Avoid electronic failures with PET heat shrink tubing

PET heat shrink tubing plays a critical role in safeguarding electronic components. It provides a robust layer of insulation that prevents electrical faults, ensuring the reliability of sensitive devices like pacemakers and defibrillators. By forming a barrier against dust and moisture, it minimizes contamination and maintains performance in sterile environments. The tubing also protects delicate parts from mechanical stress, which is vital for tools such as robotic surgical instruments. Its ability to withstand extreme temperatures ensures consistent functionality during sterilization and in challenging conditions.

Key Takeaways

PET heat shrink tubing keeps electronics safe from water and rust. It helps them work well in different places.

This tubing gives great electrical insulation. It stops short circuits and makes devices like medical tools safer.

Using PET heat shrink tubing makes electronics last longer. It lowers repair costs and reduces how often fixes are needed.

PET is stronger than PVC and other materials. It resists damage and chemicals, making it better for tough jobs.

Buying PET heat shrink tubing saves money over time. Its protection helps avoid big costs later.

Key Benefits of PET Heat Shrink Tubing

Durability and Resistance to Environmental Factors

PET heat shrink tubing offers exceptional durability and flexibility, making it a reliable choice for protecting electronic components. Its ability to withstand extreme temperatures ensures consistent performance in both high-heat and freezing conditions. For instance, in medical environments, this tubing maintains its protective properties during sterilization processes and in cold storage. Furthermore, its resistance to abrasion and moisture enhances the longevity of devices, even in harsh environments. These qualities make it indispensable for industries like healthcare, automotive, and aerospace, where reliability is critical.

AccuPath's PET heat shrink tubing stands out for its superior chemical resistance. It effectively withstands exposure to harsh cleaning agents and sterilants, ensuring that sensitive equipment remains protected. This durability not only reduces the risk of environmental damage but also minimizes maintenance costs over time.

