The Growing Use of Nitinol Tubing in Orthopedic Treatments

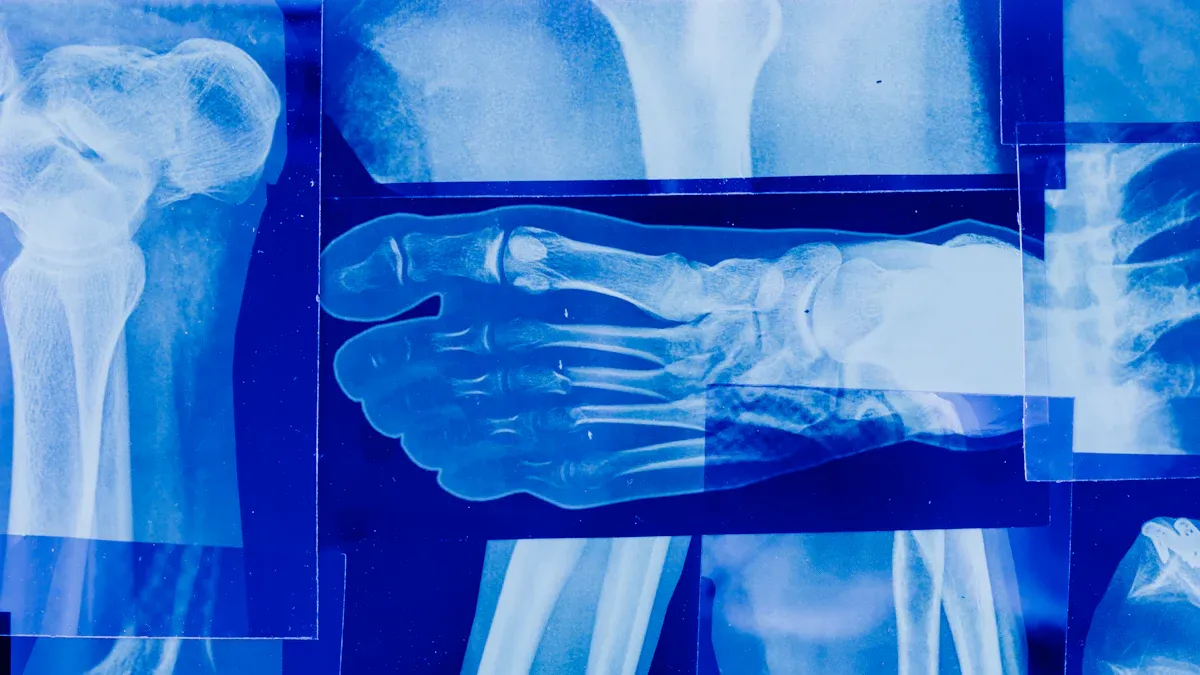

Orthopedic Nitinol tubing is changing how medical devices are made. It is especially useful in fixing bones and joints. This special material can return to its shape and bend easily. These features make it perfect for tricky medical uses. More doctors want orthopedic nitinol tubing because it helps patients heal better. Bone and joint surgeries are increasing, boosting its use in healthcare. By 2033, the nitinol market may reach $4.1 billion. It is expected to grow 7.5% yearly from 2026 to 2033. This shows how important orthopedic nitinol tubing is in modern medicine.

Key Takeaways

Nitinol tubing bends easily and goes back to its shape. This makes it great for bone surgeries.

Tools made with Nitinol help patients heal quicker after surgery.

Nitinol is safe for the body and does not rust. This makes it last a long time in medical implants.

Nitinol's special features make surgeries more precise, even in tricky spots.

New Nitinol technology might create better tools for small-cut surgeries.

Unique Properties of Orthopedic Nitinol Tubing

Shape Memory and Superelasticity

Nitinol tubing is special because it can bend and return to shape. This makes it great for fixing bones and joints. For example, NiTi plates help bones heal better than regular titanium ones. They also handle stress well, making them useful in surgeries. These features ensure nitinol devices work reliably during bone and joint repairs.

Evidence Type | Findings | Comparison |

|---|---|---|

Stiffness-matched NiTi fixation plates | Better bone healing and load transfer | Compared to regular titanium |

Superelasticity helps prevent implants from breaking. Nitinol tubing can stretch a lot without staying bent. This is important for devices that move often. It ensures the tubing stays strong and works well under pressure.

