What is PET Heat Shrink Tubing and Its Role in Electrical Insulation

PET heat shrink tubing for electrical insulation serves as a reliable solution for safeguarding electrical components. Made from polyethylene terephthalate, this material offers exceptional insulation, chemical resistance, and mechanical strength. Its ability to shrink tightly around wires and connectors ensures secure coverage, reducing the risk of electrical failures.

The global PET heat shrink tubing for electrical insulation market was valued at $1.4 billion in 2023 and is projected to reach $2.3 billion by 2032. This growth reflects increasing demand for protective solutions in electronics, automotive, and healthcare industries. Technological advancements, such as flame-retardant properties, further enhance its appeal.

Industries rely on PET heat shrink tubing for electrical insulation due to its versatility and long-term durability. It not only prevents short circuits but also withstands harsh environmental conditions, making it indispensable for electrical insulation.

Key Takeaways

PET heat shrink tubing is great for stopping short circuits. It also protects wires from damage caused by the environment.

It has strong electrical insulation and handles heat well, making it perfect for cars, electronics, and healthcare tools.

The tubing is affordable and lasts a long time. This means fewer replacements and lower repair costs.

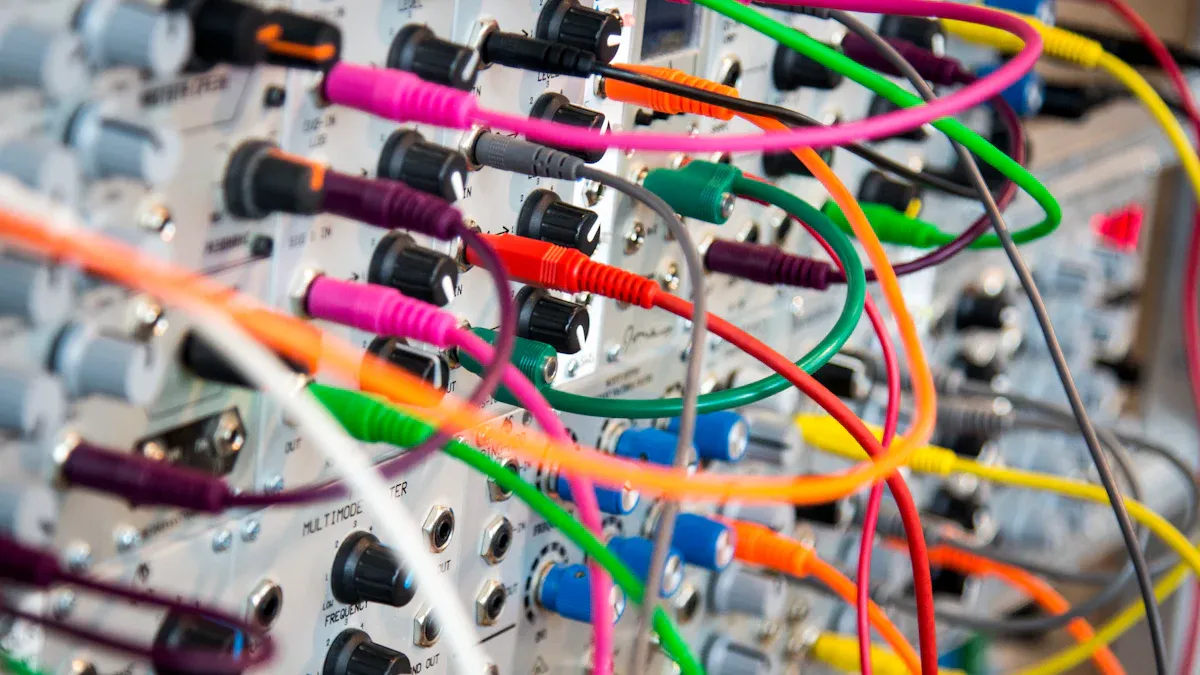

PET heat shrink tubing can be used in many ways. It comes in different sizes and colors to fit various needs.

It follows safety rules, so it’s safe for delicate places like medical devices.

What is PET Heat Shrink Tubing?

PET heat shrink tubing, short for polyethylene terephthalate heat shrink tubing, is a specialized form of heat shrinkable plastic tubing. It is widely used for electrical insulation and protection due to its unique material properties and reliable performance. This tubing is designed to shrink when exposed to heat, creating a tight and secure fit around wires, cables, and other components. Its versatility and durability make it a preferred choice across various industries.

