A Comprehensive Comparison of Nitinol and Other Orthodontic Archwire Materials

Nickel titanium braces are special in orthodontics because they are superelastic. This means they give steady force and help move teeth better. A study with 60 patients showed nickel titanium braces move teeth 1.2 mm each month. They work better than stainless steel or beta-titanium archwire. Superelastic archwire causes less pain and feels more comfortable. The average pain score is 3.2, while stainless steel braces have a score of 4.5. Superelastic features help lower pain and make treatment better. Orthodontic Archwire Nitinol Tubing gives great control, so many people choose it for braces. Nickel titanium braces work well, feel comfortable, and are reliable. Superelastic archwire is very important for braces, especially at the start of treatment. It gives steady results and less pain.

Picking the right archwire in orthodontics changes comfort, how well it works, how long it lasts, and cost. This choice helps braces work better.

Archwire Material | Tooth Movement Efficiency (mm/month) | Average Force Delivered (g) | Mean Patient Discomfort (VAS Score) |

|---|---|---|---|

Nickel–Titanium (NiTi) | 1.2 | 200 | 3.2 |

Stainless Steel (SS) | 1.0 | 220 | 4.5 |

Beta-Titanium (TMA) | 0.9 | 210 | 4.1 |

Key Takeaways

Nickel-titanium (Nitinol) archwires are superelastic. They give a steady and gentle force. This helps move teeth in a comfortable way. It works well, especially at the start of braces.

Stainless steel wires are very strong. They are best for later stages of treatment. These wires give precise control and last a long time. But they are not as flexible as Nitinol wires.

Beta titanium wires have both strength and flexibility. They are good for finishing touches. They are also good for people with nickel allergies.

Cleaning archwires the right way is important. Replacing them on time keeps them working well. This also lowers discomfort and risks like allergies or rust.

Picking the right archwire depends on many things. These include the treatment stage, comfort, allergies, cost, and personal needs. Talking to an orthodontist helps you get the best results.

Archwire Materials Overview

Orthodontists use different archwire materials to move teeth with braces. Each material has special features that change how braces feel and work. More people want braces, so the market for archwire materials is growing.

The orthodontic archwire market was about $1.5 billion in 2023. It could reach $2.4 billion by 2032.

Nickel titanium braces and stainless steel archwires are used the most.

Beta titanium and new alloys are becoming more popular for their special benefits.

Nickel-titanium orthodontic archwires make up about half the market money.

Nitinol Archwire

Nitinol archwires, or nickel titanium braces, are known for superelasticity and shape memory. These wires can bend and then go back to their original shape. Good nickel titanium wires give gentle, steady force to move teeth. Orthodontists use these wires first because they hurt less and help with big tooth moves. Nickel titanium wires need fewer changes and feel more comfortable. They stay strong for a long time, so many people pick them for braces.

Stainless Steel Archwire

Stainless steel archwires have been used in orthodontics for many years. They are strong and last long, so they are good for later stages of braces. Stainless steel wires help finish moving teeth and give good control. Orthodontists use them to hold teeth in place or make small changes. These wires do not rust and can be shaped for each patient. Studies show stainless steel wires work well and feel okay for most people.

Beta Titanium Archwire

Beta titanium archwires, or TMA wires, are both flexible and strong. These wires can bend into loops or special shapes. They do not have the same features as nickel titanium, but they are easy to shape and safe for the body. Nickel titanium wires are best for early tooth movement. Beta titanium wires are great for finishing and small details. Orthodontists like beta titanium for gentle force and for people who cannot have nickel.

