Key Differences Between Nitinol and Stainless Steel Tubing in Implantable Devices

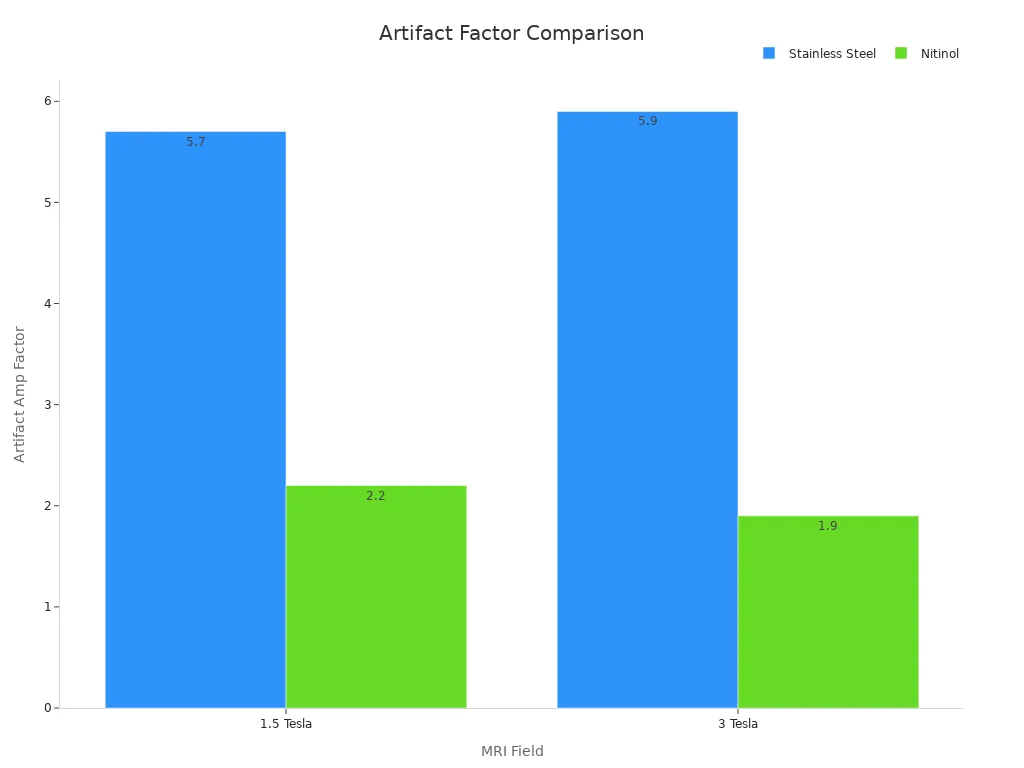

Choosing between Nitinol vs Stainless Steel Tubing for Implantable Devices depends on the specific requirements of each medical project. Nitinol tubing offers exceptional flexibility and the ability to return to its original shape, making it ideal for certain applications. On the other hand, stainless steel tubing provides greater strength and resists bending more effectively. When it comes to MRI scans, doctors notice significant differences: Nitinol tubing causes fewer imaging artifacts compared to stainless steel tubing, as illustrated below:

This comparison highlights why understanding the Nitinol vs Stainless Steel Tubing for Implantable Devices debate is crucial for biocompatibility, strength, and overall performance in medical device applications.

Key Takeaways

Nitinol tubing bends without breaking and goes back to its shape. This makes it good for flexible medical tools like stents and catheters. Stainless steel tubing is very strong and does not bend much. It works best for parts that must stay straight and give strong support. Nitinol tubing does not rust easily and is safer in MRI scans. This helps keep patients safe and makes devices work better. Making nitinol tubing needs special tools and careful work, so it costs more. Stainless steel tubing is easier and cheaper to make. Picking the right tubing depends on what the device needs. Use nitinol if you need it to bend and last a long time. Use stainless steel if you need strength and want to save money.

Nitinol vs Stainless Steel Tubing for Implantable Devices

Flexibility

Flexibility is very important when comparing nitinol and stainless steel tubing for implantable devices. Nitinol tubing is much more flexible than stainless steel tubing. It can bend and twist a lot without breaking or losing its shape. Nitinol tubing can stretch up to about 10%. Stainless steel tubing usually only stretches about 1% before it stays bent. This is because nitinol has superelasticity, so it goes back to its original shape after being bent or stretched.

