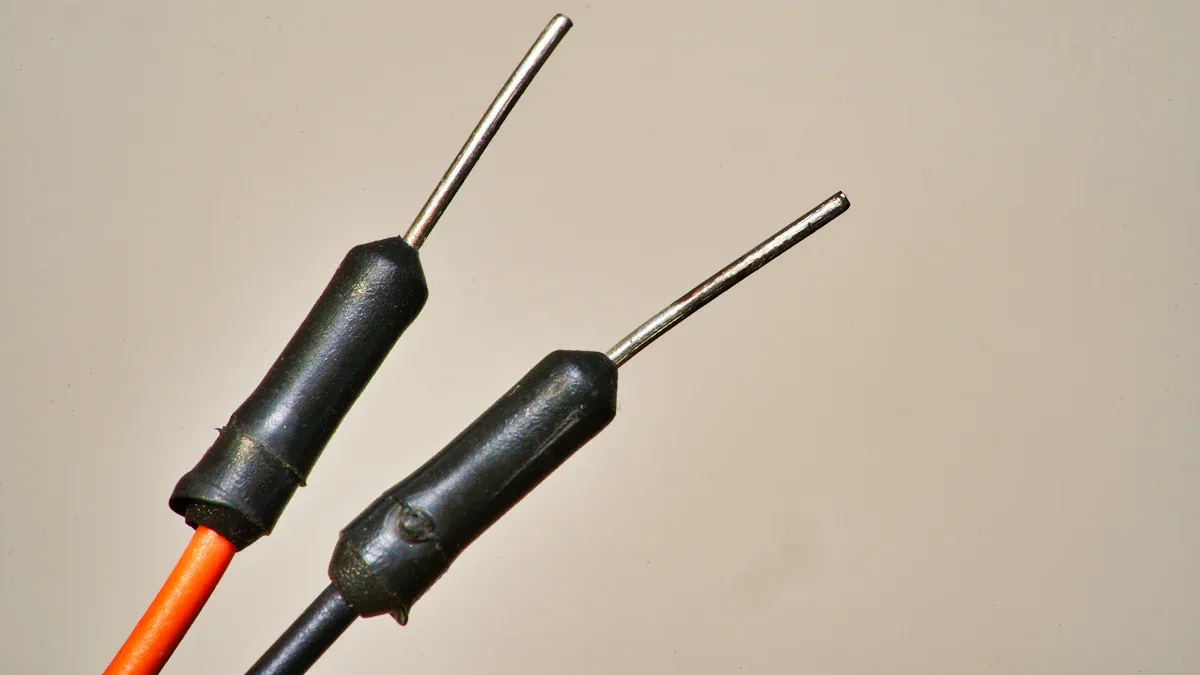

PET heat shrink for catheter reinforcement braiding made simple

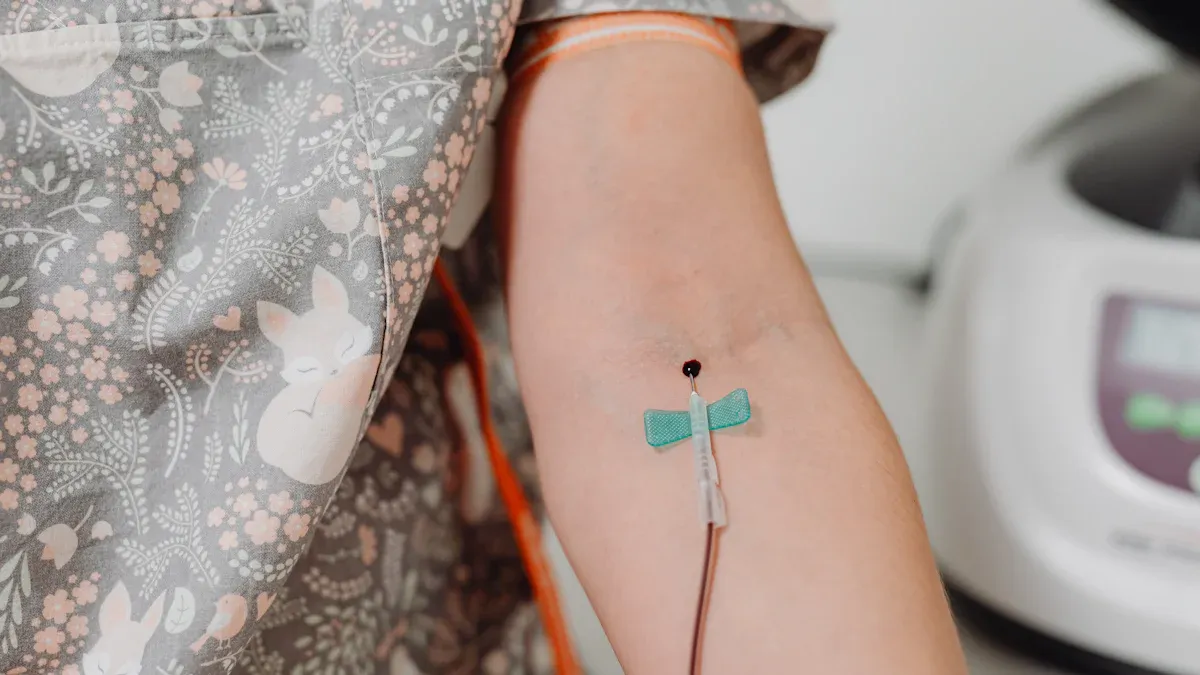

You use PET heat shrink for catheter reinforcement braiding to make catheters stronger and safer. This tubing makes the catheter stiff. It holds the braid ends in place. It also helps stop kinks from forming. The surface is smooth and lowers friction. This makes patients feel more comfortable. The process is simple and fast. PET heat shrink tubing fits tightly to any shape. It keeps out dirt and germs. You can trust it to last a long time. It stands up to fluids and cleaning many times.

Makes the catheter stronger

Lowers friction so it goes in easier

Keeps working well for a long time

Blocks dirt and germs from getting in

Stays steady even with tricky shapes

Key Takeaways

PET heat shrink tubing makes catheters stronger. This helps keep patients safe and makes catheters work better.

The tubing lowers friction. This means it is easier to put in and feels better for patients.

Ultrathin-wall PET heat shrink tubing bends easily. It does not make the catheter thick or heavy. This helps doctors move catheters more easily.

Using the right steps, like cleaning surfaces and heating correctly, helps catheters work well.

Picking the best PET tubing by looking at shrink ratio and wall thickness makes catheters last longer and work better.

What is PET heat shrink tubing?

PET heat shrink tubing is a special plastic tube. It is made from polyethylene terephthalate. You use it to cover and protect catheter braids. When you heat the tubing, it shrinks tightly around the catheter. This makes a smooth and strong layer. The process helps reinforce the catheter. It does not make the catheter bulky or stiff.