Other Alloys

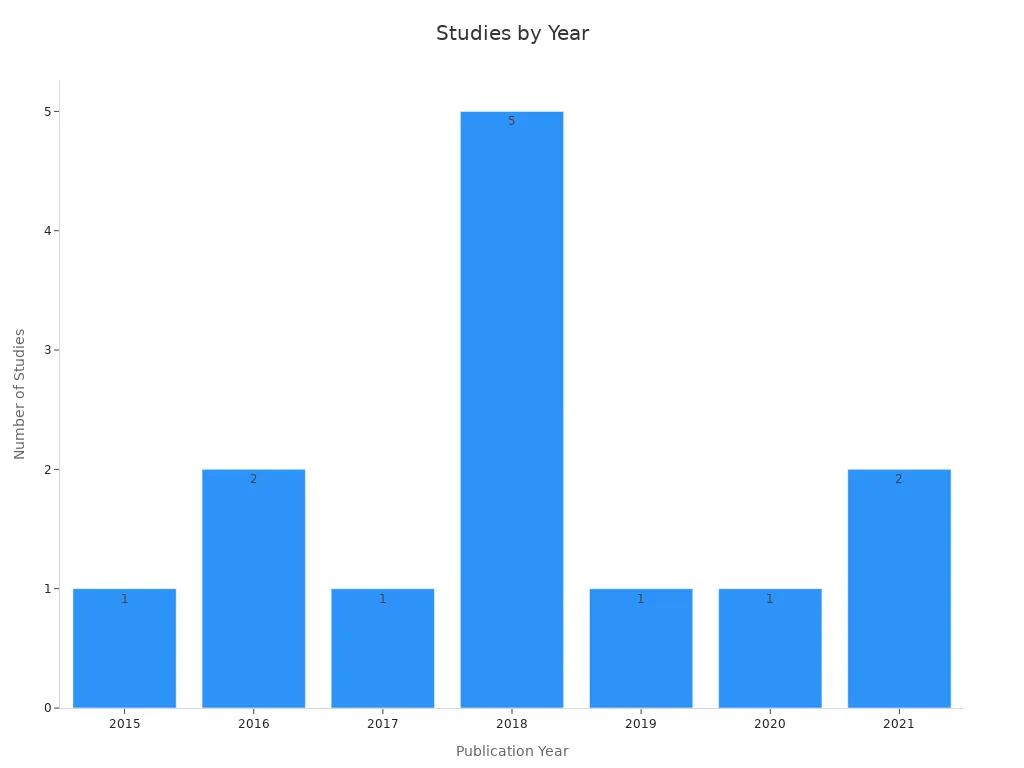

Other alloys, like titanium–molybdenum, silver-coated stainless steel, and PEEK wires, give more choices for braces. Some wires help lower friction or stop rust. New wires with copper or special coatings try to make braces more comfy and work better. The chart below shows how many studies were done on different archwire materials in recent years:

Orthodontists now have many archwire materials to pick from. The best one depends on the treatment stage, what the patient needs, and the special features of nickel titanium or other alloys.

Properties of Nitinol and Other Archwires

Superelasticity and Shape Memory

Superelastic nickel-titanium archwires are special because they can bend and go back to their old shape. They do this even after being bent a lot. This happens because the metal changes between two forms called martensite and austenite. Martensite is softer and more bendy, with a Young’s modulus from 20 to 50 GPa. Austenite is harder and stiffer, with a Young’s modulus from 40 to 90 GPa. This lets the archwire give gentle, steady force as teeth move.

Superelastic nickel-titanium wires can bounce back after being twisted or bent. When put in the mouth, they use shape memory to help move teeth. Stainless steel and beta-titanium wires do not have this superelastic behavior. Superelastic nickel-titanium wires are great for the start of braces. They are flexible and comfy, so patients feel less pain.

Property | Nitinol (NiTi) Quantitative Data | Comparison/Notes |

|---|---|---|

Young's Modulus (Martensite) | 20–50 GPa | Lower stiffness, more ductile phase |

Young's Modulus (Austenite) | 40–90 GPa | Harder, stiffer phase |

Transformation Temperatures | Dependent on Ni/Ti composition; higher Ti → higher temps | Controls shape memory effect and superelasticity |

Recoverable Strain Limit | Higher in Nitinol compared to many alloys | Enables large reversible deformation |

Transformation Stress | Low transformation stress | Facilitates superelastic behavior |

Hardness | Varies with martensitic transformation temperature and Ni content | Correlates with wear resistance and phase stability |

Wear Resistance | High due to superelasticity, shape memory effect, cyclic hardening, and phase transformation energy absorption | Superior to many conventional alloys |

Superelastic nickel-titanium wires can stretch a lot and still go back to normal. They do not bend forever because they can absorb energy. These wires last longer in the mouth because they are tough. Superelasticity and shape memory make these wires different from other types.