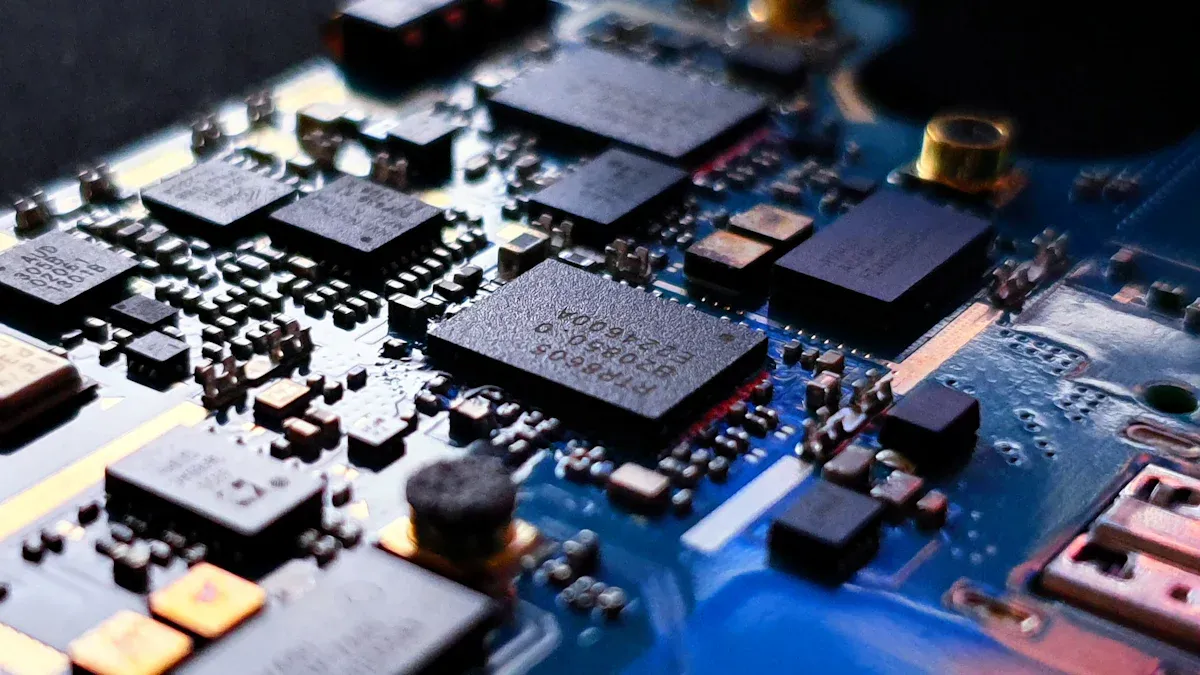

Electrical Insulation for Enhanced Safety

Safety is a top priority in electronic applications, and PET heat shrink tubing excels in providing robust electrical insulation. By creating a secure barrier around wires and components, it prevents short circuits and electrical damage. This insulation is particularly important in devices where even minor electrical faults could lead to significant failures or safety hazards.

AccuPath's PET heat shrink tubing ensures reliable electrical insulation, offering peace of mind to manufacturers and end-users alike. Its consistent performance under varying conditions makes it a trusted solution for enhancing the safety of electronic devices.

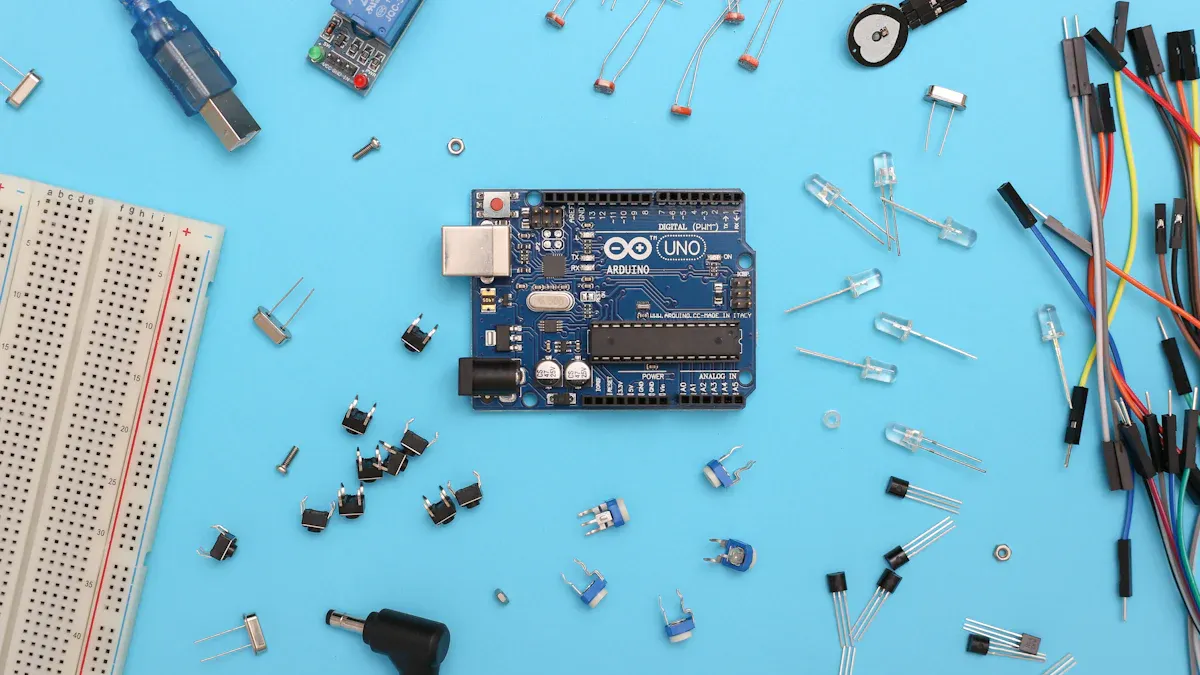

Versatility Across Various Applications

The versatility of PET heat shrink tubing is evident in its widespread use across multiple industries. From protecting delicate medical devices to insulating automotive wiring, this tubing adapts to diverse requirements. Its excellent temperature resistance and chemical resilience make it suitable for demanding applications, such as aerospace systems and industrial machinery.

The global demand for PET heat shrink tubing reflects its adaptability. Industries like electrical and electronics, automotive, and healthcare rely on specialized solutions to meet their unique needs. AccuPath's PET heat shrink tubing offers tailored options that cater to these varied applications, ensuring optimal performance and reliability.