Medical devices often need to move with the body or fit into small spaces. Nitinol tubing is flexible enough for these needs. For example, in retinal microsurgery tools, nitinol tubing at the tip lets the tool move more and bend more, so doctors can control it better. Stainless steel tubing is not as flexible and is stiffer. This makes it good for parts of devices that need to be straight and strong.

Nitinol tubing’s flexibility and kink resistance help stop damage during use, which makes devices work better and keeps patients safer.

Shape Memory

Shape memory is a special feature that makes nitinol tubing different from stainless steel tubing in medical devices. Nitinol tubing can "remember" its shape. If you bend or twist it, it goes back to its original shape when it gets warm, like at body temperature. This is important for devices that need to change shape when they are put in the body.

Many medical devices use nitinol tubing because of its shape memory. For example, stents made from nitinol tubing can be squeezed small to go into a blood vessel, then open up to their full size once inside. Stainless steel tubing does not have this ability. It cannot go back to its old shape after being bent, so it is not used in devices that need to change shape or be flexible.

The table below shows important mechanical properties for implantable devices:

Mechanical Property | Description / Relevance to Implantable Devices |

|---|---|

Shape Memory Effect | Lets implants go back to their original shape after being bent, which helps them work better and last longer. |

Superelasticity | Gives flexibility and strength, so implants can handle stress without staying bent. |

Low Stiffness | Makes the material act more like real bone, which helps bone grow around it and keeps the bone healthy. |

Damping Characteristics | Soaks up shocks and vibrations, making patients more comfortable and helping implants last longer. |

Corrosion Resistance | Keeps the material safe in the body for a long time. |

Young's Modulus (1–27 GPa) | Is close to real bone, which is important for designs that help cells stick and tissues grow. |

Influence of Ni Content | Changes how the material reacts to heat and stress, which affects how strong and tough it is. |

Nitinol tubing’s shape memory and superelasticity make it a great choice for medical devices that need to change shape or bounce back after bending. Stainless steel tubing is strong, but it cannot match nitinol’s flexibility or shape memory.

Rigidity

Rigidity means how much a material fights against bending or twisting. Stainless steel tubing is much more rigid than nitinol tubing. Tests show that stainless steel wires are about twice as stiff as nitinol wires of the same size. For example, to twist a stainless steel wire a certain amount, it turns 150°. A nitinol wire would twist 300° for the same force. This means stainless steel tubing is almost twice as hard to twist as nitinol tubing.

In medical devices, rigidity can be good or bad. Stainless steel tubing is good for parts that need to stay straight and give support. Nitinol tubing, which is less rigid, is better for parts that need to bend and move. Some medical devices use both materials together. For example, a device might have a nitinol tip for bending and a stainless steel shaft for strength.

Finding the right mix of flexibility and rigidity helps devices work better and keeps patients safer.

Comparing nitinol and stainless steel tubing for implantable devices shows big differences. Nitinol tubing is very flexible and has shape memory. Stainless steel tubing is stronger and more rigid. Doctors and engineers must think about these things when picking materials for medical devices. Nitinol tubing’s flexibility and toughness make it great for many new medical uses. Stainless steel tubing is still important for its strength and support.

Strength and Durability

Tensile Strength

Tensile strength tells us how much pulling force a material can take before it breaks. This is important for picking the right tubing for medical devices. Nitinol has an ultimate tensile strength between 500 MPa and 900 MPa. Some nitinol samples can even reach 1512 MPa. Stainless steel tubing usually starts with higher tensile strength because of work hardening. But after welding or using it many times, stainless steel can get weaker. This happens because its structure changes. Nitinol tubing keeps its superelastic plateau even after welding. This means it can stretch more than 7% before breaking. Stainless steel tubing usually breaks at lower strains.