Strength and Flexibility

Strength and flexibility are both important for archwires. Superelastic nickel-titanium wires have both. They can bend a lot without snapping, which helps move teeth gently. Studies show these wires give lighter, steady force compared to stainless steel or beta-titanium wires. This makes them good for the first part of braces when teeth need to move into place.

Superelastic nickel-titanium wires also spring back to their shape after bending. Stainless steel wires are strong but not as bendy. Beta-titanium wires bend a bit but do not have superelasticity. Superelastic nickel-titanium wires are flexible and comfy, so patients feel less pain.

Researchers found that superelastic nickel-titanium wires from different brands can work differently. Used wires get harder and stiffer than new wires. The table below shows how these things change after being used:

Property | Used NiTi Wires (Group A) | New NiTi Wires (Group B) | Statistical Significance (p-value) |

|---|---|---|---|

Nanohardness (HVIT) | 404.62 ± 40.3 MPa | 323.18 ± 8.7 MPa | 0.00 (intergroup) |

Elastic Modulus (E IT) | 44.72 ± 1.0 GPa | 42.73 ± 1.8 GPa | 0.000996 (intergroup) |

Superelastic nickel-titanium wires can change after being in the mouth. The mouth can make them stronger or stiffer. Even with these changes, they still help move teeth well.

Friction and Surface Characteristics

Friction between the archwire and bracket affects how teeth move. Less friction means teeth move easier and need less force. Superelastic nickel-titanium wires are often smoother than other wires, so they have less friction. Some wires have special coatings, like nanocoatings, to make them even smoother.

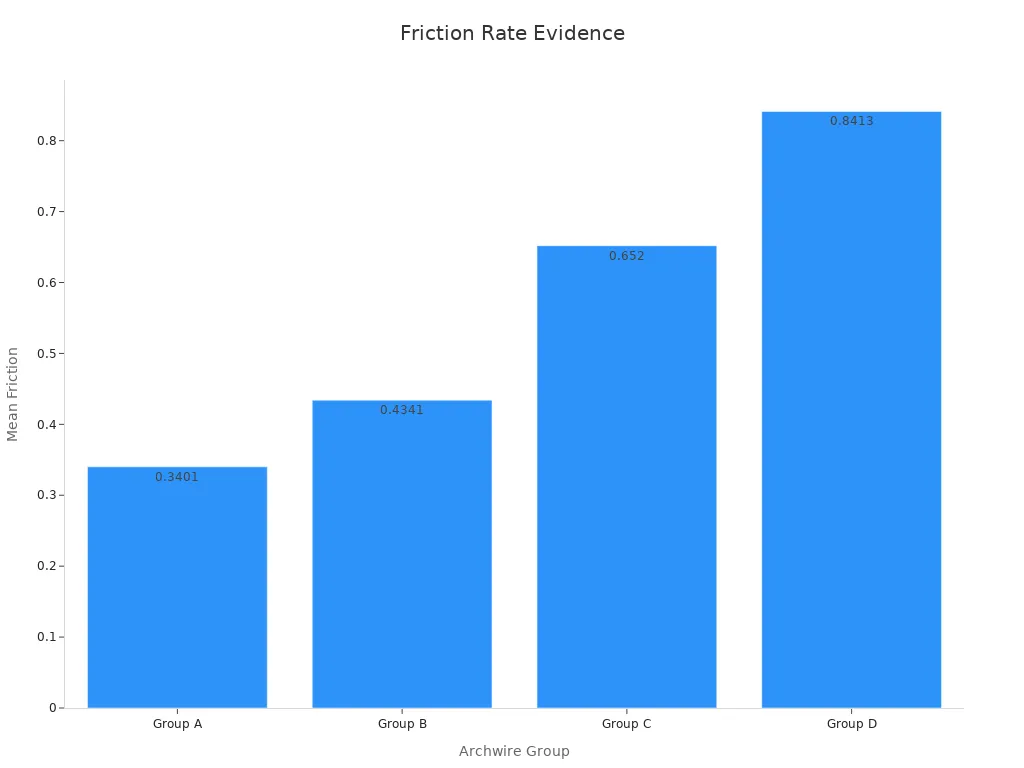

The chart below shows how different coatings change friction:

Nanocoated superelastic nickel-titanium wires have the least friction. Regular wires have the most. Special coatings help teeth move easier by making wires smoother.