Key properties for catheter reinforcement

You want your catheter to be strong and flexible. PET heat shrink tubing gives you both things. Its walls are very thin, sometimes only 0.0005 inches thick. This means you add strength but not much thickness. The tubing has a high shrink ratio, from 1.1:1 up to 3:1. This lets you fit the tubing over complex shapes and braids.

Tip: You can use thicker or thinner PET tubing in different spots. This helps you change how stiff or bendy each part of the catheter feels.

Here are some important features you get with PET heat shrink tubing:

High strength and stiffness for reinforcement

Excellent dimensional stability, so the tubing stays in place

Tight fit for braid encapsulation and a smooth finish

Ability to adjust flexibility by changing wall thickness

Minimal impact on the catheter’s final size

Property | Description |

|---|---|

Material Properties | PET with high dielectric strength and biocompatibility (ISO 10993) |

Shrink Ratios | 1.1:1 to 3:1, fits tightly to complex shapes |

Shrinking Temperature | About 150°C (302°F) |

Why PET is preferred in medical devices

PET is used in medical devices because it is safe and works well. PET heat shrink tubing is non-toxic and does not react with body fluids. It passes ISO 10993 and USP Class VI tests, so it is safe for patients. The tubing can handle sterilization, chemicals, and moisture. This means your catheter stays clean and works well, even after many uses.