How PET Heat Shrink Tubing Prevents Electronic Failures

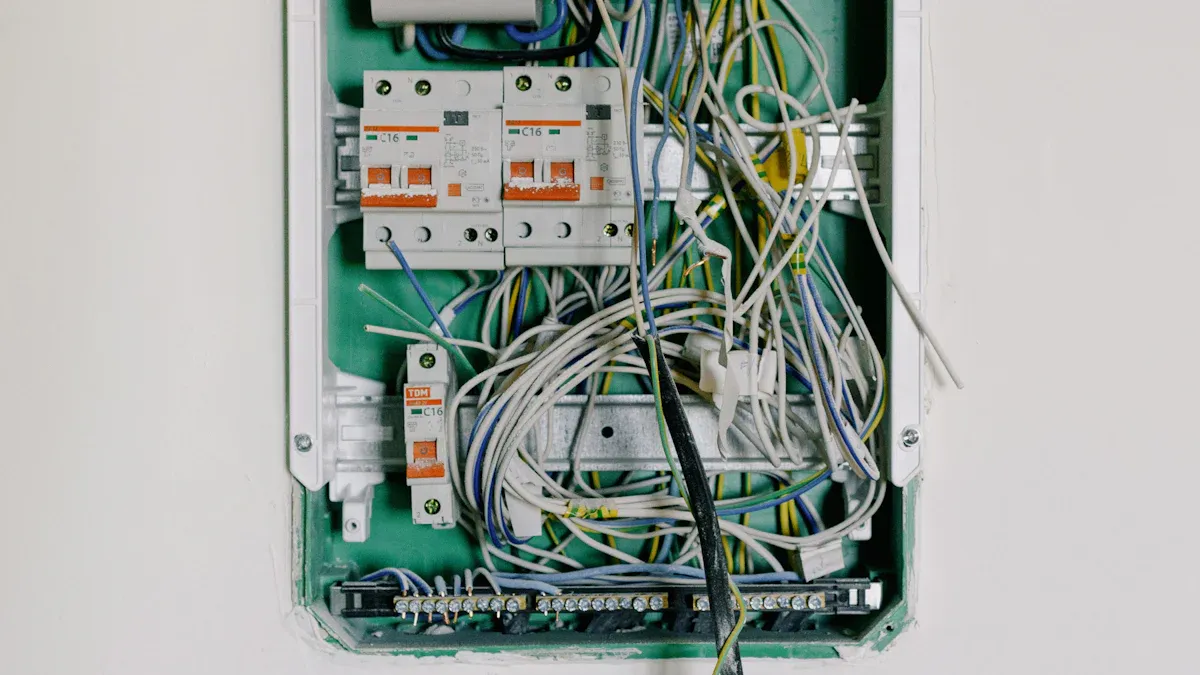

Protection Against Moisture and Corrosion

PET heat shrink tubing offers exceptional protection against moisture and corrosion. Its moisture resistance ensures that electronic components remain safe in humid or wet environments. This is particularly important for outdoor applications or devices exposed to fluctuating temperatures, where condensation can form. By creating a tight seal around wires and connectors, the tubing prevents water ingress and reduces the risk of rust or corrosion.

The chemical resistance of PET heat shrink tubing further enhances its protective capabilities. It withstands exposure to cleaning agents, oils, and other corrosive substances, making it ideal for industrial and medical applications. AccuPath's PET heat shrink tubing excels in providing this level of protection, ensuring that sensitive components remain functional and reliable over time.

Prevention of Short Circuits and Electrical Damage

Short circuits and electrical damage can lead to costly repairs or device failures. PET heat shrink tubing minimizes these risks by insulating wires and connections. Its heat shrink material conforms tightly to the shape of the components, creating a secure barrier that prevents accidental contact between conductive parts.

This insulation is critical for protecting electrical components in high-stakes environments, such as medical devices or aerospace systems. AccuPath's PET heat shrink tubing provides consistent performance, ensuring that electronic systems operate safely and efficiently. Its durability and reliability make it a trusted choice for manufacturers seeking to enhance the safety of their products.

Prolonged Lifespan of Electronic Components

The use of PET heat shrink tubing significantly extends the lifespan of electronic components. By offering protection against environmental factors, electrical damage, and mechanical stress, it ensures that devices remain operational for longer periods. This reduces the need for frequent repairs or replacements, saving both time and money.