Surface roughness also matters for friction and force. Researchers found these things:

Surface roughness was checked with a special tool to look for bumps.

Epoxy coated wires had the roughest and most uneven surfaces.

Teflon coated wires were the smoothest, like plain stainless steel wires.

Rhodium coated wires were smoother than epoxy but not as smooth as teflon.

These differences change how much friction there is and how force is lost, so good coatings are important.

Superelastic nickel-titanium wires with smooth surfaces and special coatings are more flexible and comfy. They help teeth move with less friction, so treatment is easier for patients. These wires are a top pick for many orthodontists because they are flexible and have low friction.

Superelastic nickel-titanium archwires mix superelasticity, shape memory, strength, and low friction. These things make them flexible and comfy, so they are great for braces today.

Comfort and Patient Experience

Force Delivery and Sensitivity

Orthodontic archwires affect how comfortable braces feel. The way wires push on teeth can change pain levels. Nickel-titanium wires are superelastic and give gentle, steady force. This helps teeth move smoothly and often hurts less. Heat treatment makes these wires even more bendy, which can lower pain.

Studies show the type of wire and how it is used matter for comfort. One study found some wire orders caused less pain at certain times. After the third wire was put in, one order led to less pain after 24 hours. But most studies say there is not a big difference in pain between wire types. Some people feel more pain on the first day with heat-activated nickel-titanium wires, but this gets better soon.

The way braces are made also changes how they feel. Surveys show lingual braces hurt the tongue more. Labial braces cause more pain in the cheeks and lips. These differences show both the wire and brace design affect comfort.

Orthodontists try to pick wires that move teeth well but do not hurt much.

Allergies and Biocompatibility

Biocompatibility means the wire is safe and comfy in the mouth. Some wires, like nickel-titanium, can let out nickel ions. Most of the time, the amount is not harmful, but it can still cause pain or allergies for some people. Nickel allergies are the most common metal allergy in braces. They can cause pain, swelling, or redness in the mouth.

Many things change how much nickel comes out, like the wire type, how long it is in the mouth, and even spit or brushing. Stainless steel and copper-nickel-titanium wires are more stable and good for long use. Superelastic nickel-titanium wires may let out more nickel, so they are used for shorter times.

Nickel allergies happen more in girls. Symptoms can be mouth pain or even skin problems outside the mouth. Regular check-ups and picking the right wire help lower allergy risks. Orthodontists watch patients closely to make sure the wire works well and feels okay.

Effectiveness in Orthodontic Treatment

Initial Alignment Phase

The first step in braces is moving teeth to better spots. Orthodontists use wires with superelasticity, like nickel titanium braces, in this stage. These wires bend and go back to their shape. This helps teeth move gently and steadily. Superelastic archwires are liked because they give steady force and feel more comfortable.

Studies looked at how well different wires work in the first phase. Nine trials with 571 people showed no wire was best. Multistrand stainless steel, conventional NiTi, superelastic NiTi, coaxial NiTi, copper NiTi, and thermoelastic NiTi all worked about the same. None moved teeth faster or caused less pain. The studies did not talk about root resorption, which is important.

Archwire Material | Speed of Alignment | Pain Experienced | Root Resorption Data |

|---|---|---|---|

Multistrand Stainless Steel | No significant difference | No significant difference | Not reported |

Conventional NiTi | No significant difference | No significant difference | Not reported |

Superelastic NiTi | No significant difference | No significant difference | Not reported |

Coaxial NiTi | No significant difference | No significant difference | Not reported |

Copper NiTi | No significant difference | No significant difference | Not reported |

Thermoelastic NiTi | No significant difference | No significant difference | Not reported |

A review also found superelastic NiTi wires work like conventional NiTi and multistranded stainless steel. The amount of decrowding and time needed was about the same. So, in the early phase, nickel titanium braces and other wires work about the same for most people.