Biocompatibility and Corrosion Resistance

Nitinol is safe to use in the body and doesn’t rust easily. This makes it perfect for medical implants. Studies show that polishing nitinol improves its safety and resistance to rust. For instance, Rahimipour found that surface changes make nitinol last longer. Ryhänen studied how nitinol works with human cells and found it safe.

Study | Findings | Reference |

|---|---|---|

Rahimipour et al. | Surface finish improves corrosion resistance and safety. | Link |

Ryhänen et al. | Nitinol is safe and works well with human cells. | Link |

FDA Guidance | Sets rules for testing medical device safety. | Link |

ISO 10993-1 | Global standard for testing medical device safety. | Link |

Rust resistance keeps nitinol implants working well in the body. This is very important for implants that stay inside for a long time.

Flexibility and Durability

Nitinol tubing is both flexible and strong, making it reliable. Its superelasticity helps it adjust during use. It can also handle millions of movements without breaking. For example, tests show nitinol can survive up to 10⁷ cycles of stress. This proves it is tough enough for demanding medical uses.

Performance Metric | Description |

|---|---|

Makes it flexible and easy to use. | |

Biocompatibility | Safe for use in the human body. |

Prevents damage from body fluids. | |

Dimensional precision | Fits perfectly with implant designs. |

Fatigue resistance | Handles many movements without breaking. |

Tests mimic body conditions to check nitinol’s strength and shape memory. These tests show why nitinol tubing is trusted for flexible and long-lasting medical devices.

Medical Uses of Nitinol in Orthopedics

Bone Fixation Devices

Nitinol tubing has changed how bone fixation devices work. Its ability to bend and return to shape helps it fit bones well. Bone plates made from nitinol hold fractures firmly, helping them heal faster than older materials. For example, studies show nitinol staples heal ankle fractures 40% faster than titanium ones. This makes nitinol very useful for orthopedic implants.

Application Type | How It Helps | Source |

|---|---|---|

Bone Plates | Holds fractures firmly, speeds up healing. | [Top 6 Medical Applications of Nitinol] |

Bone Staples | Heals ankle fractures 40% faster than titanium. | The Journal of Bone and Joint Surgery |

Intramedullary Implants | Uses shape memory to press bones together for better healing. | [Top 6 Medical Applications of Nitinol] |

Nitinol intramedullary implants can expand on their own. This helps press broken bones together, speeding up healing. These implants are strong and last a long time, even with repeated use. Nitinol tubing is key to these devices because it is both flexible and tough.

Spinal Implants and Fusion Systems

Spinal implants made with nitinol are very helpful. The material bends easily and adjusts to spine movements, lowering the chance of failure. Nitinol tubing is used in spinal cages and rods, keeping them strong under pressure.

Nitinol stents that expand on their own are also used in spine surgeries. They fit the spine perfectly, reducing the need for big surgeries. This design makes surgery easier and helps patients recover faster.

Nitinol guidewires are also used in spine surgeries. They are flexible and safe, helping doctors work in tricky areas. Using nitinol in spinal implants shows how useful it is in orthopedics.