PET also gives great electrical insulation. This is important if your catheter has electronic parts. PET’s high shrink ratio (up to 2:1) lets you cover tricky shapes better than PVC or polyolefin. You can trust PET to give you a strong, flexible, and safe catheter every time.

PET heat shrink for catheter reinforcement braiding: Application steps

Preparing catheter and braid

You must start with a clean surface. This helps the PET heat-shrink tubing stick well. You can use different cleaning methods to get the best results. The table below shows some ways to get the catheter ready:

Method | Description | Application |

|---|---|---|

Plasma Treatment | Changes the surface with electricity to help things stick better. | Works well for glues, inks, and coatings on many catheter materials. |

Corona Treatment | Raises surface energy so things stick better, but does not change the tube. | Used in both small and big production for catheter tubing. |

Vacuum Plasma | Treats tubes before coating to help things stick. | Good for companies that want fast and custom production. |

After cleaning, you can add the braid. Make sure the braid is flat and covers the right spot. The braid should not move during the next steps. This helps PET heat shrink for catheter reinforcement braiding work best.

Tip: Always check for dust or oil before moving on. Clean surfaces help the tubing shrink smoothly and stick well.

Applying PET heat shrink tubing

Now you can put the PET heat-shrink tubing over the catheter and braid. Place the tubing so it covers the braid all the way. Hold both ends with gentle tension. This keeps the tubing smooth and stops wrinkles.

Put the PET heat-shrink tubing on the right spot.

Hold both ends tight to stop folds or bubbles.

Make sure the tubing lines up with the braid.

You can use a fusing sleeve to bond the outer jacket to the liner. The sleeve helps the outside melt and stick to the inside. This step gives a strong and clean finish.

Note: Good alignment and tension make the PET heat shrink for catheter reinforcement braiding look neat and work well.

Heat shrinking and inspection

You are ready to shrink the tubing. Start heating in the middle of the PET heat-shrink tubing. Move the heat slowly and turn the catheter as you go. Move the heat toward each end. This helps the tubing shrink evenly and wrap tight.

Here are the best heat and time settings for PET heat-shrink tubing:

Parameter | Value |

|---|---|

Material shrink temp range | 185°F to 374°F (85°C to 190°C) |

Recommended hot box range | 300°F to 450°F (149°C to 232°C) |

Shrinkage characteristics | Should shrink tight with no gaps or bubbles |

Keep turning the catheter as you heat it. This stops air pockets and makes the tubing fit well. After shrinking, let the catheter cool. Take off the fusing sleeve if you used one. Now you can check your work.

Look for a smooth surface with no wrinkles.

Make sure the tubing covers the braid from end to end.

Check for tight wrapping and no gaps.

The heat shrinking does more than just fit the tubing. It also makes your catheter stronger. The table below shows what changes:

Mechanical Property | Effect of Heat Shrinking Process |

|---|---|

Strength | Gets better because of bonding |

Stiffness | Increases as the material flows |

Integrity | The whole assembly gets stronger |

You get a catheter that is strong and does not kink. The PET heat shrink for catheter reinforcement braiding keeps the braid in place and looks clean. The catheter stays flexible and easy to move. This means you can trust your catheter to work well in real medical use.

Tip: Always check your catheter after shrinking. Good inspection helps you find problems early and keeps every catheter safe.

You can do these steps for every catheter you make. PET heat-shrink tubing makes the process easy and works well. You get strong support, smooth braid covering, and a catheter that bends without kinking. This is why PET heat shrink for catheter reinforcement braiding is the best choice for making medical devices.

Benefits of ultrathin-wall PET heat shrink tubing

Ultrathin-wall PET heat shrink tubing has many good points for catheters. It makes catheters stiffer and stops kinks. It covers the braid well and looks neat. It also lasts a long time. The catheter stays bendy and simple to use. Let’s see how each benefit helps make medical devices safer and stronger.

