196°C ensures consistent results in extreme conditions. This capability is particularly valuable in applications where other materials, such as cold shrink tubing, may fail due to brittleness or degradation.

The low shrink temperature of PET tubing, starting at approximately 90°C, minimizes the risk of damaging sensitive components during installation. This feature enhances its suitability for delicate applications, such as medical devices and electronics. PET tubing also retains its mechanical properties even after exposure to freezing temperatures, ensuring long-term reliability in demanding environments.

Industries like aerospace and automotive benefit significantly from PET tubing's low-temperature performance. For example, in aerospace applications, it withstands rapid temperature fluctuations without compromising its protective capabilities. Similarly, in automotive wiring systems, it provides insulation and protection in cold climates, ensuring consistent performance and reliability.

Versatility Across Industries

PET heat shrink tubing is renowned for its versatility, making it suitable for a wide range of industrial applications. Its high dielectric strength and chemical resistance allow it to perform reliably in diverse operational environments. Industries such as electrical, medical, automotive, and aerospace rely on PET tubing for its superior performance and adaptability.

Electrical: PET tubing provides insulation for energy-generating devices, ensuring safety and efficiency.

Medical: Its biocompatibility and resistance to sterilization make it ideal for manufacturing catheters and other medical devices.

Automotive: It protects and insulates wiring systems, enhancing durability and reliability in vehicles.

Aerospace: PET tubing delivers reliable performance in high-temperature environments, ensuring safety and functionality.

In addition to these industries, PET tubing is widely used in electronics, telecommunications, and other sectors requiring environmental protection and strain relief. Its ability to conform to complex shapes and sizes further enhances its versatility, making it a preferred choice for applications with unique requirements.

Ease of Installation and Use

PET heat shrink tubing offers ease of installation and use, making it a practical solution for various applications. Its high shrink ratio allows it to conform tightly to irregular shapes, ensuring a secure fit. Unlike cold shrink tubing, which relies on pre-stretched elastomers, PET tubing requires heat to shrink and adapt to the desired shape. This process ensures precision and reliability, even in critical applications.

The low shrink temperature of PET tubing simplifies the installation process, reducing the risk of errors or damage to sensitive components. Its lightweight structure and flexibility further enhance its usability, allowing for quick and efficient application. Industries such as electronics and telecommunications benefit from these features, as they enable seamless integration into complex systems.

PET tubing's ease of use extends to its maintenance requirements. Its durability and resistance to wear and tear minimize the need for frequent replacements, reducing downtime and maintenance costs. This combination of practicality and performance makes PET heat shrink tubing an ideal choice for industries seeking reliable and user-friendly solutions.

PET heat shrink tubing stands out as a superior choice for industrial applications. Its exceptional performance, unmatched reliability, and environmental benefits make it indispensable across industries. The tubing's ability to operate in low-temperature environments ensures consistent results, even in demanding conditions. Its cost-effectiveness further enhances its appeal, offering long-term value without compromising quality.

Industries seeking durable and eco-friendly solutions can rely on PET heat shrink tubing to meet their needs. Its reliability and adaptability make it a top contender for critical applications.

Choosing PET heat shrink tubing ensures enhanced performance while reducing environmental impact.

FAQ

What is PET heat shrink tubing made of?

PET heat shrink tubing is made from polyethylene terephthalate, a thermoplastic polymer. This material offers high tensile strength, excellent thermal stability, and chemical resistance, making it suitable for demanding industrial applications.

How does PET tubing compare to PVC in terms of shrink ratio?

PET tubing achieves a shrink ratio of up to 75%, conforming tightly to irregular shapes. PVC tubing typically offers a lower shrink ratio of 2:1, limiting its adaptability in complex applications.

Is PET heat shrink tubing environmentally friendly?

Yes, PET tubing is eco-friendly. It can be sourced from recycled materials and renewable resources. Its recyclability reduces energy consumption, waste generation, and greenhouse gas emissions compared to non-eco-friendly alternatives.

Can PET tubing withstand extreme temperatures?

PET tubing operates efficiently across temperatures from -196°C to 135°C. It also withstands short-term exposure up to 200°C, making it ideal for applications requiring thermal stability.

What industries benefit most from PET heat shrink tubing?

Industries such as aerospace, medical devices, automotive, and electronics benefit from PET tubing. Its versatility, durability, and thermal stability make it suitable for applications requiring precision and reliability.

See Also

Essential Insights on PET Heat Shrink Tubing for Electronics

Advantages of Using FEP Heat Shrink Tubing in Healthcare

Selecting the Ideal Ultra-Thin PET Heat Shrink Tubing for Projects

The Importance of Ultra-Thin PET Heat Shrink Tubing in Medicine

Finding the Right FEP Biocompatible Heat Shrink Tubing for Use