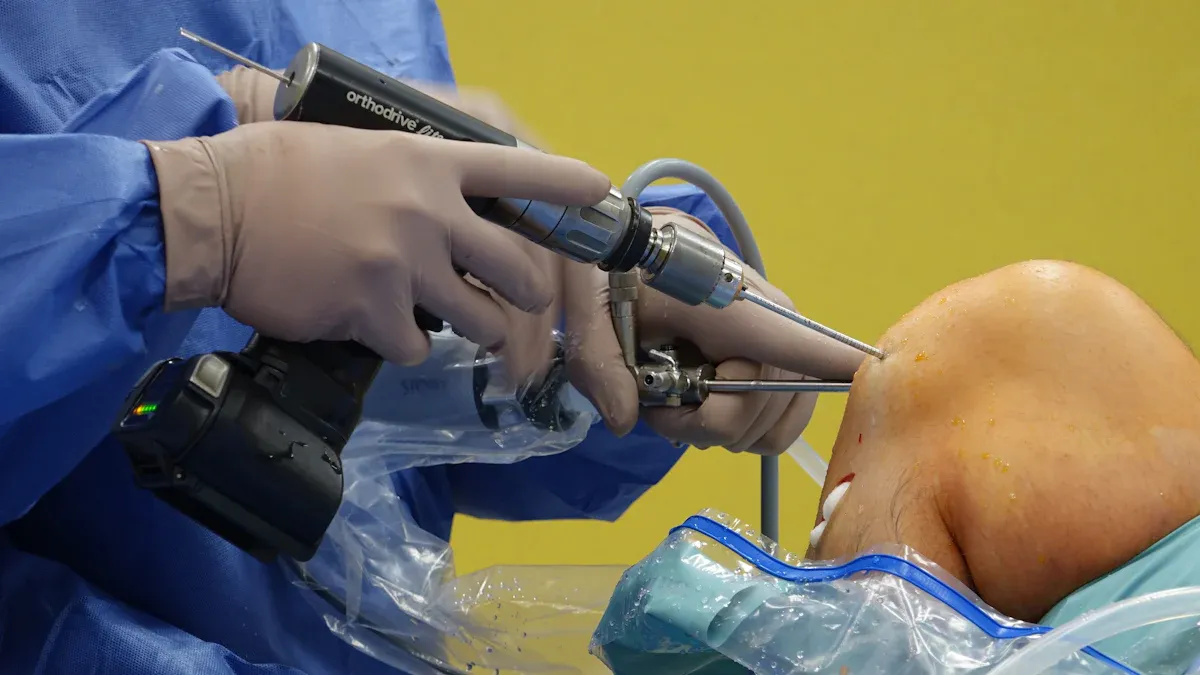

Joint Repair and Arthroscopic Tools

Nitinol tubing has improved tools for fixing joints. Its flexibility helps doctors reach hard-to-access areas like knees and shoulders. Arthroscopic tools made with nitinol have tips that can move, letting doctors place materials exactly where needed. This makes treatments more effective and reduces harm to nearby tissues.

Nitinol tubing is flexible, helping in hard-to-reach joint repairs.

Arthroscopic tools with moving tips make placing materials easier.

Targeted material delivery improves treatment and protects nearby tissues.

Nitinol archwires, used in braces, have inspired similar uses in joint repair. They keep steady pressure and adjust to movement, making them helpful in orthopedic care. Nitinol’s use in these tools shows how it improves surgeries and patient recovery.

Advantages of Nitinol Medical Devices in Orthopedics

Better Patient Results

Nitinol devices help patients heal better after surgeries. They can bend and return to shape, making them work well with body movements. This reduces problems and keeps implants strong for a long time. Nitinol tubing in implants is safe for the body and doesn’t rust. These features make healing safer and faster for patients.

Feature | How It Helps |

|---|---|

Shape Memory | Adjusts to body changes, stays strong. |

Superelasticity | Makes devices flexible, lowers risks. |

Biocompatibility | Safe for the body, avoids bad reactions. |

Corrosion Resistance | Keeps implants strong over time. |

Nitinol devices are now a key part of healthcare. They offer safe and reliable solutions for many medical needs.

Quicker Healing

Nitinol tubing helps patients recover faster after surgery. It moves with the body, reducing strain on nearby tissues. This helps fractures heal quicker than older materials. For example, nitinol staples speed up bone healing. Patients spend less time in hospitals and get back to normal life sooner.

Recovery Benefit | How It Helps |

|---|---|

Faster Healing | Speeds up recovery after surgery. |

Fewer Problems | Reduces risks and bad reactions. |

Better Precision | Makes surgeries safer and more effective. |

Nitinol’s ability to speed up healing shows its importance in modern healthcare. It helps patients recover quickly and safely.

Improved Surgery Accuracy

Nitinol devices make surgeries more accurate, especially small ones. They bend easily and keep their shape, helping doctors work in tricky areas. Nitinol guidewires and tubes stay strong even after many uses, lowering mistakes. Studies show nitinol improves surgery results. For example, one study found nitinol tools helped 49% of patients recover well, compared to 13% with regular tools. Another study showed fewer deaths with nitinol-assisted surgeries.

Nitinol’s strength and flexibility make it great for precise surgeries. It keeps setting new standards for success in medical care.

Challenges in Using Nitinol Tubing

Manufacturing Costs and Complexity

Making nitinol tubing for medical use is expensive and tricky. Nickel and titanium, the main materials, cost a lot. The process needs exact temperature and alloy control, which is hard. Few companies can make nitinol in large amounts, causing supply issues. Other cheaper materials also compete with nitinol in some markets.