Material Properties of PET

Polyethylene terephthalate (PET) is a thermoplastic polymer known for its exceptional strength and resilience. These properties make it an ideal material for heat shrink tubing. PET exhibits high tensile strength, excellent chemical resistance, and remarkable thermal stability. It can withstand continuous operating temperatures up to 150°C (302°F) and short-term exposure to temperatures as high as 200°C. Additionally, PET offers superior dielectric strength, exceeding 4,000 V/mil, ensuring reliable electrical insulation.

The following table highlights the technical measurements and benchmarks that demonstrate PET's performance:

Measurement Type | Description |

|---|---|

Mechanical Strength | Exhibits high tensile strength and abrasion resistance for demanding applications. |

Chemical Resistance | Resistant to a wide range of chemicals, oils, and solvents for protection. |

Thermal Stability | Withstands continuous operating temperatures up to 150°C (302°F). |

Tight Conformity | Conforms tightly to the shape of objects for secure protection. |

Cost-Effectiveness | Generally more cost-effective compared to FEP, suitable for budget-conscious applications. |

These properties ensure that PET heat shrink tubing performs reliably in challenging environments, providing long-term protection and insulation.

How Heat Shrink Tubing Works

Heat shrink tubing operates on a simple yet effective principle. During manufacturing, the tubing is expanded and then cooled to retain its expanded shape. When exposed to heat, the tubing shrinks back to its original size, tightly conforming to the shape of the object it covers. This process creates a secure and protective layer around wires, cables, or connectors.

The shrinking capability of PET heat shrink tubing is particularly impressive, with the ability to reduce its size by up to 50% or more. This ensures a snug fit, even for irregularly shaped components. The tubing's tight conformity not only enhances insulation but also provides mechanical protection against abrasion and environmental factors.

Why PET is Ideal for Electrical Insulation

PET heat shrink tubing stands out as an ideal choice for electrical insulation due to its combination of material properties and performance characteristics. Its high dielectric strength ensures effective insulation, preventing electrical failures and short circuits. The tubing's chemical resistance protects components from exposure to oils, solvents, and other corrosive substances, while its thermal stability allows it to perform reliably in high-temperature environments.

Moreover, PET's versatility in sizes and colors makes it suitable for a wide range of applications, from automotive wiring to medical devices. Its cost-effectiveness further enhances its appeal, offering a reliable and budget-friendly solution for insulation needs.

The following table summarizes the unique properties of PET used in heat shrink tubing:

Property | Measurement |

|---|---|

Dielectric Strength | > 4,000 V/mil |

Long-term Temperature Range | -196°C to 135°C |

Short-term Temperature Range | Up to 200°C |

Melting Point | 235°C |

Shrinkage Capability | Up to 50% or more |

These attributes, combined with PET's durability and resistance to wear, make it a trusted material for heat shrink tubing in various industries.

PET Heat Shrink Tubing for Electrical Insulation

Insulating Wires and Cables

PET heat shrink tubing plays a vital role in insulating wires and cables. Its ability to shrink tightly around electrical components ensures reliable coverage, reducing exposure to external elements. This insulation prevents moisture, dust, and chemicals from compromising the integrity of wires and cables. PET’s high dielectric strength further enhances its effectiveness, providing a robust barrier against electrical currents that could lead to failures.

Industries increasingly adopt PET heat shrink tubing for electrical insulation due to its versatility. It accommodates various wire sizes and shapes, making it suitable for automotive wiring systems, industrial machinery, and consumer electronics. Additionally, PET’s thermal stability allows it to perform well in environments with fluctuating temperatures, ensuring long-term protection for wires and cables.

Protecting Electrical Connections

Electrical connections require secure and durable protection to maintain system reliability. PET heat shrink tubing offers an effective solution by conforming tightly to connectors, creating a protective seal. This seal prevents contaminants such as oil, solvents, and dust from infiltrating the connections, which could lead to corrosion or reduced performance.

The increasing adoption of PET heat shrink tubing in industries like healthcare and electronics highlights its reliability. For instance, PET tubing complies with standards such as ISO 13485 and FDA regulations, ensuring safety and performance in medical devices. Its RoHS compliance further guarantees the absence of hazardous substances, making it a trusted choice for sensitive applications.

PET heat shrink tubing also provides mechanical protection, shielding electrical connections from physical damage caused by vibration or abrasion. This durability ensures that connections remain intact even in demanding environments, such as automotive engines or industrial equipment.

Preventing Short Circuits and Failures

Short circuits and electrical failures pose significant risks to equipment and safety. PET heat shrink tubing minimizes these risks by offering reliable insulation and protection. Its high dielectric strength prevents unintended electrical contact between wires, reducing the likelihood of short circuits.