Comparison Aspect | Nitinol Type(s) Compared | Numerical Evidence / Result | Statistical Significance |

|---|---|---|---|

Aligning Efficiency | Superelastic NiTi vs Heat-activated NiTi | No significant difference (Repeated measures ANOVA, p=0.45) | Not significant |

Pain Perception | Superelastic NiTi vs Heat-activated NiTi | Superelastic NiTi had higher pain scores (Mann Whitney U, p<0.05) | Significant |

Root Resorption | Superelastic NiTi vs Heat-activated NiTi | Greater root resorption with superelastic NiTi but not significant (Student's t-test) | Not significant |

Aligning Efficiency | NiTi (various types) vs Multistranded Stainless Steel | Similar alignment efficiency reported in multiple studies | Not significant |

Decrowding and Time for Alignment | Superelastic NiTi vs Conventional NiTi and Multistranded Stainless Steel | Similar decrowding and time taken reported in systematic reviews | Not significant |

Studies show no single wire is best for early alignment. Nickel titanium braces, stainless steel, and others all work about the same in the first phase.

Control in Later Stages

Later in braces, the goal is to control and finish tooth moves. Picking the right wire is even more important now. Stainless steel archwires are used a lot because they are strong and smooth. These wires help orthodontists make small changes and keep teeth in place.

The table below shows how wires work in later stages:

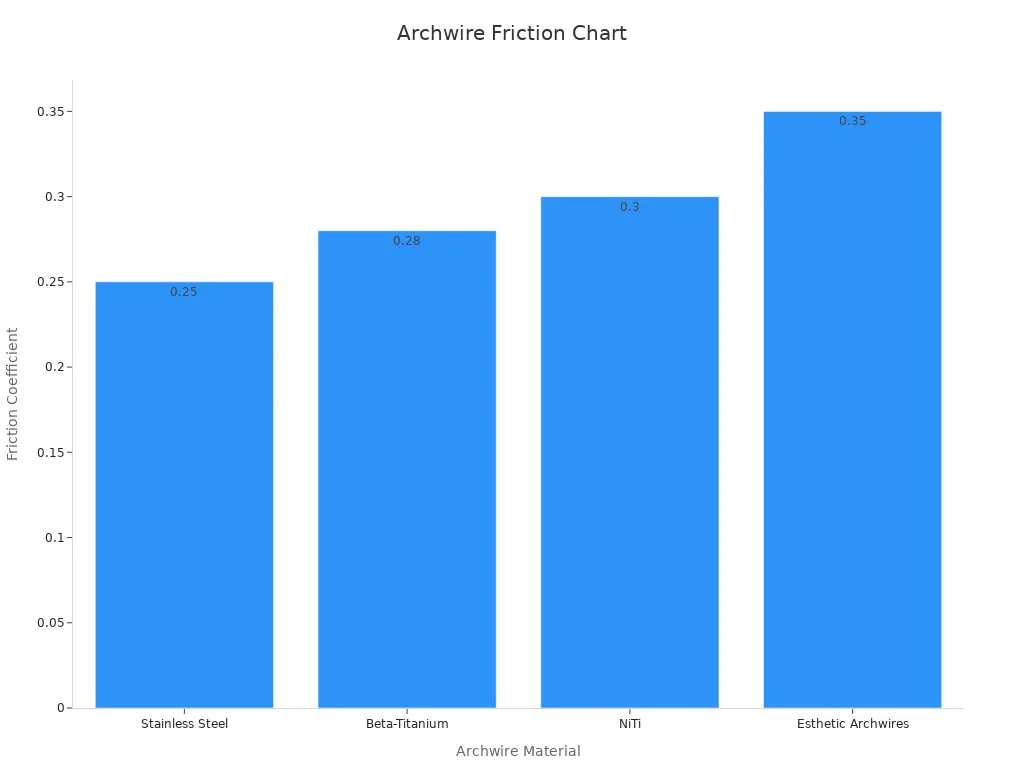

Archwire Material | Mechanical Properties | Frictional Resistance | Surface Roughness (Ra) | Clinical Stage Suitability |

|---|---|---|---|---|

Stainless Steel | High tensile strength, rigidity, high modulus of elasticity | Lowest coefficient of friction (0.25) | Smoothest surface (Ra = 0.25 µm) | Ideal for later treatment stages requiring precise tooth positioning and torque control |

Beta-Titanium | Balanced strength and flexibility | Moderate friction (0.28) | Moderate surface roughness | Suitable for moderate force application phases |

NiTi | Superelasticity, shape memory | Higher friction (0.30) | Rougher surface than stainless steel | Best for early stages needing consistent force and large tooth movements |

Esthetic Archwires | Lower mechanical strength | Highest friction (0.35) | Roughest surface | Recommended for less demanding phases prioritizing aesthetics |

Stainless steel wires give the best control at the end of treatment. Beta-titanium wires are good for medium changes because they are strong and flexible. Nickel titanium braces are best for early and middle stages when big moves are needed. Esthetic archwires look nice but do not work as well for tough jobs.