In addition to its protective qualities, PET heat shrink tubing simplifies the bundling of cables and harnessing of wires. This organized approach minimizes wear and tear, further contributing to the longevity of the components. AccuPath's PET heat shrink tubing stands out for its superior quality, making it an excellent investment for those looking to protect electrical components and maximize their lifespan.

Why PET is Superior to Other Materials

Comparison with PVC and Other Heat Shrink Tubing Options

PET heat shrink tubing outperforms PVC and other materials in several key areas. Its superior durability makes it a reliable choice for protecting sensitive components. Unlike PVC, which can become brittle over time, PET maintains its flexibility and strength even in extreme temperatures. This makes it ideal for applications requiring consistent performance in harsh environments.

Another advantage of PET heat shrink tubing is its resistance to chemicals and abrasion. PVC and other materials often degrade when exposed to cleaning agents or industrial solvents. PET, on the other hand, provides long-lasting protection for electronic components, even in demanding conditions. This resilience ensures that devices remain functional and safe.

The environmental impact of PET also sets it apart. PET heat shrink tubing is more eco-friendly than PVC, as it produces fewer harmful byproducts during manufacturing and disposal. This makes it a preferred choice for industries aiming to reduce their environmental footprint.

Cost-Effectiveness and Long-Term Value

The cost-effectiveness of PET heat shrink tubing lies in its durability and performance. While the initial cost may be slightly higher than PVC, its long-term benefits outweigh the expense. PET's ability to protect components from moisture, corrosion, and mechanical stress reduces the need for frequent repairs or replacements. This translates to significant savings over time.

PET heat shrink tubing also simplifies maintenance. Its robust insulation properties minimize the risk of electrical failures, ensuring that devices operate efficiently. By extending the lifespan of electronic components, PET provides excellent value for manufacturers and end-users alike.

Industries that rely on high-performance materials, such as aerospace and healthcare, benefit greatly from PET heat shrink tubing. Its reliability and versatility make it a cost-effective solution for protecting critical components in these fields.

PET heat shrink tubing provides essential protection for electronic components. Its durability shields devices from environmental hazards, while its electrical insulation ensures safety and reliability. This tubing adapts to various applications, making it a versatile solution for industries like healthcare, automotive, and aerospace. By using PET heat shrink tubing, manufacturers can extend the lifespan of components, reduce maintenance costs, and maintain optimal device performance. Its superior qualities make it an indispensable choice for safeguarding electronics against potential failures.

FAQ

What is PET heat shrink tubing used for?

PET heat shrink tubing provides protection for electrical components. It insulates wires, shields cables from environmental damage, and prevents short circuits. Industries like healthcare, automotive, and aerospace rely on it to ensure the safety and longevity of their devices.

How does PET heat shrink tubing improve electrical safety?

PET heat shrink tubing enhances electrical safety by creating a secure insulation layer around wires and cables. This prevents accidental contact between conductive parts, reducing the risk of short circuits and electrical failures. Its durability ensures consistent performance in demanding environments.

Can PET heat shrink tubing withstand extreme conditions?

Yes, PET heat shrink tubing performs well in extreme conditions. It resists high and low temperatures, moisture, and chemicals. This makes it suitable for applications in harsh environments, such as industrial machinery, outdoor electrical systems, and medical devices requiring sterilization.

How does PET heat shrink tubing compare to PVC?

PET heat shrink tubing offers superior durability and insulation compared to PVC. It resists chemicals, abrasion, and extreme temperatures better. Unlike PVC, PET maintains flexibility over time, making it a more reliable choice for protecting wires and cables in critical applications.

Is PET heat shrink tubing cost-effective?

PET heat shrink tubing provides long-term value. Its durability reduces the need for frequent repairs or replacements. By protecting electrical components and extending their lifespan, it minimizes maintenance costs. This makes it a cost-effective solution for industries requiring reliable insulation.

See Also

Key Insights on PET Heat Shrink Tubing for Electronics

Important Guidelines for Working with FEP Heat Shrink Tubing

Selecting the Right Ultra-Thin PET Heat Shrink Tubing

The Importance of Ultra-Thin PET Heat Shrink Tubing in Healthcare