The tubing’s ability to shrink tightly around components ensures consistent coverage, even for irregularly shaped parts. This tight conformity eliminates gaps that could expose wires or connectors to external hazards. PET’s chemical resistance further enhances its protective capabilities, shielding components from corrosive substances that could compromise insulation.

PET heat shrink tubing’s thermal stability also plays a crucial role in preventing failures. It withstands high operating temperatures, ensuring reliable performance in environments such as automotive engines or industrial machinery. As industries continue increasing adoption of PET heat shrink tubing, its role in preventing electrical failures becomes indispensable.

Benefits of PET Heat Shrink Tubing

Durability and Resistance to Wear

PET heat shrink tubing offers exceptional durability, making it a reliable choice for long-term insulation needs. Its high tensile strength and abrasion resistance ensure that it withstands wear and tear in demanding environments. This durability is particularly beneficial in industries such as electronics and advanced machinery, where components face constant mechanical stress.

The growing demand for polyester heat shrink tubing highlights its effectiveness in providing robust protection. The following table outlines key insights into its durability and wear resistance:

Key Insights | Description |

|---|---|

Demand Surge | The market is expanding due to advancements in insulation technologies. |

Widely used for protecting sensitive electronic components. | |

Advanced Machinery | Essential for shielding parts in automated systems from wear and tear. |

Technological Innovations | Enhanced polymer formulations improve mechanical strength and longevity. |

PET heat shrink tubing also offers customization options, such as varying thickness and diameter, to meet specific application requirements. These features make it a versatile solution for industries requiring reliable insulation and protection.

Thermal Stability and High-Temperature Performance

PET heat shrink tubing excels in environments with high temperatures. Its thermal stability allows it to maintain performance under continuous operating temperatures of up to 150°C (302°F) and short-term exposure to 200°C. This capability ensures that it provides consistent insulation and protection even in extreme conditions.

The introduction of multi-layered tubing has further enhanced its thermal performance. These advancements make PET heat shrink tubing suitable for applications in aerospace, automotive, and industrial equipment. For example, in automotive engines, the tubing protects wires and connectors from heat damage, ensuring system reliability.

Its ability to resist thermal degradation also contributes to its long lifespan. This makes it a cost-effective choice for industries seeking durable and high-performing insulation solutions.

Cost-Effectiveness and Long-Term Value

PET heat shrink tubing combines affordability with long-term value. Its durability reduces the need for frequent replacements, saving costs over time. Additionally, its resistance to chemicals, oils, and solvents minimizes maintenance expenses, making it an economical option for various applications.

The tubing’s versatility in sizes and designs further enhances its cost-effectiveness. Industries can select the most suitable type for their specific needs, ensuring optimal performance without overspending. Moreover, technological advancements in polymer formulations have made PET heat shrink tubing more efficient, providing better insulation and protection at competitive prices.

By choosing PET heat shrink tubing, industries can achieve reliable insulation, enhanced protection, and significant cost savings. Its long-term value makes it a preferred choice for applications across multiple sectors.

Applications of PET Heat Shrink Tubing Across Industries

PET heat shrink tubing plays a vital role in various industries, offering good electrical insulation and reliable protection for wires, cables, and components. Its versatility and durability make it indispensable for electrical and electronic applications, ensuring safety and performance in demanding environments.

Automotive and Transportation

The automotive industry relies heavily on PET heat shrink tubing for wiring harness protection. This tubing shields wires from abrasion, moisture, and extreme temperatures, ensuring the reliability of electrical systems in vehicles. It also facilitates the bundling of cables, reducing clutter and improving organization within tight spaces. PET’s thermal stability allows it to perform well in engine compartments, where high temperatures are common.

AccuPath, a leading provider of PET heat shrink tubing, offers solutions tailored to automotive needs. Their products ensure long-term durability and compliance with industry standards, making them a trusted choice for manufacturers. By using PET tubing, automotive companies enhance the safety and efficiency of their electrical systems.

Electronics and Consumer Devices

In the electronics sector, PET heat shrink tubing serves as a critical component for protecting sensitive parts. It provides insulation for wires and cables, preventing short circuits and ensuring the smooth operation of devices. Its chemical resistance safeguards components from exposure to oils and solvents, which could compromise performance.

PET tubing is widely used in consumer devices such as smartphones, laptops, and home appliances. Its ability to conform tightly to irregular shapes makes it ideal for compact designs. AccuPath’s heat shrink tubing solutions cater to the electronics industry by offering customizable sizes and colors, ensuring compatibility with diverse applications.