Clinical Outcomes

Clinical outcomes show how well braces work over time. Scientists studied how nickel titanium braces compare to other wires. Most studies say nickel titanium braces, copper-nickel-titanium, and multistranded stainless steel all work about the same for short and medium times.

Some trials found no big difference in speed or results between copper-nickel-titanium and nickel titanium braces.

Other studies showed heat-activated NiTi might move teeth a bit faster, but not always by much.

Studies comparing NiTi, multistranded stainless steel, and Titanol wires over 35 days to 6 weeks found no big differences in tooth movement or alignment.

Some research says superelastic NiTi wires may help certain teeth more, but overall results are similar for all wires.

Things like how a person’s body reacts and how the wire is put in can change results more than the wire type.

Most data show nickel titanium braces work as well as other wires for efficiency and results. The best wire depends on the treatment stage, what the patient needs, and what the orthodontist likes.

Many studies confirm there is no big difference in how well teeth line up, arch width, or tooth angle between superelastic NiTi, heat-activated copper-nickel-titanium, and other wires over up to 16 weeks. Heat-activated copper-nickel-titanium wires may be easier to use with crowded teeth, but this does not make teeth move faster or better. Most studies are short, so more long-term research is needed to fully compare nickel titanium braces and other wires.

Durability and Corrosion Resistance

Longevity in the Mouth

Orthodontic archwires have to deal with many things in the mouth. Saliva, food, and brushing can make wires wear out faster. Nickel-titanium wires last a long time, but they can change after a while. Their surface gets rougher when food and biofilm stick to them. This roughness lets more bacteria and plaque grow. That can cause gum problems. Stainless steel wires do not wear down as fast, but they can rust more quickly, especially with fluoride.