Material / Condition | Tensile Strength (MPa) | Strain at Failure (%) | Notable Mechanical Behavior / Failure Mode |

|---|---|---|---|

Nitinol (superelastic plateau) | ~500 MPa at 20°C, ~550 MPa at 30°C | >7% | Superelastic plateau; significant strain before failure |

Stainless Steel (work-hardened initial) | Higher initial UTS (varies) | Lower than nitinol | High UTS at first; loses strength after welding or repeated use |

Fatigue Resistance

Fatigue resistance shows how well a material can handle being bent or stretched over and over. Nitinol is very good at this. It can last through millions of bends without breaking. Rotary bend fatigue tests show nitinol tubing can survive up to one billion cycles. This makes nitinol great for stents and heart valves that move with the body. Stainless steel tubing also resists fatigue, but not as well as nitinol in high-cycle tests. Nitinol can survive up to 10^7 cycles at strain amplitudes from 0.5% to 2.9%. Stainless steel tubing’s fatigue strength stays steady at different speeds and in different places. Nitinol’s fatigue strength drops a little at higher speeds.

Nitinol tubing can last up to 10^7 cycles at high strain.

Stainless steel tubing keeps steady fatigue strength but does not last as long at high strain.

Nitinol’s superelasticity and shape memory help stop cracks and breaking.

Long-Term Use

Long-term durability is important for implantable medical devices. Nitinol tubing keeps its strength and flexibility for a long time, even inside the body. Fast durability tests show nitinol resists fatigue, abrasion, and kinking. This is especially true in neurovascular devices. Stainless steel tubing is also durable, but it can lose strength after welding or long use. Changes in stainless steel’s structure can cause cracks when stressed again and again. Nitinol’s smooth surface and careful manufacturing help it last longer and work better in medical devices.

Medical engineers pick nitinol tubing for its flexibility and long-lasting strength in devices that need to move or bend a lot. Stainless steel tubing is good for devices that need to stay strong and support things without moving much.

Biocompatibility and Safety in Medical Devices

Corrosion Resistance

Biocompatibility and corrosion resistance are important for medical devices. Nitinol has great corrosion resistance inside the body. It forms a thin oxide layer on its surface. This layer protects nitinol tubing from rust and damage. The layer helps nitinol last longer and keeps patients safe. Stainless steel tubing also resists corrosion, but not as well as nitinol. In some medical places, stainless steel can still rust. Chloride ions in blood or body fluids can cause small holes in stainless steel. Nitinol tubing does not get these holes as easily. That is why engineers pick nitinol for devices that need strong corrosion resistance. Stainless steel tubing works for many devices, but nitinol lasts longer against rust.

Nitinol’s strong resistance to rust and its safety help stop device problems and keep patients safe.

MRI Compatibility

MRI compatibility matters for medical devices. Nitinol tubing is not magnetic, so it does not move or heat up much in MRI scans. Tests show nitinol tubing only gets 0.1 °C warmer at 1.5 T. It does not move, even in strong magnetic fields up to 4.1 T. Nitinol tubing makes very small marks in MRI pictures. Signal loss is less than 1 mm in some scans and 4 mm in others. Stainless steel tubing is more magnetic. It makes bigger marks in MRI pictures, especially in some scan types. Some stainless steel tubing is safe in MRI at 1.5 T or 3 T, but doctors must be careful. Both nitinol and some stainless steel types are weakly magnetic. This means they do not cause big safety problems in MRI. Nitinol tubing is best for MRI because it works well and does not mess up images.

Patient Safety

Patient safety depends on how safe the material is, how well it resists rust, and if it is safe in MRI. Nitinol tubing lowers the chance of allergies and swelling. Its smooth surface and strong layer help stop problems in the body. Stainless steel tubing is safe for most people, but some may react to nickel or other metals in it. Nitinol tubing is not magnetic, so it is safer in MRI scans. Stainless steel tubing can be safe if doctors follow the rules. Devices made from nitinol tubing often work better and cause fewer problems. Both nitinol and stainless steel tubing are safe, but nitinol gives extra safety in the body, against rust, and in MRI.

Property | Nitinol Tubing | Stainless Steel Tubing |

|---|---|---|

Corrosion Resistance | Excellent | Good, but less than nitinol |

MRI Compatibility | High | Conditional, more artifacts |

Biocompatibility | Superior | Good, may cause reactions |

Medical device designers want materials that last long and are safe. Nitinol tubing meets these needs and helps keep patients safe and devices working well.