Stiffness and kink resistance

You want your catheter to be strong and not bend wrong. Ultrathin-wall PET heat shrink tubing makes it stiffer with special reinforcements. This helps the catheter work in hard procedures without folding or kinking. The smooth surface lets you use thinner tubing but still meet tough rules. The catheter can be smaller, which helps in tight spaces. The tubing keeps the end parts flexible, so you can move the catheter easily.

When you use ultrathin-wall PET heat shrink tubing, your catheter gets tough but not thick. You can guide the device easily, even in hard procedures.

Here is a table that shows the technical benefits of ultrathin-wall PET heat shrink tubing compared to thicker tubing:

Advantage | Description |

|---|---|

Enhanced Insulation | Protects sensitive parts from electrical problems |

Mechanical Protection | Shields weak spots from stress and the environment |

Flexibility | Fits odd shapes and helps the device work better |

Durability | Keeps the catheter safe for a long time |

Ultrathin-wall PET heat shrink tubing comes in many thicknesses. You can pick the best one for your job. Here are some common wall thicknesses:

Wall Thickness (in) |

|---|

0.0005 |

0.0008±0.0001 |

0.0012±0.0002 |

0.0017±0.0002 |

0.0020±0.0004 |

You can also get ultrathin-wall PET heat shrink tubing as thin as 0.00015 inches. This lets you make the catheter stronger without making it thick. The device stays light and easy to use.

Braid encapsulation and clean finish

Ultrathin-wall PET heat shrink tubing helps cover and protect the braid inside the catheter. The tubing shrinks tight and wraps around odd shapes. You get a smooth and neat finish every time. The material stands up to rubbing, chemicals, and sunlight. You can use ultrathin-wall PET heat shrink tubing for many medical jobs, and it always works well.

Feature | Description |

|---|---|

Material | Biocompatible PET that resists rubbing, chemicals, and sunlight |

Wall Thickness | Can be as thin as 0.00025in for more bend and less bulk |

Shrink Ratio | Up to 1.6:1, covers odd shapes and curves |

Applications | Works for many medical devices, makes them last longer and work better |

You want your catheter to look good and work right. Ultrathin-wall PET heat shrink tubing gives you both. The tubing is clear, so you can see the braid and check if it lines up. You avoid problems like uneven shrinking or open spots. You need a clean place to keep the tubing free from dust and dirt.

You can see the braid through the tubing for easy checks.

You keep the tubing lined up for best results.

You work in a clean space to stop problems.

Ultrathin-wall PET heat shrink tubing makes your catheter look nice and keeps the braid safe. You get a smooth surface that feels good for patients.

Abrasion resistance and durability

Ultrathin-wall PET heat shrink tubing is great at stopping wear and lasting a long time. You need your catheter to last through many uses and cleanings. The tubing is strong and keeps its shape well. It stands up to damage better than other medical plastics. You get a catheter that stays strong and works well.

Property | PET Heat Shrink Tubing | Other Medical-Grade Polymers |

|---|---|---|

Mechanical Strength | High | Changes |

Dimensional Stability | Excellent | Changes |

Abrasion Resistance | High | Changes |

Ultrathin-wall PET heat shrink tubing protects the catheter from harm during use and setup. The tubing keeps its shape in hot or cold. You can clean the catheter many times, and it still works. The tubing does not break down, so you do not need to replace the catheter often. This saves money and keeps patients safe.

Property | Impact on Catheter Lifespan |

|---|---|

Mechanical Strength | Keeps the catheter strong after many uses |

Tear Resistance | Stops damage during use or setup |

Thermal Stability | Works well in hot or cold |

Resistance to Degradation | Stays safe after many cleanings |

Wear and Tear Resistance | Needs fewer replacements, saves money |

You can trust ultrathin-wall PET heat shrink tubing to make your catheter last a long time. You keep the device safe for patients and ready for every use.

Ultrathin-wall PET heat shrink tubing also meets tough safety rules. You use tubing that is safe for medical jobs. The material does not react with body fluids or cause harm. You can feel sure your catheter is safe and strong.