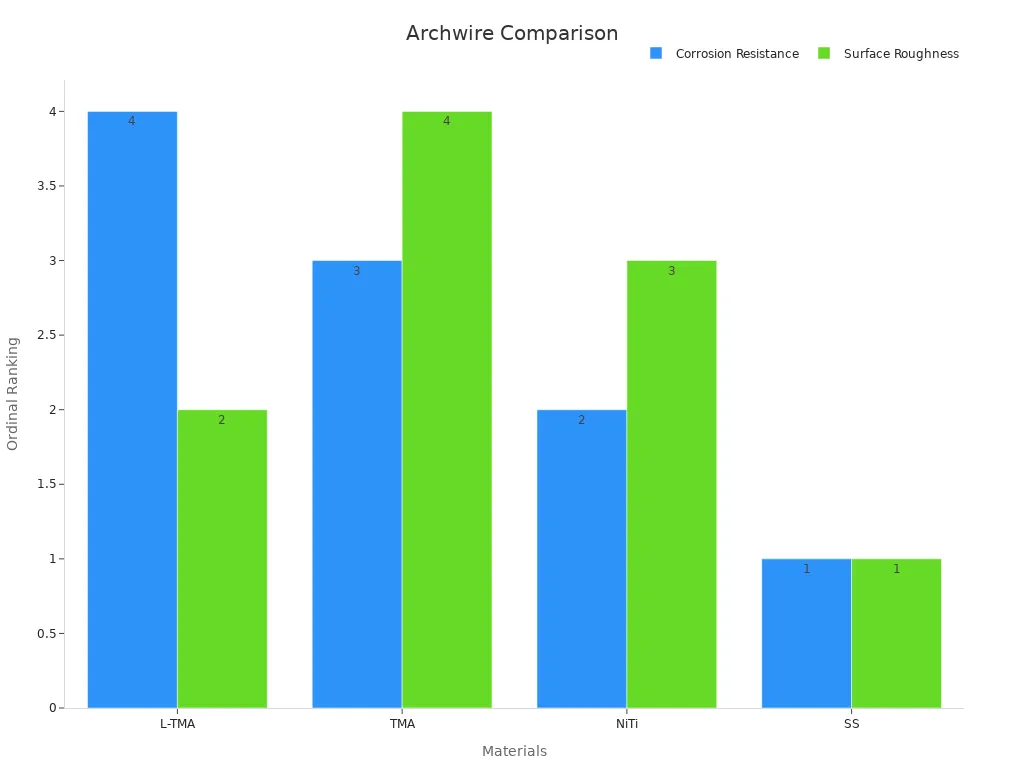

Long studies show NiTi wires lose some strength and bendiness after months. They can also break if left in too long. Titanium molybdenum alloy wires and low-friction TMA wires are best at fighting rust. Stainless steel wires are the worst at stopping rust, especially with lots of fluoride.

Archwire Material | Corrosion Resistance Ranking | Effect of Fluoride | Surface Roughness (Ra) Ranking | Key Findings |

|---|---|---|---|---|

Low-friction TMA (L-TMA) | Highest corrosion resistance | Fluoride significantly reduces corrosion resistance | Third highest | Chemical composition more influential than surface roughness; fluoride degrades protective film |

Titanium Molybdenum Alloy (TMA) | Second highest corrosion resistance | Fluoride reduces corrosion resistance | Highest surface roughness | Corrosion resistance ranking: L-TMA > TMA > NiTi > Stainless Steel |

Nickel-Titanium (NiTi) | Third highest corrosion resistance | Fluoride reduces corrosion resistance | Second highest | Surface roughness less decisive than chemical composition |

Stainless Steel (SS) | Lowest corrosion resistance | Fluoride reduces corrosion resistance | Lowest surface roughness | Fluoride-containing environments promote corrosion by breaking down oxide layers |

Special coatings, like N-doped TiO2, help wires last longer and stop rust. What the wire is made of and its coating matter more than how rough it is.

Maintenance Needs

Archwires need to be cleaned often to work well. Dirt and plaque build up on wires and make teeth harder to move. Stainless steel wires get more dirt after eight weeks, but cleaning with alcohol gauze helps. This cleaning makes wires smoother and lowers friction.

Parameter | Stainless Steel Archwires (3B vs AO brands) | Effect of Cleaning Methods (A-gauze vs Ac-gauze) |

|---|---|---|

Debris Accumulation | Significant increase after 8 weeks usage | Both A-gauze and Ac-gauze reduce debris effectively; A-gauze superior |

Surface Roughness (SR) | 3B: 0.059 μm (higher), AO: 0.037 μm (lower) | A-gauze reduces SR to near baseline, especially for 3B; Ac-gauze less effective due to rapid evaporation |

Frictional Forces | Increased after 8 weeks, no significant brand difference | Cleaning reduces friction; A-gauze preferred during friction-sensitive phases (e.g., space closure) |

Material Integrity | Chromium oxide layer resistant to solvents | Alcohol less aggressive, preserves oxide layer; Acetone more aggressive but effective for debris removal |

Clinical Recommendation | Routine cleaning at every appointment recommended | 20 seconds of A-gauze cleaning improves performance and treatment efficiency |

Nickel-titanium wires also get weaker over time. Protein and minerals can build up on them, and rust can cause tiny cracks. These changes make the wire less strong and can cause it to break. Dentists say to change wires often and clean them at every visit. Good care keeps wires strong and working well during treatment.

Cleaning wires often and changing them on time helps them work better and keeps your mouth healthy.

Cost and Value

Material Costs

Orthodontic archwire materials have different prices, strengths, and flexibility. Stainless steel archwires are popular because they are cheap and last long. Many orthodontists pick them for their strength and easy use. Beta titanium archwires cost more than stainless steel. They are flexible and strong, so they work well for hard cases and finishing.

Nickel-titanium wires, especially with special coatings, cost even more to make. These wires move teeth gently but can be too expensive for some people. Cobalt-chromium and composite archwires are used for special needs and are not as common.

Stainless steel archwires: cheap, strong, easy to bend

Beta titanium archwires: flexible and strong, cost more

Nickel-titanium archwires: advanced, cost the most, best for early treatment

Cobalt-chromium and composites: special uses, not used much

Market research uses expert talks, surveys, and data tools like SWOT and Porter’s Five Forces to study costs. New trends like heat-activated wires, digital designs, and new coatings also change prices and choices.