Manufacturability and Customization

Fabrication

Nitinol tubing and stainless steel tubing are both used in making medical devices. Stainless steel tubing is easier to make into different shapes. People can cut, shape, and weld stainless steel with normal tools. This makes it fast to produce and gives the same results each time. Nitinol tubing needs more careful work. It must be shaped at the right temperature. Special machines help nitinol tubing keep its flexibility and shape memory. Nitinol tubing can be cut very accurately, within ±10 microns. Its surface can be made very smooth, down to 0.1 micrometers. These smooth surfaces help stop tissue irritation in the body. ASTM F2516 tests show nitinol tubing stays strong and stretchy when bent or straightened.

Joining Methods

It is hard to join nitinol tubing to other materials. Regular welding does not always work well with nitinol. Nitinol’s makeup and heat sensitivity need special joining methods. Laser welding and crimping work best for nitinol tubing. Stainless steel tubing is easier to join. People can use soldering, brazing, or regular welding. When nitinol tubing and stainless steel tubing are joined together, engineers must think about how each one bends and grows with heat. Picking the right joining method keeps the device safe and working well.

Design Flexibility

Medical device designers want materials that are flexible and easy to design. Nitinol tubing is great for design flexibility. It lets people make thin, bendy tubes that can move through tricky body paths. Nitinol tubing is light and strong, which helps in pediatric catheter procedures. Studies show nitinol tubing helps patients get better faster and have better results. The table below shows important differences in design flexibility and how well each material works:

Metric / Aspect | Nitinol Tubing | Stainless Steel Tubing |

|---|---|---|

Elastic Deformation Capacity | Up to 10% strain | About 1% strain |

Fatigue Resistance | Over 600 million cycles | Moderate to low |

Clinical Success Rate (Stents) | ~97% | Lower or not reported |

Patient Implant Rejection Rate | 30% lower | Higher |

Nitinol tubing keeps its flexibility and shape memory because it is made carefully. This makes it a good choice for many medical uses. Stainless steel tubing is still a good pick when devices need to be stiff and easy to make.

Cost and Availability

Material Cost

When you look at nitinol tubing and stainless steel tubing, the price is different. Nitinol tubing costs more because it uses nickel and titanium, which are expensive. Making nitinol tubing is hard and needs special steps like cold drawing and laser cutting. It is tough to machine nitinol because of its superelasticity and shape memory. This makes it hard to keep tight sizes. Most nitinol tubes must be made just for each order, so they take longer to get and cost more. Stainless steel tubing uses cheaper materials and comes in standard sizes. It is easier to machine, so it costs less. That is why stainless steel tubing is a good choice for many medical projects.

Nitinol tubing uses pricey nickel and titanium.

Special ways of making nitinol raise its cost.

Stainless steel tubing is simple and cheap to machine.

Standard stainless steel tubes are easy to find.

Supply Chain

Stainless steel tubing is the most used metal tubing in medicine. It is stable, resists rust, and is easy to weld. This makes it easy to get. The supply chain for stainless steel is strong and steady. Medical device makers can buy stainless steel tubing from many places. Nitinol tubing is harder to make and needs special skills. Not many suppliers can work with nitinol. The supply chain for nitinol is not as strong. Because of this, stainless steel tubing is often picked when it is important to get parts quickly and at a good price.

Value for Medical Projects

Medical projects need to think about cost, how well things work, and value over time. High-purity nitinol alloys can handle twice as much bending at 10^7 cycles as regular nitinol. Polished nitinol lets out fewer nickel ions, so there is less risk of swelling. These things make nitinol tubing a good pick for devices that need to bend and last a long time. But stainless steel tubing is stronger and costs less. The table below shows some key differences:

Metric | Nitinol Tubing | Stainless Steel Tubing |

|---|---|---|

Failure Load | 66 N | 178 N |

Actuation Force (100° bend) | 0.8 N | 1.6 N |

Usable Inner Diameter | ~10% larger | Baseline |

Fatigue Resistance | Up to 2× higher | Lower |

Medical teams often pick stainless steel tubing for its strength and low price in most uses. Nitinol tubing is the best choice when a project needs to bend a lot, use less force, and last a long time.

Application Suitability in Medical Devices

Nitinol Tubing Uses

Nitinol tubing is special because it can bend and go back to its shape. This is called shape memory and superelasticity. Many medical devices use nitinol tubing for this reason. Doctors pick nitinol tubing for stents in the brain and heart. These stents open up by themselves inside blood vessels. This helps stop the device from failing. Nitinol tubing is also used in heart valves, guidewires, and catheters. These tools are used in surgeries that do not need big cuts. Nitinol tubing can bend many times without breaking. It lasts through millions of bends.