Challenge | Description |

|---|---|

Machining Difficulties | Nitinol bends during machining, making precise shapes harder to achieve. |

High Costs | Expensive materials and processes slow down market growth. |

Limited Standardization | Custom orders take longer and cost more due to lack of standards. |

These problems show the need for better ways to make nitinol cheaper and easier to get.

Nickel Sensitivity and Biocompatibility Concerns

Nitinol is safe for the body, but nickel can cause issues. Nickel ions may release due to pH, fluoride, or hygiene factors. Studies show nitinol is mostly safe, but women are more likely to have nickel sensitivity. This makes it important to pick materials carefully for implants.

Doctors must think about these risks, especially for sensitive patients. Polishing or coating nitinol can lower nickel release and make it safer.

Long-Term Performance and Durability

Nitinol is strong and flexible, but its long-term use raises questions. Stress and body fluids might weaken it over time. Lab tests show it handles millions of movements, but real-life conditions differ. Corrosion and wear could shorten its lifespan.

Researchers are working to make nitinol last longer. New alloys and surface treatments aim to stop wear and rust, keeping it reliable for years.

Future Innovations in Nitinol Tubing

Advancements in Minimally Invasive Surgery

Modern healthcare is changing with less invasive surgeries. Nitinol tubing helps make flexible tools for these procedures. Its ability to bend and return to shape lets tools move through tricky body areas. For example, nitinol guidewires and stents are used in spinal and blood vessel surgeries. These tools need small cuts, helping patients heal faster with fewer problems.

Scientists are working to improve nitinol for these surgeries. They aim to make thinner and stronger tubing for delicate body areas. These upgrades could make less invasive surgeries available to more people worldwide.

Broader Medical Applications of Nitinol

Nitinol is useful for more than fixing bones. Its special features help in many medical areas. In braces, nitinol wires straighten teeth 30% faster than steel ones. In stroke care, nitinol stent retrievers helped 49% of patients recover well in the DAWN Trial. Heart valve frames made from nitinol showed a 1.0% death rate in TAVR surgeries, compared to 2.5% in open-heart surgeries, as seen in the PARTNER 3 Trial.

Medical Use | Results |

|---|---|

Braces | Nitinol wires align teeth 30% faster than steel in 6 months. |

Stroke Devices | DAWN Trial showed 49% recovery success with nitinol stent retrievers. |

Heart Valve Frames | PARTNER 3 Trial showed 1.0% death rate for TAVR vs. 2.5% for open-heart. |

These examples show how nitinol is helping in many areas of healthcare.

Research for Enhanced Material Performance

Scientists are studying ways to make nitinol even better for medical use. They are creating new designs to improve its safety and strength. Better manufacturing methods aim to lower costs and make nitinol devices more efficient.

A study looked at stress in nitinol parts made with lasers.

It found how energy levels affect stress during production.

The study also linked stress to heat, changing old ideas about nitinol.

These studies are helping nitinol work better in surgeries and other medical uses. As research continues, nitinol tubing will become stronger and more useful, leading to exciting new medical tools.

Nitinol tubing plays a big role in medical devices today. It is especially helpful in fixing bones and joints. Its special features, like shape memory and bending ability, make it very useful. Nitinol helps patients heal faster and recover better after surgeries. It is now a key part of modern healthcare. In the future, nitinol may lead to new ideas, especially for smaller surgeries. As scientists study it more, nitinol will stay important for making better medical tools.

FAQ

What makes Nitinol tubing special for orthopedic care?

Nitinol tubing is unique because it can bend and return to shape. It adjusts to body movements and stays strong over time. It is safe for implants and doesn’t rust easily.

Is Nitinol tubing safe for people allergic to nickel?

Nitinol is mostly safe, but nickel allergies can be a problem. Polishing or coating the surface lowers nickel release, making it safer. Doctors should check if patients might react before using it.

Why is Nitinol good for small surgeries?

Nitinol is flexible and strong, which helps in small surgeries. It bends to fit tricky areas and keeps its shape during use. This improves accuracy and helps patients recover faster.

How does Nitinol help patients heal faster?

Nitinol devices move with the body, reducing stress on tissues. This helps bones heal quicker and lowers risks of problems. For example, Nitinol staples heal bones faster than older materials.

What makes making Nitinol tubing hard?

Making Nitinol tubing costs a lot and is tricky. The process needs exact control of heat and materials. Its bending ability makes shaping and finishing harder during production.