Material | Cost Level | Strength | Flexibility | Typical Use Stage |

|---|---|---|---|---|

Stainless Steel | Low | High | Low | Finishing, control |

Beta Titanium (TMA) | Medium | Medium | Medium | Detailing, finishing |

Nickel-Titanium (NiTi) | High | Medium | High | Initial alignment |

Cobalt-Chromium/Composite | High | Medium | Medium | Special cases |

Picking the right archwire depends on what the patient needs and how much money they can spend.

Insurance and Affordability

Dental insurance helps many families pay for braces. People with insurance pay less for braces than those without it. For example, metal braces cost about $5,350 without insurance. With insurance, the price drops to $3,407. Insurance pays part of the first payment and spreads help over the whole treatment. This makes braces cheaper for families.

Insurance also makes more people want braces and archwires. When insurance pays for some of the cost, more people can get braces. This makes braces and archwires easier to afford. Insurance does not always pay for every kind of archwire, so patients should check their plan.

Insurance makes braces cheaper and helps more people get the care they need.

Choosing the Right Archwire

Factors for Selection

Picking the best archwire for braces is important. Orthodontists think about many things before choosing. They look at what part of treatment the patient is in. They also care about how comfortable the wire feels. The speed of tooth movement matters too. Allergies, cost, and how the wire looks are also important. Some people want wires that are hard to see. Others want wires that move teeth faster.

Physical features like superelasticity and shape memory are key. Superelastic wires can bend and go back to their shape. This helps teeth move slowly and gently. Nickel titanium braces use these superelastic wires. People with nickel allergies need special wires. Wires like niobium-titanium-tantalum-zirconium are good for them.

Money is another thing to think about. Stainless steel wires are cheaper. But they may not feel as comfy as superelastic wires. Orthodontic archwire nitinol tubing is strong and flexible. It is superelastic too. That is why many people use it for different parts of braces.

Orthodontists pick the archwire that fits the patient’s needs, goals, and budget. This helps braces work their best.

Picking the right archwire is important for braces to work well. Superelastic nickel titanium wires give steady force and help line up teeth. They might cause a little more root resorption. Stainless steel wires are strong and give good control. Beta titanium wires are both flexible and tough. The table below shows how each wire works in the clinic:

Archwire Material | Alignment Efficiency | Pain Perception | Clinical Notes |

|---|---|---|---|

Superelastic Nickel-Titanium | Similar to others | Similar | Slightly higher root resorption |

Stainless Steel | Similar to others | Similar | Strong, less flexible |

Beta Titanium | Similar to others | Similar | Good balance of strength and comfort |

Superelastic wires are good for early tooth moves and less pain.

Stainless steel wires are best for finishing and strong control.

Beta titanium wires are great for people who need comfort and flexibility.

Patients should talk with their orthodontist about what they need. They should think about pain, how teeth move, and their goals. Getting advice that fits you helps make braces work best.

FAQ

What makes nitinol archwires different from stainless steel ones?

Nitinol archwires can bend and then go back to their shape. This is called superelasticity and shape memory. Stainless steel wires are strong but cannot do this. Nitinol wires usually feel better in the mouth.

Can someone with a nickel allergy use nitinol archwires?

People who are allergic to nickel might have problems with nitinol archwires. Orthodontists often use beta titanium or other wires without nickel for these people. Regular visits help check for any allergy signs.

How long do orthodontic archwires usually last?

Most archwires work for a few weeks or months. Dentists change them at each visit. How long they last depends on the mouth and how well you clean your teeth.

Are coated archwires better for comfort?

Coated archwires, like Teflon or rhodium, feel smoother and have less friction. Many people think they are more comfortable. But the coating can wear off after some time.

Do insurance plans cover all types of archwires?

Insurance usually pays for regular archwires, like stainless steel or basic nickel-titanium. Special wires or coatings might cost more. Patients should ask their insurance company about what is covered.

See Also

Evaluating Tensile Strength Differences Between Nitinol And Stainless Steel

Comprehensive Overview Of Nitinol Parts And Production Methods

Investigating Nitinol Tubing Uses Within Medical Device Industry

Step By Step Process Of Producing Nitinol Tubing For Medicine

Understanding The Mechanisms Of Nitinol's Memory And Elasticity