Studies show nitinol tubing helps patients heal about 20% faster. Patients feel less pain and have fewer problems during heart procedures. Nitinol tubing is safe for the body and does not rust. This makes it good for long-term use. Doctors can order nitinol tubing made just for each patient. This helps get better results.

Evidence Aspect | Supporting Data / Findings |

|---|---|

Fatigue Life Comparison | TM-1 method gives 2-3 times longer life at 10^7 bends. |

Dimensional Tolerances | Very thin nitinol tubing keeps tight sizes (±0.005mm for OD > 0.80mm). |

Biocompatibility & Corrosion Resistance | Works well in fake body fluids; special treatments make it safer. |

Clinical Evidence | 30% lower eye pressure in six months, little tissue reaction. |

Compliance with Standards | Passes ISO 13485, ISO 10993, EU MDR. |

Customization Benefits | Custom nitinol tubing lasts longer than regular types. |

Nitinol tubing is flexible and safe. It is a top pick for stents, heart valves, and tools for small surgeries.

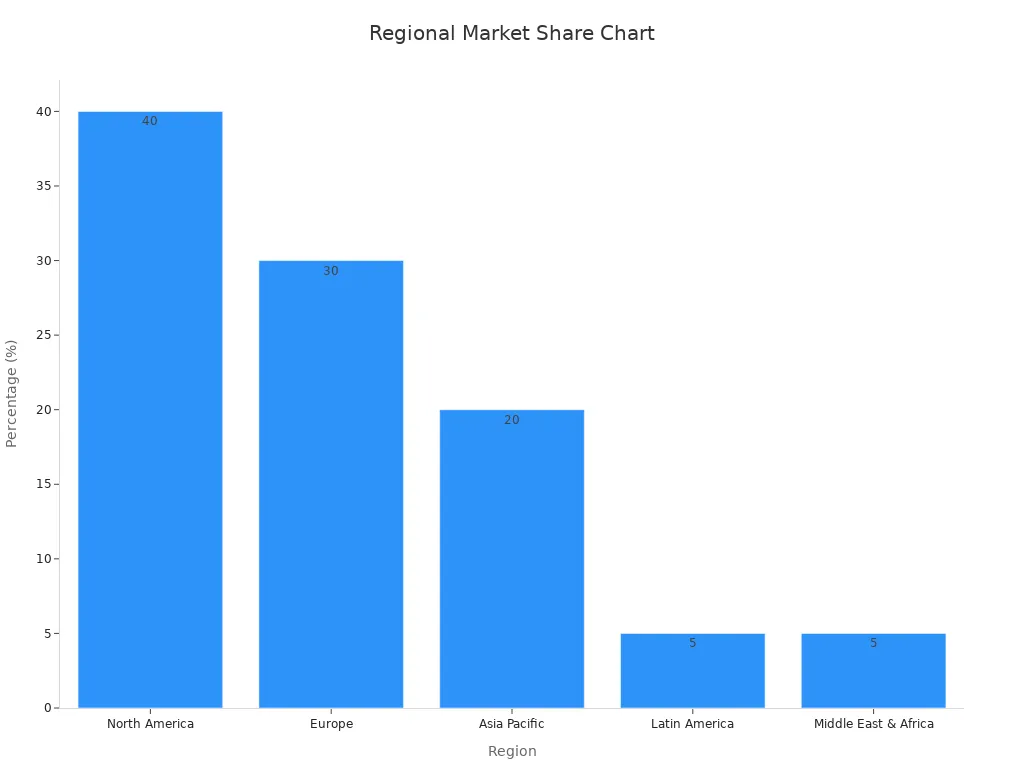

Stainless Steel Uses

Stainless steel tubing is still very important in medicine. Many devices use it because it is strong and works well. Doctors use stainless steel tubing in tools like scalpels, forceps, and endoscopes. Some heart and blood vessel devices also use stainless steel tubing. It is strong all over and does not bend easily. Hospitals like seamless stainless steel tubing for important tools. It is smooth inside and lasts a long time.

Stainless steel tubing is used in many things, like bone implants and test machines. Welded tubing is picked when price and custom shapes matter. More surgeries and new tech make the market for stainless steel tubing grow.