Ultrathin-wall PET heat shrink tubing gives you high strength, little size change, and better movement. You keep the catheter bendy and easy to guide. You get a neat finish, strong braid cover, and great durability. You make medical devices that last longer and help patients more.

Tips for best results

Selecting the right PET heat shrink tubing

Picking the right PET heat shrink tubing helps your catheters work well. You should think about a few important things to make sure your catheter is strong and works right.

Choose tubing with the right shrink ratio. A higher shrink ratio lets you cover weird shapes and makes the tubing fit tightly.

Check the wall thickness. Thinner walls help the catheter bend. Thicker walls make it stronger. The best choice gives you both strength and flexibility.

Make sure the tubing size fits your catheter. If the tubing is too big or small, it will not work well.

Pick PET tubing that can handle sterilization. Your catheters might need to go through hot steam, EtO gas, or gamma rays. Tubing that can take these keeps your catheters safe.

Choose strong PET tubing. This kind helps the tubing shrink the same way every time. It also stops problems like loose fits or tubing that does not line up.

Tip: Always use a heat source that is set right. Keep the temperature between 275°F and 350°F. This helps the tubing shrink evenly and look smooth.

Application techniques and troubleshooting

Putting PET heat shrink tubing on the right way is important. It helps your catheter work better. You want to avoid mistakes and fix problems fast.

Work in a bright place. Good light helps you see bubbles, gaps, or tubing that is not lined up.

Practice on extra pieces before you work on real catheters. This helps you learn the steps and not make mistakes.

Watch out for uneven heating. If you see wrinkles or spots that did not shrink, check your heat source. Move it slowly along the catheter.

Control the room temperature. If it is cold, shrinking is harder. Warm up the catheter first if you need to.

Pay attention to how the tubing shrinks. Too much shrinking along the length can make the tubing move. Not enough shrinking around the tube can make it loose.

Note: If the tubing does not cover the braid all the way, check the size and heat. Change them if you need to get a tight, smooth finish.

If you follow these tips, your catheters will stay strong, bendy, and safe to use. Good steps and careful choices help your catheters last longer and work better.

You can use PET heat shrink tubing to make catheters better. It helps catheters get stronger and safer for patients. The steps are easy and work for many devices. You get a strong tube that bends and feels smooth. Pre-cut tubes save time and keep everything clean. The table below shows why PET heat shrink tubing is a good pick:

Property | Benefit |

|---|---|

Mechanical Strength | Lasts longer and resists stress |

Chemical Resistance | Stays safe after cleaning and sterilization |

Ultrathin Walls | Adds strength without bulk |

Try these tips to help your own catheter projects work better.

FAQ

What makes PET heat shrink tubing a good choice for medical device designers?

You get reliable results with PET heat shrink tubing. It offers high strength and insulative properties. You can use it for many catheter types. Medical device designers trust it for safety and performance.

How does medical-grade heat-shrink tubing help prevent catheter kinks?

You use medical-grade heat-shrink tubing to add stiffness. This support keeps the catheter from bending too much. You stop kinks before they start. The tubing also helps the device move smoothly inside the body.

Can I use PET heat shrink tubing for braid-reinforced tubing?

Yes, you can use PET heat shrink tubing for braid-reinforced tubing. You get a tight fit over the braid. This keeps the braid in place and adds strength. You also protect the catheter from damage.

Is PET heat shrink tubing safe for patient use?

You can trust PET heat shrink tubing for patient safety. It meets strict medical standards. The tubing does not react with body fluids. You can sterilize it many times without losing quality.

What are the main benefits of PET heat shrink tubing in catheters?

You get a smooth finish, strong support, and long-lasting protection. The tubing resists chemicals and wear. You keep the catheter flexible and easy to use. You also block dirt and germs from getting inside.

See Also

The Role of FEP Heat Shrink Tubing in Catheter Design

Understanding FEP Heat Shrink Tubing for Autoclaving Purposes

Essential Insights on PET Heat Shrink Tubing for Electronics

Exploring Heat Shrink Tubing Applications for Electrical Insulation

The Importance of Ultra-Thin PET Tubing in Medical Applications