Industrial and Manufacturing Equipment

Industrial and manufacturing equipment often operates in harsh environments, where durability and reliability are essential. PET heat shrink tubing protects electrical connections and cables from physical damage caused by vibration, abrasion, and exposure to chemicals. Its high dielectric strength ensures good electrical insulation, reducing the risk of failures.

Key applications of heat shrink tubing in this sector include wiring insulation for automated systems and protection for heavy machinery components. AccuPath’s PET tubing stands out for its ability to withstand demanding conditions, providing long-term value and reducing maintenance costs for industrial operations.

The table below illustrates the broad usage of PET heat shrink tubing across industries:

Industry Sector | Applications |

|---|---|

Wire and Cable | Electrical insulation and protection |

Electronic Equipment | Component protection and insulation |

Automotive | Wiring harness protection |

Medical | Device protection and sterilization |

AccuPath continues to innovate in the field of PET heat shrink tubing, delivering solutions that meet the evolving needs of industries worldwide.

Medical Devices and Specialized Equipment

PET heat shrink tubing plays a critical role in the medical industry by providing reliable insulation and protection for specialized equipment. Its biocompatibility and durability make it an ideal choice for medical devices that require stringent safety and performance standards. PET tubing ensures the safe operation of devices used in diagnostics, treatment, and patient care.

Medical devices often operate in environments where exposure to chemicals, moisture, and extreme temperatures is common. PET heat shrink tubing protects sensitive components from these hazards. Its high dielectric strength prevents electrical failures, while its chemical resistance ensures long-term reliability. Additionally, PET tubing can be sterilized without compromising its structural integrity, making it suitable for reusable medical equipment.

Regulatory standards ensure the safety and effectiveness of materials used in medical devices. PET heat shrink tubing complies with several key standards, as shown in the table below:

Standard | Description |

|---|---|

USP Class VI | Evaluates biocompatibility for medical devices, requiring tests for systemic toxicity and implant reactions. |

ISO 10993 | Defines biocompatibility testing categories based on body contact and exposure duration, including tests for cytotoxicity and hemocompatibility. |

FDA Title 21 | Regulates materials used in medical devices to ensure they are non-toxic and safe for human use. |

PET heat shrink tubing is widely used in applications such as catheter insulation, surgical instrument protection, and cable management in imaging systems. Its ability to conform tightly to irregular shapes ensures secure coverage, even for complex components. This versatility, combined with its compliance with regulatory standards, makes PET tubing indispensable in the medical field.

PET heat shrink tubing offers a reliable solution for electrical insulation, combining high dielectric strength with thermal resistance. Its ability to prevent short circuits and protect against electrical leakage makes it indispensable across industries.

The global market for PET heat shrink tubing is projected to grow from $580 million in 2023 to $980 million by 2032, driven by increasing demand in sectors like automotive and electronics.

The rise of electric vehicles and advanced driver-assistance systems highlights its critical role in ensuring electrical safety.

This versatile material provides durability, cost-effectiveness, and long-term value. Industries seeking dependable insulation solutions should consider PET heat shrink tubing for their needs.

FAQ

What is the primary purpose of PET heat shrink tubing?

PET heat shrink tubing insulates and protects electrical components. It prevents short circuits, shields wires from environmental damage, and ensures reliable performance in various applications. Its ability to shrink tightly around objects enhances safety and durability.

How does PET heat shrink tubing differ from other materials?

PET tubing offers superior thermal stability, chemical resistance, and dielectric strength compared to alternatives like PVC or FEP. It withstands higher temperatures and provides long-term durability, making it ideal for demanding environments.

Can PET heat shrink tubing be used in medical devices?

Yes, PET tubing complies with medical standards like ISO 10993 and USP Class VI. It provides insulation, resists sterilization processes, and ensures safety for sensitive equipment such as catheters and surgical instruments.

Is PET heat shrink tubing environmentally friendly?

PET tubing is recyclable and complies with RoHS standards, ensuring it contains no hazardous substances. Its long lifespan reduces waste, making it a sustainable choice for insulation needs.

What industries benefit most from PET heat shrink tubing?

Automotive, electronics, medical, and industrial sectors rely heavily on PET tubing. It protects wiring harnesses, electronic components, medical devices, and machinery from damage, ensuring safety and performance in diverse applications.

See Also

Essential Information on PET Heat Shrink Tubing for Electronics

Applications of Heat Shrink Tubing for Electrical Wire Insulation

Selecting the Ideal Ultra-Thin PET Heat Shrink Tubing for Projects

Exploring FEP Non-Toxic Heat Shrink Tubing for Industrial Applications

The Importance of Ultra-Thin PET Heat Shrink Tubing in Medical Devices