Metric/Category | Data/Value |

|---|---|

Market Size (2024) | USD 1.5 billion |

Forecast Market Size (2033) | USD 2.5 billion |

Fastest Growing Application Segment | Surgery Centers (minimally invasive procedures) |

Leading Stainless Steel Type (2023) | 304 stainless steel tubing (50% market share) |

Stainless steel tubing is strong and easy to make. It is great for surgery tools, implants, and many other medical uses.

Summary Table: Nitinol vs Stainless Steel

Picking tubing for implants means thinking about many things. The table below shows how nitinol and stainless steel tubing are different in important ways for medical use:

Feature | Nitinol Tubing | Stainless Steel Tubing |

|---|---|---|

Flexibility | Very high, bends easily, returns to shape | Low, stays bent if deformed |

Shape Memory | Yes, remembers and returns to original shape | No, does not recover shape |

Rigidity | Low, allows movement | High, provides strong support |

Moderate to high, stretches up to 10% | High, but less stretch before breaking | |

Fatigue Resistance | Excellent, survives millions of cycles | Good, but less than nitinol |

Corrosion Resistance | Superior, forms protective oxide layer | Good, but can corrode in harsh fluids |

MRI Compatibility | Excellent, non-magnetic, minimal artifacts | Variable, can cause imaging artifacts |

Biocompatibility | High, low risk of reaction | Good, some risk of nickel allergy |

Manufacturability | Complex, needs special tools | Easy, standard methods |

Cost & Availability | Higher cost, less available | Lower cost, widely available |

Typical Medical Uses | Stents, heart valves, guidewires, catheters | Surgical tools, bone implants, endoscopes |

Nitinol stents open up evenly and hurt blood vessels less than stainless steel stents. In animal tests, nitinol stents kept arteries open better and had fewer blood clots. Stainless steel stents did not open as smoothly and caused more damage and bigger clots.

Doctors and engineers notice big differences in how these metals work in the body. Nitinol tubing lets devices open smoothly and lowers the chance of blood clots. Stainless steel tubing is strong but can hurt tissue more during use. Pictures from studies show nitinol stents open evenly and have fewer big clots. Stainless steel stents often have flared ends and more clots. These differences happen because each metal reacts to stress and pressure in its own way.

When choosing tubing for an implant, teams should pick the material that fits the device’s job. Nitinol is best for parts that need to bend and last a long time. Stainless steel is good for parts that must be strong, stiff, and easy to make.

Nitinol tubing gives special advantages to medical devices. It is very flexible and can return to its shape. Nitinol tubing is safe for the body. Devices that need to bend use nitinol tubing a lot. Stainless steel is better when a device must be stiff. Nitinol tubing does not rust and stays strong. Devices with nitinol tubing can last a long time. Many devices need nitinol tubing’s strong pull strength. Medical teams should think about how flexible, tough, safe, and easy to make the tubing is, and how much it costs. Nitinol tubing works for many kinds of devices. Experts can help pick the right tubing. Both nitinol tubing and stainless steel are important in medical devices.

FAQ

What makes nitinol tubing special for medical devices?

Nitinol tubing can bend a lot and go back to its shape. Doctors use it in tools that move inside the body. Its superelasticity and shape memory help devices last longer and work better.

Can stainless steel tubing be used in MRI scans?

Stainless steel tubing can make problems in MRI scans. It might make blurry spots in pictures and sometimes gets hot. Some types are safe, but nitinol tubing is usually better for MRI.

Is nitinol tubing safe for patients with metal allergies?

Nitinol tubing has nickel, but a layer on top keeps it safe. This layer lowers the chance of allergic reactions. Most people do not have problems, but doctors check for allergies first.

Which tubing is easier to customize for special devices?

Stainless steel tubing is easier to cut, shape, and weld. Makers can make many sizes fast. Nitinol tubing needs special tools and careful work, so it takes more time to make.

See Also

Discovering How Nitinol Tubing Benefits Modern Healthcare Equipment

Evaluating Nitinol Tubing Versus Stainless Steel For Tensile Strength

The Process Behind Manufacturing Nitinol Tubing For Medical Use

Ways Nitinol Tubing Is Transforming The Medical Device Industry

Improving Catheter And Implant Function With Nickel-Titanium Tubing